This is certainly one of the best book I have ever read! I bought this book for it's chapter on

exhaust, I'm still wanting to create my own headers, but have them built in stainless steel.

Don't let the title mislead you into thinking that it's all about ignition timing and carburetors/EFI

..... it's not. It's about the complete engine. It's really should be called "The Performance 4 Stroke

Engine Build" and how to select your components. It has tremendous detail, to discuss the Piston

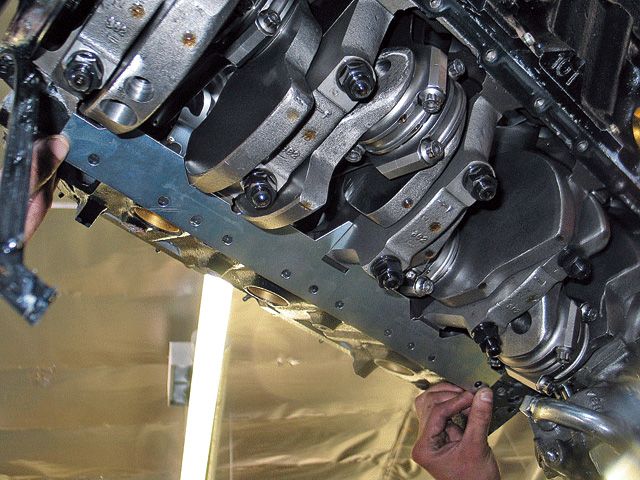

and Rings takes 33 pages and the chapter on Lubrication takes 80 pages to cover. For example, a

V8 at 8000 rpm will have about 3 pints of oil going around with the crankshaft in suspension.

When have you ever seen anything with 5 stars on Amazon?

Of course it's not as cheap as the usually paper back books we normally buy, this is a hard back

book with 600 pages, therefore the cost is about $45 new. It's been reprinted 25 times, the last

one being May 2018.

https://www.amazon.com/gp/product/0857331256/ref=ppx_yo_dt_b_asin_title_o05__o00_s00?ie=UTF8&psc=1

exhaust, I'm still wanting to create my own headers, but have them built in stainless steel.

Don't let the title mislead you into thinking that it's all about ignition timing and carburetors/EFI

..... it's not. It's about the complete engine. It's really should be called "The Performance 4 Stroke

Engine Build" and how to select your components. It has tremendous detail, to discuss the Piston

and Rings takes 33 pages and the chapter on Lubrication takes 80 pages to cover. For example, a

V8 at 8000 rpm will have about 3 pints of oil going around with the crankshaft in suspension.

When have you ever seen anything with 5 stars on Amazon?

Of course it's not as cheap as the usually paper back books we normally buy, this is a hard back

book with 600 pages, therefore the cost is about $45 new. It's been reprinted 25 times, the last

one being May 2018.

https://www.amazon.com/gp/product/0857331256/ref=ppx_yo_dt_b_asin_title_o05__o00_s00?ie=UTF8&psc=1