Ive had several guys bring in c4 corvettes with both flat tappet and roller cams that had sticky or only semi functional hydraulic lifters.

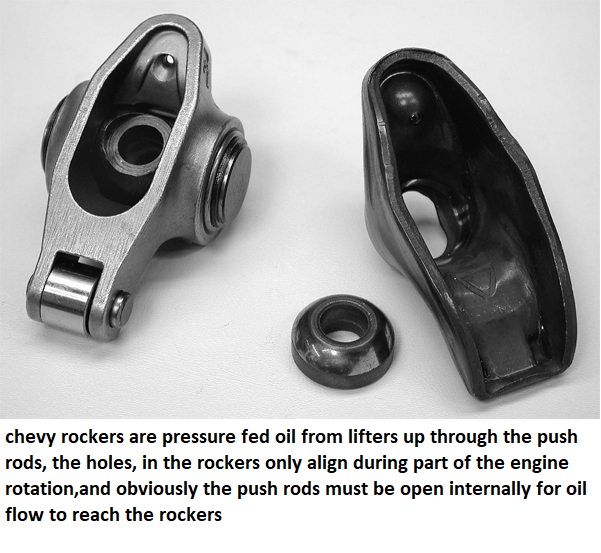

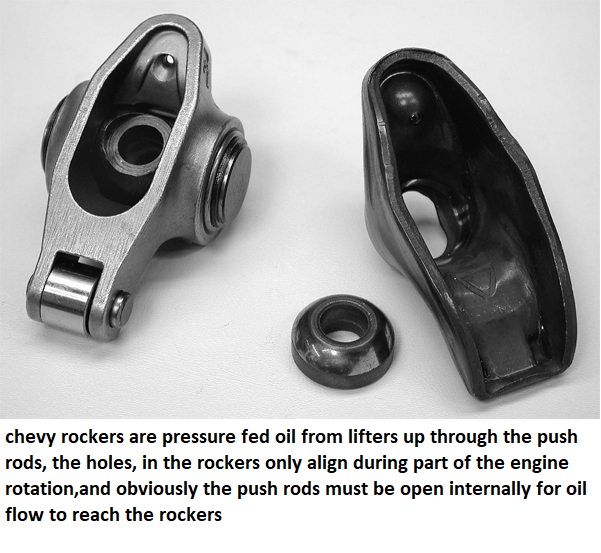

the first symptom is both noise in the valve train and little or no oil flow,

out of the push rods feeding oil flow too the rocker,

but you've got good oil pressure

keep in mind theres a huge difference between a sticky lifter and a worn lifter or cam lobe

this seems too be rather common in cars where for one reason or another the engines not been started for several months or years.

now obviously you might have mechanical issues or parts failure,

but in many cases its simply built up varnish or sludge,

or minor rust from moisture trapped in the engine during longer term storage.

first step is always doing an oil change too a good brand of high detergent 10w30 oil and a new WIX or PUREOLATOR or similar quality oil filter.

STEP TWO

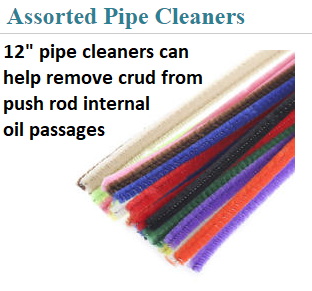

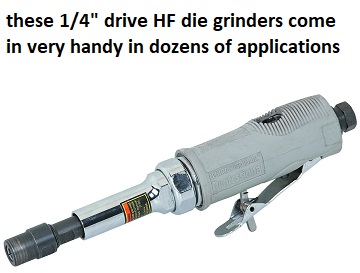

remove each push rod and soak it briefly (10-15 minutes)in a can of 50% gas and 50% carb cleaner, then use a compressor and high velocity air nozzle to blow out and verify the push rods completely clean and free of internal debris, or sludge.

re-soak and clean if required

https://www.harborfreight.com/catalog/product/view/id/13295/

to get the best results I found loosening the valve lash 1/2 turn out so, after re-installing the cleaned push rods so that the lifters click almost like solid lifters speeds up the process of getting stuck lifter internals on hydraulic lifters to free up and driving the car for a couple hours tends to do a great deal of good

adding a quart of MMO

and a can of liquid moly

https://www.amazon.com/Liqui-Moly-20004-Hydraulic-Additive/dp/B0096Y6XPC/?tag=newcarpassionate-20

seafoam engine additives all help

additive's with solvents and detergents and added lubricants certainly won,t hurt the process of removing contaminants , and temporarily allowing a few extra thousands clearance in the valve train seems to speed up the process, after youve driven the car for an hour or so with the fresh oil, new oil filter and additives youll generally find the lifters have freed up unless theres a mechanical wear issue like a damaged cam lobe or defective or worn lifter, so you can re-adjust the valves correctly

youll generally want to install hydraulic roller lifter's with the oil feed holes pointing to the rear of the engine,

but its not super critical as hydraulic pressure in the blocks lifter gallery,

oil feed passages ,

insures the roller lifters get sufficient oil flow facing in either direction.

you should read these posted link's, and sub links

http://garage.grumpysperformance.co...ter-pumps-oil-and-traps-oil.15555/#post-92843

http://garage.grumpysperformance.co...er-lifter-install-direction.11398/#post-52208

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/#post-90731

http://garage.grumpysperformance.com/index.php?threads/can-t-adjust-the-valve-lash.15404/#post-90613

http://garage.grumpysperformance.co...ulic-lifters-mystery-solved.12263/#post-60159

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/oil-pump-priming.15211/

the first symptom is both noise in the valve train and little or no oil flow,

out of the push rods feeding oil flow too the rocker,

but you've got good oil pressure

keep in mind theres a huge difference between a sticky lifter and a worn lifter or cam lobe

this seems too be rather common in cars where for one reason or another the engines not been started for several months or years.

now obviously you might have mechanical issues or parts failure,

but in many cases its simply built up varnish or sludge,

or minor rust from moisture trapped in the engine during longer term storage.

first step is always doing an oil change too a good brand of high detergent 10w30 oil and a new WIX or PUREOLATOR or similar quality oil filter.

STEP TWO

remove each push rod and soak it briefly (10-15 minutes)in a can of 50% gas and 50% carb cleaner, then use a compressor and high velocity air nozzle to blow out and verify the push rods completely clean and free of internal debris, or sludge.

re-soak and clean if required

https://www.harborfreight.com/catalog/product/view/id/13295/

to get the best results I found loosening the valve lash 1/2 turn out so, after re-installing the cleaned push rods so that the lifters click almost like solid lifters speeds up the process of getting stuck lifter internals on hydraulic lifters to free up and driving the car for a couple hours tends to do a great deal of good

adding a quart of MMO

and a can of liquid moly

https://www.amazon.com/Liqui-Moly-20004-Hydraulic-Additive/dp/B0096Y6XPC/?tag=newcarpassionate-20

seafoam engine additives all help

additive's with solvents and detergents and added lubricants certainly won,t hurt the process of removing contaminants , and temporarily allowing a few extra thousands clearance in the valve train seems to speed up the process, after youve driven the car for an hour or so with the fresh oil, new oil filter and additives youll generally find the lifters have freed up unless theres a mechanical wear issue like a damaged cam lobe or defective or worn lifter, so you can re-adjust the valves correctly

youll generally want to install hydraulic roller lifter's with the oil feed holes pointing to the rear of the engine,

but its not super critical as hydraulic pressure in the blocks lifter gallery,

oil feed passages ,

insures the roller lifters get sufficient oil flow facing in either direction.

you should read these posted link's, and sub links

http://garage.grumpysperformance.co...ter-pumps-oil-and-traps-oil.15555/#post-92843

http://garage.grumpysperformance.co...er-lifter-install-direction.11398/#post-52208

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/#post-90731

http://garage.grumpysperformance.com/index.php?threads/can-t-adjust-the-valve-lash.15404/#post-90613

http://garage.grumpysperformance.co...ulic-lifters-mystery-solved.12263/#post-60159

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/oil-pump-priming.15211/

Last edited: