Re: EFI Fuel Pumps and Fuel system design

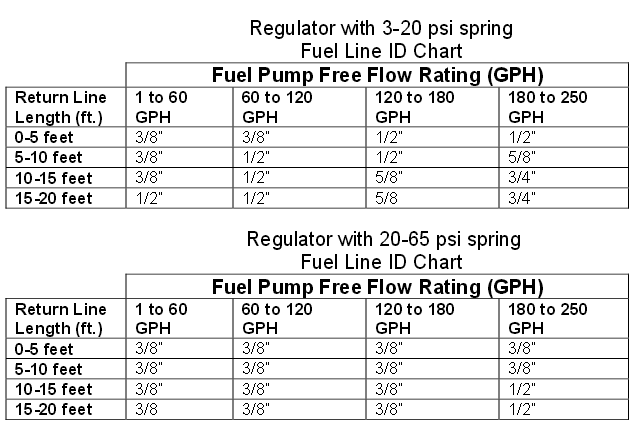

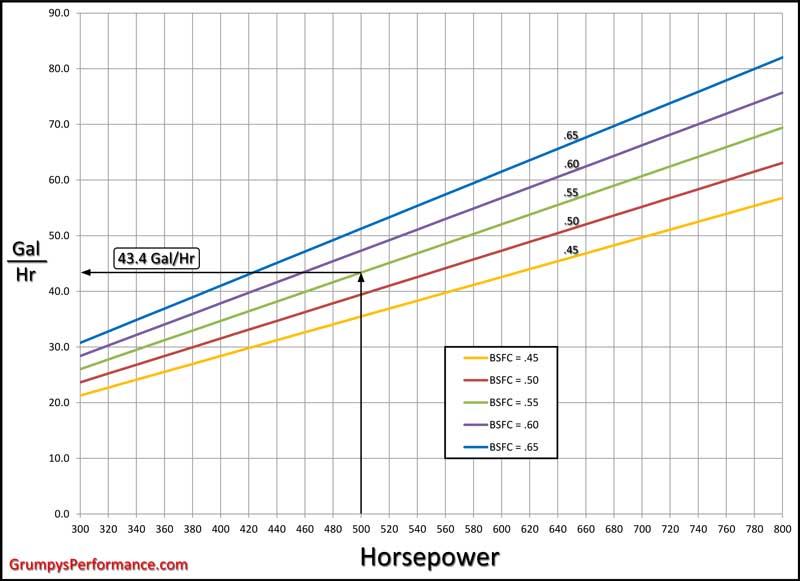

My realistic goals are a system that can handle at least 500hp with leeway. I think the Walbro will fit my needs for allot less money, close to $100 cheaper from summit racing. I have also read you don't want to go too big with your pump because the traveling gas will pick up heat as it flows. But obviously too little gas would be far more detrimental.

http://www.summitracing.com/parts/bch-61944/overview/

Bosch 044 Fuel Pump Specs:

Bosch Part Number: 0580254044

Minimum Current: 12 Volts

Operating Pressure: 72.5 PSI (5 Bar)

Minimum Flow @ Outlet: 80 GPH (300 LPH)

Fuel Pump Location: In-Line

High Temperature Reduction: 8 GPH (30 LPH)

http://walbrofuelpumps.com/GSL392-Walbro-Fuel-Pump.html

http://www.summitracing.com/parts/vpn-gsl392

Walbro GSL392 Fuel Pump

Walbro Universal Inline GSL392 Fuel Pump

Walbro universal fuel pump GSL392 is one of the most popular fuel pumps made by Walbro. is an ideal upgrades for:

GSL392 fuel pump is used in vehicles for racing or performance purposes where higher pressure fuel is necessary. Turbocharged, Supercharged.- with faulty inline fuel pumps, expensive or hard to replace in-tank fuel pumps.

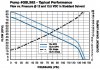

For example, at 80 PSI the standard 255 lph pump will flow around 132 liters (35 gallons) per hour. At that same 80 PSI the equivalent HP (high pressure) fuel pump will flow over 210 liters (50 gallons) per hour.

Walbro GSL392 255LPH High Pressure Inline Fuel Pump are extremely popular upgrades to vehicles with engine and performance modifications, supporting up to 650 horse power.

GSL392 Flow Chart

GSL392 Fuel Pump Specs:

- Pressure: 255 (LPH) Liters Per Hour- AMP: 20

- OE-proven second generation.

- Fits most EFI applications including turbo and supercharged.

- Variety of pressures and flows available, including high pressure performance.- All metal shell including inlet and outlet.

- 10mm x 1mm threaded inlet and outlet accept a variety of fittings.

- The 400-939 kit include two standard universal fittings which can connect to any 5/16 inch hose.- Lightweight, compact design.

- QS9000 certified.

- Made in USA

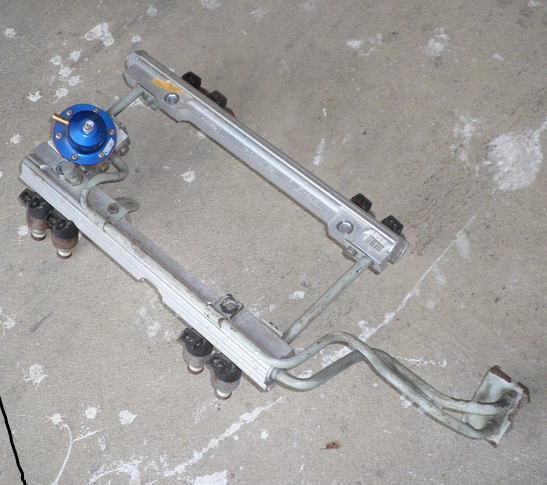

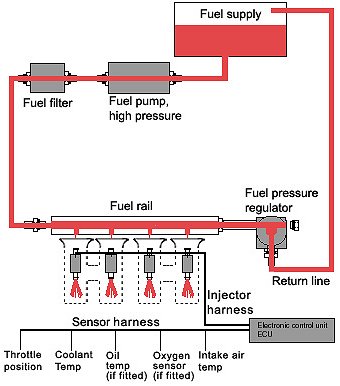

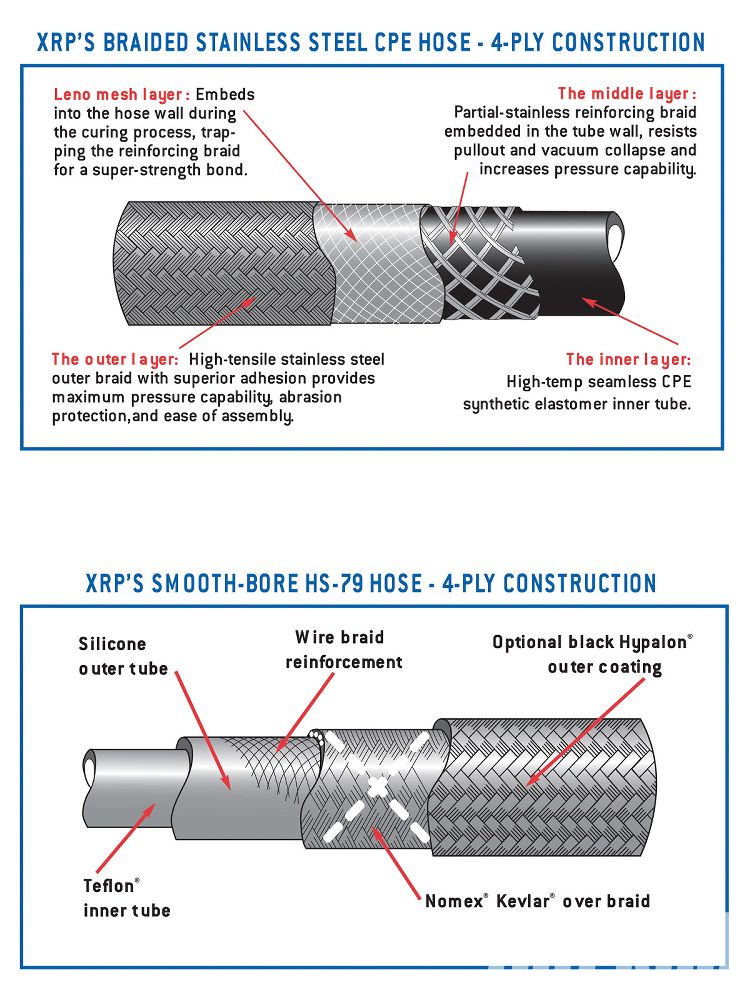

I was planning -08AN front to back feed and return lines. I feel the cost difference between the line size I can't go wrong with -08AN. The options I was thinking about for fuel line is running stainless down the straight part of my frame and also an inline cooler for the fuel like this style pictured below with PTFE braided for the other lines not sure what brand but it will not be XRP as I can not afford that option even though I wish I could (reason exotics are so expensive right there). How do you guys feel about Summit brand steel braided PTFE

http://www.summitracing.com/parts/sum-220993/overview/. Might be over kill but the coolers are cheap and readily available or am I just over thinking and it being a waste of money.

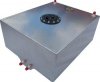

Ok now the fuel cell I see plenty of 20 gal with rear sump on ebay and on summit for around $200 I have access to a wire spool aluminum mig but after talking to the owner he say after gas and materials. Also it really should be done with a tig. I would not be really gaining much. I have had some ideas of modifying a fuel cell also but feel for my budget and realistic needs this will surfice. I could get foam and just make sure I keep up on it or I could just run it. Either way it's a huge step up from the stock gas tank that the pick up was moved on to the bottom towards the back :shock: :? . Maybe down the road I can modify it or get that tig I always wanted and build my own.

I will not forget the high flow fuel filters or the regulator I am just not to the point of figuring out exactly what products I am going to use for those yet. Opinions?