2001 s-10 4.3l 135000 mi. Friends truck. It has slow start and stumbling. I havent really dug in to this yet, but an initial check of the fuel pressure shows that as soon as the pump stops (just turning the key on/off, not starting the engine) the pressure goes to zero. With the pump running, the fuel pressure is around 60 psi. Not familar with these fuel systems, but I know that on my TPI engines, the fuel pressure holds for a long time. If it dropped, we would change out the pressure regulator. Same rule here or does this system work differently? Plan is to go over the entire system to look for leaks, etc. There is no smell of fuel anywhere, not even in the engine oil. If it was a defective injector, shouldnt we be seeing exhaust smoke of fuel in the oil?

Truck acts strange, gauges move erractically and he occassionally gets a low fuel light with a full tank of fuel. Truck is rusty, plan is to go over all the grounds to see if corrosion is a factor. I will check the fuel filter. He said the fuel pump was replaced a few years ago, so hopefully, that is not a contributing factor. Not much to go on, but any ideas as to where to start? We will be looking at this over the weekend ( time permitting).

The issue sure sounds a great deal like a defective, fuel pressure regulator.

testing that should not be a serious issue, to test and isolate and locate,

for limited testing, leak location etc.

be sure to check fuses if a problem did develop during testing.

( thats very unlikely)

btw its generally a good idea to keep a 5 gallon bucket with a soaking wet bath towel in it, handy,

when working on any fuel-related repair,

and generally you should have a running garden hose,

in easy reach just in case you make a stupid mistake...

no ones immuned to making occasional mistakes

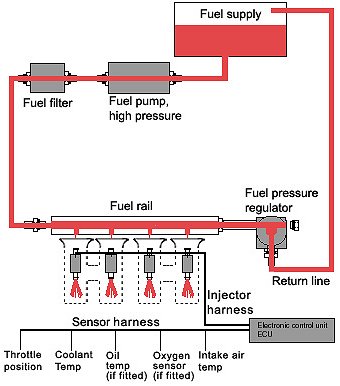

think about it,the fuel has limited places it can drain off to reduce pressure.

the fuel pressure is the result of resistance to flow ,if the fuel pump is supplying the flow, to build 60 psi.

while its running, that loss of fuel pressure indicates a loss of resistance,

IE the fuel is bleeding off ,if the fuel pressure regulator is not defective

(easily checked, block off the return line to the fuel tank temporarily,

if the problems no longer there, the fuel pressure reg is bad, )for pressure to drop fuel is flowing out and away from the fuel rails,

if its still there,with the return line blocked, the injectors are leaking ,

or the fuel pump is defective and allowing back-flow, if its the injector(S) ,

pull the plugs,and inspect them,after the pressure drops and before restarting the engine.

a leaking injector will cause an obviously partially fouled spark plug and an engine thats harder to restart,

an INFRARED temp gun will also show that cylinder(S) running cooler)

at least until the cylinder cleans up after running awhile.

http://garage.grumpysperformance.co...oblem-sources-1987-corvette.15596/#post-93275

this is the most consistently accurate I.R temp gun I've used for testing

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

Last edited: