1965SS396 said:Looking to buy a 80gph mechanical fuel pump for my '66 396. Specs:

Headers

Holley 750

Mild cam

Alum intake

0.060 bore

TH400 trans

I Don't race it. At all.

So does a 80gph pump on my setup require a regulator?

If so, will it then need a return line?

I've looked at stock pumps. Most are old NOS, and I prefer new. Much better choices at 80gph and up.

Thoughts?

Thanks

Ron

reading these links may help

http://www.harborfreight.com/fuel-pump-and-vacuum-tester-93547.html

how big a fuel pump do you need?

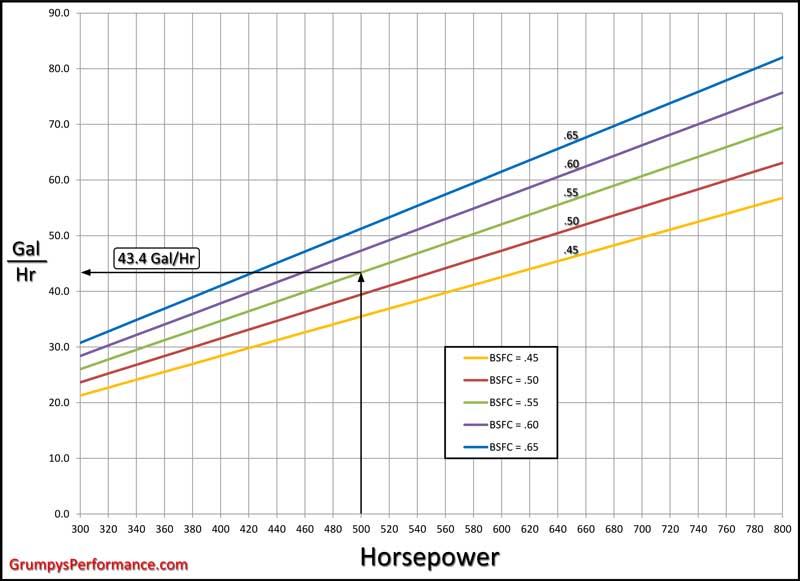

for a decent performance engine, that many guys build, I think your generally going to find an engine used on the street having under 450 rear wheel horse power equipped, with a carburetor(S) you'll need consistent fuel flow at 5-6 psi,and 80-110gph ,Holley,G.M. PERFORMANCE, SUMMIT RACING...

garage.grumpysperformance.com

http://www.summitracing.com/parts/CRT-M4530Raven18940 said:Wait, so if the fuel pump spring and not the lever arm is actually what provides fuel pressure, why doesn't a higher volume pump blow the needle and seat out at idle?

that mechanical pump you linked to is rated at 30gph,UNRESTRICTED ,

at the actual 5PSI it will flow measurably LESS thats very unlikely to supply over 400hp

and yes no matter what parts you select too use you'll find a dozen guys posting on-the internet,

that swear their engine uses that component and makes in excess of 500 hp.

not 1 in 100 of those internet heros have actually dyno tested the results,

use the posted linked charts and test the pressure and flow rates IN YOUR APPLICATION

think about what you just said!

fuel pressure and fuel flow volume are two totally different factors

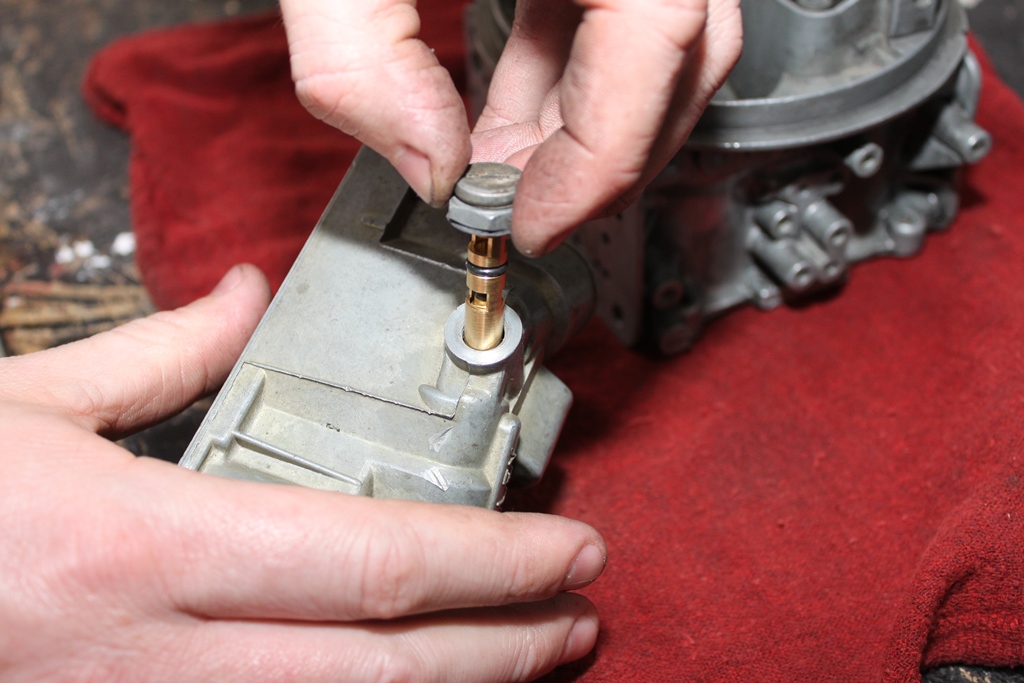

the needle/seat, in a carbs float bowl,controls the fuel level by opening and closing the needle valve, in the fuel bowl, and its designed to and generally can control fuel inlet pressures below 8 psi, the manual fuel pumps designed to supply a constant 6-8 psi in most cases

(but generally works best at 5-6 psi)volume of flow only come into play once the needle valve opens and that relates to how quickly the floats being raised back to the point the needle seat closes

YOU GENERALLY SET THE FLOATS TO JUST LET FUEL WET THE SITE PLUGS LOWER THREADS, BY ADJUSTING THE NEEDLE SEAT HEIGHT IN THE FLOAT BOWL

AGAIN PRESSURE AND FLOW RATE ARE TOTALLY DIFFERENT FACTORS

the normal manual fuel pump supplys a fuel pressure at the carb inlet port that can and probably does vary from 6-8 psi, the carbs needle valve will allow fuel to flow into the fuel bowl when the fuel level drops enough to allow the needle valve too open, the potential flow volume has little effect on the carb AS LONG AS ITS SUFFICIENT to keep up with demand and supply the carb with more than enough fuel to allow the floats to shut the needle valve when the carbs fuel bowls fill, having a surplus potential flow volume hurts nothing as long as the pressure can,t over come the floats weight ant push open the needle valve, having LESS than the required flow volume when the fuel bowl float is allowing the needle valve too fully open results in a lean miss fire at higher rpms

yes there ARE some aftermarket manual fuel pumps that produce 15 psi that will flood a carb, without a fuel pressure regulator with a return line design, in use.

http://www.summitracing.com/parts/CRT-M4530

the pump you linked to is MARGINAL but WILL more than likely work, personally ID never consider using it, simply because 30 gph at no back pressure will produce measurably less actual fuel flow once your dealing with some flow resistance, you don,t need to spend a great deal of cash but you should read the specs heres a rather inexpensive stock pump from NAPA that works Ive used several over the years

http://www.napaonline.com/Catalog/Catal ... 0481296130

(THIS IS A SBC PUMP IF YOU HAVE A BBC YOULL OBVIOUSLY NEED A SIMILAR BBC PUMP)

http://www.napaonline.com/Catalog/Buyer ... mber=68500

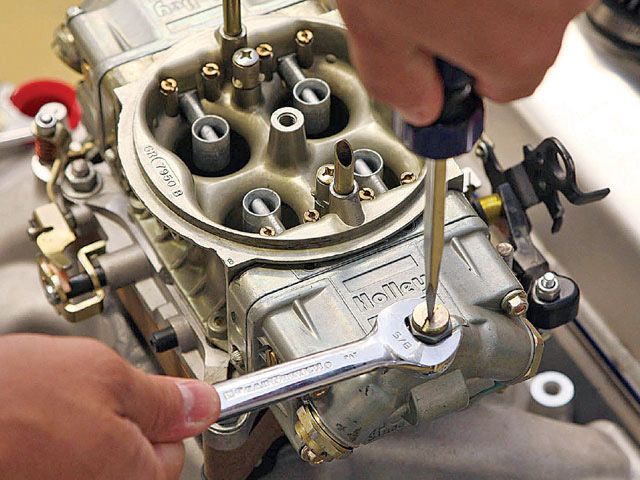

keep in mind that thats the minimum required, a fuel system has restrictions to flow rates like filters ,fitting and internal line flow restrictions requiring you to have a slightly higher actual supply volume and pressure PUMP, that the flow rate you need at the carb or fuel rail inlet, look at the chart! if your supplying a 500hp engine it shows you'll need a certain minimal fuel supply , a pump with at least 50% higher flow would be advisable to compensate for restrictions to flow

Raven18940 said:I didn't link to that, I stole this thread from the guy that started it cause he decided on the Carter pump.

I'm just trying to figure out how much pump I need for an engine making 300 HP, give or take 20, using the stock hard lines.

These are the options that seem relevant.

Carter makes these 40GPH units:

5.5-6.5 PSI

http://www.summitracing.com/parts/crt-m ... /chevrolet

OR 7.6-9 PSI

http://www.summitracing.com/parts/crt-m ... /chevrolet

An Airtex 60GPH unit:

http://www.summitracing.com/parts/atx-6 ... /chevrolet

Or a Summit 80GPH unit:

http://www.summitracing.com/parts/sum-2 ... /chevrolet

Basically my question is how big should it be to hit the fueling target I need to.

for that application Id be looking for a 5.5 psi -6.5 psi pump rated at 40-50 or maybe even a 60 gph why? theres always flow restrictions in the lines and the true supply rate is always a bit lower than the rated unrestricted flow its listed at. a few carbs have issues with flooding once the fuel pressure exceeds about 7 psi so if your not using a return style regulator its generally a good idea to stay under 7 psi,that should be the least expensive and by far simplest design.

ideally the third pump you linked too matched with a return style fuel pressure regulator would be used,yes more complicated and more expensive

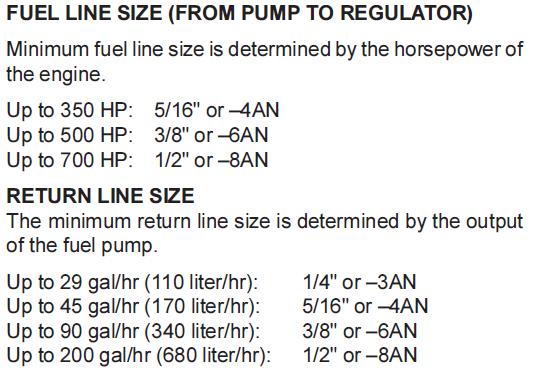

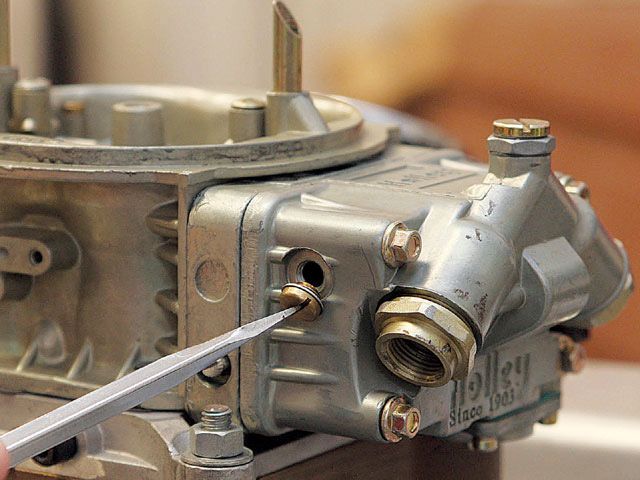

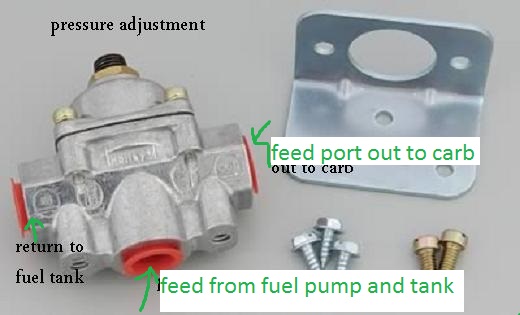

for some reason no one reads instructions and thinks the fuel return lines, supposed to be located at the bottom of the regulator and fuel should flow strait thru the regulator from side to side...WRONG! the fuel feeds up from the bottom center, and for some reason I always seem to get more consistent results with the lines hooked up as posted in the picture

BE AWARE THE FUEL PRESSURE REGULATOR MUST BE HOOKED TO AN UNRESTRICTED FLOW RETURN LINE BACK TO THE TANK TO ALLOW THE FUEL PRESSURE REGULATOR TO FUNCTION AND YOU MUST VERIFY THAT RETURN LINE IS UNRESTRICTED, IF THE RETURN LINES BLOCKED THE REGULATOR WON,T FUNCTION, BUT THE FUEL PRESSURE GAUGE MUST BE ON THE SAME SIDE OF THE FUEL PRESSURE REGULATOR THAT FEEDS THE CARBURETOR, the FEED FROM THE FUEL PUMP FEEDS THE LOWER CENTER PORT, THE LEFT SIDE IN THIS DIAGRAM FLOWS UNRESTRICTED BACK TO THE FUEL TANK, THE RIGHT SIDE FEEDS THE CARB AND FUEL PRESSURE GAUGE

Last edited by a moderator: