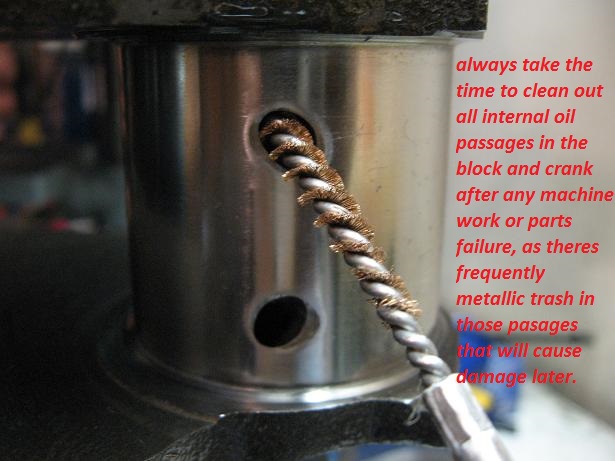

I have no idea why so many guys ignore or over-look the engines lube system, when building a high performance engine,and I then see those same guys act shocked when something rather expensive and violent happens to their engines, they act as if the very concept of a valve train failure or bearing failure is totally unpredictable, well its not!

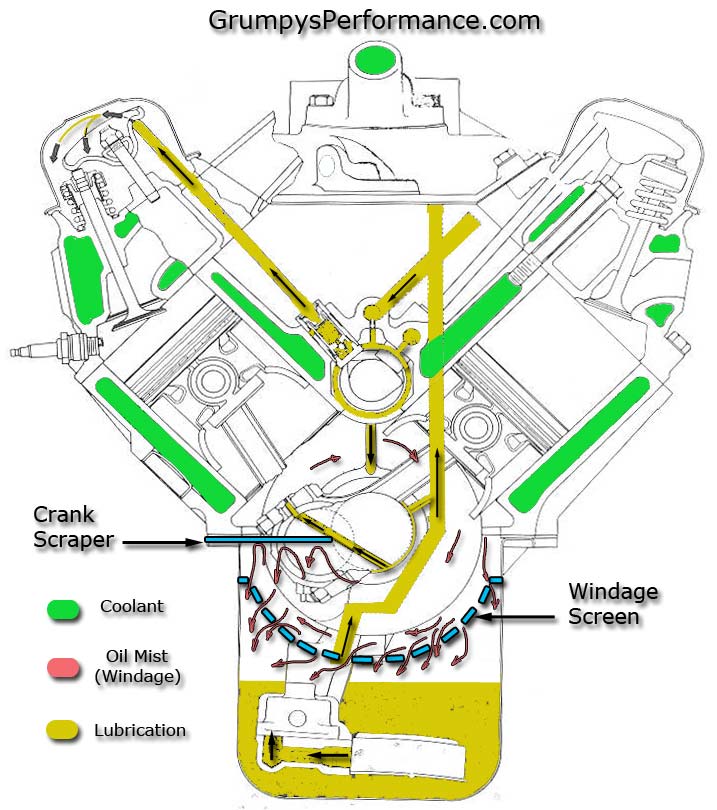

and I can assure you that maintaining consistent lubricant flow volume and pressure to cool and lubricate moving parts are requirements if your engine durability is important.

your stock engines designed to operate most of its life at under 5500rpm and probably making well under 400 horse power, yet guys some how think that the stock oil system is fully adequate if they are spinning the engine at 6500rpm and making 500hp, while the stock system does function remarkably well there are numerous well proven modifications that can enhance the lubrication efficiency.

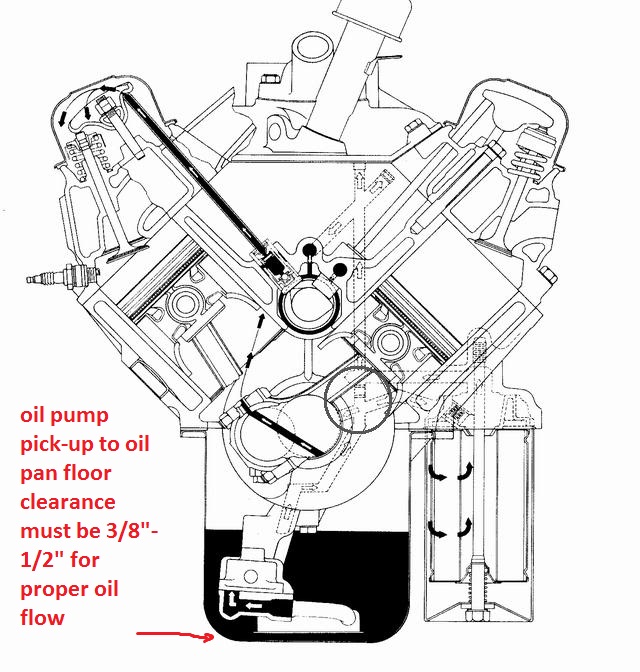

swapping a stock 4-5 quart oil pan to an aftermarket 7-8 quart baffled oil pan with a matched windage tray can significantly increase the lube systems ability to maintain consistent pressure and flow volume, and cooling of the moving parts .

remember it takes a constant bath of cooling oil flow to clean, cool and lubricate moving components and pressurized oil flow to bearings to prevent rapid wear

use a good 7-8 quart baffled oil pan

read these links

very good

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving surfaces in contact, rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on the rifle bore surface, This protective armor coating has a number of properties that are very beneficial for your rifles bore surface

moly is a bit like graphite, in that it appears to be a super fine powder suspended in a solvent carrier, that evaporates over time, put some between finger tips and rub, youll get the idea.. it spreads. like anti seize paste, and yeah it can be cleaned off hands with soapy hot water, but it gets into metal surfaces and its very dificult to remove (thats the idea)

The Moly platelets that make up the protective layers on your bore wall surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the bore to projectile surface contact

This coating effectively fills in the microscopic pores that cover the surface of all micro bore imperfections making them smoother. By filling in the craters and pores Moly improves this seal

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. The high pressures that occur between these moving surfaces that tend to squeeze normal lubricants out.

very very good

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=65

viewtopic.php?f=32&t=3071

http://www.tpub.com/content/constructio ... 64_101.htm

http://www.ttalk.info/Zddp.htm

http://auto.indiamart.com/auto-consumab ... osity.html

http://www.carbibles.com/engineoil_bible.html

http://en.wikipedia.org/wiki/Motor_oil

viewtopic.php?f=54&t=10186&p=40285#p40285

http://www.insightservices.net/testoil/ ... ctions.htm

http://www.nonlintec.com/sprite/oil_myths.pdf

http://www.mobiloil.com/USA-English/Mot ... _Guide.pdf

Functions of a Lubricant

· Lubricate

o By introducing a film between moving parts, opposing friction surfaces are separated and allowed to move freely without any interlocking of the asperities at the metal surface. By physically separating the moving parts, friction is greatly reduced. The result is less wear generated and less energy required to perform the work.

· Cool

o Lubricants absorb the heat generated at the friction surface and carry it away to a reservoir where it is allowed to cool before returning for service. Oil coolers and heat exchangers are sometimes used to more efficiently disperse heat. Lubricants are an excellent dissipater of heat.

· Clean

o Oil picks up solid contaminants and moves them away from the contact zone. The contaminants can then be removed by filtration or settling in the reservoir. Many oils have detergent characteristics to hold tiny dirt and soot particles in suspension at help prevent sludge and varnish in a system.

· Protect

o Lubricants coat component surfaces providing a barrier against moisture. The presence of moisture in the air causes oxidation, eventually leading to corrosion. Rust occurs when steel surfaces are attacked by moisture. Corrosion occurs when a metal surface is attacked by acids, a byproduct of oxidation. Oils can be fortified with alkaline reserves to counter the corrosive contaminants.

· Seal

o Many lubricants form a viscous seal to keep contaminants out of a component. Greases form physical barriers to protect against dirt and water ingress.

· Transmit Power

o Hydraulic systems use lubricants to protect sliding, contacting surfaces and as a source of fluid power. Fluid under pressure actuates moving parts.

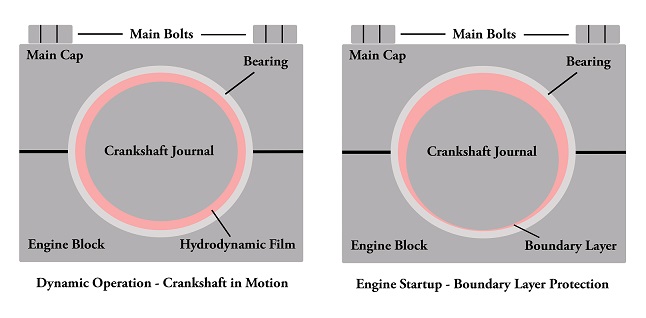

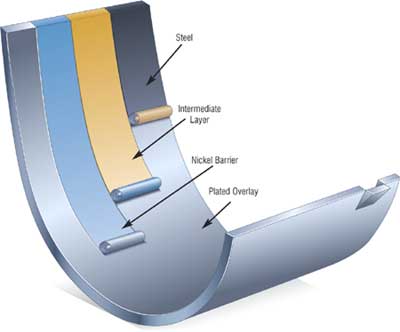

Full fluid film lubrication is defined as sufficient oil film thickness to completely separate the opposing friction surfaces and asperities. In this “perfect world†scenario, no metal to metal contact is occurring, therefore little or no wear is occurring. This will be the case when the proper lubricant is used, and the component is operating under proper load, at the proper speed, and at the proper temperature. The reduction of friction is the result of the base oil forming a physical barrier to separate the friction surfaces. In applications where this is the constant mode of lubrication, anti-wear and extreme pressure additives are not needed. However, when changes in load, speed, or lubricant properties are altered, there is a danger of severe wear due to the absence of additives.

Boundary Lubrication:

When the oil film is “squeezed†to the point where the oil film thickness is equal to the average asperity height, it is called boundary lubrication. When this occurs, severe wear is being generated as a result of asperities coming in contact with each other. This mode is commonly encountered during times of start-up and shut-down, when running speeds are slower than normal. Other common causes are overloading, shock loading, and insufficient lubrication. In cases where boundary lubrication is the norm, such as slow moving heavily loaded equipment or reversing equipment, lubricants must be fortified with extreme pressure additives to reduce friction and combat wear.

Mixed film Lubrication:

Some components operate on a combination of full fluid film and boundary lubrication known as mixed film lubrication. This occurs when the oil film is reduced and some asperities are coming in contact with each other. At this point, the oil’s anti-wear and extreme pressure additives become active and reduce friction and wear. This mode of lubrication is common in moderate speed and load applications, where variances in speed and load are expected.

Hydrodynamic Lubrication:

http://en.wikipedia.org/wiki/Hydrodynamic_lubrication

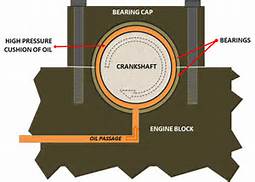

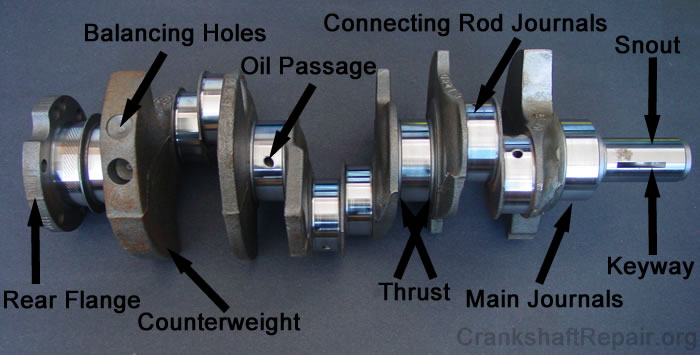

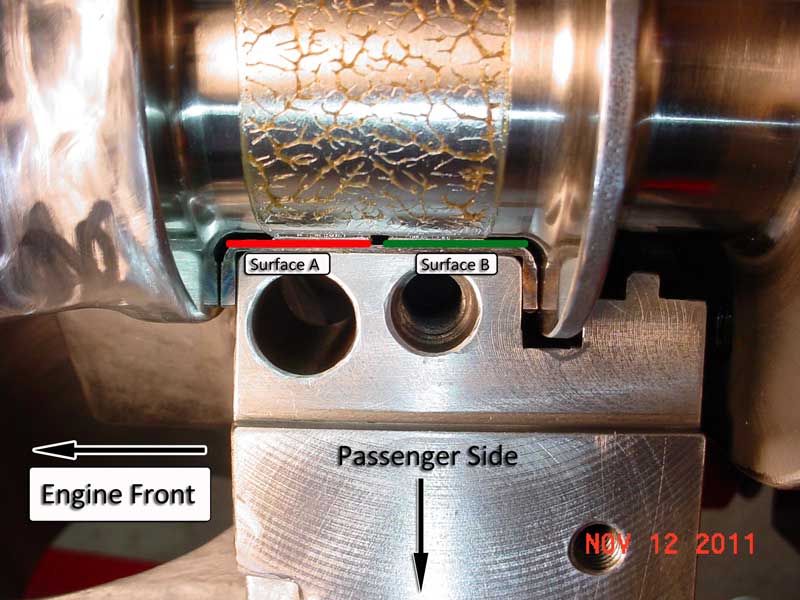

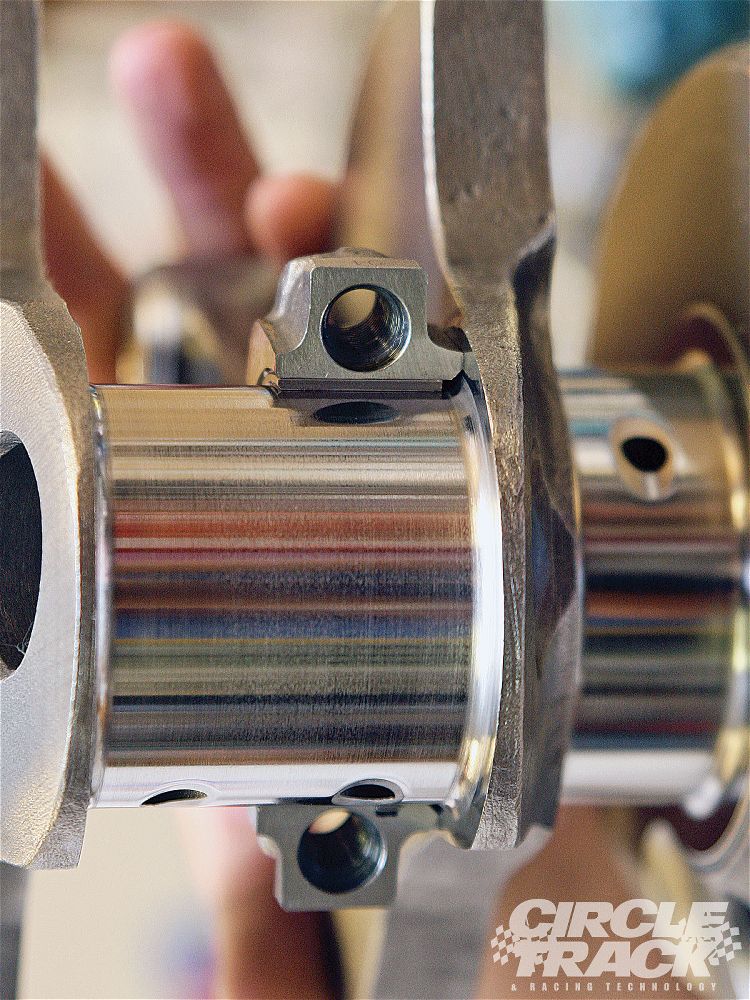

In journal bearings, friction is controlled by hydrodynamic lubrication. As a journal starts to turn in a bearing, oil is pulled into the load zone by the rotation of the shaft. The journal is lifted from the bearing by the oil wedge, allowing it to ride on top of the oil much in the same way that a log spins in water. When the proper lubricant is used, the machine is running at normal load and speed, the friction surfaces are completely separated and no wear is occurring. Once again, the whole of the lubrication and friction reduction rests on the base oil. Due to the high speed application, care must be taken to properly maintain the lubricant to ensure that a breakdown in the oil wedge does not occur. Should the lubricant fail, catastrophic bearing damage would occur.

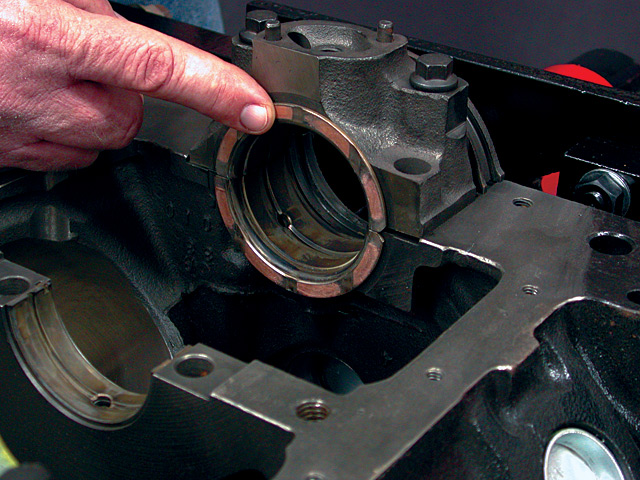

obviously, if you have coolant getting mixed with the oil theres a coolant leak into the engine, you could be dealing with a blown head gasket, leaking intake gasket, cracked cylinder head, cracked block, loose valve guide or other issues so you need to tear it down and locate the source of the coolant getting into your oil before it does major damage, which it will rather quickly

and I can assure you that maintaining consistent lubricant flow volume and pressure to cool and lubricate moving parts are requirements if your engine durability is important.

your stock engines designed to operate most of its life at under 5500rpm and probably making well under 400 horse power, yet guys some how think that the stock oil system is fully adequate if they are spinning the engine at 6500rpm and making 500hp, while the stock system does function remarkably well there are numerous well proven modifications that can enhance the lubrication efficiency.

swapping a stock 4-5 quart oil pan to an aftermarket 7-8 quart baffled oil pan with a matched windage tray can significantly increase the lube systems ability to maintain consistent pressure and flow volume, and cooling of the moving parts .

remember it takes a constant bath of cooling oil flow to clean, cool and lubricate moving components and pressurized oil flow to bearings to prevent rapid wear

use a good 7-8 quart baffled oil pan

read these links

very good

Moly exists as microscopic hexagonal crystal platelets Several molecules make up one of these platelets. A single molecule of Moly contains two sulfur atoms and one molybdenum atom. Moly platelets are attracted to metal surfaces. This attraction and the force of moving surfaces in contact, rubbing across one another provide the necessary thermochemical reaction necessary for Moly to form an overlapping protective coating like armor on the rifle bore surface, This protective armor coating has a number of properties that are very beneficial for your rifles bore surface

moly is a bit like graphite, in that it appears to be a super fine powder suspended in a solvent carrier, that evaporates over time, put some between finger tips and rub, youll get the idea.. it spreads. like anti seize paste, and yeah it can be cleaned off hands with soapy hot water, but it gets into metal surfaces and its very dificult to remove (thats the idea)

The Moly platelets that make up the protective layers on your bore wall surfaces slide across one another very easily. Instead of metal rubbing against metal, you have Moly platelets moving across one another protecting and lubricating the bore to projectile surface contact

This coating effectively fills in the microscopic pores that cover the surface of all micro bore imperfections making them smoother. By filling in the craters and pores Moly improves this seal

This overlapping coating of Moly also gives protection against loading (perpendicular) forces. The high pressures that occur between these moving surfaces that tend to squeeze normal lubricants out.

very very good

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=65

viewtopic.php?f=32&t=3071

http://www.tpub.com/content/constructio ... 64_101.htm

http://www.ttalk.info/Zddp.htm

http://auto.indiamart.com/auto-consumab ... osity.html

http://www.carbibles.com/engineoil_bible.html

http://en.wikipedia.org/wiki/Motor_oil

viewtopic.php?f=54&t=10186&p=40285#p40285

http://www.insightservices.net/testoil/ ... ctions.htm

http://www.nonlintec.com/sprite/oil_myths.pdf

http://www.mobiloil.com/USA-English/Mot ... _Guide.pdf

Functions of a Lubricant

· Lubricate

o By introducing a film between moving parts, opposing friction surfaces are separated and allowed to move freely without any interlocking of the asperities at the metal surface. By physically separating the moving parts, friction is greatly reduced. The result is less wear generated and less energy required to perform the work.

· Cool

o Lubricants absorb the heat generated at the friction surface and carry it away to a reservoir where it is allowed to cool before returning for service. Oil coolers and heat exchangers are sometimes used to more efficiently disperse heat. Lubricants are an excellent dissipater of heat.

· Clean

o Oil picks up solid contaminants and moves them away from the contact zone. The contaminants can then be removed by filtration or settling in the reservoir. Many oils have detergent characteristics to hold tiny dirt and soot particles in suspension at help prevent sludge and varnish in a system.

· Protect

o Lubricants coat component surfaces providing a barrier against moisture. The presence of moisture in the air causes oxidation, eventually leading to corrosion. Rust occurs when steel surfaces are attacked by moisture. Corrosion occurs when a metal surface is attacked by acids, a byproduct of oxidation. Oils can be fortified with alkaline reserves to counter the corrosive contaminants.

· Seal

o Many lubricants form a viscous seal to keep contaminants out of a component. Greases form physical barriers to protect against dirt and water ingress.

· Transmit Power

o Hydraulic systems use lubricants to protect sliding, contacting surfaces and as a source of fluid power. Fluid under pressure actuates moving parts.

Full fluid film lubrication is defined as sufficient oil film thickness to completely separate the opposing friction surfaces and asperities. In this “perfect world†scenario, no metal to metal contact is occurring, therefore little or no wear is occurring. This will be the case when the proper lubricant is used, and the component is operating under proper load, at the proper speed, and at the proper temperature. The reduction of friction is the result of the base oil forming a physical barrier to separate the friction surfaces. In applications where this is the constant mode of lubrication, anti-wear and extreme pressure additives are not needed. However, when changes in load, speed, or lubricant properties are altered, there is a danger of severe wear due to the absence of additives.

Boundary Lubrication:

When the oil film is “squeezed†to the point where the oil film thickness is equal to the average asperity height, it is called boundary lubrication. When this occurs, severe wear is being generated as a result of asperities coming in contact with each other. This mode is commonly encountered during times of start-up and shut-down, when running speeds are slower than normal. Other common causes are overloading, shock loading, and insufficient lubrication. In cases where boundary lubrication is the norm, such as slow moving heavily loaded equipment or reversing equipment, lubricants must be fortified with extreme pressure additives to reduce friction and combat wear.

Mixed film Lubrication:

Some components operate on a combination of full fluid film and boundary lubrication known as mixed film lubrication. This occurs when the oil film is reduced and some asperities are coming in contact with each other. At this point, the oil’s anti-wear and extreme pressure additives become active and reduce friction and wear. This mode of lubrication is common in moderate speed and load applications, where variances in speed and load are expected.

Hydrodynamic Lubrication:

http://en.wikipedia.org/wiki/Hydrodynamic_lubrication

In journal bearings, friction is controlled by hydrodynamic lubrication. As a journal starts to turn in a bearing, oil is pulled into the load zone by the rotation of the shaft. The journal is lifted from the bearing by the oil wedge, allowing it to ride on top of the oil much in the same way that a log spins in water. When the proper lubricant is used, the machine is running at normal load and speed, the friction surfaces are completely separated and no wear is occurring. Once again, the whole of the lubrication and friction reduction rests on the base oil. Due to the high speed application, care must be taken to properly maintain the lubricant to ensure that a breakdown in the oil wedge does not occur. Should the lubricant fail, catastrophic bearing damage would occur.

obviously, if you have coolant getting mixed with the oil theres a coolant leak into the engine, you could be dealing with a blown head gasket, leaking intake gasket, cracked cylinder head, cracked block, loose valve guide or other issues so you need to tear it down and locate the source of the coolant getting into your oil before it does major damage, which it will rather quickly

Last edited by a moderator: