tthorp32 said:I have a 383 stroker that has 10.5:1 compression with trick flow twisted wedge g1 heads. The max lift I can use from a cam before the valves hit a piston is .520 if I use different springs. "So long as you stay at or below 236* @ .050" Duration, No less than a 108* LSA, you can go up to about .520" lift before piston to valve clearance becomes an issue." I need help on cam selection. I want a hydraulic roller cam. It's a non roller block. I'm trying to make around 500 horsepower. It's a street strip setup with a t56 transmission. Also 1.52:1 rocker arms. Thanks in advance!

first ID point out that those are the guide lines that came with those heads and

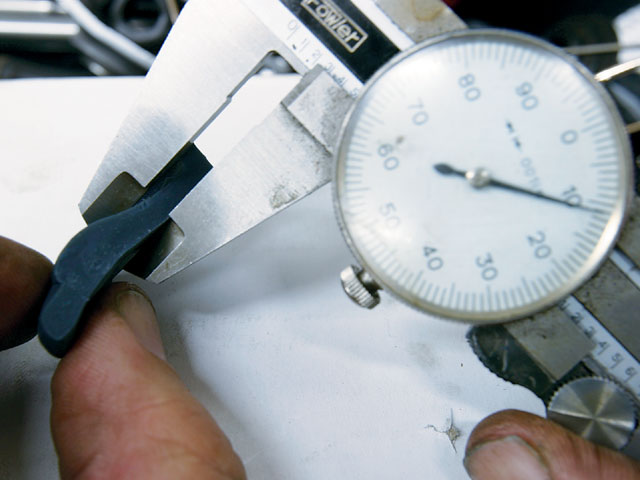

THEY DON,T ALWAYS APPLY, you NEED TO ACTUALLY MEASURE YOUR PISTON TO VALVE CLEARANCE AND VALVE TRAIN CLEARANCES

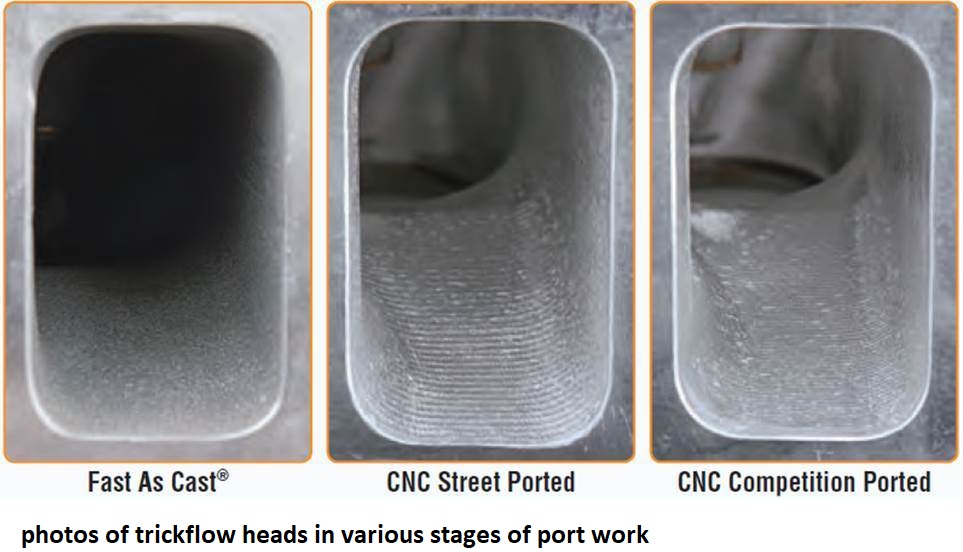

you will be taking a HUGE gamble if you don,t VERIFY your TRUE clearances, and ID also point out that the valve springs can be and should be UPGRADED for use with a roller cam as the load rates are different,on those heads currently than what you need for a hydraulic roller cam plus the fact that your valve springs and seals are at least 15 years old now, because they stopped selling those heads at least that long ago.

they are decent heads if in good condition but need better springs for a hydraulic roller cam.

It would help to know more about the car weight, rear gear, headers etc, and if you need to pass emission testing.

check the valve seals and valve guides for wear, as the G1 heads have a reputation for wearing originally installed valve guides

viewtopic.php?f=52&t=3293&p=8709&hilit=twisted+wedge#p8709

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=399

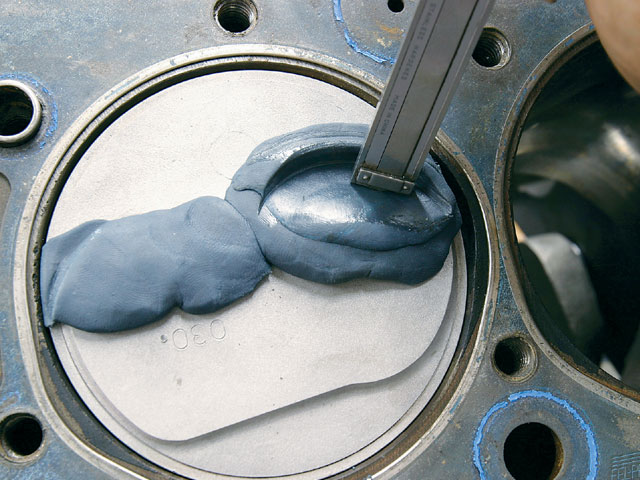

I don,t know many or in fact any engine builder that doesn,t have some good model clay in his tool box for checking clearances

or a can of wd 40 to spray on the valves and clay too prevent clay sticking to parts measured, use good quality modeling clay, some crap like kids PLAY DOUGH, is SPRINGY and won,t give exact and consistent measurements, I pick mine up at a local arts & craft supply

almost every mechanics tool box needs a few basic measuring tools and supplies

http://www.utrechtart.com/Plastalin...currency=USD&gclid=CN3G75zOw80CFQgaaQodKbgFjA

Last edited by a moderator: