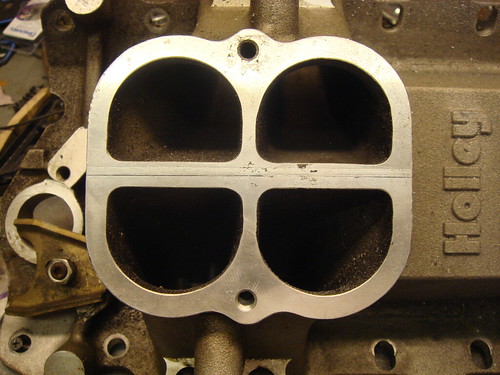

This has probably already been discussed but I'll ask anyway's. I have a brand new set of Summit Vortec heads (made by Dart). I just ordered an Edelbrock Performer RPM Vortec intake. I was wondering if you guys gasket match your intake manifolds to your heads? I always have in the past. It's been a while since I've done this kind of thing though. So I thought I'd ask.

I've heard pros and cons about doing this. Some guys say it's a must and others say it's a waist of time. I had a guy tell me the other day that aluminum heads move so much when they get heated up that when they cool down, their intake runners are in a different place then before they got heated up. He said gasket matching them would not be worth doing. My heads are iron.

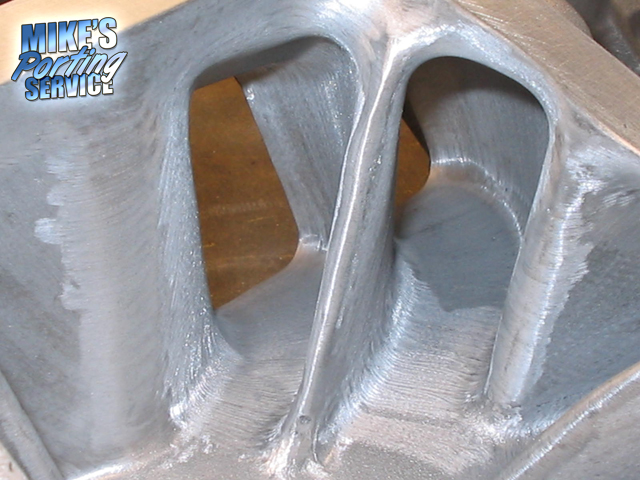

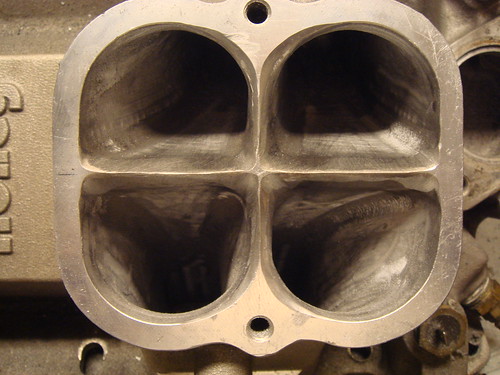

Another guy told me that you should only make the ports match up and not really gasket match them. He said if you gasket match them you usually go an inch into the runner in the intake as well as in the head. He said all that makes is a funnel like shape coming out of the intake (small to large area) into another funnel like shape going into the head (large to smaller area).

If you recommend that I do gasket match them, how do you do it? Does going into the intake and head an inch or so sound right? The castings are pretty clean. I thought about clean them up a little. I don't know if I'm going to though. I don't want to cause any damage to them. I'm not a head porter. I'd rather leave them alone if I don't think I can do it. I guess I'll wait until I take them apart to make my mind up on that.

Thanks, NYH1!

I've heard pros and cons about doing this. Some guys say it's a must and others say it's a waist of time. I had a guy tell me the other day that aluminum heads move so much when they get heated up that when they cool down, their intake runners are in a different place then before they got heated up. He said gasket matching them would not be worth doing. My heads are iron.

Another guy told me that you should only make the ports match up and not really gasket match them. He said if you gasket match them you usually go an inch into the runner in the intake as well as in the head. He said all that makes is a funnel like shape coming out of the intake (small to large area) into another funnel like shape going into the head (large to smaller area).

If you recommend that I do gasket match them, how do you do it? Does going into the intake and head an inch or so sound right? The castings are pretty clean. I thought about clean them up a little. I don't know if I'm going to though. I don't want to cause any damage to them. I'm not a head porter. I'd rather leave them alone if I don't think I can do it. I guess I'll wait until I take them apart to make my mind up on that.

Thanks, NYH1!