Im 75 and look it!,

I remember ALMOST all the mistakes I and FRIENDS MADE and what WORKED TOO!

(plus I cheat I keep notes and records on ALMOST all of the engines and cars Ive built, or worked on! over 45 plus years.) Ive come bye most of the scars and info by experience and watching closely, both my own and others experiences

your certainly not alone in having been a bit confused at times,

were ALL ignorant to these factors and how they interact in the beginning,

but IF you keep reading links and taking notes, and asking a few questions,

things will eventually become much clearer,

and you'll get a better grasp on all the concepts and how they interact

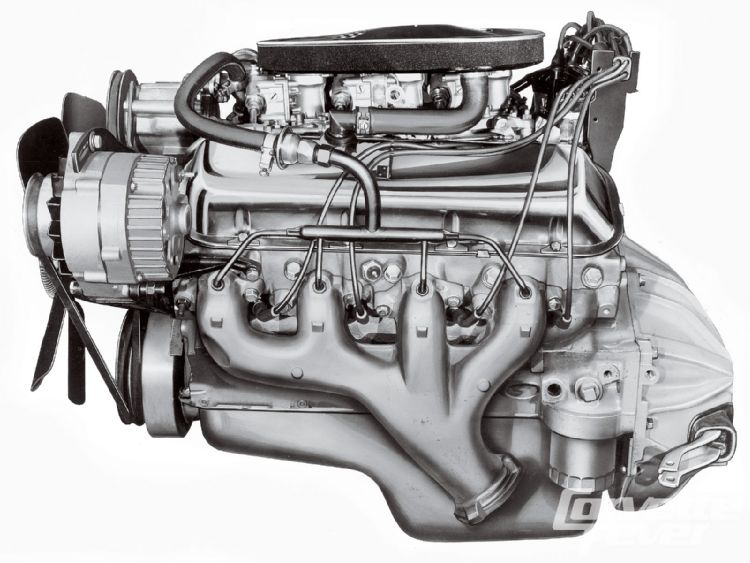

(compression,

bore to stroke ratios,

rocker ratios,

valve spring load rates,

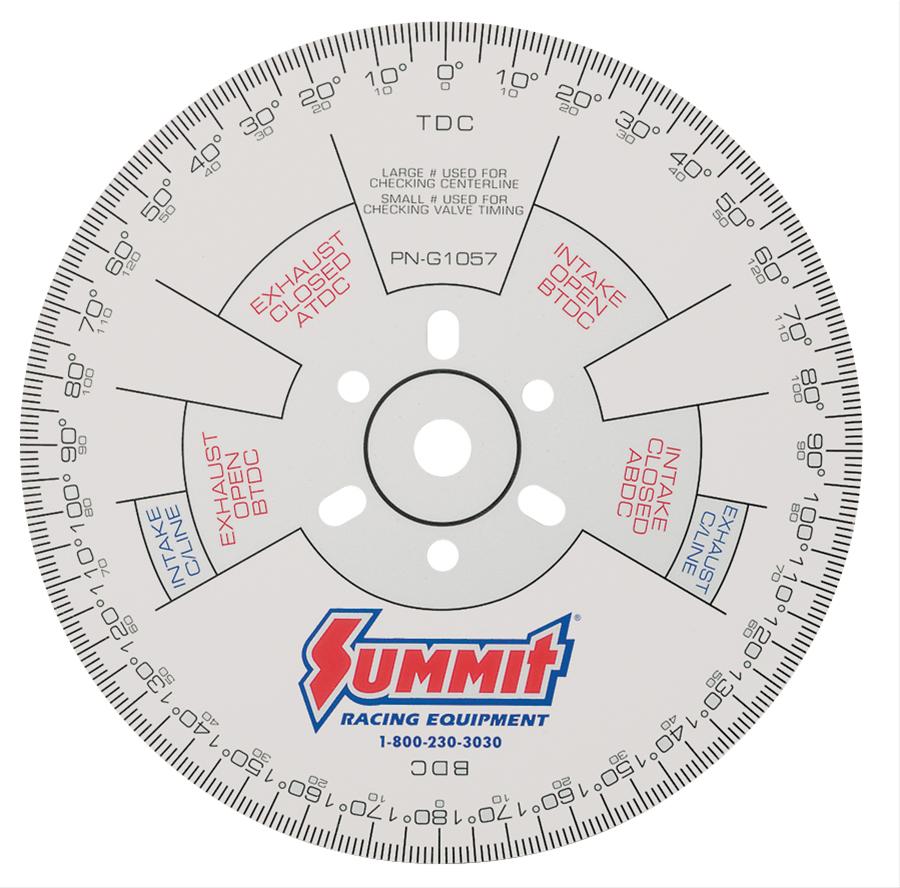

cam timing,

air flow, through heads, & intake,

and header exhaust scavenging

lubrication,

bearing cooling,

valve train control,

fluid pressures and cooling,

ignition timing, etc.)+

I'm sure if you do a few search's on this web site you'll find lots of threads and sub linked info

btw

youll eventually find dozens of engine builds on the internet, it may take you a few years,

but you'll eventually pick up on the fact ,that the vast majority of those internet engine build's intentionally just skip over or ignore a great many of the assembly processes, like the better valves, roller rockers, valve springs, port work, extensive block machine work, and don't mention they used, upgraded pistons ,rings, oil pan, ETC.

or related costs you'll be incurring, to duplicate the results they claim,

or the whole link is designed to sell some part or brand of parts, and they darn sure won,t point out your options or the associated costs and required machine work related to and mandatory in most cases to build that engine

heres some advice!

READ THROUGH THIS LINK

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

you ABSOLUTELY NEED A SHOP MANUAL FOR YOUR CAR,YEAR,MAKE,MODEL

http://www.helminc.com/helm

If there's a Corvette club in your area , JOIN IT,!

if theres a hotrodders club, JOIN IT,!

you don,t need to like all the members,.......odds are good that about 30% know far less than you do,....or are no help at all, ....30% are much more skilled,......than you are, but your there to share skills and knowledge, LEARN FROM THEM, and HELP, become familiar with the tools, take the time, and help each other, its a two way street, don,t expect help if your not willing to help others,etc.

ask some of the members for suggestions and help and BE WILLING TO HELP WITH THEIR PROBLEMS, ITS A LEARNING PROCESS

your bound to find good contacts that will be helpful and a few total jerks you'll want to totally avoid in any group, but don,t let the jerks dis-swade you from getting the benefits and making the contacts you need!

thats a valid suggestion.....you may also want to go to the local tracks DRAG RACE AND CIRCLE TRACK carry a large pad and pen and ask for contacts, clubs,suppliers,club info, etc. make friends and ask the faster guys with the better looking cars , what machine shops and garages/mechanics they would suggest, when you get in over your head. in many cases they will know who the scam artists and rip off garages are and who does good dependable work at reasonable rates, but its been my experience that the best thing you can do is join a local hot rodders or corvette club and between the members contacts and your own resources, YOU will be able to do , and should do,most work your self with some help and knowledge from the guys you make contacts with, in your local clubs, no one but YOU will do QUALITY work and take the time on the details like YOU will on YOUR CORVETTE

keep in mind that theres very few things a decent machine shop and a semi skilled corvette owner with a few friends can,t easily fix, ESPECIALLY if they are willing too take the effort too research the problem , then adjust or replace the parts that are causing the problem, theres nothing mystical or really difficult, but you'll need to know what your doing, and what needs testing and or replacing and that may take research or some investment in tools and learning test procedures, don,t be in awe, theres not a darn thing you can,t learn to do!

youll need basic mechanics tools and having 4 good 12 ton jack stands.

it helps a great deal if you take the time and effort to find a trust worthy and reasonably priced local machine shop , and trust me when I say this is critical, and yes, the machinist will seem to point out endless things that should be done to increase durability, or just allow proper component function,and a good machinist will try to guide you in component selection to help avoid mis-matched parts and low quality parts being used, yes quality parts and machine work, ALWAYS COST more than you may expect them too!

this whole forum.. is installed and maintained to make it easy for both the beginners and the very experienced hot rodders to find, or post information regarding various car and engine related subjects, youll find threads generally have links to related info,

no your not having anything extraordinary happen,

if your building your first engine and running into quite a few problems ,

with the assembly process or sloppy machine shop work!

slapping something together vs

"BUILDING AN ENGINE CORRECTLY "

are vastly different concepts

I look back on the first few engines I built when I was about 17,

and I'm amazed they even ran.

I had never heard of ring gaps,

yet in-spite of that the cars engine started and ran.

A great deal of the content in this whole web sites based

on the idea that readers can benefit from reading about how too ,

avoiding the expensive mistakes many of us older geezers made in the past,

and learning how things should have been done correctly

theres no possible way that I can know each particular problems cause, or suggest the best possible parts choice, or process to fix it, in every case ,unless you post detailed info and perhaps clear pictures. so I try to make it far easier to find answers to the more common problems and questions.

I try to give a good over view on how things work, how they can be tested and what commonly fails.

or I try to provide links to related sources to make your search for information related to any subject covered both easy to find and as extensive as you care to push into your research. I've been building engines and racing for 45 plus years and while I have done many things.

I've built well over a 170 plus engines in 45 plus years , but keep in mind thats only 2-4 engines a year most years, Im always learning and looking to learn from others in this hobby ,so if you can add useful links or information or just as questions to clarify an answer or question you read on the site,to clear up a question or find an answer too the info please do so.

http://www.harborfreight.com/cpi/cta...emnumber=34924

and a decent floor jack, and some car club friends sure helps, if you have SAFE AND STURDY ,easy access under the car maintenance and repairs are easier to do!

Ill add these tips

the most valuable tool you can acquire is as broad a selection of valid information, on exactly how and why things work in your car,s engine, drive train , and suspension , as a reference base to work from, and acquiring a good set of testing and measuring tools to verify and test with

http://carclubhunter.org/states/florida-car-clubs.htm

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

http://garage.grumpysperformance.com/index.php?threads/the-basics.3733/#post-30179

(1) do EXTENSIVE research FIRST, before....... buying parts.... or starting a modification, that INCLUDES making a detailed parts list and researching , the sources, cost, manuals etc. IE FIND OUT whats necessary to do the job, and what results you'll expect before you start

(2) ITS a HUGE advantage to have the correct tools, things like engine cranes, diagnostic test equipment, welders,lifts, etc. may seem like a big expense that's not directly moving your project forward, but there NECESSARY in some cases and ALWAYS make the project go faster and easier than trying to do without them.

(3) work SAFELY, if you could get hurt doing something, chances are very good that you will eventually find out exactly WHY you should have done it the safe rather than the fast/easy way, if you don,t think it thru and use the correct tools and precautions

(4)ITs almost ALWAYS better to have several friends help, on a project, having two or more guys thinking things thru improves your chances of getting it done correctly and safely,and keep in mind ,its always best to do your projects after helping a more experienced guy do something similar on his car so you have some experience doing it, thus be ready and available to help your buddies within their projects and don,t avoid helping so you won,t get dirty, or have some free time that's used on other guys cars vs yours...in the long run it pays big to help others

(5)ask questions and be sure you understand the answers, KNOWING what your doing before you start is a huge advantage

(6)take pictures, label wiring, put small parts in labeled ziploc bags and take notes, use the manuals, and internet, and if something won,t fit or looks wrong research rather than forcing it with a bigger hammer

now I got asked,

"what do you do, who do you call when your about to tackle a job you've never done before?"

now most guys sub out jobs to the dealer or a corvette shop when they get into areas they may not be familiar with,but I do ALL the work on my corvettes for TWO good reasons, first I could NEVER afford the shop rates and I can NEVER trust the quality of work many shops do, now ILL be the VERY FIRST GUY IN LINE to ADMIT Im in WAY over my head at times! but Ive always been able to research the processes, tools, and skills and do the work, or find someone too teach me the skills eventually, you'll NEVER learn new stuff if your not willing to tackle new projects and get in way over your current skill level....besides it USUALLY requires buying LOTS OF new tools and meeting new friends so you can,t hardly lose!

IF you take this advice seriously youll save ALOT of time and money

DO YOURSELF A HUGE FAVOR

buy these books, FIRST it will be the best money you ever spent, read them, and you will be miles ahead of the average guy. youll save thousands of dollars and thousands of hours once youve got a good basic understanding of what your trying to do!

http://www.rehermorrison.com/rmEngineBook.htm

http://www.themotorbookstore.com/resmchstvi.html

how to assemble an engine basics on video

http://www.racingjunk.com/category

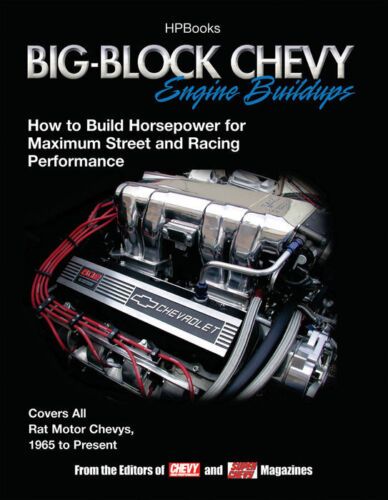

[b]these books will be useful[/b]

http://www.amazon.com/How-Rebuild-Your- ... 1557880298

http://www.amazon.com/Rebuild-Small-Blo ... 88408995X/

http://www.amazon.com/Rebuild-Small-Blo ... 95&sr=1-13

viewtopic.php?f=27&t=845&p=1281&hilit=trailer#p1281

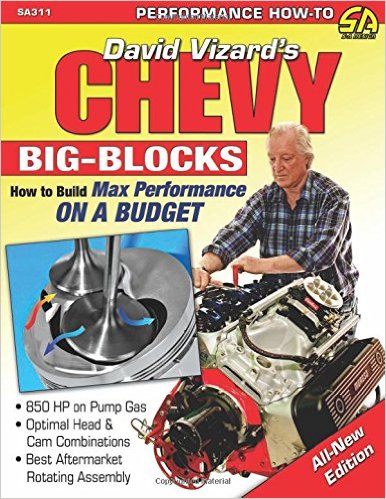

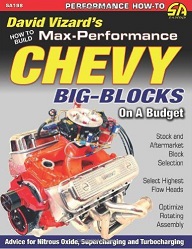

HOW TO BUILD MAX PERFORMANCE CHEVY SMALL BLOCKS ON A BUDGET by DAVID VIZARD

http://www.amazon.com/Build-Perform...=sr_1_1?ie=UTF8&s=books&qid=1195231793&sr=1-1

JOHN LINGENFELTER on modifying small-block chevy engines

http://www.amazon.com/John-Lingenfe...=sr_1_1?ie=UTF8&s=books&qid=1195231760&sr=1-1

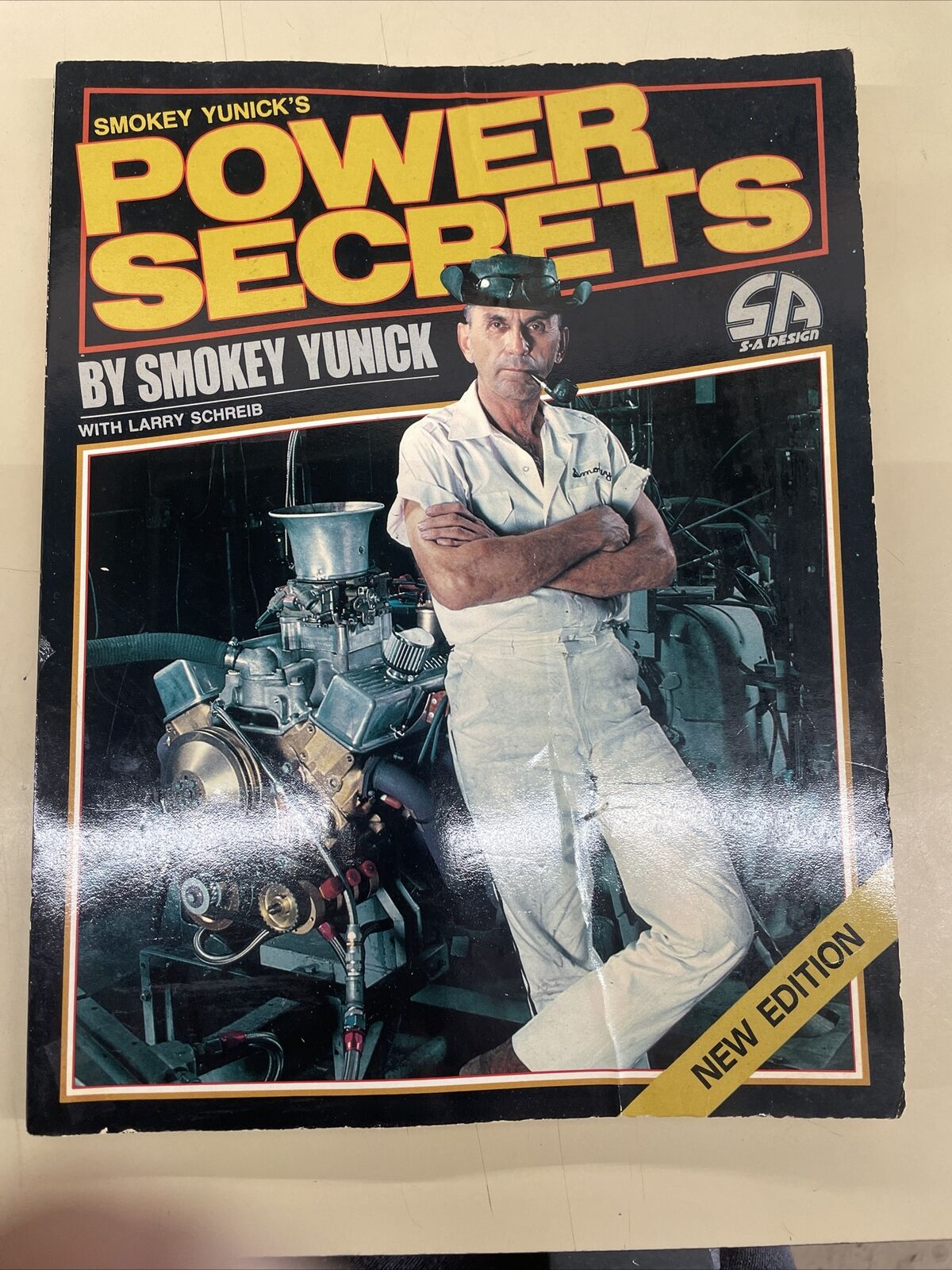

SMOKEY YUNICK,S POWER SECRETS

http://www.amazon.com/Smokey-Yunick...=sr_1_1?ie=UTF8&s=books&qid=1195231724&sr=1-1

How to Rebuild Small-Block Chevy Lt1/Lt4 Engines

http://www.amazon.com/Rebuild-Small-Block-Chevy-Engines-Hp1393/dp/1557883939/ref=pd_sim_b

I constantly see guys who get involved in mods to their cars who either don,t understand that things seldom go as planned or that even understand that even if you know what your doing that the suppliers and machine shops seldom work to your schedule, and guys who buy project cars with zero idea as to the parts they are getting in that car or their condition,or guys who then actually think they can use the car as transportation...yet still race the car on a moments notice

your at a distinct dis-advantage if you have zero idea what components were used in your engine, theres three routes to go,

(1) if it runs good just drive it and don,t worry about it

(2) you can disassemble the engine and carefully identify what you currently have so you know exactly what you have (see#1) and then if you want to make changes you know what needs changing and what you can keep

(3)find or buy a second engine or at least the major components, assemble it with a well thought thru plan, parts list and goal, while you drive the current combo(see#1) and once you have everything assembled with matched components you spend some long weekend swapping engines and drive train components, (this has the huge advantage that you have a fall back option if the new combo doesn,t meet your expectations as you can always return to the current combo in a single week ends work (see#1) yet you can potentially have a far more aggressive engine combo that kicks butt and takes names, and your not screwed for weeks or months at a time if something breaks if you race the car, and can make changes on your serious engine without truly compromising your cars value as transportation, and you can choose to keep or sell the expensive parts separately from or with the car should you ever decide to sell the vette.

Ive always suggested the THIRD option is the best, having at least two engines is the best route if your into tinkering and racing your corvette that's why I currently have six engines I own in the shop, in various con-figs, I can get the vette to perform as I choose simply by taking my time while I build, modify or test drive the corvettes optional engines as I build the test engine and swap it out for a few weeks or months of testing ,I can even rebuild or slightly change the basic transportation engine if I choose too while IM driving one of the other test engines, just remember one engine needs to stay pretty basic and dependable while on the other(S) you can let your imagination and budget run a muck as you see fit

yes theres two basic flaws to that option,

(1) YES ,you need a garage or place to store and work on the spare engine, and it helps tremendously to have a second car, (a small pick-up trucks ideal so you can transport parts to the machine shop easily, and get to work on days when the promised parts don,t arrive or the machine shop doesn,t get the work done as they assured you they would.)

(2)YES it takes a bit more money up front at first, but in the long run its almost always cheaper and easier on your wallet, and the vette spends more time actually in drivable condition rather than down waiting for parts or machine work to be done

learning new skills is a good thing, jump on in!

many new guys are reluctant to even try, the more complicated projects because of a realistic expectation that they may get in over their heads and not be able to get the car running again, Ive seen that reluctance many times.

having access to the internet and buying a shop manual and committing to the process of learning, the basics,buying a few basic tools is a necessary step.

joining at least two different hot rod or corvette clubs will help make the required contacts, in the hobby but you won,t truly learn much until you start offering to help other more experienced members on their projects, you'll learn a great deal helping the more experienced guys do the simple stuff like swapping injectors,or carbs, adjusting, rockers,welding exhaust systems, doing brake jobs, or replacing u-joints or tuning their cars, etc. but you won,t get the chance unless your willing to provide some free labor in most cases.

once you can hook up with a more experienced hot rodder who will act as a mentor you will seldom have major problems.

the question then becomes how to hook up, and where to find a mentor?

http://www.chatmag.com/topics/auto/hotrod.html

http://www.idavette.net/clubs.htm

grumpysperformance.com

I know! you've never done something and your afraid you'll mess it up,

EXAMPLE

the first time I looked over a TPI injection system I was very reluctant to start taking things apart, so as a hedge I took a dozen close up digital photos and labeled every connection with masking tape and a magic marker sharpie pen, I had no idea how the injector connectors were released and didn,t realize there was a spring retainer until Id got four removed, but after about the first dozen, I didn,t even bother looking any longer since things were so familiar.

EXAMPLE

the wife's MERCURY had the power seat control switch in the door go bad, I bought a new one,but I was very reluctant to disassemble the door panel, as I was sure ID screw it up!, but some careful inspection revealed it could easily be accessed and in 10 minutes I was done doing a job ID been hesitant to start for days.

theres a first time for nearly everything and you'll be surprised, in many cases you'll find you enjoy knowing how to do things better.....think back to how clumsy and hesitant you probably felt when you started dating,but learning new skills has its benefits

IF YOUR SMART youll buy parts and get a second engine built on a decent engine stand and assemble your hot rod engine project, taking your time and doing everything correctly rather than constantly pulling apart and mis -matching parts on the c4/lt4, its usually a good idea to have the stock original engine available for transportation as long as possible and available as a quickly swapped in replacement should the modified engine take a crap, or parts need machine work, etc.

THESE LINKS SHOULD HELP

viewtopic.php?f=50&t=11026&p=48766#p48766

http://www.amazon.com/Rebuild-Small...39/ref=sr_1_16?ie=UTF8&qid=1325362601&sr=8-16

http://forum.grumpysperformance.com/viewtopic.php?f=87&t=339&p=17657&hilit=started+hobby#p17657

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=1018&p=14885&hilit=engine+stand#p14885

viewtopic.php?f=50&t=11026

http://garage.grumpysperformance.com/index.php?threads/back-in-the-past-vs-today.15043/

http://garage.grumpysperformance.co...-for-truck-build-sbc-engine.12050/#post-57645

http://garage.grumpysperformance.co...ll-of-receipts-is-not-proof.10281/#post-46628

ID bet easily 10% of the corvettes ever sold were in some way related to guys building projects where they got in over their heads due to lack of knowledge or they got in temporary trouble financially wise, , many would still be with their previous owners if they could have swapped back the original engine while they worked out the glitches in the performance engine or had a daily driver until finances improved

I remember ALMOST all the mistakes I and FRIENDS MADE and what WORKED TOO!

(plus I cheat I keep notes and records on ALMOST all of the engines and cars Ive built, or worked on! over 45 plus years.) Ive come bye most of the scars and info by experience and watching closely, both my own and others experiences

your certainly not alone in having been a bit confused at times,

were ALL ignorant to these factors and how they interact in the beginning,

but IF you keep reading links and taking notes, and asking a few questions,

things will eventually become much clearer,

and you'll get a better grasp on all the concepts and how they interact

(compression,

bore to stroke ratios,

rocker ratios,

valve spring load rates,

cam timing,

air flow, through heads, & intake,

and header exhaust scavenging

lubrication,

bearing cooling,

valve train control,

fluid pressures and cooling,

ignition timing, etc.)+

I'm sure if you do a few search's on this web site you'll find lots of threads and sub linked info

btw

youll eventually find dozens of engine builds on the internet, it may take you a few years,

but you'll eventually pick up on the fact ,that the vast majority of those internet engine build's intentionally just skip over or ignore a great many of the assembly processes, like the better valves, roller rockers, valve springs, port work, extensive block machine work, and don't mention they used, upgraded pistons ,rings, oil pan, ETC.

or related costs you'll be incurring, to duplicate the results they claim,

or the whole link is designed to sell some part or brand of parts, and they darn sure won,t point out your options or the associated costs and required machine work related to and mandatory in most cases to build that engine

heres some advice!

READ THROUGH THIS LINK

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/

you ABSOLUTELY NEED A SHOP MANUAL FOR YOUR CAR,YEAR,MAKE,MODEL

http://www.helminc.com/helm

If there's a Corvette club in your area , JOIN IT,!

if theres a hotrodders club, JOIN IT,!

you don,t need to like all the members,.......odds are good that about 30% know far less than you do,....or are no help at all, ....30% are much more skilled,......than you are, but your there to share skills and knowledge, LEARN FROM THEM, and HELP, become familiar with the tools, take the time, and help each other, its a two way street, don,t expect help if your not willing to help others,etc.

ask some of the members for suggestions and help and BE WILLING TO HELP WITH THEIR PROBLEMS, ITS A LEARNING PROCESS

your bound to find good contacts that will be helpful and a few total jerks you'll want to totally avoid in any group, but don,t let the jerks dis-swade you from getting the benefits and making the contacts you need!

thats a valid suggestion.....you may also want to go to the local tracks DRAG RACE AND CIRCLE TRACK carry a large pad and pen and ask for contacts, clubs,suppliers,club info, etc. make friends and ask the faster guys with the better looking cars , what machine shops and garages/mechanics they would suggest, when you get in over your head. in many cases they will know who the scam artists and rip off garages are and who does good dependable work at reasonable rates, but its been my experience that the best thing you can do is join a local hot rodders or corvette club and between the members contacts and your own resources, YOU will be able to do , and should do,most work your self with some help and knowledge from the guys you make contacts with, in your local clubs, no one but YOU will do QUALITY work and take the time on the details like YOU will on YOUR CORVETTE

keep in mind that theres very few things a decent machine shop and a semi skilled corvette owner with a few friends can,t easily fix, ESPECIALLY if they are willing too take the effort too research the problem , then adjust or replace the parts that are causing the problem, theres nothing mystical or really difficult, but you'll need to know what your doing, and what needs testing and or replacing and that may take research or some investment in tools and learning test procedures, don,t be in awe, theres not a darn thing you can,t learn to do!

youll need basic mechanics tools and having 4 good 12 ton jack stands.

it helps a great deal if you take the time and effort to find a trust worthy and reasonably priced local machine shop , and trust me when I say this is critical, and yes, the machinist will seem to point out endless things that should be done to increase durability, or just allow proper component function,and a good machinist will try to guide you in component selection to help avoid mis-matched parts and low quality parts being used, yes quality parts and machine work, ALWAYS COST more than you may expect them too!

this whole forum.. is installed and maintained to make it easy for both the beginners and the very experienced hot rodders to find, or post information regarding various car and engine related subjects, youll find threads generally have links to related info,

no your not having anything extraordinary happen,

if your building your first engine and running into quite a few problems ,

with the assembly process or sloppy machine shop work!

slapping something together vs

"BUILDING AN ENGINE CORRECTLY "

are vastly different concepts

I look back on the first few engines I built when I was about 17,

and I'm amazed they even ran.

I had never heard of ring gaps,

yet in-spite of that the cars engine started and ran.

A great deal of the content in this whole web sites based

on the idea that readers can benefit from reading about how too ,

avoiding the expensive mistakes many of us older geezers made in the past,

and learning how things should have been done correctly

theres no possible way that I can know each particular problems cause, or suggest the best possible parts choice, or process to fix it, in every case ,unless you post detailed info and perhaps clear pictures. so I try to make it far easier to find answers to the more common problems and questions.

I try to give a good over view on how things work, how they can be tested and what commonly fails.

or I try to provide links to related sources to make your search for information related to any subject covered both easy to find and as extensive as you care to push into your research. I've been building engines and racing for 45 plus years and while I have done many things.

I've built well over a 170 plus engines in 45 plus years , but keep in mind thats only 2-4 engines a year most years, Im always learning and looking to learn from others in this hobby ,so if you can add useful links or information or just as questions to clarify an answer or question you read on the site,to clear up a question or find an answer too the info please do so.

http://www.harborfreight.com/cpi/cta...emnumber=34924

and a decent floor jack, and some car club friends sure helps, if you have SAFE AND STURDY ,easy access under the car maintenance and repairs are easier to do!

Ill add these tips

the most valuable tool you can acquire is as broad a selection of valid information, on exactly how and why things work in your car,s engine, drive train , and suspension , as a reference base to work from, and acquiring a good set of testing and measuring tools to verify and test with

http://carclubhunter.org/states/florida-car-clubs.htm

http://garage.grumpysperformance.com/index.php?threads/should-you-buy-bare-or-assembled-heads.534/

http://garage.grumpysperformance.com/index.php?threads/the-basics.3733/#post-30179

(1) do EXTENSIVE research FIRST, before....... buying parts.... or starting a modification, that INCLUDES making a detailed parts list and researching , the sources, cost, manuals etc. IE FIND OUT whats necessary to do the job, and what results you'll expect before you start

(2) ITS a HUGE advantage to have the correct tools, things like engine cranes, diagnostic test equipment, welders,lifts, etc. may seem like a big expense that's not directly moving your project forward, but there NECESSARY in some cases and ALWAYS make the project go faster and easier than trying to do without them.

(3) work SAFELY, if you could get hurt doing something, chances are very good that you will eventually find out exactly WHY you should have done it the safe rather than the fast/easy way, if you don,t think it thru and use the correct tools and precautions

(4)ITs almost ALWAYS better to have several friends help, on a project, having two or more guys thinking things thru improves your chances of getting it done correctly and safely,and keep in mind ,its always best to do your projects after helping a more experienced guy do something similar on his car so you have some experience doing it, thus be ready and available to help your buddies within their projects and don,t avoid helping so you won,t get dirty, or have some free time that's used on other guys cars vs yours...in the long run it pays big to help others

(5)ask questions and be sure you understand the answers, KNOWING what your doing before you start is a huge advantage

(6)take pictures, label wiring, put small parts in labeled ziploc bags and take notes, use the manuals, and internet, and if something won,t fit or looks wrong research rather than forcing it with a bigger hammer

now I got asked,

"what do you do, who do you call when your about to tackle a job you've never done before?"

now most guys sub out jobs to the dealer or a corvette shop when they get into areas they may not be familiar with,but I do ALL the work on my corvettes for TWO good reasons, first I could NEVER afford the shop rates and I can NEVER trust the quality of work many shops do, now ILL be the VERY FIRST GUY IN LINE to ADMIT Im in WAY over my head at times! but Ive always been able to research the processes, tools, and skills and do the work, or find someone too teach me the skills eventually, you'll NEVER learn new stuff if your not willing to tackle new projects and get in way over your current skill level....besides it USUALLY requires buying LOTS OF new tools and meeting new friends so you can,t hardly lose!

IF you take this advice seriously youll save ALOT of time and money

DO YOURSELF A HUGE FAVOR

buy these books, FIRST it will be the best money you ever spent, read them, and you will be miles ahead of the average guy. youll save thousands of dollars and thousands of hours once youve got a good basic understanding of what your trying to do!

http://www.rehermorrison.com/rmEngineBook.htm

http://www.themotorbookstore.com/resmchstvi.html

how to assemble an engine basics on video

http://www.racingjunk.com/category

[b]these books will be useful[/b]

http://www.amazon.com/How-Rebuild-Your- ... 1557880298

http://www.amazon.com/Rebuild-Small-Blo ... 88408995X/

http://www.amazon.com/Rebuild-Small-Blo ... 95&sr=1-13

viewtopic.php?f=27&t=845&p=1281&hilit=trailer#p1281

HOW TO BUILD MAX PERFORMANCE CHEVY SMALL BLOCKS ON A BUDGET by DAVID VIZARD

http://www.amazon.com/Build-Perform...=sr_1_1?ie=UTF8&s=books&qid=1195231793&sr=1-1

JOHN LINGENFELTER on modifying small-block chevy engines

http://www.amazon.com/John-Lingenfe...=sr_1_1?ie=UTF8&s=books&qid=1195231760&sr=1-1

SMOKEY YUNICK,S POWER SECRETS

http://www.amazon.com/Smokey-Yunick...=sr_1_1?ie=UTF8&s=books&qid=1195231724&sr=1-1

How to Rebuild Small-Block Chevy Lt1/Lt4 Engines

http://www.amazon.com/Rebuild-Small-Block-Chevy-Engines-Hp1393/dp/1557883939/ref=pd_sim_b

I constantly see guys who get involved in mods to their cars who either don,t understand that things seldom go as planned or that even understand that even if you know what your doing that the suppliers and machine shops seldom work to your schedule, and guys who buy project cars with zero idea as to the parts they are getting in that car or their condition,or guys who then actually think they can use the car as transportation...yet still race the car on a moments notice

your at a distinct dis-advantage if you have zero idea what components were used in your engine, theres three routes to go,

(1) if it runs good just drive it and don,t worry about it

(2) you can disassemble the engine and carefully identify what you currently have so you know exactly what you have (see#1) and then if you want to make changes you know what needs changing and what you can keep

(3)find or buy a second engine or at least the major components, assemble it with a well thought thru plan, parts list and goal, while you drive the current combo(see#1) and once you have everything assembled with matched components you spend some long weekend swapping engines and drive train components, (this has the huge advantage that you have a fall back option if the new combo doesn,t meet your expectations as you can always return to the current combo in a single week ends work (see#1) yet you can potentially have a far more aggressive engine combo that kicks butt and takes names, and your not screwed for weeks or months at a time if something breaks if you race the car, and can make changes on your serious engine without truly compromising your cars value as transportation, and you can choose to keep or sell the expensive parts separately from or with the car should you ever decide to sell the vette.

Ive always suggested the THIRD option is the best, having at least two engines is the best route if your into tinkering and racing your corvette that's why I currently have six engines I own in the shop, in various con-figs, I can get the vette to perform as I choose simply by taking my time while I build, modify or test drive the corvettes optional engines as I build the test engine and swap it out for a few weeks or months of testing ,I can even rebuild or slightly change the basic transportation engine if I choose too while IM driving one of the other test engines, just remember one engine needs to stay pretty basic and dependable while on the other(S) you can let your imagination and budget run a muck as you see fit

yes theres two basic flaws to that option,

(1) YES ,you need a garage or place to store and work on the spare engine, and it helps tremendously to have a second car, (a small pick-up trucks ideal so you can transport parts to the machine shop easily, and get to work on days when the promised parts don,t arrive or the machine shop doesn,t get the work done as they assured you they would.)

(2)YES it takes a bit more money up front at first, but in the long run its almost always cheaper and easier on your wallet, and the vette spends more time actually in drivable condition rather than down waiting for parts or machine work to be done

learning new skills is a good thing, jump on in!

many new guys are reluctant to even try, the more complicated projects because of a realistic expectation that they may get in over their heads and not be able to get the car running again, Ive seen that reluctance many times.

having access to the internet and buying a shop manual and committing to the process of learning, the basics,buying a few basic tools is a necessary step.

joining at least two different hot rod or corvette clubs will help make the required contacts, in the hobby but you won,t truly learn much until you start offering to help other more experienced members on their projects, you'll learn a great deal helping the more experienced guys do the simple stuff like swapping injectors,or carbs, adjusting, rockers,welding exhaust systems, doing brake jobs, or replacing u-joints or tuning their cars, etc. but you won,t get the chance unless your willing to provide some free labor in most cases.

once you can hook up with a more experienced hot rodder who will act as a mentor you will seldom have major problems.

the question then becomes how to hook up, and where to find a mentor?

http://www.chatmag.com/topics/auto/hotrod.html

http://www.idavette.net/clubs.htm

grumpysperformance.com

I know! you've never done something and your afraid you'll mess it up,

EXAMPLE

the first time I looked over a TPI injection system I was very reluctant to start taking things apart, so as a hedge I took a dozen close up digital photos and labeled every connection with masking tape and a magic marker sharpie pen, I had no idea how the injector connectors were released and didn,t realize there was a spring retainer until Id got four removed, but after about the first dozen, I didn,t even bother looking any longer since things were so familiar.

EXAMPLE

the wife's MERCURY had the power seat control switch in the door go bad, I bought a new one,but I was very reluctant to disassemble the door panel, as I was sure ID screw it up!, but some careful inspection revealed it could easily be accessed and in 10 minutes I was done doing a job ID been hesitant to start for days.

theres a first time for nearly everything and you'll be surprised, in many cases you'll find you enjoy knowing how to do things better.....think back to how clumsy and hesitant you probably felt when you started dating,but learning new skills has its benefits

IF YOUR SMART youll buy parts and get a second engine built on a decent engine stand and assemble your hot rod engine project, taking your time and doing everything correctly rather than constantly pulling apart and mis -matching parts on the c4/lt4, its usually a good idea to have the stock original engine available for transportation as long as possible and available as a quickly swapped in replacement should the modified engine take a crap, or parts need machine work, etc.

THESE LINKS SHOULD HELP

viewtopic.php?f=50&t=11026&p=48766#p48766

http://www.amazon.com/Rebuild-Small...39/ref=sr_1_16?ie=UTF8&qid=1325362601&sr=8-16

http://forum.grumpysperformance.com/viewtopic.php?f=87&t=339&p=17657&hilit=started+hobby#p17657

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=1018&p=14885&hilit=engine+stand#p14885

viewtopic.php?f=50&t=11026

http://garage.grumpysperformance.com/index.php?threads/back-in-the-past-vs-today.15043/

http://garage.grumpysperformance.co...-for-truck-build-sbc-engine.12050/#post-57645

http://garage.grumpysperformance.co...ll-of-receipts-is-not-proof.10281/#post-46628

ID bet easily 10% of the corvettes ever sold were in some way related to guys building projects where they got in over their heads due to lack of knowledge or they got in temporary trouble financially wise, , many would still be with their previous owners if they could have swapped back the original engine while they worked out the glitches in the performance engine or had a daily driver until finances improved

Last edited by a moderator: