this is an area of performance car building that I find most guys either guess at or ignore, few guys do any research, or if they do, its only to ask a buddy what rear gear ratio they are running.

the fact is its all easily calculated and get reasonable close and many guys can,t tell they are not running the best available choice, if they get way off, they frequently blame the engine or cam selected

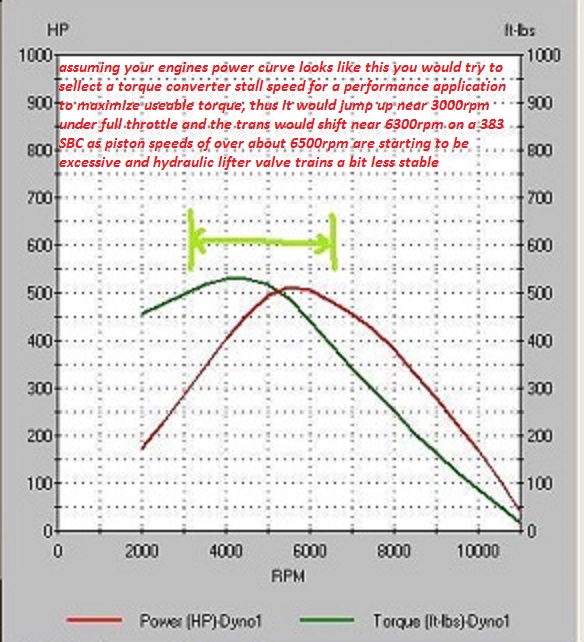

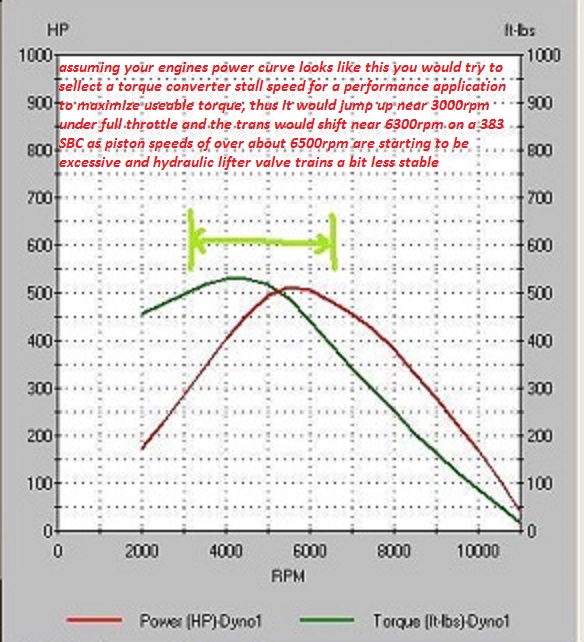

I'm always rather amused that so many guys want to get so darn confused about what is basically brutally simple, the purpose of a performance torque converter is to allow near instant access too and full use off and efficient use of the engines peak torque over most of its power band, the transmission must of course be set up to shift to the next lower gear each time the engine rpms start to exceed the ideal power range or drop back into the ideal power band if the torque available is no longer sufficient to easily move the car, to do this you simply need to know the cars drive train gearing tire size and the engines power band and red-line or upper rpm limitations, and the engines lower rpm power band effective limitations and a dyno tuning test session easily determines those factors, obviously you match YOUR engines limitations and power curve to the torque converter rear gear and engine, so under full throttle conditions you would want the engine to almost instantly access the engines 3000rpm range and the transmission to shift to the next gear every time rpms hit 6300rpm in THAT particular example, as THAT would allow maximum access to the engine torque curve.

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

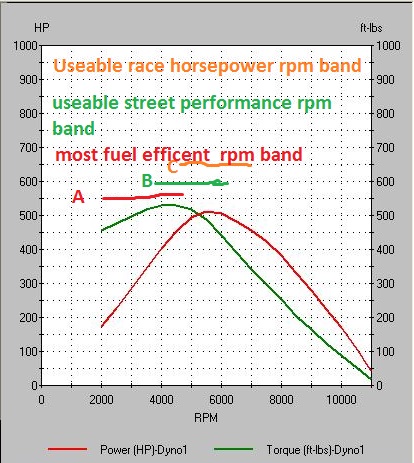

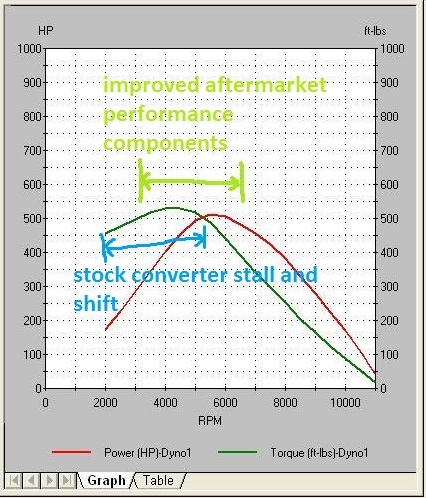

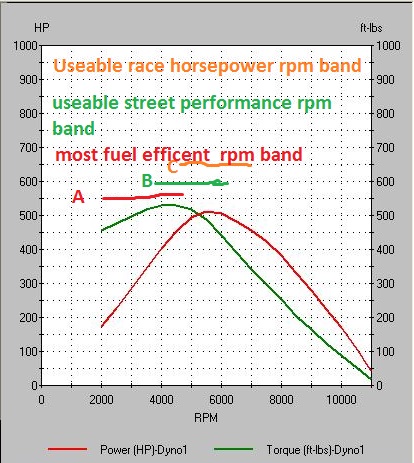

heres what DD200o software predicts my current corvette engines power curve is, I have a 700r4 transmission and 24.6: tall tires , you should be able to easily see why I selected a 3000rpm stall converter and added a shift kit to the transmission that allows it to reach a bit over 6000rpm under full throttle load shifts (I tried to get it to 6300 but they don,t make a kit that I could find at a reasonable cost)

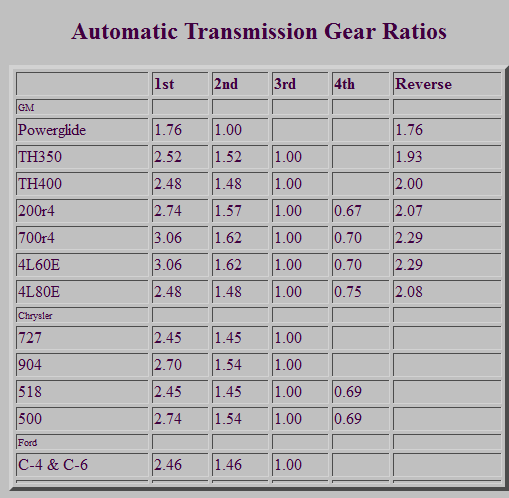

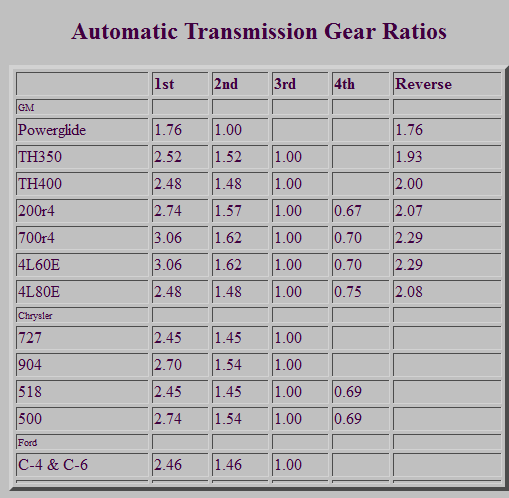

given that info...if we take 10.5 and divide that by the 3.06 first gear in my current transmission we get a 3.43:1 rear gear ratio.

see info posted below.

I purchased a 4l80E for my corvettes eventual BIG BLOCK engine swap, its first gear ratio of 2.48 suggest a 4.11 rear gears about correct,many guys will not use the over drive top gear in their calculations for drag racing rear gears as they feel that they will perform best if those O.D. top gears are not considered.

http://users.erols.com/srweiss/calcrpm.htm

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://www.superchevy.com/how-to/tr...can-handle-1000-hp/?cx_source=cxrecs#cxrecs_s

https://700r4l60e.com/

reasonably expected E.T. from engine rear wheel horse power and car total weight with you driving it. REMEMBER THIS IS REAR WHEEL NOT FLYWHEEL HP IN THE CALCULATIONS AND YOUR WEIGHT IS INCLUDED IN THE CAR

http://www.wallaceracing.com/et-hp-mph.php

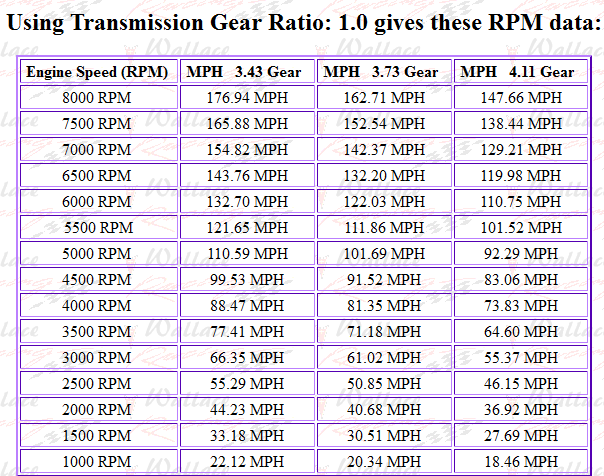

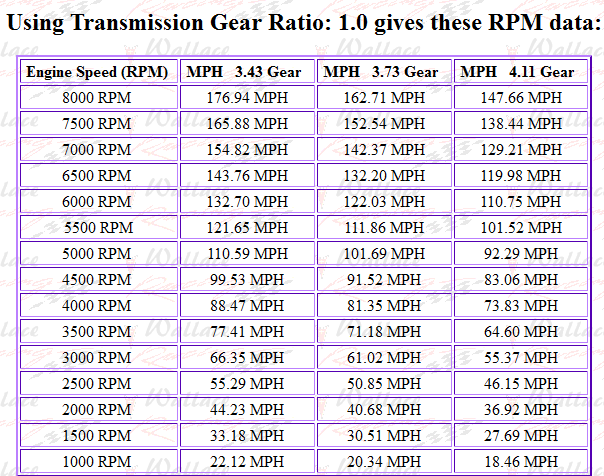

lets assume your horse power and weight calcs result in a very quick street corvette that can clock a 120 MPH 1/4 mile speed and you have 24.5" diameter rear tires, a bit of math shows youll be spinning that engine near 6200rpm with a 3.73:1 rear gear ratio with a 1:1 top gear transmission, and thats a very common result in a well built corvette drive train,that still allows considerably more top speed once O.D. is used

http://users.erols.com/srweiss/calcrpm.htm

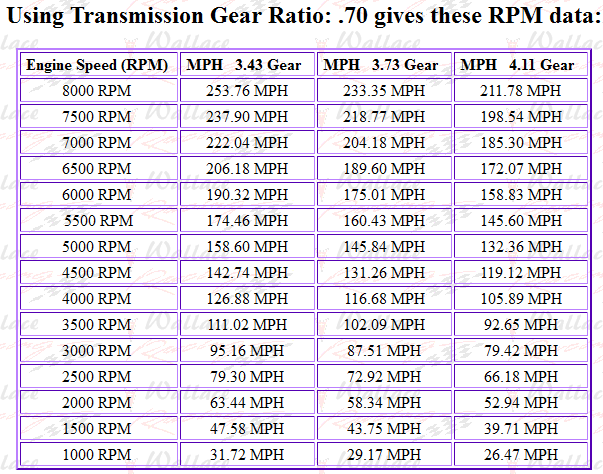

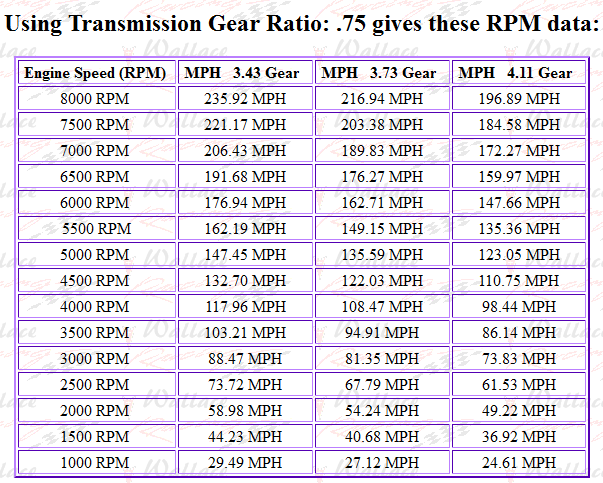

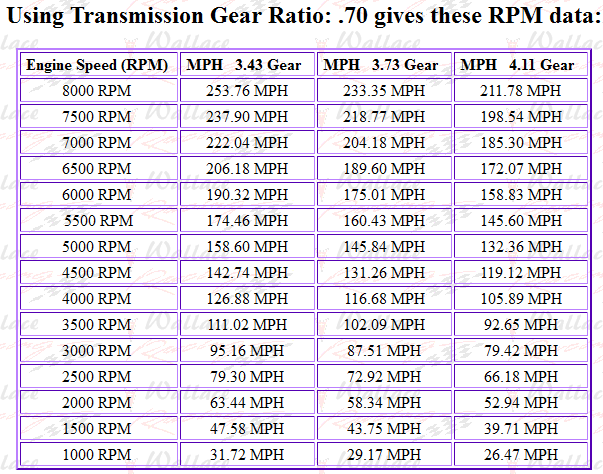

heres the result if I had a TH400

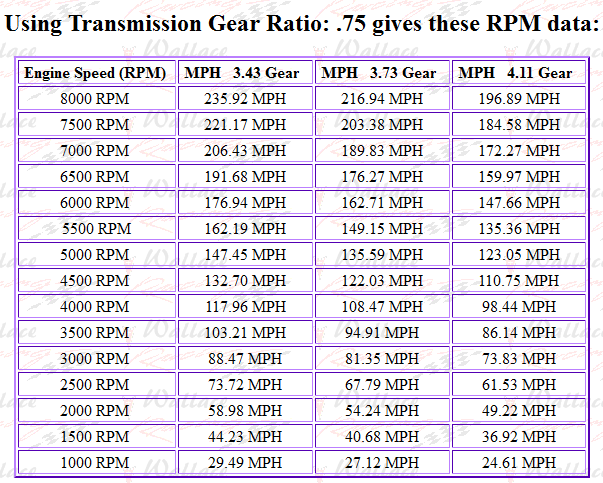

heres the result if I had a 700r4

heres the result if I had a 4L80E

GIVEN THAT THE INDEPENDENT REAR IN MY 1985 CORVETTES NEVER GOING TO LAST UNDER THE BIG BLOCK POWER CURVE IT SEEMS LIKE A DIFFERENT DIFFERENTIAL WILL BE NEEDED

every engine has a certain rpm range where its able to make the best torque, its torque that gets the car moving, gear the car so it spends almost all its time spinning in its most efficient power band, and youll maximize the engine's ability to put power to the pavement, gear the car so it spends most of its time below that power band or set the transmission and gearing so it shifts to the next gear well below, the horse power peak and efficiency suffers.

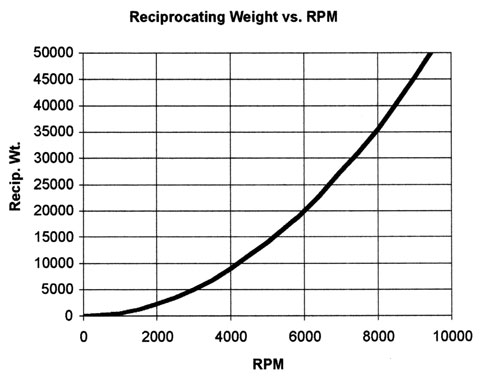

now obviously factors like car weight, exhaust restriction,engine compression limits due to low octane fuel, and tire diameter will effect your results, and valve train stress, transmission shift points and piston speed and port cross sectional areas tend to limit engine rpms on the upper end of the rpm range.

the higher the torque the engine produces the higher the converter stall speed is likely to be but its never an exact ratio relationship

Keep in mind when selecting a new performance torque converter that there are design limitations and strength limits to all designs, if your old engine made about 370 ft lbs and stalled near 2500 rpm, and

your new engine makes 470 ft lbs of torque thats about a 25% increase, in torque.

so you might, quite reasonably expect or guess that the stall speed would jump about 25% from 2500 rpm to near 3125 rpm,

( example 2500rpm x 1.25%-3125 rpm)

While that sounds reasonable, the real world is not as predictable.

In my experience it won,t necessarily jump a totally predictable amount,

simply because there is a wide variation in the torque converter designs,and engine torque curves and cam characteristics, compression ratios, displacements etc.

Id expect it to jump a bit less, to maybe nearer too 2950 rpm from my experience.

this is based on what I've seen when guys bolt the same converter and transmission they formally had behind a performance 350- 383 SBC

behind a new 454-496 BBC engine

ID also point out that occasionally youll find a converter that worked just fine behind a SBC,

fails when you introduce it to a 25%-50% torque increase with a BBC swap

For performance applications ,as a general rule the first gear ratio of your transmission multiplied times your rear gear ratio should fall in the 10:1-10.5:1 range, you need to know your tire diameter, and you generally don,t want to have the engine spinning at over about 3000rpm at 70 mph if you use the car for transportation, or well under its best operational rpm range most of the time and you certainly don,t want the automatic transmission to shift at well under your peak power or have a stall torque converter speed well below the effective power band.

If you were gearing the car to actually race it you would expect to be spinning the engine at peak effective rpms on the power band as you run through the lights at the end of the track, if your engine peaks near 6300 rpm like the software dyno posted here shows about 500 flywheel horse power and thats about 400 rear wheel horse power and you take the corvettes weight of about 3400 lbs

http://www.wallaceracing.com/et-hp-mph.php

the calculator suggests 11.89 seconds and MPH of 113.69 MPH.

Id get the car to reach 6400 rpm at 120 mph

horse power is measured/ calculated with the formula torque x rpm divided by 5252-- hp

THUS ITS THE FORCE OR TORQUE MULTIPLIED BY, THE RPM THAT IT CAN BE APPLIED AT, THAT DETERMINES THE RATE AT WHICH THAT FORCE AVAILABLE OR WORK CAN BE ACCOMPLISHED

EXAMPLE

450 FT LBS OF TORQUE AT 3500RPM= 300 HP

450 FT LBS OF TORQUE AT 6500RPM= 557 HP

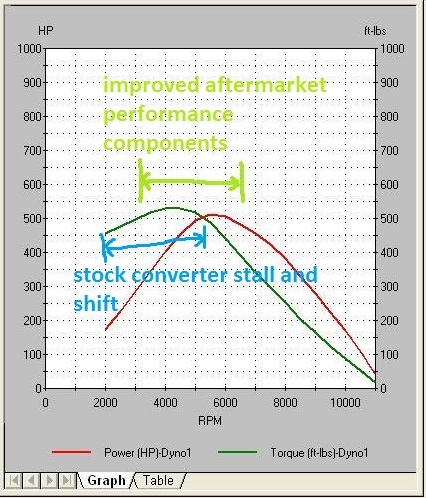

on a street performance car application, the goal, is usually gearing the car to maximize the usable torque curve, while maintaining reasonable mileage and engine durability.

on a race car application, the goal, is usually gearing the car to maximize the usable horse power available, this mandated the use of a higher average RPM curve,where your willing to swap some efficiency for greater average power.

that allows all the shift points to be a bit higher rpm than the horse power peak, allowing each shift to have the engine fall in rpms to land very close to the torque peak, thus maximizing the useable horse power and torque

obviously there would be significant changes in components selected for each application moving the torque and peak power in each application, but for clarity Ill use the same dyno chart and point out the different power curve sections you would tend to gear the car for, and modify the shift points to access

do a few calculations, think about the rpm band

YOUR engine makes its best power in,

and YOUR tire diameter

and YOUR cars weight

and YOUR rear gearing,

and YOUR trans GEARING

http://www.wallaceracing.com/calcrgr.php

http://www.wallaceracing.com/gear-speed.php

http://www.wallaceracing.com/Calculators.htm

https://700r4l60e.com/

http://vexer.com/automotive-tools/speed-rpm-calculator

http://vexer.com/automotive-tools/1-4-mile-ET-HP-MPH-calculator

http://www.tciauto.com/tc/racing-calculators/

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=10705&p=46582&hilit=better+expected#p46582

USE THE LINKED CALCULATORS

http://www.wallaceracing.com/gear-speed.php

http://www.race-cars.net/calculators/et_calculator.html

http://www.wallaceracing.com/calc-rgr.php

http://www.datsuns.com/Tech/whentoshift.htm

http://www.frontrange4x4.com/forums/sho ... nformation

http://www.carcraft.com/techarticles/cc ... to_01.html

http://purplesagetradingpost.com/sumner ... index.html

http://www.tciauto.com/tc/gear-ratios

http://www.5speeds.com/ratios.html

yes as always theres those dreaded INFO links, you would rather ignore too finding your own applications answers

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.com/index.php?threads/matching-the-combo.11020/#post-48707

http://tire-size-conversion.com/gear-ratio-calculator/

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-50173

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://www.bgsoflex.com/auto.html

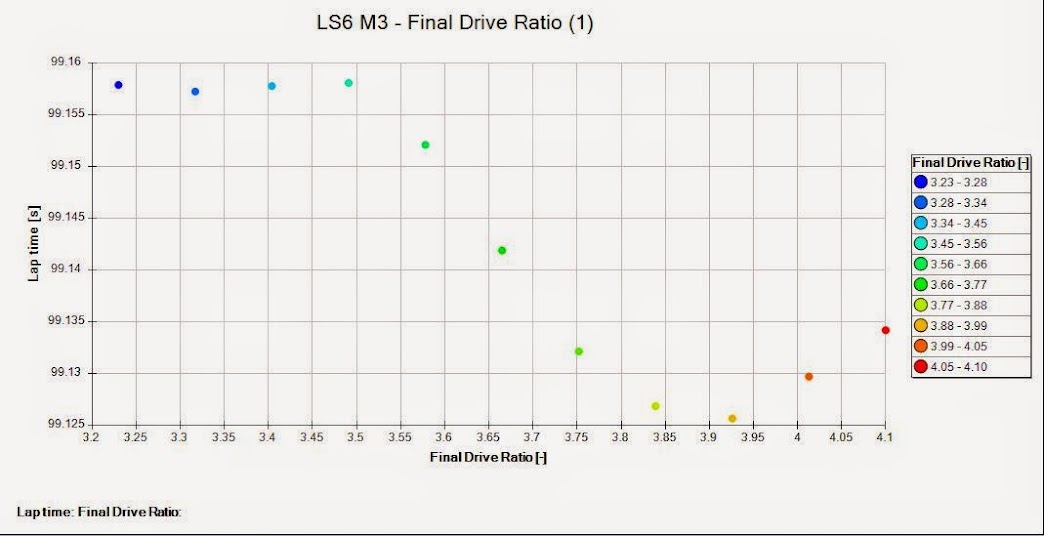

heres a darn good couple of chart's showing the effect on the cars lap time's that the selection of the correct rear gear ratio had, keep in mind this will need to be tested with every engine and drive train combo, and obviously the type of track, or speeds and tire diameter , your engines power curve, the car weight and the suspensions and tires will effect the results

In response to Jens

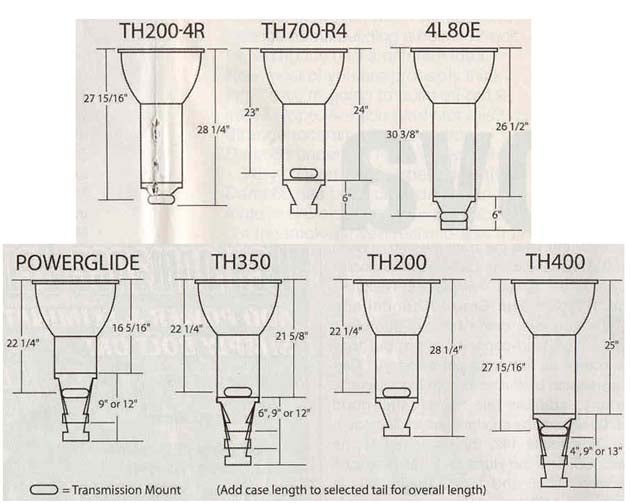

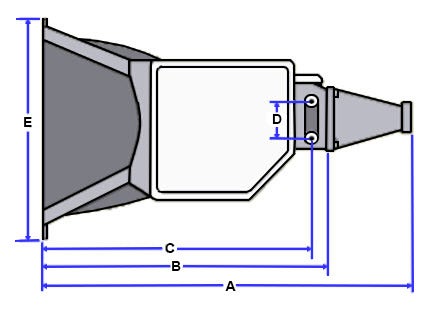

Here since they keep disappearing. http://www.crankshaftcoalition.com/wiki/images/9/9...

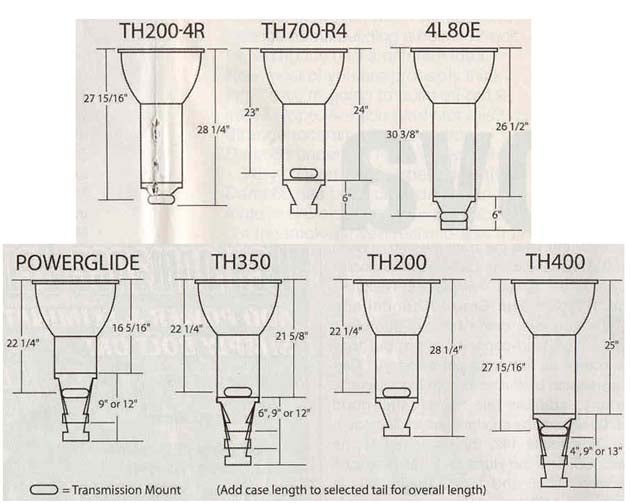

Return to Dimensions of common GM automatics

Dimensions.jpg

http://www.crankshaftcoalition.com/wiki/images/3/3...

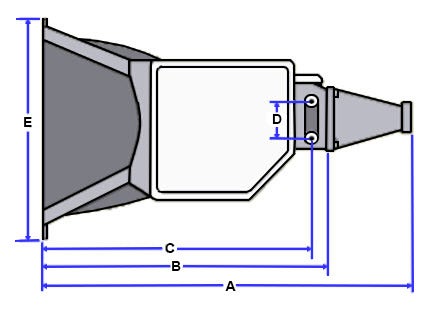

All dimensions are in inches.

Powerglide (bellhousing pattern - Chevrolet, Fit-all)

Style A B C D E

short shaft 25 23/64 16 5/16 20 9/16 3 ¾ 19

TCI shorty 17 15/16 16 5/16 20 9/16 N/A 19

long shaft 27 9/16 16 5/16 20 9/16 3 ¾ 19

TH350 (bellhousing pattern - Chevrolet, BOP, Fit-All)

Style A B C D E

6" tailshaft 27 11/16 21 5/8 20 3/8 3 ¾ 19 1/8

9" tailshaft 30 11/16 21 5/8 20 3/8 3 ¾ 19 1/8

12" tailshaft 33 27/32 21 5/8 20 3/8 3 ¾ 19 1/8

TH400 (bellhousing pattern - Chevrolet, BOP)

Style A B C D E

C tailshaft 28 3/8 24 5/16 26 15/16 4 ¼ 20

D tailshaft 33 27/32 24 5/16 27 15/16 4 ¼ 20

13" tailshaft 37 7/8 24 5/16 27 21/32 1 ¾ 20

2004R (bellhousing pattern - BOP, Fit-All)

Style A B C D E

All 27 11/16 integral tailhousing 27 3 ¾ 19 1/8

700R4 4L60 (4L60E 1993-1995) (bellhousing pattern - Chevrolet)

Style A B C D E

All except Corvette 30 ¾ 23 3/8 22 ½ 3 ¾ 20

Corvette(1982-1996) 29 7/8 23 3/8 22 ½ 3 ¾ 20

4L60E/4L65E 1996-Later (bellhousing pattern - Chevrolet/removable)

Style A B C D E

All except Corvette & LS1 30 ¾ 21 ¾ 23 3/16 3 ¾ 18 ¼

Corvette (transaxle) N/A N/A

LS1-style (1998-later) 31 5/32 21 ¾ 23 19/32 3 ¾ 18 ¼

4L80E/4L85E 1991-Later (bellhousing pattern - Chevrolet)

Style A B C D E

Std. 2wd 32 11/16 26 30 3/8 4 ¼ 20

HD 2wd 31 15/16 26 30 3/8 4 ¼ 20

HD long 33 26 30 3/8 4 ¼ 20

4 X 4 29 26 30 3/8 N/A 20

[edit] Weights

Weight (approximate, in pounds):

Powerglide- wet 110

TH200C- 96

TH350- wet 130

TH400- wet 140

TH2004R- 132

4L60E- wet 175

4L80E- wet 255

the fact is its all easily calculated and get reasonable close and many guys can,t tell they are not running the best available choice, if they get way off, they frequently blame the engine or cam selected

I'm always rather amused that so many guys want to get so darn confused about what is basically brutally simple, the purpose of a performance torque converter is to allow near instant access too and full use off and efficient use of the engines peak torque over most of its power band, the transmission must of course be set up to shift to the next lower gear each time the engine rpms start to exceed the ideal power range or drop back into the ideal power band if the torque available is no longer sufficient to easily move the car, to do this you simply need to know the cars drive train gearing tire size and the engines power band and red-line or upper rpm limitations, and the engines lower rpm power band effective limitations and a dyno tuning test session easily determines those factors, obviously you match YOUR engines limitations and power curve to the torque converter rear gear and engine, so under full throttle conditions you would want the engine to almost instantly access the engines 3000rpm range and the transmission to shift to the next gear every time rpms hit 6300rpm in THAT particular example, as THAT would allow maximum access to the engine torque curve.

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55651

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

heres what DD200o software predicts my current corvette engines power curve is, I have a 700r4 transmission and 24.6: tall tires , you should be able to easily see why I selected a 3000rpm stall converter and added a shift kit to the transmission that allows it to reach a bit over 6000rpm under full throttle load shifts (I tried to get it to 6300 but they don,t make a kit that I could find at a reasonable cost)

given that info...if we take 10.5 and divide that by the 3.06 first gear in my current transmission we get a 3.43:1 rear gear ratio.

see info posted below.

I purchased a 4l80E for my corvettes eventual BIG BLOCK engine swap, its first gear ratio of 2.48 suggest a 4.11 rear gears about correct,many guys will not use the over drive top gear in their calculations for drag racing rear gears as they feel that they will perform best if those O.D. top gears are not considered.

http://users.erols.com/srweiss/calcrpm.htm

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://www.superchevy.com/how-to/tr...can-handle-1000-hp/?cx_source=cxrecs#cxrecs_s

https://700r4l60e.com/

reasonably expected E.T. from engine rear wheel horse power and car total weight with you driving it. REMEMBER THIS IS REAR WHEEL NOT FLYWHEEL HP IN THE CALCULATIONS AND YOUR WEIGHT IS INCLUDED IN THE CAR

http://www.wallaceracing.com/et-hp-mph.php

lets assume your horse power and weight calcs result in a very quick street corvette that can clock a 120 MPH 1/4 mile speed and you have 24.5" diameter rear tires, a bit of math shows youll be spinning that engine near 6200rpm with a 3.73:1 rear gear ratio with a 1:1 top gear transmission, and thats a very common result in a well built corvette drive train,that still allows considerably more top speed once O.D. is used

http://users.erols.com/srweiss/calcrpm.htm

heres the result if I had a TH400

heres the result if I had a 700r4

heres the result if I had a 4L80E

GIVEN THAT THE INDEPENDENT REAR IN MY 1985 CORVETTES NEVER GOING TO LAST UNDER THE BIG BLOCK POWER CURVE IT SEEMS LIKE A DIFFERENT DIFFERENTIAL WILL BE NEEDED

every engine has a certain rpm range where its able to make the best torque, its torque that gets the car moving, gear the car so it spends almost all its time spinning in its most efficient power band, and youll maximize the engine's ability to put power to the pavement, gear the car so it spends most of its time below that power band or set the transmission and gearing so it shifts to the next gear well below, the horse power peak and efficiency suffers.

now obviously factors like car weight, exhaust restriction,engine compression limits due to low octane fuel, and tire diameter will effect your results, and valve train stress, transmission shift points and piston speed and port cross sectional areas tend to limit engine rpms on the upper end of the rpm range.

the higher the torque the engine produces the higher the converter stall speed is likely to be but its never an exact ratio relationship

Keep in mind when selecting a new performance torque converter that there are design limitations and strength limits to all designs, if your old engine made about 370 ft lbs and stalled near 2500 rpm, and

your new engine makes 470 ft lbs of torque thats about a 25% increase, in torque.

so you might, quite reasonably expect or guess that the stall speed would jump about 25% from 2500 rpm to near 3125 rpm,

( example 2500rpm x 1.25%-3125 rpm)

While that sounds reasonable, the real world is not as predictable.

In my experience it won,t necessarily jump a totally predictable amount,

simply because there is a wide variation in the torque converter designs,and engine torque curves and cam characteristics, compression ratios, displacements etc.

Id expect it to jump a bit less, to maybe nearer too 2950 rpm from my experience.

this is based on what I've seen when guys bolt the same converter and transmission they formally had behind a performance 350- 383 SBC

behind a new 454-496 BBC engine

ID also point out that occasionally youll find a converter that worked just fine behind a SBC,

fails when you introduce it to a 25%-50% torque increase with a BBC swap

For performance applications ,as a general rule the first gear ratio of your transmission multiplied times your rear gear ratio should fall in the 10:1-10.5:1 range, you need to know your tire diameter, and you generally don,t want to have the engine spinning at over about 3000rpm at 70 mph if you use the car for transportation, or well under its best operational rpm range most of the time and you certainly don,t want the automatic transmission to shift at well under your peak power or have a stall torque converter speed well below the effective power band.

If you were gearing the car to actually race it you would expect to be spinning the engine at peak effective rpms on the power band as you run through the lights at the end of the track, if your engine peaks near 6300 rpm like the software dyno posted here shows about 500 flywheel horse power and thats about 400 rear wheel horse power and you take the corvettes weight of about 3400 lbs

http://www.wallaceracing.com/et-hp-mph.php

the calculator suggests 11.89 seconds and MPH of 113.69 MPH.

Id get the car to reach 6400 rpm at 120 mph

horse power is measured/ calculated with the formula torque x rpm divided by 5252-- hp

THUS ITS THE FORCE OR TORQUE MULTIPLIED BY, THE RPM THAT IT CAN BE APPLIED AT, THAT DETERMINES THE RATE AT WHICH THAT FORCE AVAILABLE OR WORK CAN BE ACCOMPLISHED

EXAMPLE

450 FT LBS OF TORQUE AT 3500RPM= 300 HP

450 FT LBS OF TORQUE AT 6500RPM= 557 HP

on a street performance car application, the goal, is usually gearing the car to maximize the usable torque curve, while maintaining reasonable mileage and engine durability.

on a race car application, the goal, is usually gearing the car to maximize the usable horse power available, this mandated the use of a higher average RPM curve,where your willing to swap some efficiency for greater average power.

that allows all the shift points to be a bit higher rpm than the horse power peak, allowing each shift to have the engine fall in rpms to land very close to the torque peak, thus maximizing the useable horse power and torque

obviously there would be significant changes in components selected for each application moving the torque and peak power in each application, but for clarity Ill use the same dyno chart and point out the different power curve sections you would tend to gear the car for, and modify the shift points to access

do a few calculations, think about the rpm band

YOUR engine makes its best power in,

and YOUR tire diameter

and YOUR cars weight

and YOUR rear gearing,

and YOUR trans GEARING

http://www.wallaceracing.com/calcrgr.php

http://www.wallaceracing.com/gear-speed.php

http://www.wallaceracing.com/Calculators.htm

https://700r4l60e.com/

http://vexer.com/automotive-tools/speed-rpm-calculator

http://vexer.com/automotive-tools/1-4-mile-ET-HP-MPH-calculator

http://www.tciauto.com/tc/racing-calculators/

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=10705&p=46582&hilit=better+expected#p46582

USE THE LINKED CALCULATORS

http://www.wallaceracing.com/gear-speed.php

http://www.race-cars.net/calculators/et_calculator.html

http://www.wallaceracing.com/calc-rgr.php

http://www.datsuns.com/Tech/whentoshift.htm

http://www.frontrange4x4.com/forums/sho ... nformation

http://www.carcraft.com/techarticles/cc ... to_01.html

http://purplesagetradingpost.com/sumner ... index.html

http://www.tciauto.com/tc/gear-ratios

http://www.5speeds.com/ratios.html

yes as always theres those dreaded INFO links, you would rather ignore too finding your own applications answers

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.com/index.php?threads/matching-the-combo.11020/#post-48707

http://tire-size-conversion.com/gear-ratio-calculator/

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-50173

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://www.bgsoflex.com/auto.html

heres a darn good couple of chart's showing the effect on the cars lap time's that the selection of the correct rear gear ratio had, keep in mind this will need to be tested with every engine and drive train combo, and obviously the type of track, or speeds and tire diameter , your engines power curve, the car weight and the suspensions and tires will effect the results

In response to Jens

Here since they keep disappearing. http://www.crankshaftcoalition.com/wiki/images/9/9...

Return to Dimensions of common GM automatics

Dimensions.jpg

http://www.crankshaftcoalition.com/wiki/images/3/3...

All dimensions are in inches.

Powerglide (bellhousing pattern - Chevrolet, Fit-all)

Style A B C D E

short shaft 25 23/64 16 5/16 20 9/16 3 ¾ 19

TCI shorty 17 15/16 16 5/16 20 9/16 N/A 19

long shaft 27 9/16 16 5/16 20 9/16 3 ¾ 19

TH350 (bellhousing pattern - Chevrolet, BOP, Fit-All)

Style A B C D E

6" tailshaft 27 11/16 21 5/8 20 3/8 3 ¾ 19 1/8

9" tailshaft 30 11/16 21 5/8 20 3/8 3 ¾ 19 1/8

12" tailshaft 33 27/32 21 5/8 20 3/8 3 ¾ 19 1/8

TH400 (bellhousing pattern - Chevrolet, BOP)

Style A B C D E

C tailshaft 28 3/8 24 5/16 26 15/16 4 ¼ 20

D tailshaft 33 27/32 24 5/16 27 15/16 4 ¼ 20

13" tailshaft 37 7/8 24 5/16 27 21/32 1 ¾ 20

2004R (bellhousing pattern - BOP, Fit-All)

Style A B C D E

All 27 11/16 integral tailhousing 27 3 ¾ 19 1/8

700R4 4L60 (4L60E 1993-1995) (bellhousing pattern - Chevrolet)

Style A B C D E

All except Corvette 30 ¾ 23 3/8 22 ½ 3 ¾ 20

Corvette(1982-1996) 29 7/8 23 3/8 22 ½ 3 ¾ 20

4L60E/4L65E 1996-Later (bellhousing pattern - Chevrolet/removable)

Style A B C D E

All except Corvette & LS1 30 ¾ 21 ¾ 23 3/16 3 ¾ 18 ¼

Corvette (transaxle) N/A N/A

LS1-style (1998-later) 31 5/32 21 ¾ 23 19/32 3 ¾ 18 ¼

4L80E/4L85E 1991-Later (bellhousing pattern - Chevrolet)

Style A B C D E

Std. 2wd 32 11/16 26 30 3/8 4 ¼ 20

HD 2wd 31 15/16 26 30 3/8 4 ¼ 20

HD long 33 26 30 3/8 4 ¼ 20

4 X 4 29 26 30 3/8 N/A 20

[edit] Weights

Weight (approximate, in pounds):

Powerglide- wet 110

TH200C- 96

TH350- wet 130

TH400- wet 140

TH2004R- 132

4L60E- wet 175

4L80E- wet 255

Last edited: