reading through the start sequence may help isolate the problems source

Id sure try to isolate the issue to a problem with sensors, ignition or fuel delivery.

owning a factory shop manual for your year corvette and a multi meter is a big help as is a code reader.

if your corvette won,t start or run, don,t panic its usually easy to locate the problems source, buy a CHEVY SHOP MANUAL FOR YOUR YEAR CORVETTE! RULE#1 never assume a damn thing ISOLATE ,TEST AND VERIFY...

garage.grumpysperformance.com

A recurring theme has been replayed over and over, READ THE LINKED INFO CAREFULLY THERES NOT A DAMN THING YOU CAN'T FIND AND FIX WITH A FEW TOOLS, AND SOME FAMILIARITY WITH THE CORVETTE< A SHOP MANUAL IS A HUGE HELP Id strongly suggest you systematically verify the cause rather than making...

garage.grumpysperformance.com

Brian may be onto something, the oil pressure bypass switch in the TPI is a very common source,

if oil pressure falls below about 6 lbs the ignition cuts out by design

for similar issues ID suggest replacing it as they are cheap and easy to replace.

the switch may not be the only potential issue but its a known potential problem.

are you pulling any trouble codes?

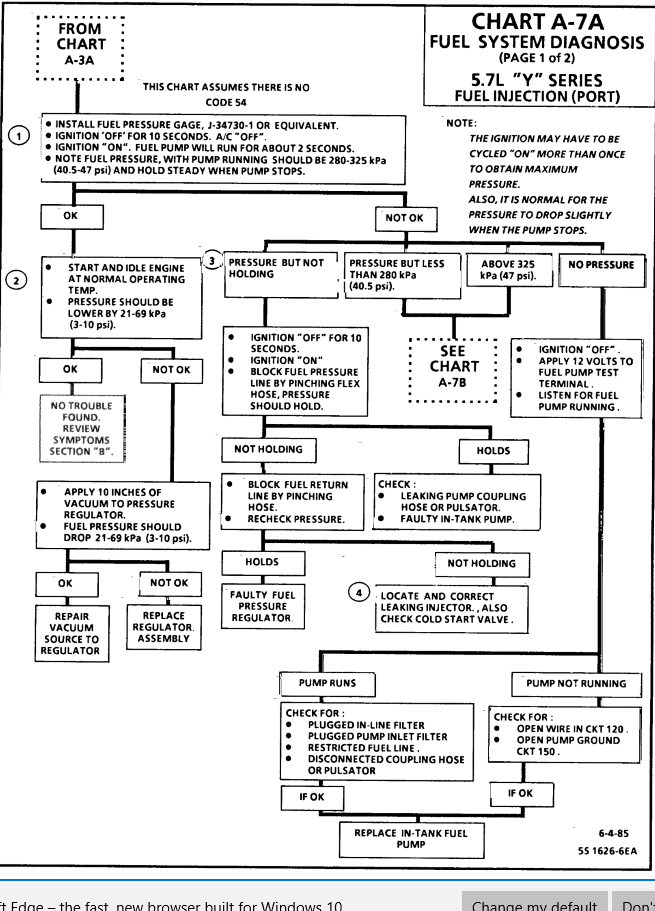

whats the fuel pressure ?

is it consistent?

it should be in the 37 psi-39 psi range!

when you turn the key the fuel pump comes on, but it will cut off if oil pressure drops below about 6 psi

Id connect a multi meter to the coil voltage and see if its cutting out causing the ignition to cut off.

You need to think carefully, don,t assume anything.

TEST AND VERIFY EVERY COMPONENT AND SENSOR FUNCTION!

Id suggest pulling trouble codes and verifying the basics of engine function,

are you actually getting spark at ALL the plugs?

are you getting injector pulse from the injector wire harness, do you have fuel pressure?

have you been checking the too verify your actually getting fuel out of the injectors,into the cylinders?

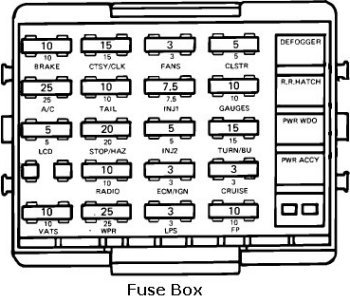

are all the fuses in the panel good?

have you verified that your alternator produces 13.5 plus volts,

that your getting spark at all the spark plugs ,have you verified the spark plugs are actually arcing and not fuel fouled?

your getting compression in all cylinders, all the rockers move, as the engine rotates?

ALL the sensors are fully functional,

your getting at least 10 psi of oil pressure as the engine spins while its trying to start,

you need to see the fuel pressure is consistently at 38-42 psi.

you need to verify the fuel filter and fuel pressure regulator and return line are functioning as designed.

verify all the electrical grounds are good,

and you use a noid tester to verify your getting the injector pulse.

what most people fail to do is test and verify, you can,t assume anything.

youll want too verify, youve got no plenum or runner vacuum leaks, and the catalytic converters are NOT restricting exhaust flow, theres no excessive exhaust system back pressure.

just because the injectors have pressure in the fuel rail, and get a pulse does NOT insure fuel flow thru them,

and having fuel rail pressure does not insure ITS GOOD fuel,

it can be tainted with water or rust particles in the fuel,

preventing fuel atomizing in the cylinders.

clogged catalytic converters can easily cause the engine to fail to flow air,

checking the plenum vacuum and exhaust back pressure and reading the exhaust fuel/air ratio,

use of an infrared temp gun, to verify cylinder exhaust temps are reasonably equal and a multi meter to set the TPS sensor and verify the ignition wire resistance will help.

simple stuff like verifying the firing order that you just know is correct (which may not be , so VERIFY IT) get over looked

and testing the coil and oxygen sensors and temp sensors sure helps.

After you verify theres consistent strong electrical spark at the spark plugs when your trying to start the engine and fuel pressure is consistent at the fuel rails,and your getting at least 7-8 psi of oil pressure,

IF you suspect a fuel delivery related issue, a good long spray of starter fluid into the throttle body and trying to start the engine with that extra fuel source may prove informative, if it trys to start with the extra fuel in the plenum but failed to start without it, its a good indicator the injectors are plugged or defective

have you removed and cleaned the IAC?

IAC and TPS Adjustment

Idle Air Control

Tools needed:

- Torx bit # T-20

- Paper Clip

- Small Punch

Take the paper clip and open it up and form it into a big "U" shape. Insert the clip ends into the ALDL in the ‘A’ and ‘B’ pins.

Turn on the ignition, but don’t start the engine. Wait 30 seconds. Now, go remove the connector from the IAC.

Start engine. You are now going to adjust "minimum air". There is a Torx screw on the side of the throttle body. This is what needs to be turned to adjust minimum air, or more commonly known as "idle speed". It comes from the factory with a protective metal cap over it. If the cap is still there, use a small punch to knock it out. Set the idle speed to 450 rpm, rotating the Torx screw clockwise to raise rpm, and counter-clockwise to lower rpm. Once the idle rpm is set, turn off the engine.

Re-connect the connector onto the IAC. Start engine. Idle speed is now once again governed by the ECM, but your idle should be smooth and steady, approximately 600 rpm in Drive (for unmodified cars).

If you set an SES light by having the IAC disconnected, then after shutting down the engine disconnect the negative battery terminal. Wait 5 minutes. This will clear the ECM of all trouble codes. Re-connect the battery and drive the car for 20 minutes to allow the ECM to relearn your driving style.

Throttle Position Switch (TPS)

Tools needed:

- Digital Volt-Ohm-Meter (VOM)

- Jumper Wires (make your own)

- Auto Xray Scanner (if available) will eliminate the need for VOM and jumper wires.

Turn on ignition, but don’t start the engine.

With a scanner: plug in the scanner and read the TPS voltage. It should be 0.54Volts +/- 0.075Volts

With VOM and jumper wires: disconnect the connector from the TPS. Using your jumper wires, make a connection allowing some room for the VOM terminals to contact the jumper leads and read the TPS voltage.

If out of spec, loosen the two screws holding the TPS to the throttle body, and slightly rotate the TPS up or down, reading the voltage until it comes into specification. Tighten screws. Using the throttle lever, rotate the throttle to WOT (wide open throttle). The TPS voltage should be over 4.0 volts. Close the throttle again, and then slowly open it to WOT, observing the voltage reading. It should increase progressively and in a linear fashion. If it sticks or jumps or falls off at all while doing this check, that could mean a bad TPS switch and could be a cause of stumbling and driveability problems.

After setting the correct voltage, turn off ignition switch. Remove jumpers/scanner and reconnect the TPS connector as required.

have you measured the resistance ohms on every injector?

read these links and

related sub links

pull trouble codes

http://garage.grumpysperformance.co...oven-facts-if-your-in-doubt.13051/#post-84695

http://forum.grumpysperformance.com/viewtopic.php?f=32&t=1401&p=8895&hilit=start+sequence#p8895

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/lots-of-wiring-info-diagrams.317/#post-83877

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/

http://garage.grumpysperformance.com/index.php?threads/multi-meters.3110/#post-71867

http://garage.grumpysperformance.com/index.php?threads/1990-corvette-no-spark.13857/#post-70888

http://garage.grumpysperformance.com/index.php?threads/diagnoseing-tpi-lt1-problems.1241/

http://garage.grumpysperformance.com/index.php?threads/code-scanners-software.3096/#post-76256

http://garage.grumpysperformance.co...and-verify-each-possibility.11219/#post-50642

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/#post-34357

http://garage.grumpysperformance.co...an-obdii-reader-analizer-ect.8136/#post-29007

http://garage.grumpysperformance.com/index.php?threads/multi-meters.3110/#post-16799

http://garage.grumpysperformance.co...elay-switch-locations-and-info.728/#post-9217

http://garage.grumpysperformance.co...i-and-scan-tool-software-links.469/#post-6061

http://garage.grumpysperformance.co...asic-trouble-shooting-on-the-c4.302/#post-367

links to info that may help

https://www.themotorbookstore.com/c...MIrei9nJqr7gIVD4iGCh3orQayEAQYAiABEgJUMPD_BwE

http://www.larryselectricsite.com/downloads/tpiinstructions.pdf

https://howellefi.com/wp-content/up...t-or-LT1-Fuel-Injection-Harness-1985-1992.pdf

https://www.hotrodhardware.com/inde...d=7157/category_id=1579/mode=prod/prd7157.htm

https://www.ronfrancis.com/images/TP30-INST.pdf

http://www.jimsperformance.com/tpibuy.html

https://www.hotrodhandbooks.com.au/eBooks/TPI/TPI On Line-03-1.html