Z28 said:

When I ran it, I ran a 13.2 with 4.5 fuel pressure. I raised it to 6.5 and ran the 12.9. I didn't try for higher, I thought 6.5 was pushing limits. I do have a return line.

Another thing, the total timing is set at 34.

Fuel float bowl levels are right at the bottom of sight glass.

Through a couple of trial & error tunes and backfires through the carb, I replaced the power valve with a brand new one. This was all prior to the race track. I'll research that a bit more though.

are you referring to power valve NUMBERS or fuel pressure measured at the carb inlet port?

fuel pressure should not exceed 5 psi in most carb applications

if you want to lean it out youll want a lower numerical power valve, IE if your now getting richer as the throttle opens Id go back to a 4.5 power valve and slightly larger primary carb jets, keep in mind jets provide the base line ,power valves ADD fuel as the vacuum drops as air flow increases.

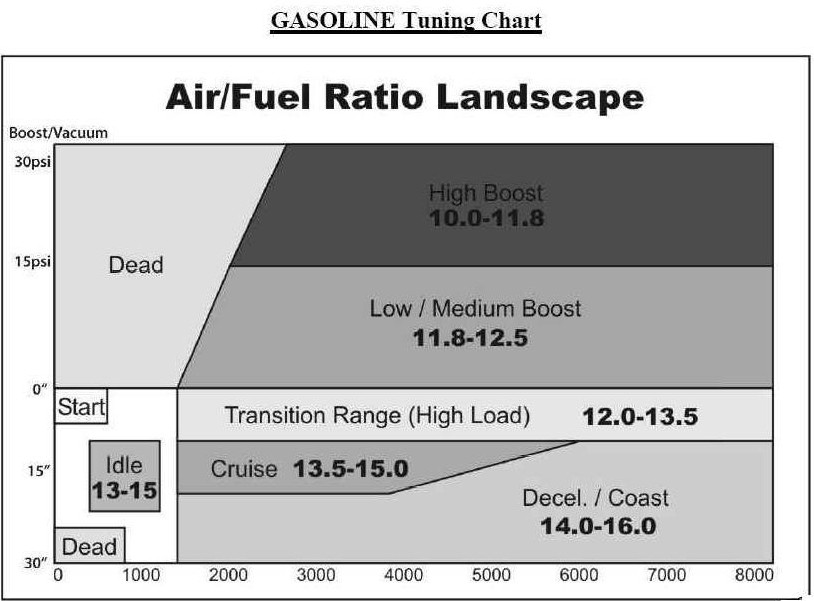

btw Ive generally found you would be best served trying for about 13.7:1-14.2:1 fuel/air ratio at idle with a consistent and predictable but slow enrichment curve that gets you close to about 12.6:1 at wide open throttle above about 3500rpm, this tends to reduce plugs getting fouled

POWER ENRICHMENT SYSTEM

The power enrichment system supplies additional fuel to the

main system during heavy load or full power situations. Holley

carburetors utilize a vacuum operated power enrichment system

and a selection of power valves is available to “time” this sys-

tem’s operation to your specific needs.

Each Holley power

valve is stamped with a number to indicate the vacuum opening

point. For example, the number “65” indicates that the power

valve will open when the engine vacuum drops to 6.5" or

below. An accurate vacuum gauge, such as Holley P/N

26-501,

should be used when determining the correct power

valve to use. A

competition or race engine which has a long

duration high overlap camshaft will have low manifold vacuum

at idle speeds. If the vehicle has a manual transmission, take

the vacuum reading with the engine thoroughly warmed up and

at idle. If the vehicle is equipped with an automatic transmis-

sion, take the vacuum reading with the engine thoroughly

warmed up and idling in gear. In either case, the power valve

selected should be 1/2 the intake manifold vacuum reading

taken. EXAMPLE: 13” Hg vacuum reading divided by 2 = 6.5

power valve. If your reading divided by 2 lands on an even

number you should select the next lowest power valve. EXAM-

PLE: 8” Hg vacuum reading divided by 2 = 4 power valve.

Since there is no #4 power valve you should use a 3.5.

Most of the popular Holley “Street Legal” and “Street

Performance” carburetors incorporate a power valve blow-out

protection system. A special check valve is located in the throt-

tle body expressly for this purpose. This check valve is

designed to be normally open but will quickly seat to close off

the internal vacuum passage when a backfire occurs. Once

closed, the check valve interrupts the pressure wave caused by

the backfire, thus protecting the power valve.

If you have a carburetor older than 1992 (or you have experi-

enced an extreme backfire) and expect a blown power valve,

use this simple test. TEST: At idle turn your idle mixture screws

(found on the side of the metering block) all the way in. If your

engine dies the power valve is not blown