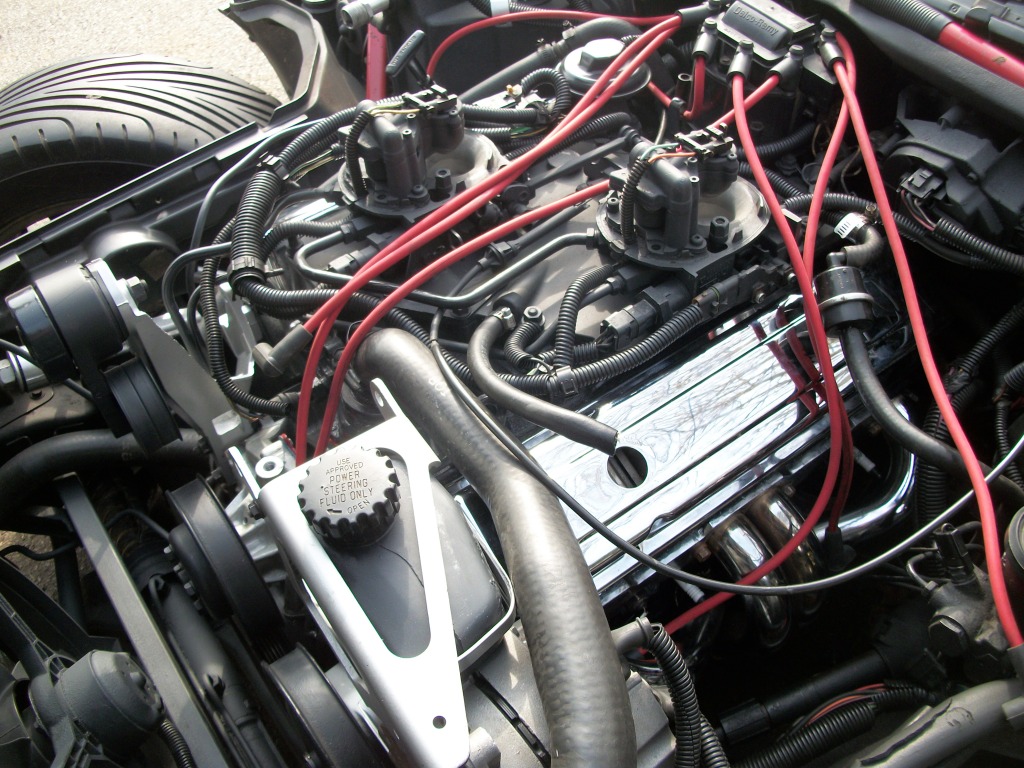

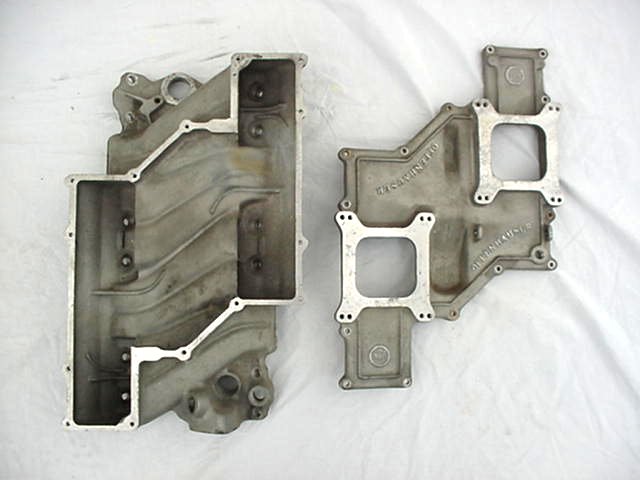

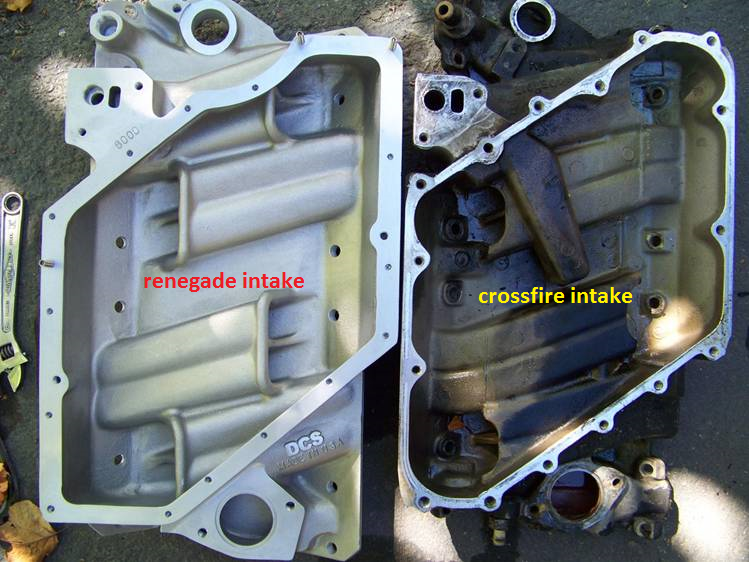

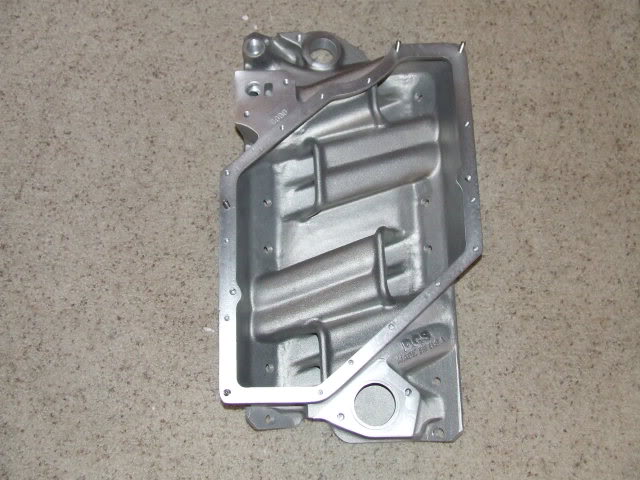

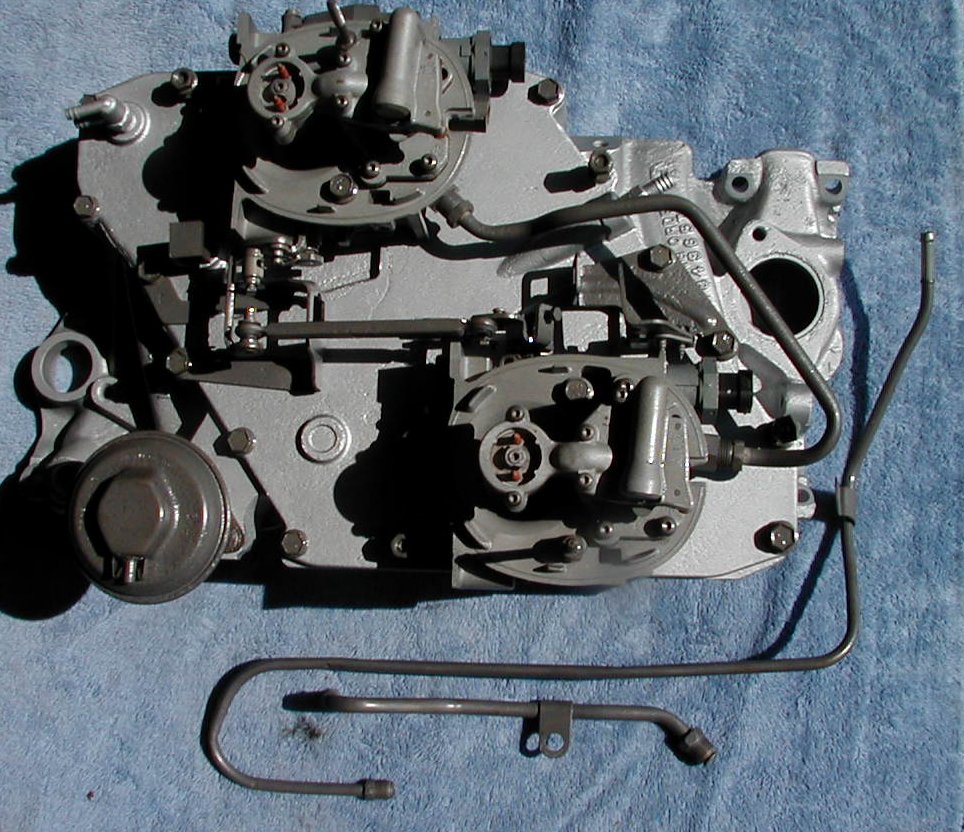

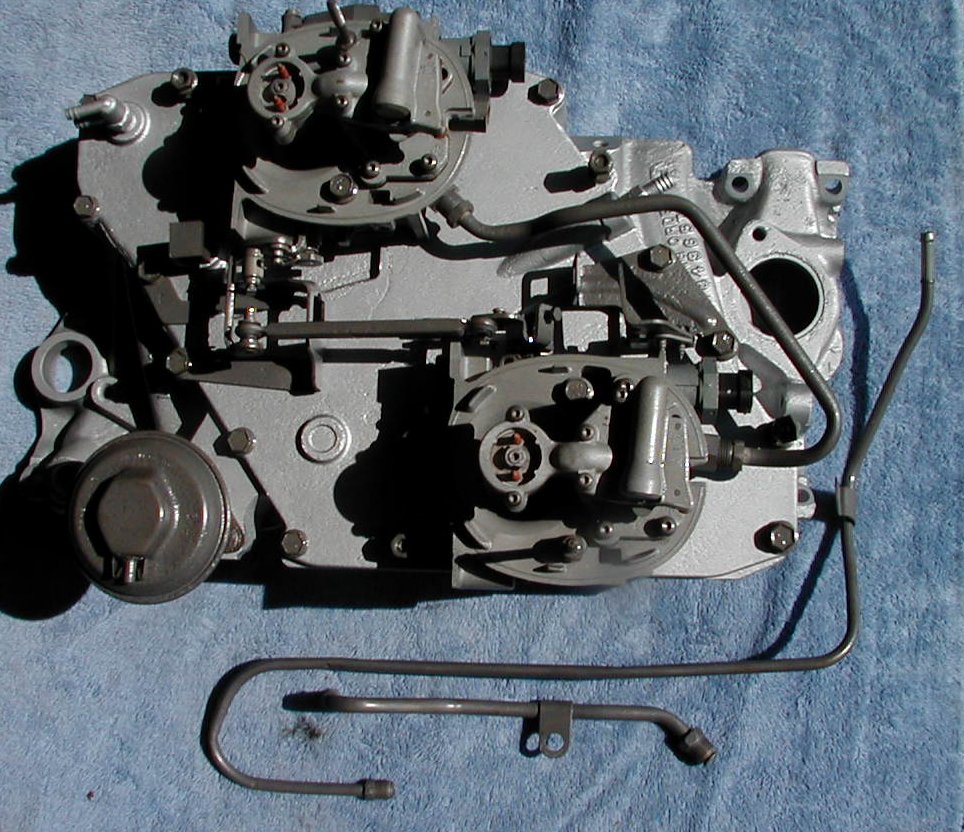

Got these pics from another forum; they are of the new Renegade manifold for the CFI installed on a 1984.

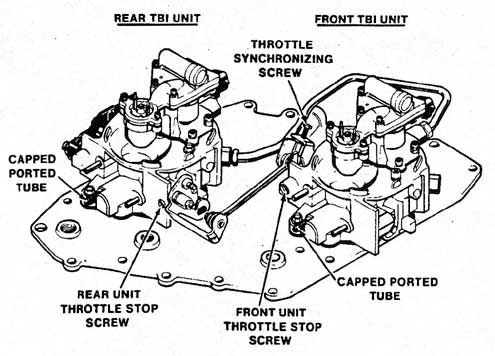

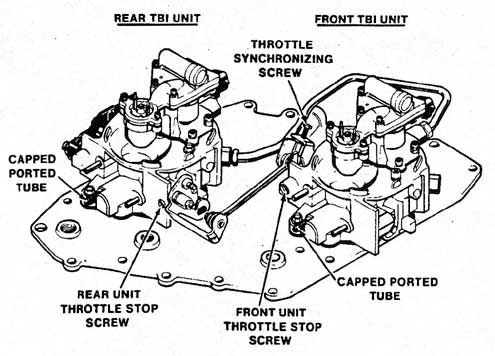

The following is a statement from the makers DCS:

Please note that we are not releasing any internal pics or technical specs at this time. The reason for this is the design is not 100% finalized - we are still tweaking things. But here is some basic info.

* Runner cross sectional area is presently approx 30% larger.

* There is a 20% taper from inlet to outlet.

* True Crossram design style with optimized runner configuration but modified for our application.

* The outlet is slightly smaller than a 1205 gasket. This is done to make sure there are no leaks and a good seal is obtained.

* Plenum area is 20% larger than stock.

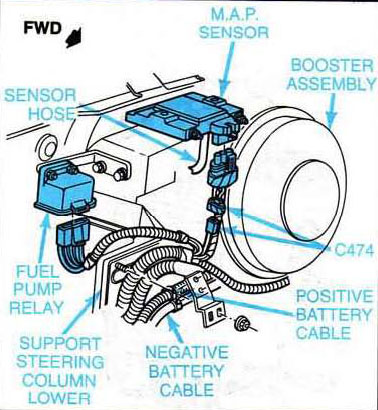

* True OE design on the top plate. All brackets are in their stock locations. Just bolt it on and everything is located where it should be.

* Same overall height as the stock manifold.

* EGR is built in if it is needed.

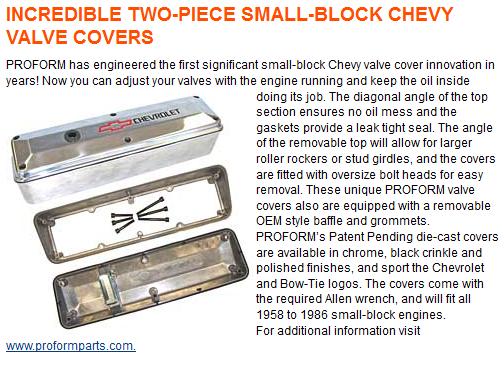

* No issues with removing valve covers.

http://www.technovelocity.com/chevyhack ... olish.html

462624

350

76-87

1.94/1.50 2.02/1.60

heads tend to crack if over heated or incorrectly torqued

if you have zero deck to head distance I'd suggest a .040-.042 thick head gasket should be used

for a 9.3 compression, 327 with a 3.08 rear gear, and auto trans, Id suggest a cam like a crane 114132

https://www.summitracing.com/parts/crn-114132

with the correct matched components 350 hp should be doable, btw mild port and bowl area clean-up can allow these heads to have improved flow, they will never be a great choice but they can be improved

use of long tube headers a low restriction exhaust and a cam with a bit more lift and duration can help compensate for the restrictive ports some what.

I would certainly suggest a decent performance dual plane intake be selected,and port matched, and you certainly don,t need to spend a fortune

something like this easily improves flow if matched up correctly

https://www.summitracing.com/parts/wnd-8150

http://www.usaperform.com/sbc-torqu...-lifter-kit-275-deg-278-deg-435-455-lift.html

http://garage.grumpysperformance.com/index.php?threads/refresh-1982-crossfire-vette.14173/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-60990

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

We decided to use my 84 as the mule because of the hood clearance concerns. 82 Vettes are roomier in the engine compartment.

YOU MAY WANT TO READ THRU THESE LINKs

http://www.thecubestudio.com/CrossfireT ... ration.htm

http://www.thecubestudio.com/CrossfireT ... ancing.htm

http://www.thecubestudio.com/CrossfireT ... ration.htm

http://crossfireinjection.net/DCS News.html

http://www.technovelocity.com/chevyhack ... olish.html

this may interest you

http://www.ecklerscorvette.com/corv...nifold-crossfire-injection-1982-and-1984.html

THE HEADS ON THE 1984 cross fire corvettes are pathetic also

Heads: Iron, casting number 462624

Chamber Volume: 76cc

Intake Valve size: 1.94"

Exhaust Valve size: 1.50"

Intake Port Volume: 158cc

Flow Numbers:

.100

44/41

93.2%

.200

101/82

81.2%

.300

155/125

80.6%

.400

182/137

75.3%

.500

196/140

71.4%

Average

159/121

76.3%

NOW COMPARE THOSe NUMBERS

viewtopic.php?f=32&t=5521&p=16619&hilit=head+flow+numbers#p16619

viewtopic.php?f=52&t=333&p=27234&hilit=head+flow+numbers#p27234

viewtopic.php?f=52&t=462&p=24466&hilit=head+flow+numbers#p24466

viewtopic.php?f=52&t=5078&p=18935&hilit=head+flow+numbers#p18935

viewtopic.php?f=52&t=401&p=17237&hilit=head+flow+numbers#p17237

viewtopic.php?f=52&t=5364&p=16066&hilit=head+flow+numbers#p16066

http://www.airflowresearch.com/articles ... 5/A-P1.htm

viewtopic.php?f=52&t=2630&p=13142&hilit=head+flow+numbers#p13142

viewtopic.php?f=52&t=1563&p=11967&hilit=head+flow+numbers#p11967

viewtopic.php?f=52&t=4221&p=11119&hilit=head+flow+numbers#p11119

viewtopic.php?f=52&t=8460&p=32923#p32923

viewtopic.php?f=52&t=322&p=9895&hilit=head+flow+numbers#p9895

if you have a cross fire 1984 corvette with dual throttle body injection your dealing with what is eventually a very restrictive set of heads fed by an extremely restrictive intake on an engine thats designed to operate at under 4000rpm, that makes a factory rated power curve under 220 hp.

your original cross fire throttle body injection intake was and is VERY RESTRICTIVE, there are far better intake manifolds, cylinder heads and cams available, to upgrade a cross fire corvette. , for both upgrading the TBI or swapping to a carburetor fueled engine

READ A FEW LINKS, and sub links, it should take you a few hours to read most of the related info but it could save you weeks of work and a good deal of ca$h

viewtopic.php?f=32&t=1148&p=2333&hilit=1984+crossfire#p2333

viewtopic.php?f=32&t=1401

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=2697

viewtopic.php?f=32&t=10096&p=39656&hilit=shop+manual#p39656

IF YOU WANT A CROSS FIRE CORVETTES ENGINE TO BREATH YOULL NEED TO MAKE CHANGES

http://www.crossfireinjection.net/renegade.htm

renegade intake

http://www.cranecams.com/product/cart.php?m=product_detail&p=23790

mild cam

better heads

http://www.airflowresearch.com/index.php?cPath=24_117

roller rockers

http://www.ebay.com/itm/Scorpion-Ro...-16-/391143932929?hash=item5b11fec401&vxp=mtr

The following is a statement from the makers DCS:

Please note that we are not releasing any internal pics or technical specs at this time. The reason for this is the design is not 100% finalized - we are still tweaking things. But here is some basic info.

* Runner cross sectional area is presently approx 30% larger.

* There is a 20% taper from inlet to outlet.

* True Crossram design style with optimized runner configuration but modified for our application.

* The outlet is slightly smaller than a 1205 gasket. This is done to make sure there are no leaks and a good seal is obtained.

* Plenum area is 20% larger than stock.

* True OE design on the top plate. All brackets are in their stock locations. Just bolt it on and everything is located where it should be.

* Same overall height as the stock manifold.

* EGR is built in if it is needed.

* No issues with removing valve covers.

http://www.technovelocity.com/chevyhack ... olish.html

462624

350

76-87

1.94/1.50 2.02/1.60

heads tend to crack if over heated or incorrectly torqued

if you have zero deck to head distance I'd suggest a .040-.042 thick head gasket should be used

for a 9.3 compression, 327 with a 3.08 rear gear, and auto trans, Id suggest a cam like a crane 114132

https://www.summitracing.com/parts/crn-114132

with the correct matched components 350 hp should be doable, btw mild port and bowl area clean-up can allow these heads to have improved flow, they will never be a great choice but they can be improved

use of long tube headers a low restriction exhaust and a cam with a bit more lift and duration can help compensate for the restrictive ports some what.

I would certainly suggest a decent performance dual plane intake be selected,and port matched, and you certainly don,t need to spend a fortune

something like this easily improves flow if matched up correctly

https://www.summitracing.com/parts/wnd-8150

http://www.usaperform.com/sbc-torqu...-lifter-kit-275-deg-278-deg-435-455-lift.html

http://garage.grumpysperformance.com/index.php?threads/refresh-1982-crossfire-vette.14173/

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-60990

http://garage.grumpysperformance.co...lsa-effects-your-compression-torque-dcr.1070/

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

We decided to use my 84 as the mule because of the hood clearance concerns. 82 Vettes are roomier in the engine compartment.

YOU MAY WANT TO READ THRU THESE LINKs

http://www.thecubestudio.com/CrossfireT ... ration.htm

http://www.thecubestudio.com/CrossfireT ... ancing.htm

http://www.thecubestudio.com/CrossfireT ... ration.htm

http://crossfireinjection.net/DCS News.html

http://www.technovelocity.com/chevyhack ... olish.html

this may interest you

http://www.ecklerscorvette.com/corv...nifold-crossfire-injection-1982-and-1984.html

THE HEADS ON THE 1984 cross fire corvettes are pathetic also

Heads: Iron, casting number 462624

Chamber Volume: 76cc

Intake Valve size: 1.94"

Exhaust Valve size: 1.50"

Intake Port Volume: 158cc

Flow Numbers:

.100

44/41

93.2%

.200

101/82

81.2%

.300

155/125

80.6%

.400

182/137

75.3%

.500

196/140

71.4%

Average

159/121

76.3%

NOW COMPARE THOSe NUMBERS

viewtopic.php?f=32&t=5521&p=16619&hilit=head+flow+numbers#p16619

viewtopic.php?f=52&t=333&p=27234&hilit=head+flow+numbers#p27234

viewtopic.php?f=52&t=462&p=24466&hilit=head+flow+numbers#p24466

viewtopic.php?f=52&t=5078&p=18935&hilit=head+flow+numbers#p18935

viewtopic.php?f=52&t=401&p=17237&hilit=head+flow+numbers#p17237

viewtopic.php?f=52&t=5364&p=16066&hilit=head+flow+numbers#p16066

http://www.airflowresearch.com/articles ... 5/A-P1.htm

viewtopic.php?f=52&t=2630&p=13142&hilit=head+flow+numbers#p13142

viewtopic.php?f=52&t=1563&p=11967&hilit=head+flow+numbers#p11967

viewtopic.php?f=52&t=4221&p=11119&hilit=head+flow+numbers#p11119

viewtopic.php?f=52&t=8460&p=32923#p32923

viewtopic.php?f=52&t=322&p=9895&hilit=head+flow+numbers#p9895

if you have a cross fire 1984 corvette with dual throttle body injection your dealing with what is eventually a very restrictive set of heads fed by an extremely restrictive intake on an engine thats designed to operate at under 4000rpm, that makes a factory rated power curve under 220 hp.

your original cross fire throttle body injection intake was and is VERY RESTRICTIVE, there are far better intake manifolds, cylinder heads and cams available, to upgrade a cross fire corvette. , for both upgrading the TBI or swapping to a carburetor fueled engine

READ A FEW LINKS, and sub links, it should take you a few hours to read most of the related info but it could save you weeks of work and a good deal of ca$h

viewtopic.php?f=32&t=1148&p=2333&hilit=1984+crossfire#p2333

viewtopic.php?f=32&t=1401

viewtopic.php?f=32&t=596

viewtopic.php?f=32&t=2697

viewtopic.php?f=32&t=10096&p=39656&hilit=shop+manual#p39656

IF YOU WANT A CROSS FIRE CORVETTES ENGINE TO BREATH YOULL NEED TO MAKE CHANGES

http://www.crossfireinjection.net/renegade.htm

renegade intake

http://www.cranecams.com/product/cart.php?m=product_detail&p=23790

mild cam

better heads

http://www.airflowresearch.com/index.php?cPath=24_117

roller rockers

http://www.ebay.com/itm/Scorpion-Ro...-16-/391143932929?hash=item5b11fec401&vxp=mtr

Last edited by a moderator: