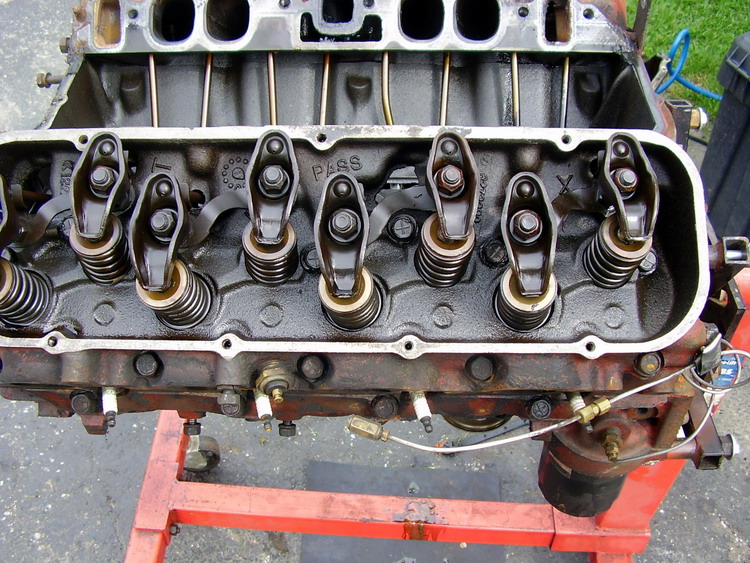

If youve got an older engine with a good deal of sludge from less than ideal maintenance..and if the engine RUNS ,Id pull the valve covers and inspect the condition of the engine, if its moderate, I,d drain the current oil, replace the oil filter, and throw two quarts of marvel mystery oil into the engine, along with several quarts of a good 10w30 oil, so the dip stick reads correctly and let it run for a few hours and change the oil and oil filter, again, , now do that several times,over the next few days, adding two quarts of marvel mystery oil in place of two qts of the regular oil, at each oil change and changing the oil and filter after a few days then,pull the valve covers after a few of these oil changes , youll find most of the crud has dissolved, after one or two changes of oil and new oil filters, as the marvel mystery oil added to the fresh regular oil has lots of solvents and detergents in it, resulting in an oil filter that quickly fills up with the freed up crud as it breaks free! so use cheaper , standard oil , mixed with the MMO,as its only going to be in the engine a few days to carry crud to the oil filter

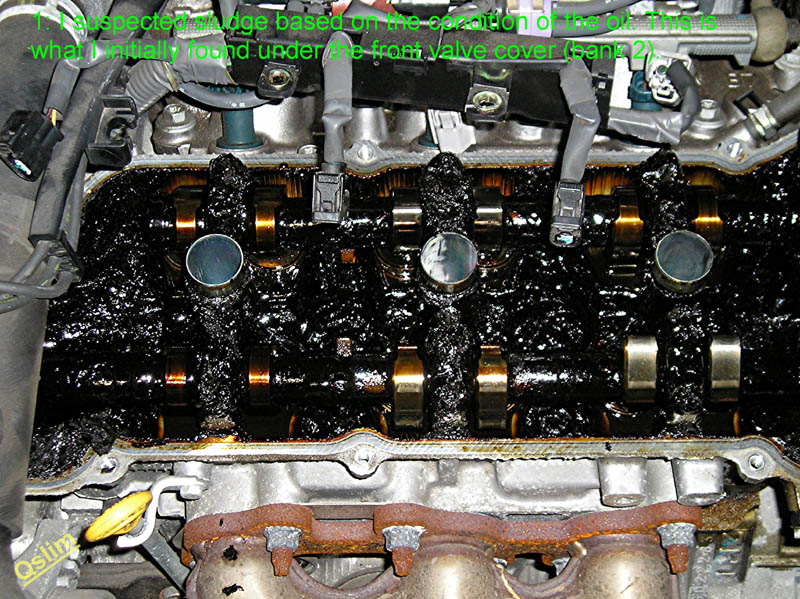

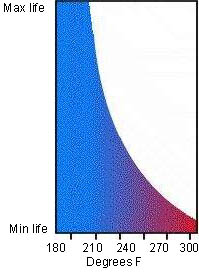

youll be amazed at the amount of crud that breaks free and how fast the oil turns into slime as the sludge gets taken into solution by the detergent oil mix, oils with high paraffin content are especially prone to building sludge if the engines not seen frequent oil changes and long drives as short hops don,t build the heat necessary to get the crud dissolved, oil must reach 215F to effectively burn off moisture that quickly forms acids from combustion gases if left in the oil.

oil heated past about 245F tends to eventually break down, so you need to maintain the engine with regular oil and filter changes and run it long enough to burn off moisture that forms from condensation.

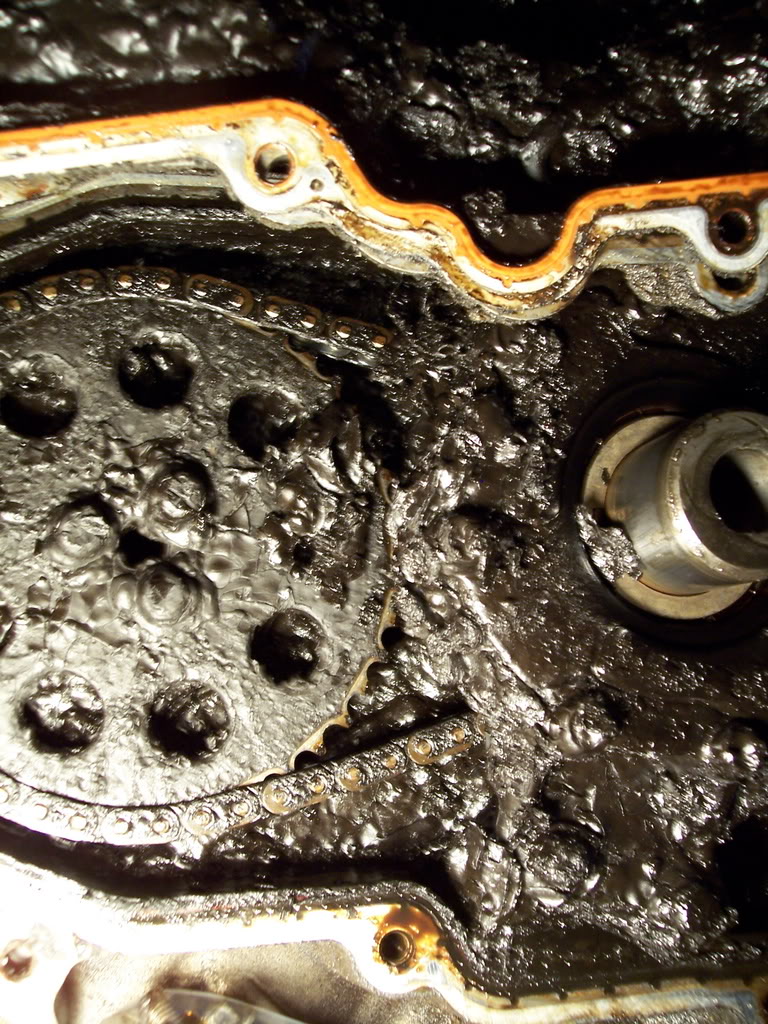

youll occasionally see advice saying to pour a couple quarts of diesel fuel in an engine after you drain the oil and let it drain out before replacing the oil filter and oil, this process has potential benefits but also some risks , Id avoid this as the risks tend to be higher than the potential benefits, and I darn sure would not run the engine with a couple quarts of diesel fuel mixed with the oil as Ive seen posted as a cure for sludge as thats a sure way to screw up bearings and ring seal.

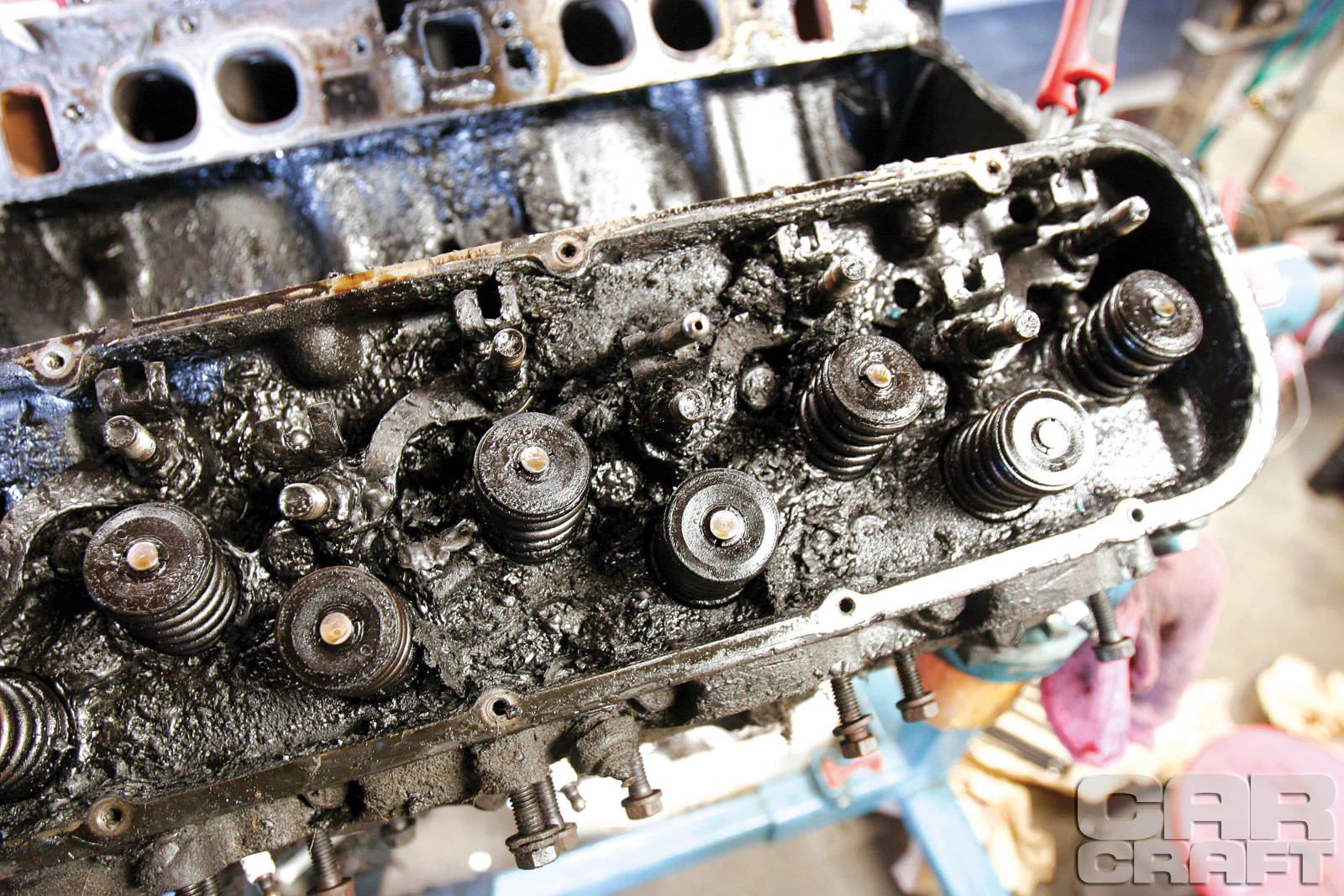

now if you pull the valve cover and the waxy sludge build-up , that looks like some one mixed a gallon of old rotten axle grease with peanut butter,covers the rockers, and you can barely see the heads it would be smart to pull the intake ,and front timing cover and oil pan ,along with the valve covers and start a rebuild because you can easily see the engines never had decent regular maintenance and its very likely too have excessive wear on moving parts, bearings and rings as all that sludge is a sure indication its never had frequent oil changes or decent oil used, but I know some guys will try to flush the engine out by putting a large oil change drain pan under the oil pan, then removing the drain plug and repeatedly pouring a couple gallons of diesel fuel mixed 50%/50% with cheap oil repeatedly thru the engine to try to dissolve the majority of the sludge that formed before they do the oil change routine listed above, in this thread, and yeah occasionally the flush out, works, but usually it breaks loose a ton of old crud and you find you need a rebuild anyway , if you go that route change oil and oil filters very frequently the first couple days as theres going to be lots of loose crud in the engine

youll be amazed at the amount of crud that breaks free and how fast the oil turns into slime as the sludge gets taken into solution by the detergent oil mix, oils with high paraffin content are especially prone to building sludge if the engines not seen frequent oil changes and long drives as short hops don,t build the heat necessary to get the crud dissolved, oil must reach 215F to effectively burn off moisture that quickly forms acids from combustion gases if left in the oil.

oil heated past about 245F tends to eventually break down, so you need to maintain the engine with regular oil and filter changes and run it long enough to burn off moisture that forms from condensation.

youll occasionally see advice saying to pour a couple quarts of diesel fuel in an engine after you drain the oil and let it drain out before replacing the oil filter and oil, this process has potential benefits but also some risks , Id avoid this as the risks tend to be higher than the potential benefits, and I darn sure would not run the engine with a couple quarts of diesel fuel mixed with the oil as Ive seen posted as a cure for sludge as thats a sure way to screw up bearings and ring seal.

now if you pull the valve cover and the waxy sludge build-up , that looks like some one mixed a gallon of old rotten axle grease with peanut butter,covers the rockers, and you can barely see the heads it would be smart to pull the intake ,and front timing cover and oil pan ,along with the valve covers and start a rebuild because you can easily see the engines never had decent regular maintenance and its very likely too have excessive wear on moving parts, bearings and rings as all that sludge is a sure indication its never had frequent oil changes or decent oil used, but I know some guys will try to flush the engine out by putting a large oil change drain pan under the oil pan, then removing the drain plug and repeatedly pouring a couple gallons of diesel fuel mixed 50%/50% with cheap oil repeatedly thru the engine to try to dissolve the majority of the sludge that formed before they do the oil change routine listed above, in this thread, and yeah occasionally the flush out, works, but usually it breaks loose a ton of old crud and you find you need a rebuild anyway , if you go that route change oil and oil filters very frequently the first couple days as theres going to be lots of loose crud in the engine