NewbVetteGuy

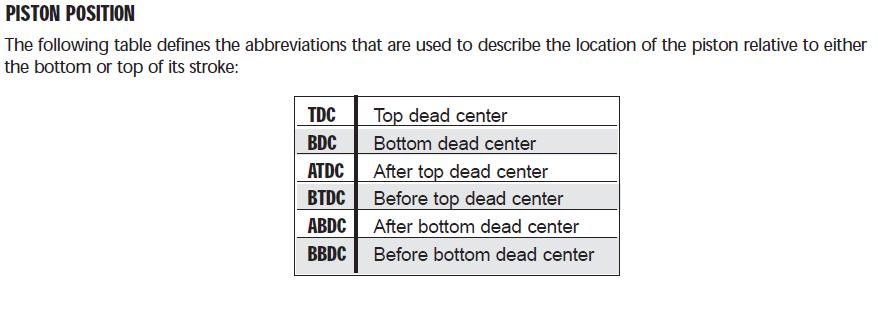

Well-Known Member

I THINK I've read what little is out there regarding the FIRST Fuel Injection TPI-style (but not performance) SBC intakes. I've read all the Grumpy's threads on the subject, to my knowledge and the major build threads on the ThirdGen site, but I still have questions that I'm hoping Grumpy can answer, as there's just not a lot of people out there with experience or in-depth analysis of this intake.

Background (My Car): I've got a single-family 1979 L82 Corvette that I was recently given by my parents who bought in the car in 1979. Originally they bought "his and hers" C3 Corvettes: a 1978 L2 manual for my dad, and a 1979 L82 automatic with all the option except for the CB for my mom. Then I was born in 1980 and my sister in 1982; my sister was diagnosed with cancer before she was 1 year old so they sold the 78 to help with the hospital bills, but kept the 79 forever, although it rarely if ever got driven or plated. I was given the car early this year with 13,600 miles on it after it had been sitting for about 12 years; it required a LOT of love from a mechanic to get it up and running again.

My goals:

Goals

[*] Plenty of fun, tire-burning low to mid RPM torque- in Grumpy and Lingenfelte style

[*] Longevity/ reliability -this is a family car with only 14.9k miles now; it's been in my family almost 40 years and I'd love to see it stay there for another 40 years; I don't plan on beating the crap out of the car and dumping it on someone else; reliability is important

[*]Increase in fuel economy vs. stock L82 (my 4L60e transmission's overdrive and lockup torque converter will help, as will the EFI, but I don't want the cam to be too crazy and just completely kill fuel economy)

[*] Given my previous goals; don't leave too much extra HP on the table "wasted" -the heads have so much potential

[*] Also in Grumpy style, to properly plan this build in detail so I don't have to learn something the "hard way" -my wife is only going to let me do this once

[*] I want to be in decent shape to be able to get even more tire-shredding torque if /when anything requires the bottom-end to be rebuilt in the future- I'd like to keep the numbers-matching original block and make it a Stroker 396, or 383, if the budget absolutely required it- 396s are just so much rare and cooler, IMHO

"Knowns" in my build:

[*]GEN1 L82 SBC 350 (good bottom-end to build off of)- I'm looking to have an entirely new top-end and not touch the bottom-end right now

[*]Heads: ATK's casting of the Profiler aluminum heads 64cc combustion chamber; 195CC intake- I've been told that the flow numbers are not over-inflated but, who knows; I've read Grumpy's opinions on head intake ports not actually creating huge issues with low RPM torque in a well-planned build, but as I will be living with this as an SBC 350 for hopefully quite a few years, I need to still have the torque while it's an SBC 350 and I think these heads have plenty of flow to scale up to 383 or 396, given my focus on torque and not max HP. If I need to get them ported or CNCed larger when I go the stroker motor; or completely ditch them for larger heads, I can get to that bridge then.

Note: The ATK casting of the Profilers have reduced exhaust flow #'s because they're standard height, standard sized exhaust ports; I'm ok with this as fitment with my existing FlowTech 1 5/8th headers is important to me. I'll just go with a larger duration on the exhaust lobe on my cam to make up for it.

Lift CFM Lift CFM

0.200 144 0.200 107

0.300 207 0.300 142

0.400 250 0.400 172

0.500 268 0.500 187

0.600 270 0.600 196

0.700 271 0.700 203

[*]Exhaust: long tube headers 1 5/8" with 3" collector down to 2.5" true dual exhaust (Flowtech Coated), H-pipe, no cats, high flow mufflers

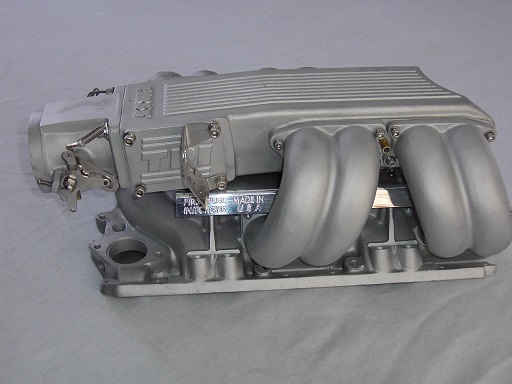

[*]Intake: FIRST Fuel Injection intake- not sure on what to have done to it...

[*]Curb weight 3,650lbs but down to 3,400-3,450 when the top-end goes in (lighter weight battery, spare tire removed, Steeroids rack and pinion conversion, composite rear spring)

[*]4L60e Monster Transmission with super torquey low 1st gear (computer controller version of a 700r4) -Stage1 build built for 450ft lbs of torque

[*]2,300-2,500 lockup torque converter with carbon lockup clutch; quality from Monster.com but still a 12" factory physical style

[*] TCI EZ-TCU trans computer to control shift points, shift firmness and lockup strategy (fuel economy and performance improvement & configurable)

[*]4 row aluminum radiator to keep temps cool -mentioning because hoping it will help with reducing pinging risk- Chinese "Champion"

[*]Cold Air Intake-not sure what to get but this will happen; I refuse to give this up and my dynamic compression is right around 8.5:1 so I'll need the cold air to help keep detonation at bay

[*]I'm willing to run premium fuel, if necessary 91 octane is readily available, 92 if I hunt for it; 93 doesn't exist in Washington, really

[*]EFI system will be going in this winter/spring- The Holley Terminator /HP is widely available used and will support a sequential multi port setup which is what I would like. I also want ignition control and electric fan control, so Holley or FAST are definition options. The FAST integrates well with my trans controller, too.

[*]355 rear gears

[*]I've pretty much settled on retrofit hydraulic rollers and a roller cam; If I have to go with the Morel Cheapos that only support lower RPMs, I will, but I'd love to get a higher RPM-capable set if I can find a deal- I keep looking

[*]Quality steel or stainless steel roller rockers

[*]"Appropriate" roller cam springs

[*] Static CR with FelPro 0.015" gaskets = 10.1-10.2

I'm looking for some detailed recommendations on the FIRST Intake and whether it's going to out-of-the-box be a huge power limitation for me and what RPM I can expect the torque peak at. I've seen mixed results from flow meters reported with the FIRST intake; Grumpy's reported huge POTENTIAL when ported out of this thing, but I really am curious, at least for my 350 build, what the flow is like out-of-the-box. I've heard that there's some issues with a couple of the runners and that the flow through runner 8 could be as low as like 221 CFM; with my heads flowing 268CFM @ 0.500" lift that would be a HUGE restriction to airflow and would (I think) lower my torque peak and HP curve peak rpm (and therefore total HP).

I tried to use DesktopDyno but the flow numbers varying at inches mercury vs. inches of air just confused the hell out of me. I'm not sure if when I do the calculation I should use the air flow reported by the poorest flowing runner or if I should go with the average. (Either Ezobens's flow bench results from here aren't awe-inspiring: http://www.thirdgen.org/forums/tpi/687060-megaram-first-ffi-tpi-2.html)

I can tell from some dyno results how much HP I stand to lose vs. a normal dual plane intake, but I'm not really sure how much torque I stand to gain by going with the FIRST, either so even an hp/ torque cost benefit analysis is difficult, currently.

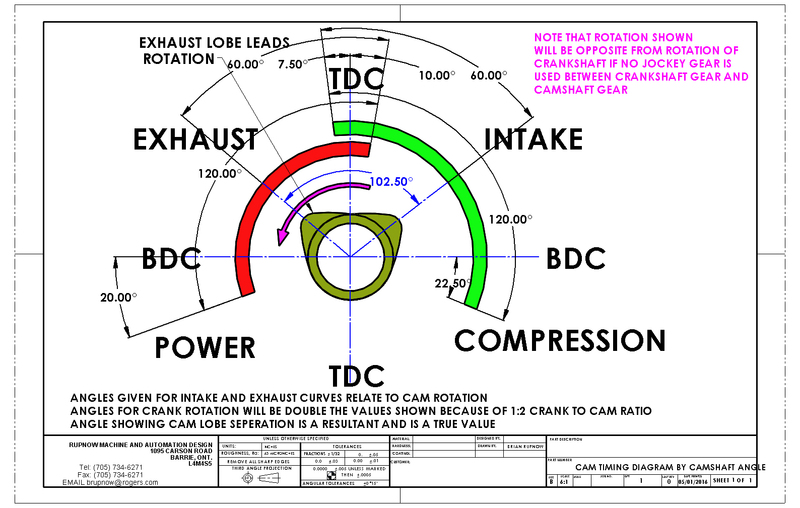

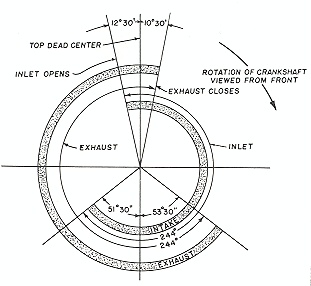

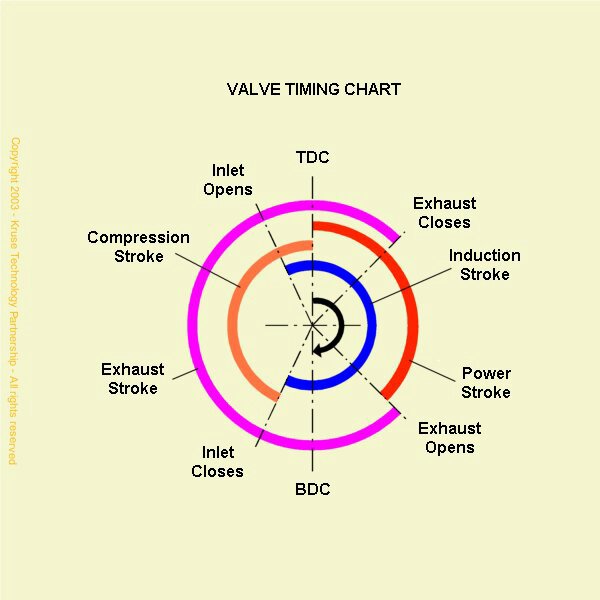

I'm also very much interested in CAM recommendations. I originally posted my goals and build details on Speedtalk.com- thinking I'd go with a typical dual plane intake and Mike Jones responded with a cam recommendation of:

Cam# SBCR, HR68340-69340-110

264/268 @.006"

216/220 @.050"

.340"/.340" Lobe Lift

.510"/.510" Valve lift

110 LSA

107 ICL

And then clarified in another thread that he'd usually recommend a slightly increased LSA or duration, but didn't provide any specific details as obviously the custom cam guys really make money by you buying the cam from them so they don't want to provide too many details. -I'm interested in learning and I can't really get the custom cam guys to provide any details or WHY they'd recommend those changes from the cam when going to a FIRST TPI-style intake...

I realize if I end up having a shop do a 383 or 396 conversion for me later that I'll need a bigger cam and I'll need dished pistons to keep the CR at the acceptable level, I'd need a new oil pan; I know that going beyond 383 means a forged crank and probably forged pistons if spinning above 6,000 RPM may ever happen; I'm also assuming that a 383 or a 396 and beyond 6,000 RPM probably wouldn't work well with my 195cc heads, so I really probably should assume an RPM max of 6,000 anyway. -I'm also afraid I'd probably be reaching the limitations of my 1 5/8" full length headers with a 396 build topping out at 6,000 RPM, too.

What else do I need to know? Anything I screwed up? (Again any Stroker motor I hope is at least 5-10 years in my future; so SBC 350 for this build.)

Adam

Background (My Car): I've got a single-family 1979 L82 Corvette that I was recently given by my parents who bought in the car in 1979. Originally they bought "his and hers" C3 Corvettes: a 1978 L2 manual for my dad, and a 1979 L82 automatic with all the option except for the CB for my mom. Then I was born in 1980 and my sister in 1982; my sister was diagnosed with cancer before she was 1 year old so they sold the 78 to help with the hospital bills, but kept the 79 forever, although it rarely if ever got driven or plated. I was given the car early this year with 13,600 miles on it after it had been sitting for about 12 years; it required a LOT of love from a mechanic to get it up and running again.

My goals:

Goals

[*] Plenty of fun, tire-burning low to mid RPM torque- in Grumpy and Lingenfelte style

[*] Longevity/ reliability -this is a family car with only 14.9k miles now; it's been in my family almost 40 years and I'd love to see it stay there for another 40 years; I don't plan on beating the crap out of the car and dumping it on someone else; reliability is important

[*]Increase in fuel economy vs. stock L82 (my 4L60e transmission's overdrive and lockup torque converter will help, as will the EFI, but I don't want the cam to be too crazy and just completely kill fuel economy)

[*] Given my previous goals; don't leave too much extra HP on the table "wasted" -the heads have so much potential

[*] Also in Grumpy style, to properly plan this build in detail so I don't have to learn something the "hard way" -my wife is only going to let me do this once

[*] I want to be in decent shape to be able to get even more tire-shredding torque if /when anything requires the bottom-end to be rebuilt in the future- I'd like to keep the numbers-matching original block and make it a Stroker 396, or 383, if the budget absolutely required it- 396s are just so much rare and cooler, IMHO

"Knowns" in my build:

[*]GEN1 L82 SBC 350 (good bottom-end to build off of)- I'm looking to have an entirely new top-end and not touch the bottom-end right now

[*]Heads: ATK's casting of the Profiler aluminum heads 64cc combustion chamber; 195CC intake- I've been told that the flow numbers are not over-inflated but, who knows; I've read Grumpy's opinions on head intake ports not actually creating huge issues with low RPM torque in a well-planned build, but as I will be living with this as an SBC 350 for hopefully quite a few years, I need to still have the torque while it's an SBC 350 and I think these heads have plenty of flow to scale up to 383 or 396, given my focus on torque and not max HP. If I need to get them ported or CNCed larger when I go the stroker motor; or completely ditch them for larger heads, I can get to that bridge then.

Note: The ATK casting of the Profilers have reduced exhaust flow #'s because they're standard height, standard sized exhaust ports; I'm ok with this as fitment with my existing FlowTech 1 5/8th headers is important to me. I'll just go with a larger duration on the exhaust lobe on my cam to make up for it.

Lift CFM Lift CFM

0.200 144 0.200 107

0.300 207 0.300 142

0.400 250 0.400 172

0.500 268 0.500 187

0.600 270 0.600 196

0.700 271 0.700 203

[*]Exhaust: long tube headers 1 5/8" with 3" collector down to 2.5" true dual exhaust (Flowtech Coated), H-pipe, no cats, high flow mufflers

[*]Intake: FIRST Fuel Injection intake- not sure on what to have done to it...

[*]Curb weight 3,650lbs but down to 3,400-3,450 when the top-end goes in (lighter weight battery, spare tire removed, Steeroids rack and pinion conversion, composite rear spring)

[*]4L60e Monster Transmission with super torquey low 1st gear (computer controller version of a 700r4) -Stage1 build built for 450ft lbs of torque

[*]2,300-2,500 lockup torque converter with carbon lockup clutch; quality from Monster.com but still a 12" factory physical style

[*] TCI EZ-TCU trans computer to control shift points, shift firmness and lockup strategy (fuel economy and performance improvement & configurable)

[*]4 row aluminum radiator to keep temps cool -mentioning because hoping it will help with reducing pinging risk- Chinese "Champion"

[*]Cold Air Intake-not sure what to get but this will happen; I refuse to give this up and my dynamic compression is right around 8.5:1 so I'll need the cold air to help keep detonation at bay

[*]I'm willing to run premium fuel, if necessary 91 octane is readily available, 92 if I hunt for it; 93 doesn't exist in Washington, really

[*]EFI system will be going in this winter/spring- The Holley Terminator /HP is widely available used and will support a sequential multi port setup which is what I would like. I also want ignition control and electric fan control, so Holley or FAST are definition options. The FAST integrates well with my trans controller, too.

[*]355 rear gears

[*]I've pretty much settled on retrofit hydraulic rollers and a roller cam; If I have to go with the Morel Cheapos that only support lower RPMs, I will, but I'd love to get a higher RPM-capable set if I can find a deal- I keep looking

[*]Quality steel or stainless steel roller rockers

[*]"Appropriate" roller cam springs

[*] Static CR with FelPro 0.015" gaskets = 10.1-10.2

I'm looking for some detailed recommendations on the FIRST Intake and whether it's going to out-of-the-box be a huge power limitation for me and what RPM I can expect the torque peak at. I've seen mixed results from flow meters reported with the FIRST intake; Grumpy's reported huge POTENTIAL when ported out of this thing, but I really am curious, at least for my 350 build, what the flow is like out-of-the-box. I've heard that there's some issues with a couple of the runners and that the flow through runner 8 could be as low as like 221 CFM; with my heads flowing 268CFM @ 0.500" lift that would be a HUGE restriction to airflow and would (I think) lower my torque peak and HP curve peak rpm (and therefore total HP).

I tried to use DesktopDyno but the flow numbers varying at inches mercury vs. inches of air just confused the hell out of me. I'm not sure if when I do the calculation I should use the air flow reported by the poorest flowing runner or if I should go with the average. (Either Ezobens's flow bench results from here aren't awe-inspiring: http://www.thirdgen.org/forums/tpi/687060-megaram-first-ffi-tpi-2.html)

I can tell from some dyno results how much HP I stand to lose vs. a normal dual plane intake, but I'm not really sure how much torque I stand to gain by going with the FIRST, either so even an hp/ torque cost benefit analysis is difficult, currently.

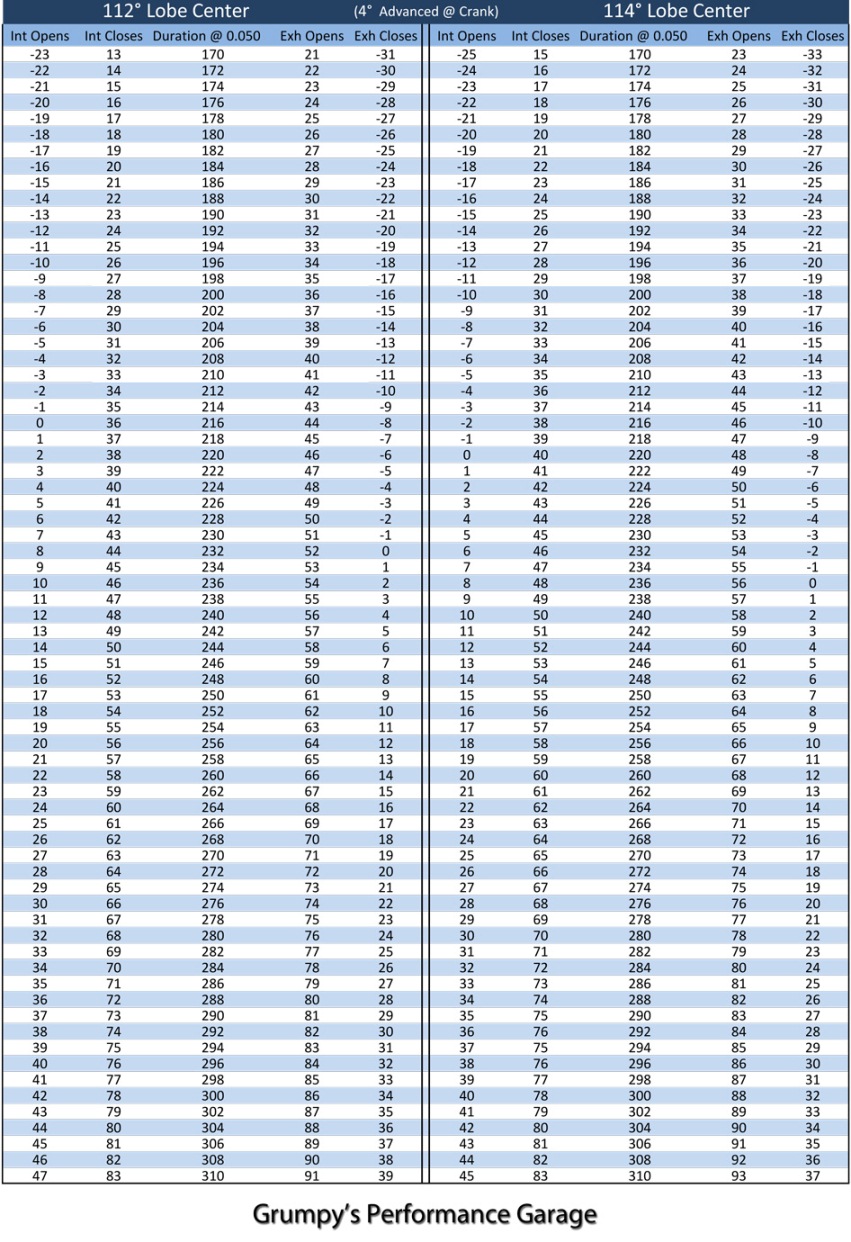

I'm also very much interested in CAM recommendations. I originally posted my goals and build details on Speedtalk.com- thinking I'd go with a typical dual plane intake and Mike Jones responded with a cam recommendation of:

Cam# SBCR, HR68340-69340-110

264/268 @.006"

216/220 @.050"

.340"/.340" Lobe Lift

.510"/.510" Valve lift

110 LSA

107 ICL

And then clarified in another thread that he'd usually recommend a slightly increased LSA or duration, but didn't provide any specific details as obviously the custom cam guys really make money by you buying the cam from them so they don't want to provide too many details. -I'm interested in learning and I can't really get the custom cam guys to provide any details or WHY they'd recommend those changes from the cam when going to a FIRST TPI-style intake...

I realize if I end up having a shop do a 383 or 396 conversion for me later that I'll need a bigger cam and I'll need dished pistons to keep the CR at the acceptable level, I'd need a new oil pan; I know that going beyond 383 means a forged crank and probably forged pistons if spinning above 6,000 RPM may ever happen; I'm also assuming that a 383 or a 396 and beyond 6,000 RPM probably wouldn't work well with my 195cc heads, so I really probably should assume an RPM max of 6,000 anyway. -I'm also afraid I'd probably be reaching the limitations of my 1 5/8" full length headers with a 396 build topping out at 6,000 RPM, too.

What else do I need to know? Anything I screwed up? (Again any Stroker motor I hope is at least 5-10 years in my future; so SBC 350 for this build.)

Adam