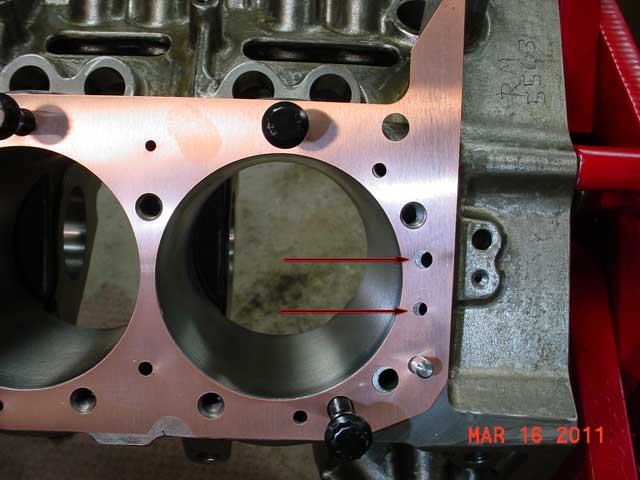

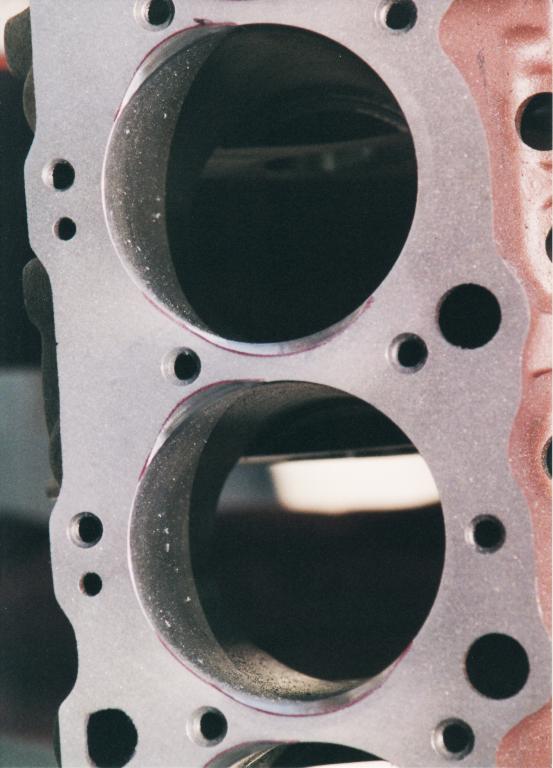

when your assembling your engine one mistake thats fairly common it use of a head gasket that has a bore that is too small,

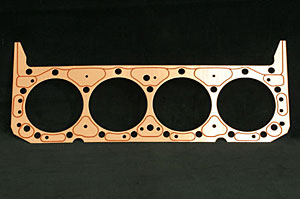

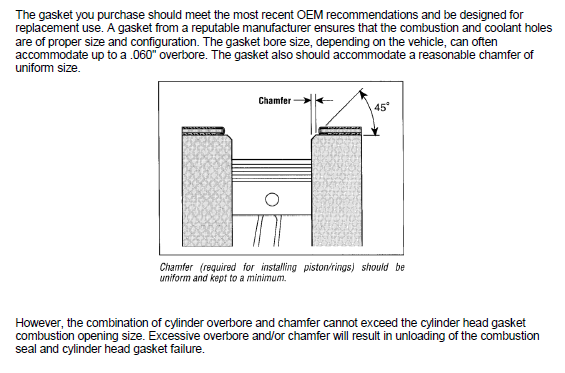

Your head gasket needs to be flush with or better yet , a bit larger than the blocks bore; maybe .020" .030-(ideal) to even .040" over bore size might be close too ideal, as the edge of the gasket needs to be even with or ideally a bit recessed far enough back into the recess between the block and heads to maintain effective cooling and not stick out enough into the engines bore, to provide a potential hot edge that would promote detonation The edge of the gasket sealing ring needs to be far enough recessed from the edge of the bore to get some effective heat transfer cooling, without being recessed enough to effect the compression or provide a dead air space for carbon residue to collect, effectively reducing too much compression or allowing volume of fuel/air mix to remain unburnt out around the edge of the upper cylinder that won't ignite due to, its being effectively cooled by the close contact with the cooler surfaces much like the quench area.

try to find a gasket that in that .020-.030 (ideal) up to .060 over bore size range, if you must go larger thats preferable too going smaller but far from ideal.

If you take the time to call and ask, most head manufacturers will be able to recommend the correct head gaskets for their cylinder heads

http://www.jegs.com/i/SCE-Gaskets/829/T ... tId=753475

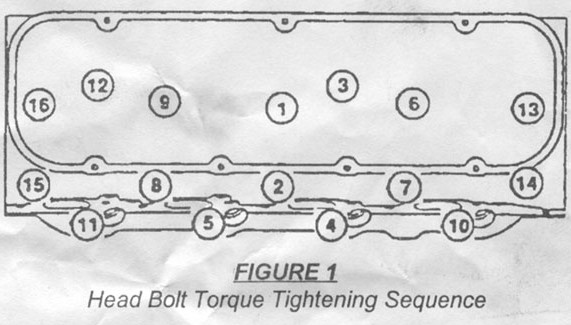

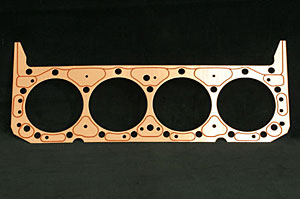

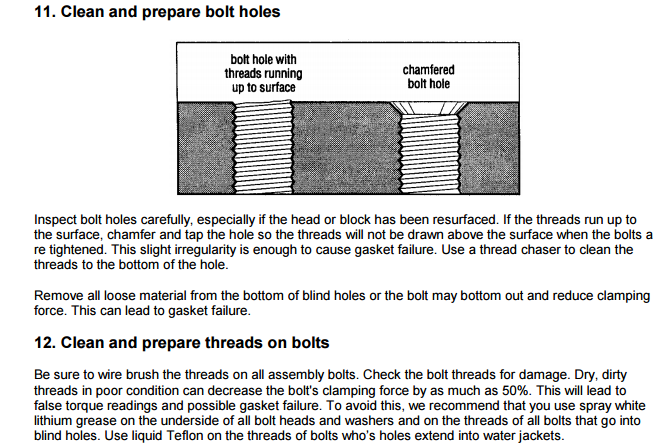

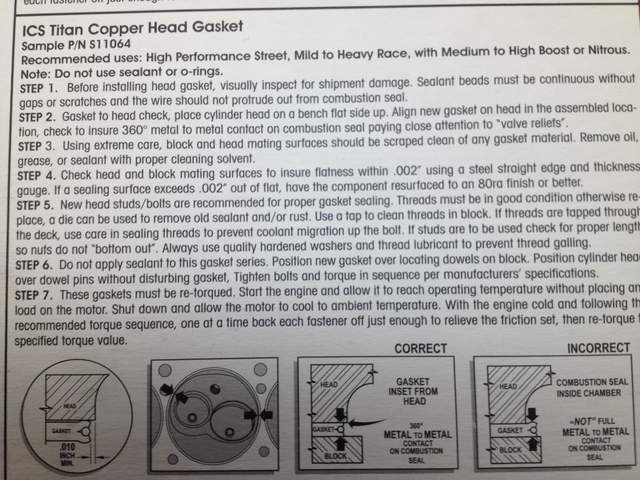

when installing almost any head gasket, but especially with a copper head gasket be sure to put on two wet even coats on both sides of the head gasket and install and torque while the copper coat sprays still damp, the spray fills in micro flaws in the machined surface

http://www.goodvibesracing.com/SBC_Head_Gaskets.htm

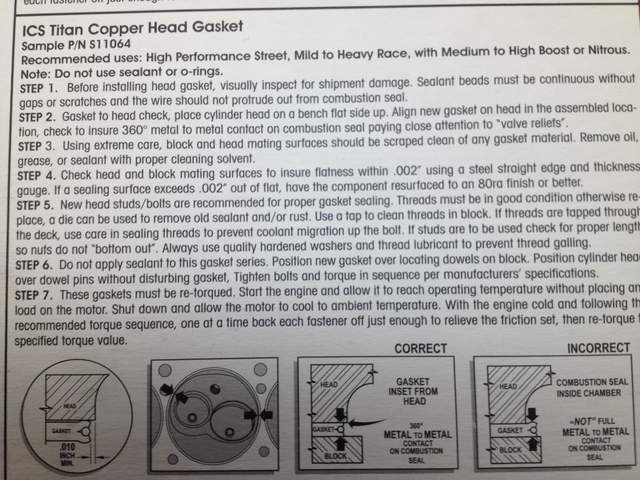

Keep in mind there are solid copper head gaskets , Ive used for decades that you simply spray with copper coat and install damp and torque in place, and the TITAN style with a steel fire ring, sandwiched between to layers of copper, Ive never used the titan style but have used the solid copper gaskets extensively with good results, in both cases the head gasket must be slightly recessed between the head and block ,not sticking out into the edge of the combustion chamber

look thru the linked info

http://en.wikipedia.org/wiki/Head_gasket

http://www.fel-progaskets.com/

http://www.rolmfg.com/media/pdf/sealspa ... let_EN.pdf

viewtopic.php?f=50&t=6931&p=22695#p22695

http://www.crankshaftcoalition.com/wiki/Head_gasket

viewtopic.php?f=50&t=1222

http://www.store.partsdinosaur.com/product576.html

viewtopic.php?f=50&t=1277&p=2737&hilit=copper+coat#p2737

http://www.scegaskets.com/ (best IVE found)

viewtopic.php?f=50&t=1859&p=5683&hilit=copper#p5683

viewtopic.php?f=53&t=726&p=5640&hilit=copper#p5640

http://www.import-car.com/Article/61817

/internal_engine_repairs_uncovering_the_culprits_that_cause_head_gaskets_to_fail.aspx

viewtopic.php?f=50&t=827&p=6153#p6153

Ive used those many times, very successfully

viewtopic.php?f=50&t=827&p=6153#p6153

viewtopic.php?f=50&t=1859&p=4869&hilit=gaskets+copper#p4869

viewtopic.php?f=57&t=74&p=4123&hilit=anode#p4123

viewtopic.php?f=50&t=2681&p=6950&hilit=copper+coat#p6950

http://www.valvedirectory.com/valve_04122006.html

Your head gasket needs to be flush with or better yet , a bit larger than the blocks bore; maybe .020" .030-(ideal) to even .040" over bore size might be close too ideal, as the edge of the gasket needs to be even with or ideally a bit recessed far enough back into the recess between the block and heads to maintain effective cooling and not stick out enough into the engines bore, to provide a potential hot edge that would promote detonation The edge of the gasket sealing ring needs to be far enough recessed from the edge of the bore to get some effective heat transfer cooling, without being recessed enough to effect the compression or provide a dead air space for carbon residue to collect, effectively reducing too much compression or allowing volume of fuel/air mix to remain unburnt out around the edge of the upper cylinder that won't ignite due to, its being effectively cooled by the close contact with the cooler surfaces much like the quench area.

try to find a gasket that in that .020-.030 (ideal) up to .060 over bore size range, if you must go larger thats preferable too going smaller but far from ideal.

If you take the time to call and ask, most head manufacturers will be able to recommend the correct head gaskets for their cylinder heads

http://www.jegs.com/i/SCE-Gaskets/829/T ... tId=753475

when installing almost any head gasket, but especially with a copper head gasket be sure to put on two wet even coats on both sides of the head gasket and install and torque while the copper coat sprays still damp, the spray fills in micro flaws in the machined surface

http://www.goodvibesracing.com/SBC_Head_Gaskets.htm

Keep in mind there are solid copper head gaskets , Ive used for decades that you simply spray with copper coat and install damp and torque in place, and the TITAN style with a steel fire ring, sandwiched between to layers of copper, Ive never used the titan style but have used the solid copper gaskets extensively with good results, in both cases the head gasket must be slightly recessed between the head and block ,not sticking out into the edge of the combustion chamber

look thru the linked info

http://en.wikipedia.org/wiki/Head_gasket

http://www.fel-progaskets.com/

http://www.rolmfg.com/media/pdf/sealspa ... let_EN.pdf

viewtopic.php?f=50&t=6931&p=22695#p22695

http://www.crankshaftcoalition.com/wiki/Head_gasket

viewtopic.php?f=50&t=1222

http://www.store.partsdinosaur.com/product576.html

viewtopic.php?f=50&t=1277&p=2737&hilit=copper+coat#p2737

http://www.scegaskets.com/ (best IVE found)

viewtopic.php?f=50&t=1859&p=5683&hilit=copper#p5683

viewtopic.php?f=53&t=726&p=5640&hilit=copper#p5640

http://www.import-car.com/Article/61817

/internal_engine_repairs_uncovering_the_culprits_that_cause_head_gaskets_to_fail.aspx

viewtopic.php?f=50&t=827&p=6153#p6153

Ive used those many times, very successfully

viewtopic.php?f=50&t=827&p=6153#p6153

viewtopic.php?f=50&t=1859&p=4869&hilit=gaskets+copper#p4869

viewtopic.php?f=57&t=74&p=4123&hilit=anode#p4123

viewtopic.php?f=50&t=2681&p=6950&hilit=copper+coat#p6950

http://www.valvedirectory.com/valve_04122006.html

Last edited by a moderator: