I would point out that use of safety wired nuts and castle nuts with cotter pins, is in many applications, a separate,

and in my opinion better option ,

in that its both secure and easily removed if required, and less temp sensitive than chemical bonding agents.

yes obviously there are applications where loc-tite is the better option, and places where anti-seize and a castle nut and cotter pin or safety wire use is the best option.

http://garage.grumpysperformance.co...afety-wire-locking-fasteners.4306/#post-67524

http://garage.grumpysperformance.co...afety-wire-locking-fasteners.4306/#post-67524

http://garage.grumpysperformance.co...afety-wire-locking-fasteners.4306/#post-48044

http://garage.grumpysperformance.com/index.php?threads/header-gaskets.1045/page-2#post-55418

http://www.superchevy.com/how-to/brakes/1408-how-to-safety-wire-your-bolts-tight/

http://garage.grumpysperformance.com/index.php?threads/cotter-pins.4733/#post-12852

on aluminum head's its almost alway's best to use studs to secure headers when you can,

as a stud has the threads full length engaged and very low stress , and significantly more surface area spreading the load,

than a bolt will ever allow,don,t forget too use anti-seize on the stud threads

shop around, the cost of the studs are not as high if you shop carefully, try a local bolt supply or hardware store.

http://garage.grumpysperformance.com/index.php?threads/header-gaskets.1045/page-2#post-55418

https://www.jegs.com/p/ARP/ARP-Exhaust-Header-Studs/744890/10002/-1

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

BTW, its not really all that rare to find that the headers you have present a spark plug wire clearance issue,

SPACING THE HEADER FLANGE A BIT FURTHER AWAY FROM THE CYLINDER HEAD WITH A SPACER PLATE CAN AT TIMES BE HELPFUL

that makes installing the spark plug boots in such a way that they don,t contact the hot metal surfaces almost impossible , this can sometimes be helped a great deal by the addition of a header flange, or SPACER PLATE, that MATCHES YOUR PARTICULAR ENGINES CYLINDER HEAD EXHAUST PORT AND HEADERS,

thats significantly thicker being welded to the existing header flange , to space it out further away from the cylinder heads, obviously you don,t want to do this without testing all the clearances so installing the extra header flange with an exhaust gasket on both the cylinder head surface and between the header flange spacer and the existing headers as a test is strongly suggested as a test.

THIS IS ALSO USEFUL AT TIMES TO ADAPT THE ENGINE TO A DIFFERENT BOLT PATTERN OR SPACING

http://www.jegs.com/i/JEGS-Performance-Products/555/30790/10002/-1?parentProductId=977236

heres where you get spacer header flange plates

http://www.jegs.com/p/JEGS-Performance-Products/JEGS-Header-Exhaust-Flanges/1127498/10002/-1

http://www.summitracing.com/search/Part-Type/Header-Flanges/

http://www.hedmanhusler.com/Hedder-Flanges-without-Stubs

http://rehermorrison.com/product/adapter-plates/

Accel Extreme 9000 Ceramic Wire Sets

ACCEL now offers the cure for burnt spark plug wire boots with Extreme 9000 Ceramic Wire kits. The 8mm Ferro-Spiral core wire now has ceramic boots on the spark plug end of the wires that will withstand up to 2,000° F. If you are running headers with close tolerances, an engine bay with little room, or an RV with boots that melt because of heat, these wire kits are the answer. and yeah! youll still need the heat resistant plug boots to prevent the wires from melting past the ceramic plug boot

http://www.stage8.com

http://store.summitracing.com/partdetail.asp?part=ARP-400-1101&autoview=sku

try 12 point sockets also, once its out replace all the bolts with stainless socket head cap screws, and use anti seize on the threads, with star lock washers under thier heads

I would strongly suggest BOTH stainless bolts and the use of ANTI SEIZE on the threads

http://store.summitracing.com/partdetail.asp?autofilter=1&part=SUM-SP1502&N=700+324400+115&autoview=sku

http://store.summitracing.com/egnsearch.asp?N=700+115+317370&D=317370

read full caption

Doing The Twist Safety Wire

Safety wiring works equally well on nuts or bolts, in fact its the most dependable option to keep header bolts from getting loose

http://www.harborfreight.com/hand-tools/pliers/9-inch-safety-wire-twister-45341.html

obviously theres options

http://forum.grumpysperformance.com/viewtopic.php?f=50&t=4306&p=11353#p11353

http://www.harborfreight.com/hand-tools/pliers/9-inch-safety-wire-twister-45341.html

http://forum.grumpysperformance.com/viewtopic.php?f=27&t=970&p=1691#p1691

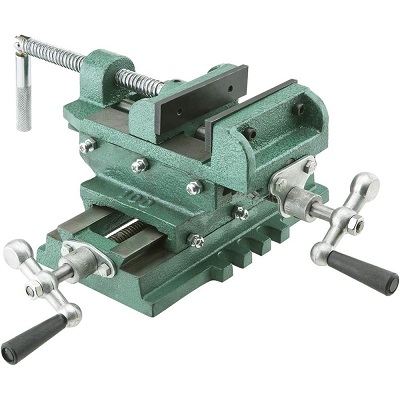

EVERY SHOP needs a drill press, hydraulic press and a decent welder, I can,t imagine how you can work without basic tools, now you don,t need the best one ever made but a decent floor mount drill press is a huge asset to any shop, the special pliers and wire combined cost less than $20

http://www.grizzly.com/products/12-Speed-Heavy-Duty-14-Floor-Drill-Press/G7944

http://www.grizzly.com/products/Cross-Sliding-Vise/G1064

yeah if you can swing the cost a MILL is even better

as to a JIG to drill bolts

you simply clamp a $3 thread rod nut, of the proper thread type (3/8-16 in this case) in a mill or drill press vise, tighten it up firmly , thread in the bolt . line it up and drill as required

I think youll find that in some applications socket head cap screws are easier to use/install

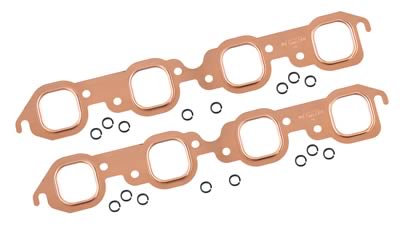

if the header flange is strait and flat and your useing a decent gasket (personally I prefer the copper ones) and youve coated the bolt threads in ANTI-SEIZE like you should have almost any decent 6"-8" box end wrench can be used to snug the bolts up firmly

I suppose youve never seen these, in most cases they are a great option as they don,t require a great deal of room , around thier perimeter to access or turn them

Last edited by a moderator: