you can try re-tightening the clamping bolts

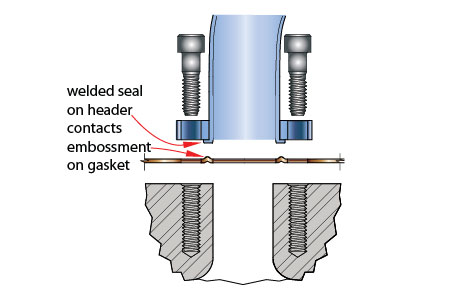

and if the exhaust header or manifold gaskets surface has not been damaged that should work, but if the gaskets damaged it will need to be replaced, thats one reason the soft copper gaskets are rather favored,

using anti-seize paste on bolt or stud threads helps prevent future problems

and failure to use anti-seize paste on any header or exhaust manifold bolt or stud will eventually cause problems ESPECIALLY if you use them on aluminum heads

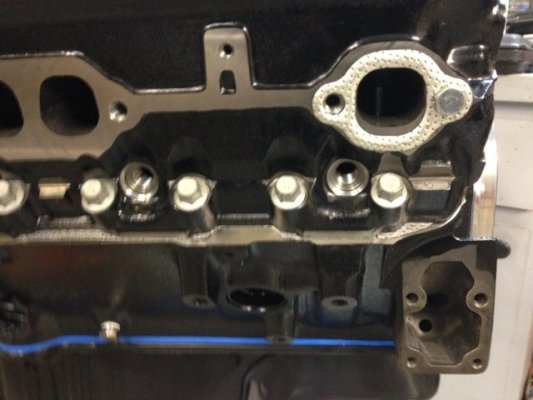

on aluminum head its almost alway's best to use studs to secure headers when you can,

as a stud has the threads full length engaged and very low stress , and significantly more surface area spreading the load,

than a bolt will ever allow,don,t forget too use anti-seize on the stud threads

http://garage.grumpysperformance.com/index.php?threads/header-gaskets.1045/page-2#post-55418

https://www.jegs.com/p/ARP/ARP-Exhaust-Header-Studs/744890/10002/-1

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

A: The exhaust manifolds are formed from the factory using fine grain cast iron, and like most metals, it expands and contracts during duty cycles of heating and cooling. This expansion happens naturally, and at first, the manifold and mounting studs are in a state of “elastic deformation.” Elastic deformation is basically expansion and contraction over a period of time retaining the original size and shape. Each duty cycle will provide tension stress on the studs or bolts that hold the manifold in place. The mounting hardware exhibits flexibility over time. However, as the manifold continues to expand and contract more dimensionally, each consecutive time creates larger and larger tension forces that move beyond the elastic state of deformation and become what is referred to as “plastic deformation.” Basically the manifold stretches beyond return and fractures the mounting stud, leaving the manifold permanently deformed and dimensionally changed. This expansion and stretching of the manifold bolts over numerous duty cycles eventually causes too much tension on the bolt(s), stretching them beyond capacity and causing them to fail.

I would point out that use of safety wired nuts and castle nuts with cotter pins, is in many applications, a separate,

and in my opinion better option ,

in that its both secure and easily removed if required, and less temp sensitive than chemical bonding agents.

yes obviously there are applications where loc-tite is the better option, and places where anti-seize and a castle nut and cotter pin or safety wire use is the best option.

http://garage.grumpysperformance.co...afety-wire-locking-fasteners.4306/#post-67524

http://garage.grumpysperformance.com/index.php?threads/cotter-pins.4733/#post-12852

Information provided by: ProMaxx Tools[/quote]

https://www.youtube.com/watch?v=Kj-kmIbSQvk

https://www.youtube.com/watch?v=Kj-kmIbSQvk

https://www.northwestfastener.com/d...ket-cap-screw-alloy-steel-1-hole-s-plain.html

because they are hard to damage,

using safety wire pliers and drilled bolt heads helps reduce leaks

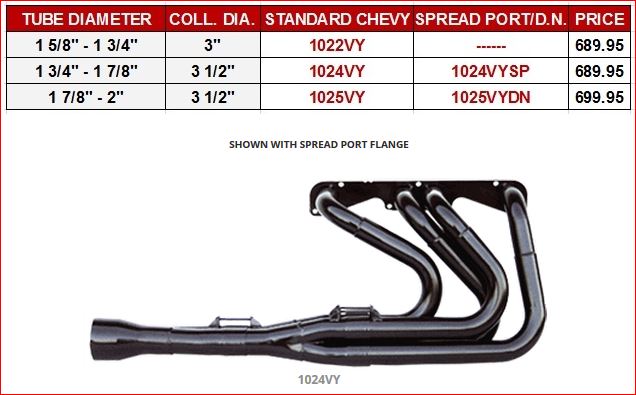

maybe this info will help,if you intend to use larger size exhaust primary tube header designs, on a sbc , (as I'mm sure you'll find out the exhaust manifold bolt hole locations make bolt and wrench clearance, when installing anything larger than about a 1 5/8" header tube,on most SBC engines , a P.I.T.A. and yes I've used them in the past

Yes theres a work-around that allows up to 2" tube headers to be used,

no they don,t squish the header tube narrow and taller

they suggest you use the adapter plates designed to make the installation of the larger diameter tubes much easier,

to allow the larger tube with more clearance and use a different bolt spacing and pattern,

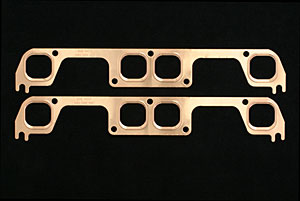

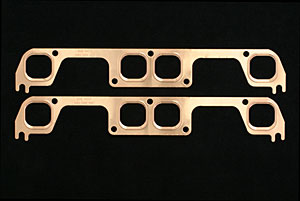

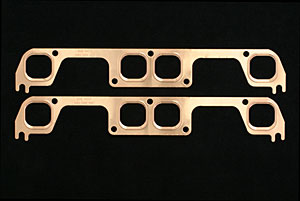

look closely at the pictures of both the header and adapter

yes the holes in the adapter look small,

thats because, they correctly assume if you, or anyone else,

are using these they must be building a custom exhaust .

and either have prior experience or be willing to ask for instructions,

you WILL need to take the time and effort to custom machine and port match the plates exhaust port,

it needs too be ported larger to match your cylinder heads exhaust port shape and header primary tubes exact location,

yes this some times results in part of the recessed screw heads being machined away,

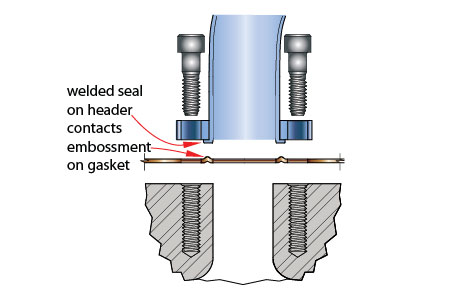

and no thats not an issue and yes copper header gaskets are commonly used

http://www.jegs.com/webapp/wcs/stor...&submodel=&engine=&Nrpp=&No=&persistYmm=false

http://www.jegs.com/i/Moroso/710/67...MIqOvSi9Lt1gIVB4JpCh1DlAYNEAQYBSABEgL2rvD_BwE

http://www.jegs.com/i/Hooker/520/11...MIqOvSi9Lt1gIVB4JpCh1DlAYNEAQYASABEgKPDfD_BwE

used a generous application of ANTI-SEIZE,

on the flush mount socket head screws, in the adapter plates, that screw to the cylinder heads,

if you think about it its rather difficult for the adapter plate bolts to loosen as the header clamps them in place,

and I simply used one copper exhaust header gasket between the adapter plates and header flanges ,

I used a thick , sprayed on coat of copper coat gasket cement,between the adapter plates and cylinder heads and had zero leaks.

obviously locking the fasteners,with a fool proof locking system, once they are correctly tightened in place to clamp the gaskets firmly, so they can.t come loose is a smart precaution

http://www.wikihow.com/Lock-Wire-Drilled-Head-Bolts

https://www.youtube.com/watch?v=oOEbMsi ... fudEmnJNWo

drilling bolts

https://www.youtube.com/watch?v=SGssNWC_2I8

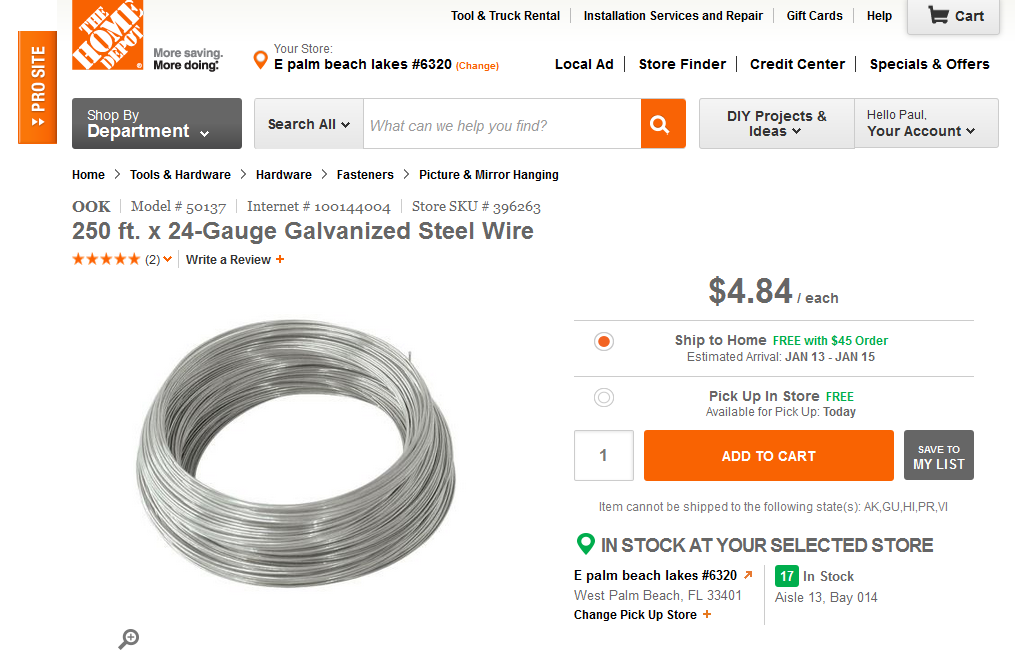

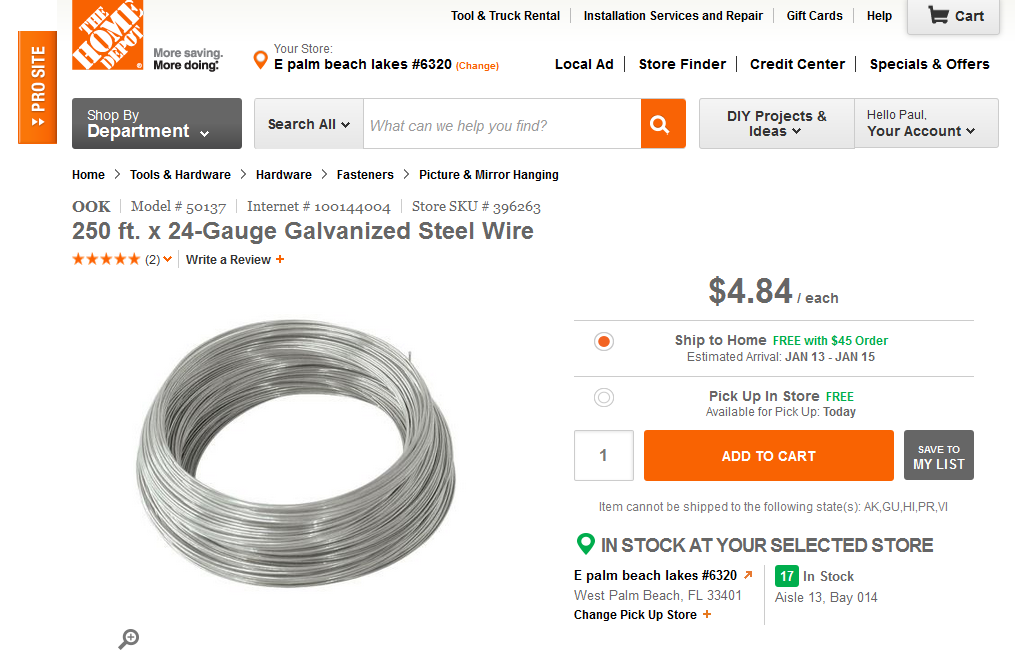

http://www.homedepot.com/p/OOK-250-ft-x ... /100144004

http://www.amazon.com/SK-7716-Automatic ... reversible

in some cases you might choose cotter pins

viewtopic.php?f=50&t=4733&p=12852&hilit=cotter#p12852

HARBOR FREIGHT SELLS STAINLESS LOCK WIRE

http://www.harborfreight.com/0041-inch- ... -8895.html

and if the exhaust header or manifold gaskets surface has not been damaged that should work, but if the gaskets damaged it will need to be replaced, thats one reason the soft copper gaskets are rather favored,

using anti-seize paste on bolt or stud threads helps prevent future problems

and failure to use anti-seize paste on any header or exhaust manifold bolt or stud will eventually cause problems ESPECIALLY if you use them on aluminum heads

What causes an exhaust manifold stud/bolt to break?

on aluminum head its almost alway's best to use studs to secure headers when you can,

as a stud has the threads full length engaged and very low stress , and significantly more surface area spreading the load,

than a bolt will ever allow,don,t forget too use anti-seize on the stud threads

http://garage.grumpysperformance.com/index.php?threads/header-gaskets.1045/page-2#post-55418

https://www.jegs.com/p/ARP/ARP-Exhaust-Header-Studs/744890/10002/-1

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

I would strongly suggest BOTH stainless bolts studs and the use of ANTI SEIZE on the threads

A: The exhaust manifolds are formed from the factory using fine grain cast iron, and like most metals, it expands and contracts during duty cycles of heating and cooling. This expansion happens naturally, and at first, the manifold and mounting studs are in a state of “elastic deformation.” Elastic deformation is basically expansion and contraction over a period of time retaining the original size and shape. Each duty cycle will provide tension stress on the studs or bolts that hold the manifold in place. The mounting hardware exhibits flexibility over time. However, as the manifold continues to expand and contract more dimensionally, each consecutive time creates larger and larger tension forces that move beyond the elastic state of deformation and become what is referred to as “plastic deformation.” Basically the manifold stretches beyond return and fractures the mounting stud, leaving the manifold permanently deformed and dimensionally changed. This expansion and stretching of the manifold bolts over numerous duty cycles eventually causes too much tension on the bolt(s), stretching them beyond capacity and causing them to fail.

I would point out that use of safety wired nuts and castle nuts with cotter pins, is in many applications, a separate,

and in my opinion better option ,

in that its both secure and easily removed if required, and less temp sensitive than chemical bonding agents.

yes obviously there are applications where loc-tite is the better option, and places where anti-seize and a castle nut and cotter pin or safety wire use is the best option.

http://garage.grumpysperformance.co...afety-wire-locking-fasteners.4306/#post-67524

http://garage.grumpysperformance.com/index.php?threads/cotter-pins.4733/#post-12852

Information provided by: ProMaxx Tools[/quote]

https://www.northwestfastener.com/d...ket-cap-screw-alloy-steel-1-hole-s-plain.html

because they are hard to damage,

using safety wire pliers and drilled bolt heads helps reduce leaks

maybe this info will help,if you intend to use larger size exhaust primary tube header designs, on a sbc , (as I'mm sure you'll find out the exhaust manifold bolt hole locations make bolt and wrench clearance, when installing anything larger than about a 1 5/8" header tube,on most SBC engines , a P.I.T.A. and yes I've used them in the past

Yes theres a work-around that allows up to 2" tube headers to be used,

no they don,t squish the header tube narrow and taller

they suggest you use the adapter plates designed to make the installation of the larger diameter tubes much easier,

to allow the larger tube with more clearance and use a different bolt spacing and pattern,

look closely at the pictures of both the header and adapter

yes the holes in the adapter look small,

thats because, they correctly assume if you, or anyone else,

are using these they must be building a custom exhaust .

and either have prior experience or be willing to ask for instructions,

you WILL need to take the time and effort to custom machine and port match the plates exhaust port,

it needs too be ported larger to match your cylinder heads exhaust port shape and header primary tubes exact location,

yes this some times results in part of the recessed screw heads being machined away,

and no thats not an issue and yes copper header gaskets are commonly used

http://www.jegs.com/webapp/wcs/stor...&submodel=&engine=&Nrpp=&No=&persistYmm=false

http://www.jegs.com/i/Moroso/710/67...MIqOvSi9Lt1gIVB4JpCh1DlAYNEAQYBSABEgL2rvD_BwE

http://www.jegs.com/i/Hooker/520/11...MIqOvSi9Lt1gIVB4JpCh1DlAYNEAQYASABEgKPDfD_BwE

used a generous application of ANTI-SEIZE,

on the flush mount socket head screws, in the adapter plates, that screw to the cylinder heads,

if you think about it its rather difficult for the adapter plate bolts to loosen as the header clamps them in place,

and I simply used one copper exhaust header gasket between the adapter plates and header flanges ,

I used a thick , sprayed on coat of copper coat gasket cement,between the adapter plates and cylinder heads and had zero leaks.

obviously locking the fasteners,with a fool proof locking system, once they are correctly tightened in place to clamp the gaskets firmly, so they can.t come loose is a smart precaution

http://www.wikihow.com/Lock-Wire-Drilled-Head-Bolts

https://www.youtube.com/watch?v=oOEbMsi ... fudEmnJNWo

drilling bolts

https://www.youtube.com/watch?v=SGssNWC_2I8

http://www.homedepot.com/p/OOK-250-ft-x ... /100144004

http://www.amazon.com/SK-7716-Automatic ... reversible

in some cases you might choose cotter pins

viewtopic.php?f=50&t=4733&p=12852&hilit=cotter#p12852

HARBOR FREIGHT SELLS STAINLESS LOCK WIRE

http://www.harborfreight.com/0041-inch- ... -8895.html

Last edited: