pdq67 said:Back again..

Guys,

Are 200 cc intake port, 2.02"/1.60" valve cast-iron heads with 49 cc chambers OK here.

I am thinking about installing 2.02"/1.60" valves in my rebuildable 305HO, -601 heads vs buying the 200 cc intake port heads..

I measured my -601's and my set stock cc at 53 and 55 cc's chamber-wise and have right at 160 cc intake ports.

Is 200 cc intake ports too big for an 8,000 rpm 301??

Please advise..

Thanks..

pdq67

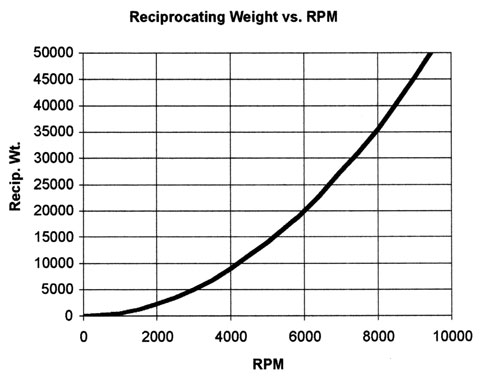

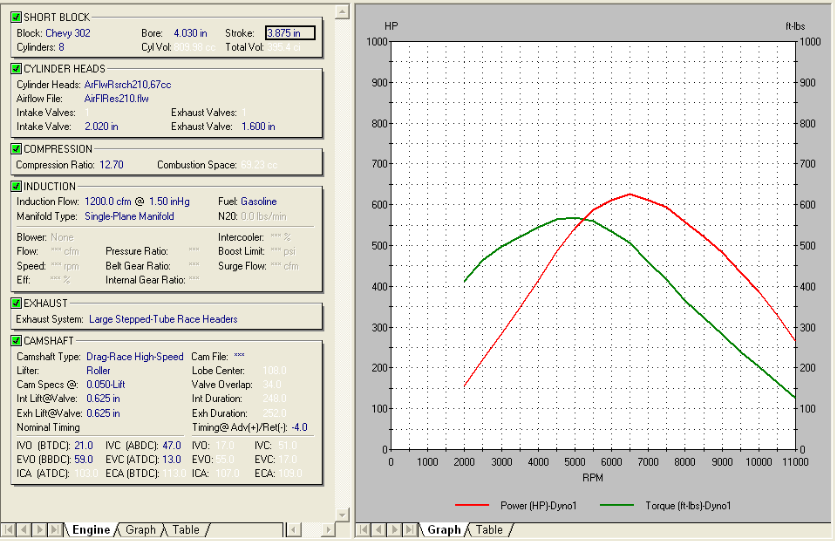

I does not matter if your building a 283 sbc or a 632 BBC, the math is readily available to calculate the correct matching components to your intended power,rpm and fuel/air requirements, all factors that match the intended rpm range, power curve and air and fuel requirements,header design, cam, lift and duration and lobe separation angles are easily calculated, it just takes a bit of research and reading links.

the physics of air flow,compression, quench, cam acceleration rates, header scavenging , don,t magically change if the cars built by FORD,BUICK,CHEVY,DODGE,or PONTIAC, the factors can be calculated

port throats generally run 80%-85% of total valve diameter because you need to maintain sufficient valve seat contact area to allow sealing and cooling and some wear during operation

READ LINKS AND SUB-LINKS

USE THE CALCULATORS and CHARTS

ASK QUESTIONS IF YOU DON,T UNDERSTAND WHATS POSTED

THINK BEFORE BUYING PARTS THAT DON,T MATCH

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

http://garage.grumpysperformance.com/index.php?threads/calculating-header-design.185/

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/

http://garage.grumpysperformance.com/index.php?threads/valve-seat-angles-and-air-flow.8460/

http://garage.grumpysperformance.com/index.php?threads/more-port-flow-related-info.322/

http://garage.grumpysperformance.com/index.php?threads/calculating-overlap-and-lsa-or-lca-etc.480/

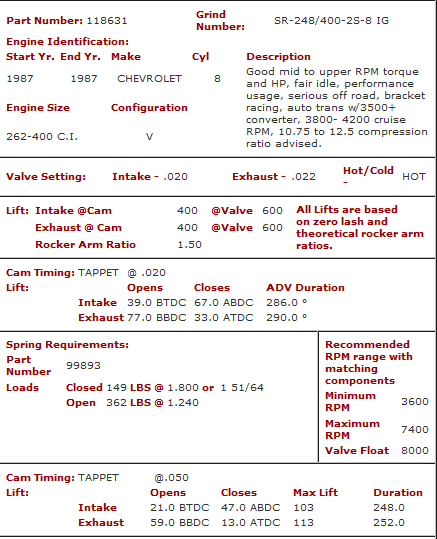

http://garage.grumpysperformance.com/index.php?threads/how-to-read-a-cam-spec-card.1477/

http://garage.grumpysperformance.co...-the-charts-calculators-and-basic-math.10705/

http://garage.grumpysperformance.co...alves-and-polishing-combustion-chambers.2630/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.co...ing-parts-and-a-logical-plan.7722/#post-51341

http://garage.grumpysperformance.com/index.php?threads/tuning-a-tunnel-ram-intake.5175/#post-15029

Calculating the valve curtain area

The following equation mathematically defines the available flow area for any given valve diameter and lift value:

Area = valve diameter x 0.98 x 3.14 x valve lift

Where 3.14 = pi (π)

For a typical 2.02-inch intake valve at .500-inch lift, it calculates as follows:

Area = 2.02 x 0.98 x 3.14 x 0.500 = 3.107 square inches

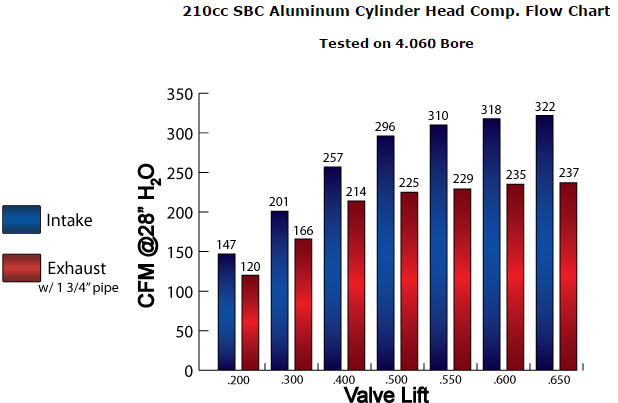

here's a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

...........................sq inches........port cc

edelbrock performer rpm ....1.43.............170

vortec......................1.66.............170

tfs195......................1.93.............195

afr 180.....................1.93.............180

afr 195.....................1.98.............195

afr 210.....................2.05.............210

dart pro 200................2.06.............200

dart pro 215................2.14.............215

brodix track 1 .............2.30.............221

dart pro 1 230..............2.40.............230

edelbrock 23 high port .....2.53.............238

edelbrock 18 deg............2.71.............266

tfs 18 deg..................2.80.............250

I'm rather AMAZED that when ever I mention the fact theres actual tests, and well known math calculations for ideal fuel /air ratio, exhaust back pressure in the exhaust system,and intake plenum vacuum , fuel distribution, bearing surface speeds, rpm limitations , and ignition timing , valve float, air flow rates in the intake ports , port stall and they look at you like you are 9 feet tall and just stepped of a flying saucer

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations , don,t guess ask questions!

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.wallaceracing.com/Calculators.htm

http://users.erols.com/srweiss/

http://www.csgnetwork.com/automotiveconverters.html

http://www.bgsoflex.com/auto.html

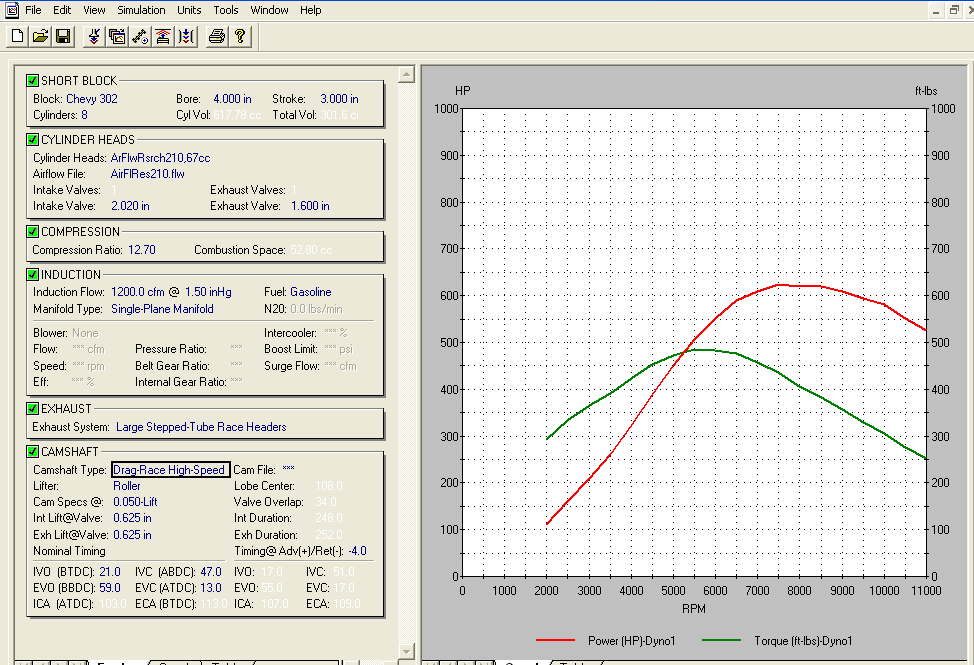

SOFTWARES AVAILABLE

http://www.virtualengine2000.com/products.htm

http://performancetrends.com/Engine-Analyzer.htm

http://www.camquest.com/

http://www.virtualengine2000.com/calculator.htm

http://www.proracingsim.com/desktopdyno.htm

http://www.land-and-sea.com/dyno-max-data-acquisition-software/demo.htm

Last edited: