You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello from south east England

- Thread starter Goatlips

- Start date

great to have you joint the fun! please post pictures and info on your car and engine build up!

GOATLIPS POSTED THIS

hi guys

looking to replace my solid roller for something hotter here in my combo

388 ci chevy

bowtie block 4.125 bore

3.625 stroke

6 inch rod

11cc dish custom piston

belt drive

crower solid roller 236/244 on 112 .588 lift

AFR227cc heads 65cc

behive springs 185/380

10.5 comp

shaft rockers 1.6/1.5

TWM throttle bodys on a IDA intake manifold

EFI and wasted spark

TKO600 gearbox with 3.54:1

2200lbs car

sunday afternoon car with little strip

http://www.lunatipower.com/CamSpecCard. ... mber=60133

or

http://www.lunatipower.com/CamSpecCard. ... mber=60134

What are your thoughts??

The obvious first questions got to be whats the current cams power curve lacking, that your trying to change?

, and do you have a DYNO showing the current engine parameters ?

yes theres zero doubt you can make better peak power, but what does the current cam do or not do that you want changed?

Hi grumpy,

It mainly drives too smooth with a light chop on idle, it as massive tq off idle which I feel is not required, as its a lightweight cobra I would like to move the powerband upwards for a more of a shove come on cam experience.

Do you remember my last 350ci motor years ago?

I do have a dyno print out.

yes I remember, but I also remember you have a street driven car with a 3.54:1 rear gear ratio.

now if your willing to loose a good deal of low rpm torque for more peak power..Id want to know whats the max lift your valve train can accept, the spring load rates and what rpm limitations you can use or expect.

Max lift is .710 but max flow is .650 would be a max lift. The springs fitted are beehives set at 185/380 I rev it to 7k rpm no worries now.

hi guys

looking to replace my solid roller for something hotter here in my combo

388 ci chevy

bowtie block 4.125 bore

3.625 stroke

6 inch rod

11cc dish custom piston

belt drive

crower solid roller 236/244 on 112 .588 lift

AFR227cc heads 65cc

behive springs 185/380

10.5 comp

shaft rockers 1.6/1.5

TWM throttle bodys on a IDA intake manifold

EFI and wasted spark

TKO600 gearbox with 3.54:1

2200lbs car

sunday afternoon car with little strip

http://www.lunatipower.com/CamSpecCard. ... mber=60133

or

http://www.lunatipower.com/CamSpecCard. ... mber=60134

What are your thoughts??

The obvious first questions got to be whats the current cams power curve lacking, that your trying to change?

, and do you have a DYNO showing the current engine parameters ?

yes theres zero doubt you can make better peak power, but what does the current cam do or not do that you want changed?

Hi grumpy,

It mainly drives too smooth with a light chop on idle, it as massive tq off idle which I feel is not required, as its a lightweight cobra I would like to move the powerband upwards for a more of a shove come on cam experience.

Do you remember my last 350ci motor years ago?

I do have a dyno print out.

yes I remember, but I also remember you have a street driven car with a 3.54:1 rear gear ratio.

now if your willing to loose a good deal of low rpm torque for more peak power..Id want to know whats the max lift your valve train can accept, the spring load rates and what rpm limitations you can use or expect.

Max lift is .710 but max flow is .650 would be a max lift. The springs fitted are beehives set at 185/380 I rev it to 7k rpm no worries now.

A very commonly made mistake is to assume in cases like this, where you have a combo thats performing fairly well,but needs a bit more upper rpm power, that you can make a fairly radical increase in cam duration, too gain that required increase in upper rpm air flow rates, too potentially increase power while not adversely effecting the lower rpm power. OK looking over many dozens of some what similar builds its rather obvious that you can very easily reach a point where you can reach or exceed a tipping point, that will have you trading off that mid and low rpm torque for increasingly lower gains.

the first cam you linked to would in my opinion be by far the better choice of the two you selected, but even thats likely to be just a bit to large of an increase, to effectively match your combo, every choice is a compromise, adding 8-10 degrees duration should move the whole power band up 500 plus rpms

http://www.lunatipower.com/CamSpecCard. ... mber=60133

yes you could fairly easily in this case increase the duration to about 8-10 degrees more and add a bit more lift, I would certainly think after doing a few software dyno comparison runs that a cam in the 242-244 duration @ .050 lift, and ..558-.600 lift range would get you to where you want to be, but ID sure try to find one built on a 108-110 LSA to try to maximize the mid rpm torque so you don,t loose a great deal more that you intend to, because with a 3.54 rear gear and only 10.5:1 COMPRESSION, and those valve spring load rates, you could easily trade off far more low and mid rpm power for minimal gains if you get to radical on the cam selected.

keep in mind that your valve springs won,t work well at maintaining valve train stability if you increase the lifter acceleration rates much more that the current cam, with those valve spring load rates, so altho there will be a tendency to want to go with a cam with greater lift increasing the lobe acceleration rates will cause stability issues AND RUNNING HYDRAULIC ROLLER LIFTERS YOUR NOT GOING TO BE ABLE TO SIGNIFICANTLY INCREASE YOUR USEABLE RPM BAND MUCH OVER THE CURRENT CAM, WHAT YOU CAN DO IS MAXIMIZE THE TORQUE CURVE IN THE 4500RPM-6500RPM RANGE.

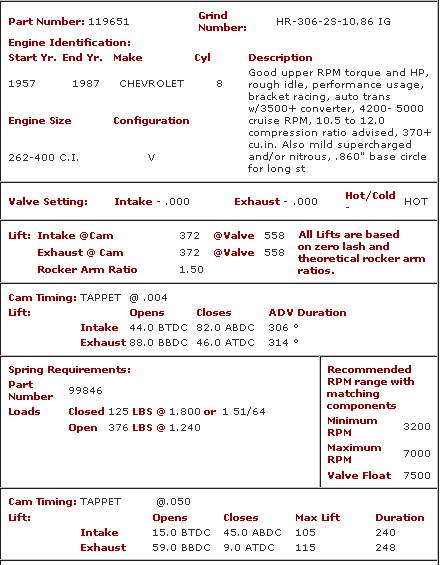

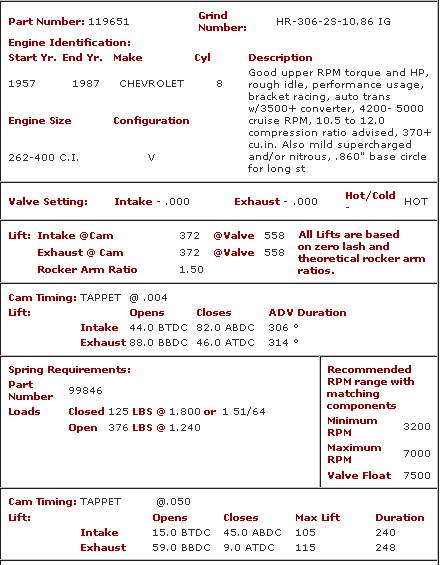

heres my choice

A MECHANICAL ROLLER LIKE THIS CROWER LISTED BELOW IS MOST LIKELY A GOOD OPTION

JUST as a bit of info I used this crane roller (#119651) in a 12:1 compression 406 engine build with similar but slightly smaller brodix 215cc port heads heads and a single plane intake to push a 1988 corvette one of my friends owned into the mid 10 second range so with your larger cylinder heads you should not need a huge cam duration increase

viewtopic.php?f=32&t=430&p=529#p529

the first cam you linked to would in my opinion be by far the better choice of the two you selected, but even thats likely to be just a bit to large of an increase, to effectively match your combo, every choice is a compromise, adding 8-10 degrees duration should move the whole power band up 500 plus rpms

http://www.lunatipower.com/CamSpecCard. ... mber=60133

yes you could fairly easily in this case increase the duration to about 8-10 degrees more and add a bit more lift, I would certainly think after doing a few software dyno comparison runs that a cam in the 242-244 duration @ .050 lift, and ..558-.600 lift range would get you to where you want to be, but ID sure try to find one built on a 108-110 LSA to try to maximize the mid rpm torque so you don,t loose a great deal more that you intend to, because with a 3.54 rear gear and only 10.5:1 COMPRESSION, and those valve spring load rates, you could easily trade off far more low and mid rpm power for minimal gains if you get to radical on the cam selected.

keep in mind that your valve springs won,t work well at maintaining valve train stability if you increase the lifter acceleration rates much more that the current cam, with those valve spring load rates, so altho there will be a tendency to want to go with a cam with greater lift increasing the lobe acceleration rates will cause stability issues AND RUNNING HYDRAULIC ROLLER LIFTERS YOUR NOT GOING TO BE ABLE TO SIGNIFICANTLY INCREASE YOUR USEABLE RPM BAND MUCH OVER THE CURRENT CAM, WHAT YOU CAN DO IS MAXIMIZE THE TORQUE CURVE IN THE 4500RPM-6500RPM RANGE.

heres my choice

A MECHANICAL ROLLER LIKE THIS CROWER LISTED BELOW IS MOST LIKELY A GOOD OPTION

JUST as a bit of info I used this crane roller (#119651) in a 12:1 compression 406 engine build with similar but slightly smaller brodix 215cc port heads heads and a single plane intake to push a 1988 corvette one of my friends owned into the mid 10 second range so with your larger cylinder heads you should not need a huge cam duration increase

viewtopic.php?f=32&t=430&p=529#p529

How about this cam below. It has a very low Hydraulic Intensity at 38° (288-250=38) and probably more area under the valve lift curve. It's hard to find a cam with all the specs you want and then also has to be suitable with the valve springs you already have.

The intended RPM range is 3000 to 7000 rpm, should be able to feel it hit the torque like you requested. With your rocker ratio on the intakes of 1.6, that will give you .608/.584 lift. After you subtract out the lifter clearances you have an actual valve lift of .582/556.

The cam is going to be hard on the valve springs, so you will want to test them every so often to make sure they are surviving Ok. If you are not willing to check valve springs, then this may not be the cam for you.

It would be interesting to swap the rockers and put the 1.6 on the exhaust to see how that changes the engine characteristics.

STREET ROLLER / Performance Level 4 - Intended for performance oriented hotstreet

applications. 8620 steel billet.

RPM Power Range: 3000 to 7000 / Redline: 7500 maximum.

Attachments

viewtopic.php?f=52&t=727

Theres dozens of factors that will effect your results from exhaust scavenging to air temps, fuel octane, to ignition advance curve, you can do a few calculations and youll find the dynamic compression of those cams, remember you can generally advance the cams about 2 degrees and retard them about 6 degrees from the DOT-TO-DOT install location

(most cams have 4 degrees advance built in currently)

Ive found the crower 00471 hydraulic roller worked rather well in street car engines installed retarded 4 degrees in 10.5"1 compression 383 , your solid roller is very similar

so theres some adjust-ability and things like oil temp and coolant temp effect your results but you generally want to find a cam with a dynamic compression in the 8:1 range, get below about 7.7:1 and torque usually suffers, get above about 8.8:1 and your going to run a significant risk of getting into detonation with even high test pump gas.you can run premium octane fuel, get the quench right, run a richer fuel/air ratio and modify the ignition timing advance curve, make sure the coolant and oil temps stay low and get away with the numbers higher than 8:1 but the higher you push the limits the more you court detonation

related threads

viewtopic.php?f=50&t=208&p=16848&hilit=detonation+damage#p16848

viewtopic.php?f=70&t=5372&p=16094&hilit=detonation+damage#p16094

viewtopic.php?f=57&t=4701&p=15021&hilit=detonation+damage#p15021

viewtopic.php?f=55&t=613&p=12677&hilit=detonation+damage#p12677

viewtopic.php?f=52&t=4081&p=13147&hilit=quench+swirl#p13147

viewtopic.php?f=52&t=1070&p=9909&hilit=detonation+damage#p9909

viewtopic.php?f=53&t=3443&p=9118&hilit=detonation+damage#p9118

viewtopic.php?f=52&t=5962&p=18389&hilit=lobe+acceleration+rates#p18389

viewtopic.php?f=44&t=937&p=1922&hilit=detonation+damage#p1922

Theres dozens of factors that will effect your results from exhaust scavenging to air temps, fuel octane, to ignition advance curve, you can do a few calculations and youll find the dynamic compression of those cams, remember you can generally advance the cams about 2 degrees and retard them about 6 degrees from the DOT-TO-DOT install location

(most cams have 4 degrees advance built in currently)

Ive found the crower 00471 hydraulic roller worked rather well in street car engines installed retarded 4 degrees in 10.5"1 compression 383 , your solid roller is very similar

so theres some adjust-ability and things like oil temp and coolant temp effect your results but you generally want to find a cam with a dynamic compression in the 8:1 range, get below about 7.7:1 and torque usually suffers, get above about 8.8:1 and your going to run a significant risk of getting into detonation with even high test pump gas.you can run premium octane fuel, get the quench right, run a richer fuel/air ratio and modify the ignition timing advance curve, make sure the coolant and oil temps stay low and get away with the numbers higher than 8:1 but the higher you push the limits the more you court detonation

related threads

viewtopic.php?f=50&t=208&p=16848&hilit=detonation+damage#p16848

viewtopic.php?f=70&t=5372&p=16094&hilit=detonation+damage#p16094

viewtopic.php?f=57&t=4701&p=15021&hilit=detonation+damage#p15021

viewtopic.php?f=55&t=613&p=12677&hilit=detonation+damage#p12677

viewtopic.php?f=52&t=4081&p=13147&hilit=quench+swirl#p13147

viewtopic.php?f=52&t=1070&p=9909&hilit=detonation+damage#p9909

viewtopic.php?f=53&t=3443&p=9118&hilit=detonation+damage#p9118

viewtopic.php?f=52&t=5962&p=18389&hilit=lobe+acceleration+rates#p18389

viewtopic.php?f=44&t=937&p=1922&hilit=detonation+damage#p1922

GOATLIPS POSTED THIS

"Mmm yes, but I think I'll like to stay with the solid roller, if I need to change the springs then I will do so, while the heads are off I could reduce the chamber cc from 65 to 61 and get another half point in compression to 11.0:1

I got a custom solid roller made for this engine 249/249 on 108 inverse radius with .401 lobe lift and that cam lost 50ftlbs TQ low down with no extra HP at the top, excatly the same top end hp as the milder cam I have now. Really strange?! So be it they was both tested with a vic jnr intake and 750 BG carb on both cams. "

THIS RESPONSE POSTED ABOVE IS A VERY COMMON RESULT, of increasing duration and lift past what the engine can effectively use for one reason or another, especially with a restrictive exhaust or when the valve train can,t keep up with the increased cam lobe acceleration rates, but it can be from other factors like not enough effective compression, remember the piston compressed zero untill both valve seat, and adding duration effectively costs you low rpm compression.

I would not be in a huge rush to change parts until you test what you have.

ID bet a bit of tuning on the current cam,(retard it a few degrees) checking the headers (back pressure if your running a exhaust behind them) and measuring the intake plenum vacuum, verify the fuel/air ratio, and ignition advance curve every 500rpm, would give you clues as to what needs, or might need, changing and would get you useful info.

"Mmm yes, but I think I'll like to stay with the solid roller, if I need to change the springs then I will do so, while the heads are off I could reduce the chamber cc from 65 to 61 and get another half point in compression to 11.0:1

I got a custom solid roller made for this engine 249/249 on 108 inverse radius with .401 lobe lift and that cam lost 50ftlbs TQ low down with no extra HP at the top, excatly the same top end hp as the milder cam I have now. Really strange?! So be it they was both tested with a vic jnr intake and 750 BG carb on both cams. "

THIS RESPONSE POSTED ABOVE IS A VERY COMMON RESULT, of increasing duration and lift past what the engine can effectively use for one reason or another, especially with a restrictive exhaust or when the valve train can,t keep up with the increased cam lobe acceleration rates, but it can be from other factors like not enough effective compression, remember the piston compressed zero untill both valve seat, and adding duration effectively costs you low rpm compression.

I would not be in a huge rush to change parts until you test what you have.

ID bet a bit of tuning on the current cam,(retard it a few degrees) checking the headers (back pressure if your running a exhaust behind them) and measuring the intake plenum vacuum, verify the fuel/air ratio, and ignition advance curve every 500rpm, would give you clues as to what needs, or might need, changing and would get you useful info.

GOATLIPS POSTED THIS

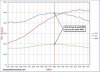

Grumps here's the dyno sheet

http://i1309.photobucket.com/albums/s63 ... 597f4b.jpg

my first impression is that, with over 400 ft lbs from 2800rpm to 6500rpm and a peak torque of 495 ft lbs and 530 plus peak hp I don,t see anything to really complain about, that should move a 2200 lb car rather briskly , your peak torque starts to level off and drop near 5000rpm, so you know thats the point in the rpm band thats starting to restrict air flow efficiency, do you have exhaust back pressure and intake plenum vacuum data info?

btw it looks like your running a bit LEAN for max power

Grumps here's the dyno sheet

http://i1309.photobucket.com/albums/s63 ... 597f4b.jpg

my first impression is that, with over 400 ft lbs from 2800rpm to 6500rpm and a peak torque of 495 ft lbs and 530 plus peak hp I don,t see anything to really complain about, that should move a 2200 lb car rather briskly , your peak torque starts to level off and drop near 5000rpm, so you know thats the point in the rpm band thats starting to restrict air flow efficiency, do you have exhaust back pressure and intake plenum vacuum data info?

btw it looks like your running a bit LEAN for max power

goatlips said:Running a bit lean, 13.2 AFR??

we pulled it to 7k and it still made 500hp with just under 400tq.

No idea about plenum info as its efi individual runners IDA intake.

Yes the side pipe exh system is not all that great on cobras. Think I have 1 7/8 manifolds and 3 inch inside the side pipe.

The car is super quick, I just wanted to bleed off the low end TQ and move it up top as you can't even load this engine in a light weight car. The engine will pull the car in 5th gear at 30mph and still accelerate well.

goatlips said:Running a bit lean, 13.2 AFR??

yes I think the power curve would increase if you got that down nearer 12.8:1

we pulled it to 7k and it still made 500hp with just under 400tq.

No idea about plenum info as its efi individual runners IDA intake.

Yes the side pipe exh system is not all that great on cobras. Think I have 1 7/8 manifolds and 3 inch inside the side pipe.

Id suggest drilling a tiny hole some place it can,t be easily seen and using a vacuum/pressure gauge to record exhaust pressure from 4000rpm and up

The car is super quick, I just wanted to bleed off the low end TQ and move it up top as you can't even load this engine in a light weight car. The engine will pull the car in 5th gear at 30mph and still accelerate well.

sounds like you built pretty much what you asked too, and expected too build a few months back when we discussed this during the build phase. it also occurs to me to ask what your individual throttle bore size is you might be restricting flow on the intake.

goatlips said:Ok I could richen it up a bit, I thought they make more power slightly leaner.

Where abouts is the best place to measure back pressure?? After the collect but before the baffle??

YES After or in the rear of the collector but before the sound baffles

try to measure your runner cross sectional area also you might be getting up into port stall

l

goatlips said:What sort of figs should I be seeing??

I did not dyno my engine with the cars headers or exh but something that needs checking.

Yes I've got my lambda probe there so ill use that point.

less than 3psi positive pressure, for sure, ideally it will be less than 1 psi of back pressure

my calculations show you need about a MINIMUM, of 2.5 sq inches of intake port cross section

50mm, is about 3 sq inches so in theory your ok

http://www.wallaceracing.com/ca-calc.php

goatlips said:http://i1309.photobucket.com/albums/s636/clarky427/image_zpse499f15c.jpg

Grumps this is the same engine, but on a vic jnr intake, 750bg carb and msd dissy. Note the difference in TQ

his was the first cam we tested. ...249/249 on 108 with .401 lobe lift using a 1.6/1.5 rocker.

I paid $430 for this custom cam that did not seam to work. Lost lots of TQ and gained nothing!!

Again with a carb and vic jnr intake. Because it was poor we never tested it with the individual runners in which it was designed for.

.

, you might have made a mistake not testing that cam with the INDIVIDUAL RUNNER EFI intake, it looks like its designed to take advantage of the intakes inertial ram tunning characteristics which the common plenum edelbrock intake won,t provide.

WHEN I ran stack injection like this

on my 496 big block it performed vastly better with a cam that had a tight lsa and similar intake and exhaust duration, than it did with a single carb intake I tried earlier, but I think testing your exhaust back pressure at higher rpm levels will show its slightly restricted

RELATED INFO

viewtopic.php?f=55&t=4502&p=21483&hilit=+ram+injection+stacks+tuning#p21483

viewtopic.php?f=56&t=495

viewtopic.php?f=55&t=109

WHEN I ran stack injection like this

on my 496 big block it performed vastly better with a cam that had a tight lsa and similar intake and exhaust duration, than it did with a single carb intake I tried earlier, but I think testing your exhaust back pressure at higher rpm levels will show its slightly restricted

RELATED INFO

viewtopic.php?f=55&t=4502&p=21483&hilit=+ram+injection+stacks+tuning#p21483

viewtopic.php?f=56&t=495

viewtopic.php?f=55&t=109

This data and graph are from the first dyno run on the previous page. I just made an Excel file from it and then plotted the torque, HP and BMEP.

The torque and BMEP both peak at the same RPM of 4900. I suspect this is always the case and not just a coincidence.

I also added one column to the table called "A/F Ratio" and calculated the value from the "Lambda Ratio". I didn't know what the Lambda ratio was, but it appears to me that it is just "Stoichiometric Ratio" divided by the actual ratio. So I used this formula for the A/F Ratio column.....

Lambda x 14.7 = A/F Ratio

This is what Grumpyvette said about it: [Thought it would be easier to understand while looking at the graph]

my first impression is that, with over 400 ft lbs from 2800rpm to 6500rpm and a peak torque of 495 ft lbs and 530 plus peak hp I don,t see anything to really complain about, that should move a 2200 lb car rather briskly , your peak torque starts to level off and drop near 5000rpm, so you know thats the point in the rpm band thats starting to restrict air flow efficiency, do you have exhaust back pressure and intake plenum vacuum data info?

btw it looks like your running a bit LEAN for max power

This is the dyno data post on the previous page that the above is based on.

Attachments

DAMN! I WISH I HAD YOUR COMPUTER SKILLS!

but your correct the graph makes it easier to see the data

but your correct the graph makes it easier to see the data