Obviously the engine can be improved after 30 plus years of further advancements in engine design and testing since 1988,

obviously it costs a good deal to maximize any engine combos potential, but there are certainly ways to do it and get impressive results if you have deep financial pockets! obviously verify the current two turbos are in good condition and be aware that there are several newer more efficient turbo designs and more effective inter-coolers now available.

http://www.turbodynamics.co.uk/technical/diagnostics/diagnostic-procedures/

my 1985 corvette came with a factory oil cooler, that runs engine coolant through separate but contacting internal passages, this warms the oil faster getting it flowing but tends to reduce the heat engine oil can reach as it absorbs oil heat effectively transferring it too the engine coolant on the car, where its transferred too air flow through the radiator

http://www.superchevy.com/how-to/15044-1991-chevrolet-corvette-oil-cooler-maintenance/

http://www.batinc.net/mocal-central.htm

http://www.mocal.co.uk/FAQ.html

http://www.batinc.net/laminova.htm

from the factory. . . . . . . . . .

INSPECTION

Visually inspect the turbocharger and exhaust manifold gasket surfaces. Replace stripped or eroded mounting studs.

Visually inspect the turbocharger for cracks. The following cracks are NOT acceptable:

Cracks in the turbine and compressor housing that go completely through.

Cracks in the mounting flange that are longer than 15 mm (0. 6 in. ).

Cracks in the mounting flange that intersect bolt through-holes.

Two (2) Cracks in the mounting flange that are closer than 6. 4 mm (0. 25 in. ) together.

Visually inspect the impeller and compressorwheel fins for nicks, cracks, or chips. Note: Some impellers may have a factory placed paint mark which, after normal operation, appears to be a crack. Remove this mark with a suitable solvent to verify that it is not a crack.

Visually inspect the turbochargercompressor housing for an impeller rubbing condition (Inspect Compressor Housing for Impeller Rubbing Condition). Replace the turbocharger if the condition exists.

Measure the turbocharger axial end play:

Install a dial indicator as shown in (Measure Turbocharger Axial End Play). Zero the indicator at one end of travel.

Move the impeller shaft fore and aft and record the measurement. Allowable end play is 0. 026 mm (0. 0001 in. ) MIN. and 0. 127 mm (0. 005 in. ) MAX. If the recorded measurement falls outside these parameters, replace the turbocharger assembly.

Measure the turbocharger bearing radial clearance:

Insert a narrow blade or wire style feeler gauge between the compressorwheel and the housing (Measure Turbocharger Bearing Radial Clearance).

Gently push the compressorwheel toward the housing and record the clearance.

With the feeler gauge in the same location, gently push the compressorwheel away from the housing and again record the clearance.

Subtract the smaller clearance from the larger clearance. This is the radial bearing clearance.

Allowable radial bearing clearance is 0. 33 mm (0. 013 in. ) MIN. and 0. 50 mm (0. 020 in. ) MAX. If the recorded measurement falls outside these specifications, replace the turbocharger assembly.

larger displacement, larger injectors, and better flowing heads, intake and exhaust will all boost power.

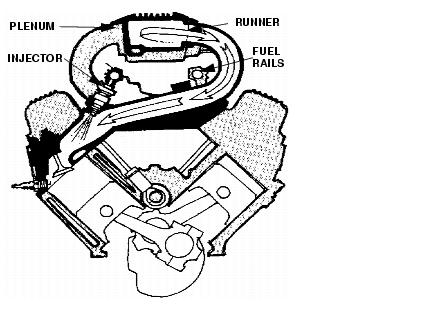

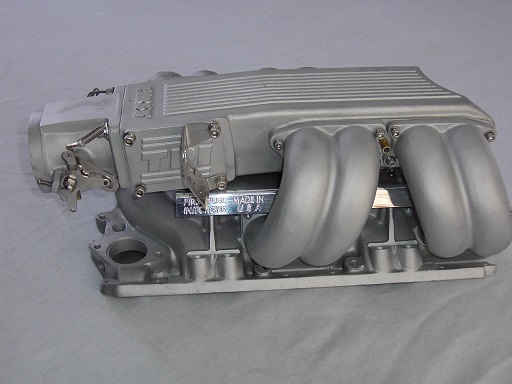

your original TPI intake manifold is VERY RESTRICTIVE, an aftermarket version flows significantly more air with less flow restriction, that of course will require larger injectors, like something in the 55 -60 lb range

THIS IS THE BEST TPI STYLE INTAKE AVAILABLE

http://www.firstfuelinjection.com

Id point out that your budget limitations are mostly the major factor here, the MASSIVE torque would

mostly be related to the twin inter-cooled turbo design, but remember the engine was originally a 350, and they used as many of the original components as they could to lower cost, so obviously the low restriction 3" stainless exhaust with low restriction mufflers and an (X) pipe would be one area to look into seriously.

obviously you won,t be using the headers but the rest of the exhaust would be beneficial.

a bit more agressive hydraulic roller cam like a crane 119661 and 1.6:1 roller rockers would allow the better heads to flow better,

https://www.summitracing.com/parts/crn-119661

increasing the displacement to 383-or even 406 or 427 would pay off in a noticeable boost in over all power.

https://www.summitracing.com/parts/drt-03124272

http://www.ebay.com/itm/SBC-427-COMPLETE-BALANCED-KIT-W-215-DART-ALUM-HEADS/201870615109?_trksid=p2047675.c100011.m1850&_trkparms=aid=222007&algo=SIC.MBE&ao=1&asc=41376&meid=8948ea45e1d24a5ab1aac05a6d6c71db&pid=100011&rk=6&rkt=8&mehot=pp&sd=331049248320

https://www.summitracing.com/parts/ctr-15-240m

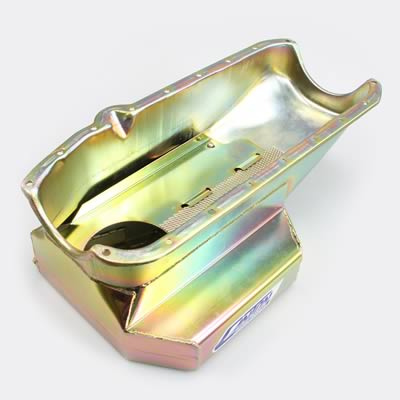

personally I would add a 7 quart road race baffled oil pan and an oil cooler and trans fluid cooler

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

next would be the cylinder heads as the original cylinder heads are comparatively restrictive compared to what is now available after almost 30 more years of research, Id sure look into something like,

the 75cc combustion chamber 210cc AFR heads, or similar DART SBC heads

http://www.airflowresearch.com/210cc-sbc-race-cylinder-head/

Id be looking at a 3.54:1-or-3.73:1 rear gear ratio and beefing up the transmission,

and use of a 2800 rpm stall converter.

properly matched parts and careful assembly are key to getting good results but doing the mentioned improvements should conservatively boost results an additional 200-to-250 hp over the original combo, so 800 hp-900 hp is certainly possible with a 406-427 turbo sbc combo

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/

http://garage.grumpysperformance.co...electing-a-torque-converter-stall-speed.1715/

http://garage.grumpysperformance.co...late-gear-ratios-and-when-to-shift-calcs.555/

all it takes is a tiny bit of research and some math to calculate the ideal rear differential gearing, tires size etc. and transmission gear ratios, and you can certainly select the correct torque converter stall speed if you have a dyno graph of your engines power curve without much difficulty, an hour or so spent in reading and research will provide you with a great deal better performance from most cars.

and a couple days worth of research and doing some math on all of the power trains component parts will provide you with a wealth of info that can prevent you from making costly mistakes.

A tiny bit of related info

http://forum.grumpysperformance.com/viewtopic.php?f=69&t=636&p=850#p850

http://cherry84.joby.se/

http://www.joby.se/turbo/gt4288n/

http://www.joby.se/corvette/mods/2008-01_turbo/