read this related linked info

http://garage.grumpysperformance.com/index.php?threads/finding-related-links-and-info.10255/

http://garage.grumpysperformance.co...ust-because-you-see-limited-new-threads.5128/

http://garage.grumpysperformance.co...ber-of-people-that-don-t-use-resources.12125/

yeah Im sure some guys would rather shoot themselves vs

read all the linked and sub linked info, and watch the linked videos,

in the threads on this web site!

but doing so can save you a good deal of wasted cash and time!

I post a good deal of the info to help guys,

who would rather learn from other people's mistakes

than lose & waste their time and their own cash

and yeah I was young once,and convinced I knew it all...

but I learned over time,

reality has a way of kicking you in the nuts to get your attention.

on this web site you'll find you'll NEED TOO get used to reading links,

in that process you'll learn a great deal, this is never a cheap hobby, but its a whole lot more expensive if you have to buy replacement parts if you don,t do things correctly the first time and use the best parts you can afford, and understand your personal limitations, and exactly what you can expect from the choices you make,

I started this forum partly because Id previously posted hundreds of detailed repair instructional threads in a different forum

and the whole section of the forum was deleted with zero warning, thus wasting hundreds of hours of work, I figured the only way to prevent a recurrence was too have some control.. hence I started the forum

THE WEB SITES PURPOSE IS TO HELP YOU AVOID MAKING MOST OF THE MORE COMMON MISTAKES,

more experienced members can post helpful tips, hints, and links, and post info on the mistakes or areas to avoid

and HELP YOU BUILD, REPAIR, AND PLAN OUT A VERY SUCCESSFUL PROJECT,

WHILE POINTING OUT WHAT TOOLS AND MACHINE WORK, BENEFIT YOUR PROJECT,

AT the LOWEST REASONABLE COST HOPEFULLY SAVING YOU A LOT OF CASH AND WASTED TIME IN THE PROCESS.

HOPEFULLY SAVING YOU A LOT OF CASH AND WASTED TIME IN THE PROCESS.

while pointing out the more common mistakes and better options, AND MORE DURABLE PARTS,

most of us work on very limited budgets so avoiding mistakes is critical.

it makes zero sense to answer

,endless revisions of similar questions, its easier to answer in depth,

and keep all the related info in a few closely related links ,

with sub links, this makes far better use of your time ,

than searching though hundreds of threads each having only bits of related info

this whole forum.. is installed and maintained, UPGRADED AND IMPROVED ALMOST HOURLY.

to make it easy for both the beginners and the very experienced hot rodders to find, or post information regarding various car and engine related subjects, youll find threads generally have links to related info,

no your not having anything extraordinary happen,

if your building your first engine and running into quite a few problems ,

with the assembly process or sloppy machine shop work!

YOU'LL MISS A GREAT DEAL OF INFO,

IF YOU SKIP READING LINKS AND SUB_LINKS ,SCATTERED THROUGH MOST THREADS

slapping something together vs

"BUILDING AN ENGINE CORRECTLY "

are vastly different concepts

I look back on the first few engines I built when I was about 17,

and I'm amazed they even ran.

I had never heard of ring gaps,

yet in-spite of that the cars engine started and ran.

A great deal of the content in this whole web sites based

on the idea that readers can benefit from reading about how too ,

avoiding the expensive mistakes many of us older geezers made in the past,

and learning how things should have been done correctly

theres no possible way that I can know each particular problems cause, or suggest the best possible parts choice, or process to fix it, in every case ,unless you post detailed info and perhaps clear pictures. so I try to make it far easier to find answers to the more common problems and questions.

I try to give a good over view on how things work, how they can be tested and what commonly fails.

or I try to provide links to related sources to make your search for information related to any subject covered both easy to find and as extensive as you care to push into your research. I've been building engines and racing for 45 plus years and while I have done many things.

I've built well over a 170 plus engines in 45 plus years , but keep in mind thats only 2-4 engines a year most years, Im always learning and looking to learn from others in this hobby ,so if you can add useful links or information or just as questions to clarify an answer or question you read on the site,to clear up a question or find an answer too the info please do so.

yeah I do exist!, Im just an old geezer thats been building a few engines every year for 45 plus years ,

the web sites designed to allow the members to do the research required and get the correct answer's so they can avoid most of the wasted time and money that I wasted, over the last 55 years, learning how to do or get the mods done on my and my friends cars, the real world modifications that actually benefit the performance car and engine building process.

after all a car that needs constant repairs or maintenance,

or one that does not run up to its potential is not much fun, too own or drive.

so it makes a lot of sense to know exactly how things work, and to buy and install the correct components to maximize durability and performance and to avoid wasting time and money on things that don,t work, or doing things incorrectly.

While I'm sure 99% of the people reading this won,t really understand,

I really enjoy taking my time to carefully check, assemble , clearance, and do everything correctly!

I tend to feel bad if I know an engines needs some precision work or some clearances checked, and the person who I,m building it for,

wants to skip the step or ignore doing it correctly.

very few people seem to know whats involved in correctly assembling an engine and even fewer are willing to take the time and effort to do it correctly or are willing to pay some one else to do so.

I used to do engine builds, as a semi serious side business when I was younger , and while I always have had, and still do have a long line of local guys wanting to have me work on their cars its never been more than a serious hobby,that I've constantly tried to be exceptionally good at! and while, I rarely do more than break even on cost because I rarely charge more than the parts and supplies cost

(again, I view this as a HOBBY and do things correctly at my pace.)

I almost NEVER work on an engine without the owner hands-on locally simply because theres always a hundred small decisions to be made, as to what needs to be done in machine work and parts selection, and the costs add up rapidly and its always been far easier to point out why I think certain things need to be addressed , and have the local guy pay for the parts and machine work, himself that way he realizes I'M not making squat on the deal, even thought its costing him an arm & a leg in his opinion.and I found out decades ago most people don,t care to spend the time and effort and cash required .

I freely admit I've never been all that concerned with making a profit , I have done a great many car and engine builds ,

but rarely have I made any profits while doing them, and when I did the cash instantly went for better precision tools or new tools, or

THE SHOP I built was never intended to be more or less than a really good place to have the correct precision tools , the required room and lift, etc.

to build engines at my pace, and fix cars , and engines for myself or my friends

I've been building engines for over 50 years, and enjoy doing it correctly at my own pace, some guys collect stamps or butter-flys, some are skilled and use talent to build objects that require experience and knowledge like Stradivarius violins,

,some guys drink or smoke dope, for me, personally I feel best taking the time and effort to carefully assemble and tune engine's, is rewarding and relaxing.

or teaching someone local , hands on, why and how things are done correctly and having the correct tools on hand to do that!

yes its a fact we all have a limited life expectancy,

thats one reason I started and maintain the web site,

as I'd like too pass on as much hard won experience and knowledge as I can,

to allow the younger members to have the ability to avoid a great deal of the wasted time and effort that GAINING THAT KNOWLEDGE AND EXPERIENCE requires,

of those that refuse to read linked info,and do minimal research before jumping blindly into areas they may not be familiar with,

too thus avoid the need too repeat common and costly mistakes I and others have already made in the past

yes I'm older and slower , but I'm also much more knowledgeable, much more experienced , I have more tools , so doing the work takes less effort and its more enjoyable.... and yeah! at times (RARELY)

I just say ... screw it!

I'm skipping what I planed ,today,

due to a near total lack of.....

give a flying F%^& if it gets done today!

but thats RARE as it gets me out of the house,

and temporarily away from the endless , ever expanding, wifes honey do list!

so

HELL YES!

FOLLOW YOUR DREAM ,

AND PLAN CAREFULLY AND SAVE!

it is always helps to post your location,when posting questions, at least the city & state your located in because theres a good chance an experienced hobbyist or mechanic on this site may be reading this, located local to you, who is willing to help either for free or at low cost! or at least post advices and places to get parts locally

welcome to the site, while we have a great deal of hot rod and engine related info to share , learned over many decades and many very skilled members, the sites NOT connected with the LATE gumpy jenkins, BTW I have also talked with the late GRUMPY JENKINS and DOZENS of other older , more experience RACERS

I got to get a tool carrier like this that works for hot dogs

If any thing the sites name is more related to, how my wifes constantly referred to me for the last 45 years

IF you have questions on any car related subject or need help, let us know, ESPECIALLY if your local to myself or other members, as we might be able to help, and its not all that rare to find new friends that you might never have met otherwise , locally by posting on this site

there's almost alway options, as you gain are/wisdom, you tend to look back on some decisions you made in the past, and say to yourself %%^&*&

what was I thinking??

Theres almost always several routes that anyone can take to accomplish similar goals and that a good deal of research rarely hurts.

I know from personal experience that one of the huge issues I personally had was running into "DEALS" or really good prices on components that did not match or work towards improving my projects, that frequently resulted in me not having the required funds when the deal on the parts I really wanted happened, and of course diving right into spending a good deal of time and cash building or rebuilding what you currently have access to, rather than what you really intended to build.!

its really a good idea to take the effort to plan out your cars build with as many of the characteristics and ideal components listed

and take the effort to make sure the parts all work reasonably well at the engine rpm and power levels, you intend to operate at... obviously be realistic and keep your bank balance, and skill level and availability of a place to work and tool access in mind!

IVE posted lots of info over the years and its a waste of time and effort to re-post much of it so ILL use links to previous posts on different sites frequently, and only re-post some info and this site should also prevent the info's loss when different web sites I post on,change servers like has happened in the past when much researched data was lost, it makes no sense that many forums restrict searches to the last 6 months or only a year, theres tons of info that might have been posted that you can no longer accessto the many more faithful members of the forum this is probably not going to be any surprise but to the newer and less frequent visitors it may be!

OLDER THREADS CONSTANTLY GET NEW INFO ADDED

I see no reason at all to start a new thread anytime a previously discussed subject is being re-addressed, for minor changes or additions , so If I see related info that may be useful I frequently go back and add it , as links or corrections to older threads, and I spend hours a day searching for new info off site and posting it here,doing so!

and that may not always show up as new info, so just because youve read thru a thread several weeks ago doesn,t mean theres not a good deal more linked info or upgrades or corrections having been added since then, the object is to limit your needing to search thru dozens, or even hundreds of similar threads like on most sites, force you to do, to find the bits of info you need, youll also find I try hard to include all useful links to speed up any search, and yeah! I,m well aware you can get lost in a ton of sub links but youll also spend a great deal less total time and get more useful info in doing it that way than in random hit or miss searches like on most sites

example

if I find a new link , or related info ,to show how to do almost anything, like tig weld an exhaust , or a fast way to clean rust , or how to tune your car or verify a components function ID usually place the link to the new info in a previous related thread, not start a new thread

WHY DID I START THE SITE?

AFTER The THIRD site I post on in this year that was closed or said they were closing, or re-configured and then lost all MY old posted data, OR RESTRICTED SEARCHES TO ONLY THE LAST CALENDAR YEAR, I felt it was mandatory to save the research and I figured there's a ton of good useful info that was being lost, and I did a great deal of research and my experience that would be wasted, so the only way to prevent that was to start someplace I had control over.

that's what I started the site for!

to have the more experienced members help as many people learn,

the skills it took most of us decades to acquire,

without needing to spend all that wasted time and AVOID the long expensive process,

of dealing with all the crappy machine shops ,

wasting money on parts and modifications that don't work,

and waste all that time & money in the process.

I was lucky at times that I had several skilled mentors,

but I also remember making hundreds of stupid mistakes ,

mistakes made simply because I didn't know better at that time!

and wasting a great deal of my limited cash on junk parts, simply learning what was important and what was trash.

I've always said they should make any design engineer work with experienced line mechanics too actually remove and install any and all parts they design on a mock-up car long before they go into production and any sub-component or major assembly that can't be replaced as a unit, in under 1/2-1 hour with common hand tools on a fully assembled car MUST be redesigned, or the area around it that's preventing its easy access must be redesigned to allow that ease of replacement.... its all too obvious some components are assembled or installed before the body or interior is in place with zero concern for future access, or maintenance , well we all know that's unlikely..

I bet I spend 85% -90% or more of my time on the site, ADDING, or CORRECTING info or pictures or graphs or ADDING LINKS, or anything else I can do to constantly upgrade already existing posts so guys will have far fewer threads to look thru to find info on a related subject.

it makes very little sense to me on most sites there's a post on a subject and the guy might ask a question and he might get a half valid answer, but theres rarely any follow-up or even rarer, that someone points out some related info that could save the guy hour or hundreds of dollars if he knew about it....

now hypothetical example

let's say a guy asked how to remove a damper from a crank, because his DAMPER has had the TDC mark obviously rotate, so it no longer indicates TDC

to me it just makes sense to post a few links on the thread links for,

verifying TDC

replacing a TIMING TAB

SETTING IGNITION TIMING

replacing a timing chain

replacing a front crank seal

using a damper tool

OPTIONAL ARP DAMPER BOLTS

repairing striped crank threads

replacing an oil pan gasket

working safely on a firmly supported car

do you gentlemen feel that's helpful or a waste of time?

Its not like the guys forced to read the links but it sure should make things a whole lot easier if he's run into trouble, if he's taken the time to read the links, but it should help a great deal and save time if he does read the links

It takes a bit of wheeling and dealing and research but if you keep looking through the bargain trader, craigs list and have rather extensive contacts or join a few corvette or muscle car clubs , over time you can collect a rather amazing collection of good quality big block chevy , pontiac, dodge or caddy,engine,& drive train compatible parts and build a fairly fast car without spending yourself into the poor house, but it takes research and patience and an understanding of what your doing and what you need to do it, and the ability to do a great deal of the work yourself so your not spending all your time and effort supporting the local speed shops and machine shops

BTW if your interested??

"GRUMPYVETTE", is a contraction, or NICKNAME, based on my wife always bitching about my attitude over the years, if I'm under the corvette working and she calls me to do some darn silly thing like answer the phone while Im under the car, as in (WHY ARE YOU SO DAMN GRUMPY EVERY TIME YOU HAVE TO GET OUT FROM UNDER THE HOOD OR OUT FROM UNDER THE CAR (CORVETTEs) are what I usually work on)shes told more than one person over the years ("OLD GRUMPYVETTES UNDER THE CAR,ILL HAVE HIM CALL YOU WHEN HE GETS OUT OF THE SHOP!")

__________________

MOST OF THE PICTURES ARE A COUPLE YEARS OLD AND WERE TAKEN ON or BEFORE THE FIRST DAY WE GOT ELECTRIC POWER, EVERYTHING WAS BEING STUFFED IN AT RANDOM AS IT LOOKED LIKE RAIN AND MANY OF THE LARGER TOOLS AND WELDERS WERE NOT UNLOADED YET

no Im not a computer, like the rumors say, just an old geezer! in a red shirt and a old hat...notice the similarity to the avatar

a few more pics, its still a total mess while Im in the process of BUILDING and moving in but IM getting there slowly, I could only get a few of the BBC engines in the shop, I prefer to work on, into the camera/shot

I get asked this frequently

how old are you?how do you know this stuff?

answer, I'm just an old (76) now retired HOTRODDER and mechanical engineer ,whos been building cars and engines, helping my friends on a semi constant basis for well over 55 years,

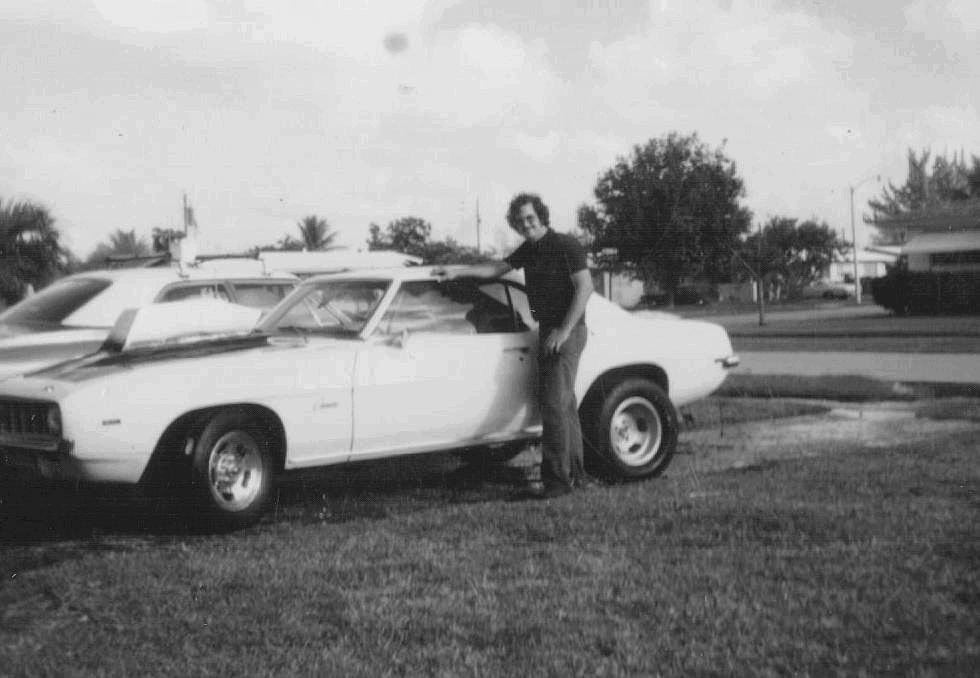

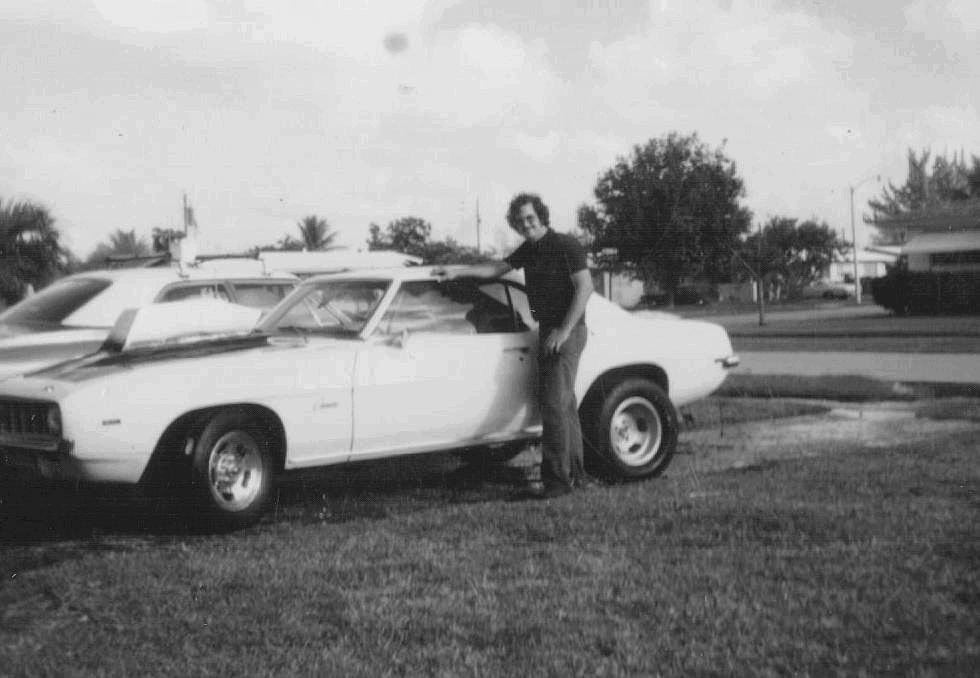

here,s a picture of me in 1970 (55 years ago) with a 1969 camaro I installed a BBC-496 with a tunnel ram into, then later CROWER FUEL INJECTION

its almost always a good idea to post the city and state you live in, and don,t be afraid to ask questions or post pictures, as there,s at least some chance someone reading about your problem, or question, that has skills and a desire to help might read these posts that lives near you!

what might look like a huge insurmountable issue to most newer guys might be something far less complicated to fix by a member with a great deal more experience, and there's lots of things that might take a great deal of typing to explain on the site that take far less effort to show you how to fix or adjust in person, or problems that require use of a tool you might not have or even know exists

I've seen younger guys spend all weekend trying to get some older muscle car up and running, and the problem was basically a lack of experience working on a car that won,t have trouble codes to download and a carburetor vs computer controlled injection, they were familiar with, just knowing how to adjust valves, set timing and use a dwell meter, and tune a carburetor or trouble shoot in general is something that takes time to learn (experience) and a bit of hands on time watching some old geezer can do wonders.

while I very briefly worked at a chevy dealership as a mechanic

(I was 18 at the time)

I learned the most simply by owning and racing several corvettes for decades

(always have owned one or more,since the 1968)

(currently own a 1985 and 1996)

and having built well in excess of 140 plus engines you eventually are forced to learn a few things along the way.

,and while that may sound like a lot its only 3-5 engines a year over the last 48 years , and at one point I was doing it as a side business.

most of us learn from our mistakes, but you get to bye-pass a great deal of aggravation, if you learn from an older mechanic if he's willing to teach or help, some guy who already knows how to avoid making those mistakes because he has the experience, and believe me most of us older geezers made our share, but learned in the process.

I obviously have a character flaw, regarding charging for work done!

I'm certainly not into this hobby, or helping other people, as a source of income,

I enjoy teaching and watching the frequently amazed reaction when guys find they can solve problems or build something far better than they might have imagined , but as a source of income....well its never been a good personal source, probably because I don't feel charging for something I enjoy doing is really justified, plus I remember dozens of times I was over charged for automotive repair work, in the past and I feel, in many cases I don't want to stunt or restrict , some young guys enjoyment of his car or prevent them from learning based on a lack of funds if I can help.

one of the reasons I started the site was that I got so frustrated , dealing with people ,I've ordered parts from or paid to do work, and machine shops that, did crappy work, that

I've dealt with in the past, that in my opinion, either over charge, or give out bad , purposely wrong or only minimal information, just so the younger guys will have difficulty or require a return to a shop, that generates them more cash flow.

in many cases, when I was younger, I got frustrated too the point I wanted to scream, as it was all to obvious that many of the repair shops dealerships, and machine shops were only interested in draining your wallet and refused to answer questions, or allow me to watch what was being done,(and many charged for work that was never done, or done very poorly)

if a repair shop or machine shop had taken a few minutes to explain my choices or explain the difference in part quality, what my options were, and choices I had, or explained the correct installation or adjustment, I could have learned a great deal faster how to correctly maintain,tune and race a car, and how to do my own repair work, make the correct parts choices so parts seldom failed, IF I had an honest mentor, that showed me what I needed to check or verify and showed me why work was necessary, I could and would have learned a great deal faster, and that of course was not what they wanted

so I decided to make it a whole lot easier on the younger guys by starting this site,probably partly due to past frustration , dealing with people solely intent on making money vs helping others.

yes I occasionally did find a few older experienced mentors , willing to teach a younger guy, but they were and are few and far between, so I decided to help where I can.

yes unlike most sites these threads generally have links and sub-links, if you care to learn take the time and effort to browse, through those, youll be amazed at the depth of related info

THERES SEVERAL DOZEN too a hundred plus or more,closely RELATED THREADS ON THE WEB SITE, ON MOST ENGINE BUILDING SUBJECTS< WHY NOT REGISTER , AND SPEND A LITTLE TIME DOING RESEARCH, YOU'LL VERY QUICKLY FIND THAT ANY ONE THREAD HOLDS FAR LESS THAN 2% OF THE RELATED INFO

The main reason I built the website was to allow guys who are willing to read, and ask questions, too skip the time and effort it took me to learn to build engines correctly

http://garage.grumpysperformance.com/index.php?threads/down-the-rabbit-hole-with-alice.10933/

now you can see I started out 45 plus years back, just as enthusiastic, about big block cars and needing to learn a good deal more about what I was doing, as most of us do!

I've always had a great deal of curiosity, and a bit of competitive streak, about learning how and why things mechanical work, and being a tool junky and gear head certainly doesn,t help, as I've frequently taken on projects just to see if I could noticeably improve results over what I see other guys accomplish.

I've built and raced a few corvettes,G.T.O.s ROAD RUNNERS, CAMAROS, Ive build or rebuild over a hundred engines, swapped suspensions, and learned on the way.

I spent decades in my younger days trying to learn how to do as much as I could,

about how things worked and what machinists, engine builders mechanics and tuners do,

and could never understand, the all too common ,mental attitude I found so prevalent, that

"If we teach you whats involved, or how to do something...

theres no reason for you to pay us excessive labor and machinist fees "

that's one of the main reasons I set up this web site! to give everyone a good start, and a way to avoid the bull "S#1T "

and attitude that was based on, "IF I keep you ignorant you have to pay me"

I always felt that helping as many people as possible to learn about and enjoy the hobby was the goal,

(probably why I've been busy but generally mostly broke, but I sleep well knowing I've helped hundreds of people

IVE learned to K.I.S.S. (KEEP IT SIMPLE STUPID)

IVE learned that a FEW QUALITY parts will BEAT lots of junk

IVE learned careful clearancing and attention to details makes a HUGE DIFFERENCE

IVE learned researching and learning from other people mistakes is FAR cheaper and faster than making your own in a car build.

IVE learned to do extensive research BEFORE buying parts

IVE learned NEVER BUY PARTS that you get on (DEALS) if they don't match your goals

I've learned that building engines for maximum AVERAGE TQ IN the RPM RANGE you'll use the car

beats building for maximum PEAK hp numbers

IVE learned asking lots of questions is far cheaper than making lots of mistakes

IVE learned that a cars performance depends a great deal on its POWER TO WEIGHT RATIO.

IVE learned that to have fun,your combo must be BOTH dependable and faster than MOST but not ALL the competition (most guys will never afford the expense in being the fastest car in your area)

IVE learned a CAR that breaks down is a TOTAL P.I.T.A. and RELIEABILITY is VERY IMPORTANT!

yeah, there's no doubt at all that the number and cost of tools you need to accumulate ,

frequently come close too or at times even exceed the the number of parts you actually install on any properly built cars.

you obviously run the risk of eventually rationalizing the need to justify the tool obsession,

by building a new or second car to further make the purchase of the tools,

and learning all the related skills seem , like its rational.

its a bit like the reloading cartridges hobby.. there's always the need to upgrade tools,

and once you have the tools you might as well buy a new revolver or rifles,

since ammo won't cost much now that you have the tools.

tool junky , and hand loading,& engine building insanity,

is a infectious, communicable virus, you can even catch over the internet.

and like many of you IM broke most of the time, because of this hobby,but always glad to help out

the best bit of advice I can give , is if your in the process of assembling an engine,

or doing some mods to the car,

and you see ANYTHING that looks odd, out of place ,

makes you doubt you did something correctly ,

or you find something does not quite fit,

or you see something just not something you expected,

STOP AND ASK QUESTIONS..,,,

think things through.... but don't proceed until you know your 100% correct.

DO THE REQUIRED RESEARCH and

don't GO ANY FURTHER UNTIL YOUR CERTAIN YOUR CORRECT

There is a reason why you are asking this question,

ASK YOUR MACHINIST AND VERIFY HIS ANSWERS

the just get a bigger hammer approach is surely the fastest way to get in serious trouble that will cost your a ton of cash and time wasted

I just try hard to buy anything in the world of tools, that I can afford to purchase, that helps increase my skill and tool use in building better engines each time I build a new engine, thus I have a large and ever expanding set of engine assembly , precision tools , and a desire to learn everything I can about engine assembly, and yes an ever increasing number of tool chest's and ever increasing skills as I learn to use those new tools. (yeah I admit I'm a tool junky) yeah, you might be amazed at the quantity of tools and tool chests and knowledge I gained over the last 55 plus years and over a hundred plus engine builds, ( yes I certainly made mistakes on the first few engines, just like every one does, but that's all part of the learning curve, every one goes through if your serious about learning the skill set required to build engines correctly,!) and its one reason I try hard to post as much information/ knowledge, and frequently upgrade or post new info, about engine assembly and tool use, as I can to prevent readers from making mistakes I can now avoid, due to learning from my mistakes and mistakes I see other people make!

http://garage.grumpysperformance.com/index.php?threads/finding-related-links-and-info.10255/

http://garage.grumpysperformance.co...ust-because-you-see-limited-new-threads.5128/

http://garage.grumpysperformance.co...ber-of-people-that-don-t-use-resources.12125/

yeah Im sure some guys would rather shoot themselves vs

read all the linked and sub linked info, and watch the linked videos,

in the threads on this web site!

but doing so can save you a good deal of wasted cash and time!

I post a good deal of the info to help guys,

who would rather learn from other people's mistakes

than lose & waste their time and their own cash

and yeah I was young once,and convinced I knew it all...

but I learned over time,

reality has a way of kicking you in the nuts to get your attention.

on this web site you'll find you'll NEED TOO get used to reading links,

in that process you'll learn a great deal, this is never a cheap hobby, but its a whole lot more expensive if you have to buy replacement parts if you don,t do things correctly the first time and use the best parts you can afford, and understand your personal limitations, and exactly what you can expect from the choices you make,

I started this forum partly because Id previously posted hundreds of detailed repair instructional threads in a different forum

and the whole section of the forum was deleted with zero warning, thus wasting hundreds of hours of work, I figured the only way to prevent a recurrence was too have some control.. hence I started the forum

THE WEB SITES PURPOSE IS TO HELP YOU AVOID MAKING MOST OF THE MORE COMMON MISTAKES,

more experienced members can post helpful tips, hints, and links, and post info on the mistakes or areas to avoid

and HELP YOU BUILD, REPAIR, AND PLAN OUT A VERY SUCCESSFUL PROJECT,

WHILE POINTING OUT WHAT TOOLS AND MACHINE WORK, BENEFIT YOUR PROJECT,

AT the LOWEST REASONABLE COST

HOPEFULLY SAVING YOU A LOT OF CASH AND WASTED TIME IN THE PROCESS.

HOPEFULLY SAVING YOU A LOT OF CASH AND WASTED TIME IN THE PROCESS.while pointing out the more common mistakes and better options, AND MORE DURABLE PARTS,

most of us work on very limited budgets so avoiding mistakes is critical.

it makes zero sense to answer

,endless revisions of similar questions, its easier to answer in depth,

and keep all the related info in a few closely related links ,

with sub links, this makes far better use of your time ,

than searching though hundreds of threads each having only bits of related info

this whole forum.. is installed and maintained, UPGRADED AND IMPROVED ALMOST HOURLY.

to make it easy for both the beginners and the very experienced hot rodders to find, or post information regarding various car and engine related subjects, youll find threads generally have links to related info,

no your not having anything extraordinary happen,

if your building your first engine and running into quite a few problems ,

with the assembly process or sloppy machine shop work!

YOU'LL MISS A GREAT DEAL OF INFO,

IF YOU SKIP READING LINKS AND SUB_LINKS ,SCATTERED THROUGH MOST THREADS

slapping something together vs

"BUILDING AN ENGINE CORRECTLY "

are vastly different concepts

I look back on the first few engines I built when I was about 17,

and I'm amazed they even ran.

I had never heard of ring gaps,

yet in-spite of that the cars engine started and ran.

A great deal of the content in this whole web sites based

on the idea that readers can benefit from reading about how too ,

avoiding the expensive mistakes many of us older geezers made in the past,

and learning how things should have been done correctly

theres no possible way that I can know each particular problems cause, or suggest the best possible parts choice, or process to fix it, in every case ,unless you post detailed info and perhaps clear pictures. so I try to make it far easier to find answers to the more common problems and questions.

I try to give a good over view on how things work, how they can be tested and what commonly fails.

or I try to provide links to related sources to make your search for information related to any subject covered both easy to find and as extensive as you care to push into your research. I've been building engines and racing for 45 plus years and while I have done many things.

I've built well over a 170 plus engines in 45 plus years , but keep in mind thats only 2-4 engines a year most years, Im always learning and looking to learn from others in this hobby ,so if you can add useful links or information or just as questions to clarify an answer or question you read on the site,to clear up a question or find an answer too the info please do so.

yeah I do exist!, Im just an old geezer thats been building a few engines every year for 45 plus years ,

the web sites designed to allow the members to do the research required and get the correct answer's so they can avoid most of the wasted time and money that I wasted, over the last 55 years, learning how to do or get the mods done on my and my friends cars, the real world modifications that actually benefit the performance car and engine building process.

after all a car that needs constant repairs or maintenance,

or one that does not run up to its potential is not much fun, too own or drive.

so it makes a lot of sense to know exactly how things work, and to buy and install the correct components to maximize durability and performance and to avoid wasting time and money on things that don,t work, or doing things incorrectly.

While I'm sure 99% of the people reading this won,t really understand,

I really enjoy taking my time to carefully check, assemble , clearance, and do everything correctly!

I tend to feel bad if I know an engines needs some precision work or some clearances checked, and the person who I,m building it for,

wants to skip the step or ignore doing it correctly.

very few people seem to know whats involved in correctly assembling an engine and even fewer are willing to take the time and effort to do it correctly or are willing to pay some one else to do so.

I used to do engine builds, as a semi serious side business when I was younger , and while I always have had, and still do have a long line of local guys wanting to have me work on their cars its never been more than a serious hobby,that I've constantly tried to be exceptionally good at! and while, I rarely do more than break even on cost because I rarely charge more than the parts and supplies cost

(again, I view this as a HOBBY and do things correctly at my pace.)

I almost NEVER work on an engine without the owner hands-on locally simply because theres always a hundred small decisions to be made, as to what needs to be done in machine work and parts selection, and the costs add up rapidly and its always been far easier to point out why I think certain things need to be addressed , and have the local guy pay for the parts and machine work, himself that way he realizes I'M not making squat on the deal, even thought its costing him an arm & a leg in his opinion.and I found out decades ago most people don,t care to spend the time and effort and cash required .

I freely admit I've never been all that concerned with making a profit , I have done a great many car and engine builds ,

but rarely have I made any profits while doing them, and when I did the cash instantly went for better precision tools or new tools, or

THE SHOP I built was never intended to be more or less than a really good place to have the correct precision tools , the required room and lift, etc.

to build engines at my pace, and fix cars , and engines for myself or my friends

I've been building engines for over 50 years, and enjoy doing it correctly at my own pace, some guys collect stamps or butter-flys, some are skilled and use talent to build objects that require experience and knowledge like Stradivarius violins,

,some guys drink or smoke dope, for me, personally I feel best taking the time and effort to carefully assemble and tune engine's, is rewarding and relaxing.

or teaching someone local , hands on, why and how things are done correctly and having the correct tools on hand to do that!

yes its a fact we all have a limited life expectancy,

thats one reason I started and maintain the web site,

as I'd like too pass on as much hard won experience and knowledge as I can,

to allow the younger members to have the ability to avoid a great deal of the wasted time and effort that GAINING THAT KNOWLEDGE AND EXPERIENCE requires,

of those that refuse to read linked info,and do minimal research before jumping blindly into areas they may not be familiar with,

too thus avoid the need too repeat common and costly mistakes I and others have already made in the past

yes I'm older and slower , but I'm also much more knowledgeable, much more experienced , I have more tools , so doing the work takes less effort and its more enjoyable.... and yeah! at times (RARELY)

I just say ... screw it!

I'm skipping what I planed ,today,

due to a near total lack of.....

give a flying F%^& if it gets done today!

but thats RARE as it gets me out of the house,

and temporarily away from the endless , ever expanding, wifes honey do list!

so

HELL YES!

FOLLOW YOUR DREAM ,

AND PLAN CAREFULLY AND SAVE!

it is always helps to post your location,when posting questions, at least the city & state your located in because theres a good chance an experienced hobbyist or mechanic on this site may be reading this, located local to you, who is willing to help either for free or at low cost! or at least post advices and places to get parts locally

welcome to the site, while we have a great deal of hot rod and engine related info to share , learned over many decades and many very skilled members, the sites NOT connected with the LATE gumpy jenkins, BTW I have also talked with the late GRUMPY JENKINS and DOZENS of other older , more experience RACERS

I got to get a tool carrier like this that works for hot dogs

If any thing the sites name is more related to, how my wifes constantly referred to me for the last 45 years

IF you have questions on any car related subject or need help, let us know, ESPECIALLY if your local to myself or other members, as we might be able to help, and its not all that rare to find new friends that you might never have met otherwise , locally by posting on this site

there's almost alway options, as you gain are/wisdom, you tend to look back on some decisions you made in the past, and say to yourself %%^&*&

what was I thinking??

Theres almost always several routes that anyone can take to accomplish similar goals and that a good deal of research rarely hurts.

I know from personal experience that one of the huge issues I personally had was running into "DEALS" or really good prices on components that did not match or work towards improving my projects, that frequently resulted in me not having the required funds when the deal on the parts I really wanted happened, and of course diving right into spending a good deal of time and cash building or rebuilding what you currently have access to, rather than what you really intended to build.!

its really a good idea to take the effort to plan out your cars build with as many of the characteristics and ideal components listed

and take the effort to make sure the parts all work reasonably well at the engine rpm and power levels, you intend to operate at... obviously be realistic and keep your bank balance, and skill level and availability of a place to work and tool access in mind!

IVE posted lots of info over the years and its a waste of time and effort to re-post much of it so ILL use links to previous posts on different sites frequently, and only re-post some info and this site should also prevent the info's loss when different web sites I post on,change servers like has happened in the past when much researched data was lost, it makes no sense that many forums restrict searches to the last 6 months or only a year, theres tons of info that might have been posted that you can no longer accessto the many more faithful members of the forum this is probably not going to be any surprise but to the newer and less frequent visitors it may be!

OLDER THREADS CONSTANTLY GET NEW INFO ADDED

I see no reason at all to start a new thread anytime a previously discussed subject is being re-addressed, for minor changes or additions , so If I see related info that may be useful I frequently go back and add it , as links or corrections to older threads, and I spend hours a day searching for new info off site and posting it here,doing so!

and that may not always show up as new info, so just because youve read thru a thread several weeks ago doesn,t mean theres not a good deal more linked info or upgrades or corrections having been added since then, the object is to limit your needing to search thru dozens, or even hundreds of similar threads like on most sites, force you to do, to find the bits of info you need, youll also find I try hard to include all useful links to speed up any search, and yeah! I,m well aware you can get lost in a ton of sub links but youll also spend a great deal less total time and get more useful info in doing it that way than in random hit or miss searches like on most sites

example

if I find a new link , or related info ,to show how to do almost anything, like tig weld an exhaust , or a fast way to clean rust , or how to tune your car or verify a components function ID usually place the link to the new info in a previous related thread, not start a new thread

WHY DID I START THE SITE?

AFTER The THIRD site I post on in this year that was closed or said they were closing, or re-configured and then lost all MY old posted data, OR RESTRICTED SEARCHES TO ONLY THE LAST CALENDAR YEAR, I felt it was mandatory to save the research and I figured there's a ton of good useful info that was being lost, and I did a great deal of research and my experience that would be wasted, so the only way to prevent that was to start someplace I had control over.

that's what I started the site for!

to have the more experienced members help as many people learn,

the skills it took most of us decades to acquire,

without needing to spend all that wasted time and AVOID the long expensive process,

of dealing with all the crappy machine shops ,

wasting money on parts and modifications that don't work,

and waste all that time & money in the process.

I was lucky at times that I had several skilled mentors,

but I also remember making hundreds of stupid mistakes ,

mistakes made simply because I didn't know better at that time!

and wasting a great deal of my limited cash on junk parts, simply learning what was important and what was trash.

I've always said they should make any design engineer work with experienced line mechanics too actually remove and install any and all parts they design on a mock-up car long before they go into production and any sub-component or major assembly that can't be replaced as a unit, in under 1/2-1 hour with common hand tools on a fully assembled car MUST be redesigned, or the area around it that's preventing its easy access must be redesigned to allow that ease of replacement.... its all too obvious some components are assembled or installed before the body or interior is in place with zero concern for future access, or maintenance , well we all know that's unlikely..

I bet I spend 85% -90% or more of my time on the site, ADDING, or CORRECTING info or pictures or graphs or ADDING LINKS, or anything else I can do to constantly upgrade already existing posts so guys will have far fewer threads to look thru to find info on a related subject.

it makes very little sense to me on most sites there's a post on a subject and the guy might ask a question and he might get a half valid answer, but theres rarely any follow-up or even rarer, that someone points out some related info that could save the guy hour or hundreds of dollars if he knew about it....

now hypothetical example

let's say a guy asked how to remove a damper from a crank, because his DAMPER has had the TDC mark obviously rotate, so it no longer indicates TDC

to me it just makes sense to post a few links on the thread links for,

verifying TDC

replacing a TIMING TAB

SETTING IGNITION TIMING

replacing a timing chain

replacing a front crank seal

using a damper tool

OPTIONAL ARP DAMPER BOLTS

repairing striped crank threads

replacing an oil pan gasket

working safely on a firmly supported car

do you gentlemen feel that's helpful or a waste of time?

Its not like the guys forced to read the links but it sure should make things a whole lot easier if he's run into trouble, if he's taken the time to read the links, but it should help a great deal and save time if he does read the links

It takes a bit of wheeling and dealing and research but if you keep looking through the bargain trader, craigs list and have rather extensive contacts or join a few corvette or muscle car clubs , over time you can collect a rather amazing collection of good quality big block chevy , pontiac, dodge or caddy,engine,& drive train compatible parts and build a fairly fast car without spending yourself into the poor house, but it takes research and patience and an understanding of what your doing and what you need to do it, and the ability to do a great deal of the work yourself so your not spending all your time and effort supporting the local speed shops and machine shops

BTW if your interested??

"GRUMPYVETTE", is a contraction, or NICKNAME, based on my wife always bitching about my attitude over the years, if I'm under the corvette working and she calls me to do some darn silly thing like answer the phone while Im under the car, as in (WHY ARE YOU SO DAMN GRUMPY EVERY TIME YOU HAVE TO GET OUT FROM UNDER THE HOOD OR OUT FROM UNDER THE CAR (CORVETTEs) are what I usually work on)shes told more than one person over the years ("OLD GRUMPYVETTES UNDER THE CAR,ILL HAVE HIM CALL YOU WHEN HE GETS OUT OF THE SHOP!")

__________________

MOST OF THE PICTURES ARE A COUPLE YEARS OLD AND WERE TAKEN ON or BEFORE THE FIRST DAY WE GOT ELECTRIC POWER, EVERYTHING WAS BEING STUFFED IN AT RANDOM AS IT LOOKED LIKE RAIN AND MANY OF THE LARGER TOOLS AND WELDERS WERE NOT UNLOADED YET

no Im not a computer, like the rumors say, just an old geezer! in a red shirt and a old hat...notice the similarity to the avatar

a few more pics, its still a total mess while Im in the process of BUILDING and moving in but IM getting there slowly, I could only get a few of the BBC engines in the shop, I prefer to work on, into the camera/shot

I get asked this frequently

how old are you?how do you know this stuff?

answer, I'm just an old (76) now retired HOTRODDER and mechanical engineer ,whos been building cars and engines, helping my friends on a semi constant basis for well over 55 years,

here,s a picture of me in 1970 (55 years ago) with a 1969 camaro I installed a BBC-496 with a tunnel ram into, then later CROWER FUEL INJECTION

its almost always a good idea to post the city and state you live in, and don,t be afraid to ask questions or post pictures, as there,s at least some chance someone reading about your problem, or question, that has skills and a desire to help might read these posts that lives near you!

what might look like a huge insurmountable issue to most newer guys might be something far less complicated to fix by a member with a great deal more experience, and there's lots of things that might take a great deal of typing to explain on the site that take far less effort to show you how to fix or adjust in person, or problems that require use of a tool you might not have or even know exists

I've seen younger guys spend all weekend trying to get some older muscle car up and running, and the problem was basically a lack of experience working on a car that won,t have trouble codes to download and a carburetor vs computer controlled injection, they were familiar with, just knowing how to adjust valves, set timing and use a dwell meter, and tune a carburetor or trouble shoot in general is something that takes time to learn (experience) and a bit of hands on time watching some old geezer can do wonders.

while I very briefly worked at a chevy dealership as a mechanic

(I was 18 at the time)

I learned the most simply by owning and racing several corvettes for decades

(always have owned one or more,since the 1968)

(currently own a 1985 and 1996)

and having built well in excess of 140 plus engines you eventually are forced to learn a few things along the way.

,and while that may sound like a lot its only 3-5 engines a year over the last 48 years , and at one point I was doing it as a side business.

most of us learn from our mistakes, but you get to bye-pass a great deal of aggravation, if you learn from an older mechanic if he's willing to teach or help, some guy who already knows how to avoid making those mistakes because he has the experience, and believe me most of us older geezers made our share, but learned in the process.

I obviously have a character flaw, regarding charging for work done!

I'm certainly not into this hobby, or helping other people, as a source of income,

I enjoy teaching and watching the frequently amazed reaction when guys find they can solve problems or build something far better than they might have imagined , but as a source of income....well its never been a good personal source, probably because I don't feel charging for something I enjoy doing is really justified, plus I remember dozens of times I was over charged for automotive repair work, in the past and I feel, in many cases I don't want to stunt or restrict , some young guys enjoyment of his car or prevent them from learning based on a lack of funds if I can help.

one of the reasons I started the site was that I got so frustrated , dealing with people ,I've ordered parts from or paid to do work, and machine shops that, did crappy work, that

I've dealt with in the past, that in my opinion, either over charge, or give out bad , purposely wrong or only minimal information, just so the younger guys will have difficulty or require a return to a shop, that generates them more cash flow.

in many cases, when I was younger, I got frustrated too the point I wanted to scream, as it was all to obvious that many of the repair shops dealerships, and machine shops were only interested in draining your wallet and refused to answer questions, or allow me to watch what was being done,(and many charged for work that was never done, or done very poorly)

if a repair shop or machine shop had taken a few minutes to explain my choices or explain the difference in part quality, what my options were, and choices I had, or explained the correct installation or adjustment, I could have learned a great deal faster how to correctly maintain,tune and race a car, and how to do my own repair work, make the correct parts choices so parts seldom failed, IF I had an honest mentor, that showed me what I needed to check or verify and showed me why work was necessary, I could and would have learned a great deal faster, and that of course was not what they wanted

so I decided to make it a whole lot easier on the younger guys by starting this site,probably partly due to past frustration , dealing with people solely intent on making money vs helping others.

yes I occasionally did find a few older experienced mentors , willing to teach a younger guy, but they were and are few and far between, so I decided to help where I can.

yes unlike most sites these threads generally have links and sub-links, if you care to learn take the time and effort to browse, through those, youll be amazed at the depth of related info

THERES SEVERAL DOZEN too a hundred plus or more,closely RELATED THREADS ON THE WEB SITE, ON MOST ENGINE BUILDING SUBJECTS< WHY NOT REGISTER , AND SPEND A LITTLE TIME DOING RESEARCH, YOU'LL VERY QUICKLY FIND THAT ANY ONE THREAD HOLDS FAR LESS THAN 2% OF THE RELATED INFO

The main reason I built the website was to allow guys who are willing to read, and ask questions, too skip the time and effort it took me to learn to build engines correctly

http://garage.grumpysperformance.com/index.php?threads/down-the-rabbit-hole-with-alice.10933/

now you can see I started out 45 plus years back, just as enthusiastic, about big block cars and needing to learn a good deal more about what I was doing, as most of us do!

I've always had a great deal of curiosity, and a bit of competitive streak, about learning how and why things mechanical work, and being a tool junky and gear head certainly doesn,t help, as I've frequently taken on projects just to see if I could noticeably improve results over what I see other guys accomplish.

I've built and raced a few corvettes,G.T.O.s ROAD RUNNERS, CAMAROS, Ive build or rebuild over a hundred engines, swapped suspensions, and learned on the way.

I spent decades in my younger days trying to learn how to do as much as I could,

about how things worked and what machinists, engine builders mechanics and tuners do,

and could never understand, the all too common ,mental attitude I found so prevalent, that

"If we teach you whats involved, or how to do something...

theres no reason for you to pay us excessive labor and machinist fees "

that's one of the main reasons I set up this web site! to give everyone a good start, and a way to avoid the bull "S#1T "

and attitude that was based on, "IF I keep you ignorant you have to pay me"

I always felt that helping as many people as possible to learn about and enjoy the hobby was the goal,

(probably why I've been busy but generally mostly broke, but I sleep well knowing I've helped hundreds of people

IVE learned to K.I.S.S. (KEEP IT SIMPLE STUPID)

IVE learned that a FEW QUALITY parts will BEAT lots of junk

IVE learned careful clearancing and attention to details makes a HUGE DIFFERENCE

IVE learned researching and learning from other people mistakes is FAR cheaper and faster than making your own in a car build.

IVE learned to do extensive research BEFORE buying parts

IVE learned NEVER BUY PARTS that you get on (DEALS) if they don't match your goals

I've learned that building engines for maximum AVERAGE TQ IN the RPM RANGE you'll use the car

beats building for maximum PEAK hp numbers

IVE learned asking lots of questions is far cheaper than making lots of mistakes

IVE learned that a cars performance depends a great deal on its POWER TO WEIGHT RATIO.

IVE learned that to have fun,your combo must be BOTH dependable and faster than MOST but not ALL the competition (most guys will never afford the expense in being the fastest car in your area)

IVE learned a CAR that breaks down is a TOTAL P.I.T.A. and RELIEABILITY is VERY IMPORTANT!

yeah, there's no doubt at all that the number and cost of tools you need to accumulate ,

frequently come close too or at times even exceed the the number of parts you actually install on any properly built cars.

you obviously run the risk of eventually rationalizing the need to justify the tool obsession,

by building a new or second car to further make the purchase of the tools,

and learning all the related skills seem , like its rational.

its a bit like the reloading cartridges hobby.. there's always the need to upgrade tools,

and once you have the tools you might as well buy a new revolver or rifles,

since ammo won't cost much now that you have the tools.

tool junky , and hand loading,& engine building insanity,

is a infectious, communicable virus, you can even catch over the internet.

and like many of you IM broke most of the time, because of this hobby,but always glad to help out

the best bit of advice I can give , is if your in the process of assembling an engine,

or doing some mods to the car,

and you see ANYTHING that looks odd, out of place ,

makes you doubt you did something correctly ,

or you find something does not quite fit,

or you see something just not something you expected,

STOP AND ASK QUESTIONS..,,,

think things through.... but don't proceed until you know your 100% correct.

DO THE REQUIRED RESEARCH and

don't GO ANY FURTHER UNTIL YOUR CERTAIN YOUR CORRECT

There is a reason why you are asking this question,

ASK YOUR MACHINIST AND VERIFY HIS ANSWERS

the just get a bigger hammer approach is surely the fastest way to get in serious trouble that will cost your a ton of cash and time wasted

I just try hard to buy anything in the world of tools, that I can afford to purchase, that helps increase my skill and tool use in building better engines each time I build a new engine, thus I have a large and ever expanding set of engine assembly , precision tools , and a desire to learn everything I can about engine assembly, and yes an ever increasing number of tool chest's and ever increasing skills as I learn to use those new tools. (yeah I admit I'm a tool junky) yeah, you might be amazed at the quantity of tools and tool chests and knowledge I gained over the last 55 plus years and over a hundred plus engine builds, ( yes I certainly made mistakes on the first few engines, just like every one does, but that's all part of the learning curve, every one goes through if your serious about learning the skill set required to build engines correctly,!) and its one reason I try hard to post as much information/ knowledge, and frequently upgrade or post new info, about engine assembly and tool use, as I can to prevent readers from making mistakes I can now avoid, due to learning from my mistakes and mistakes I see other people make!

Last edited by a moderator: