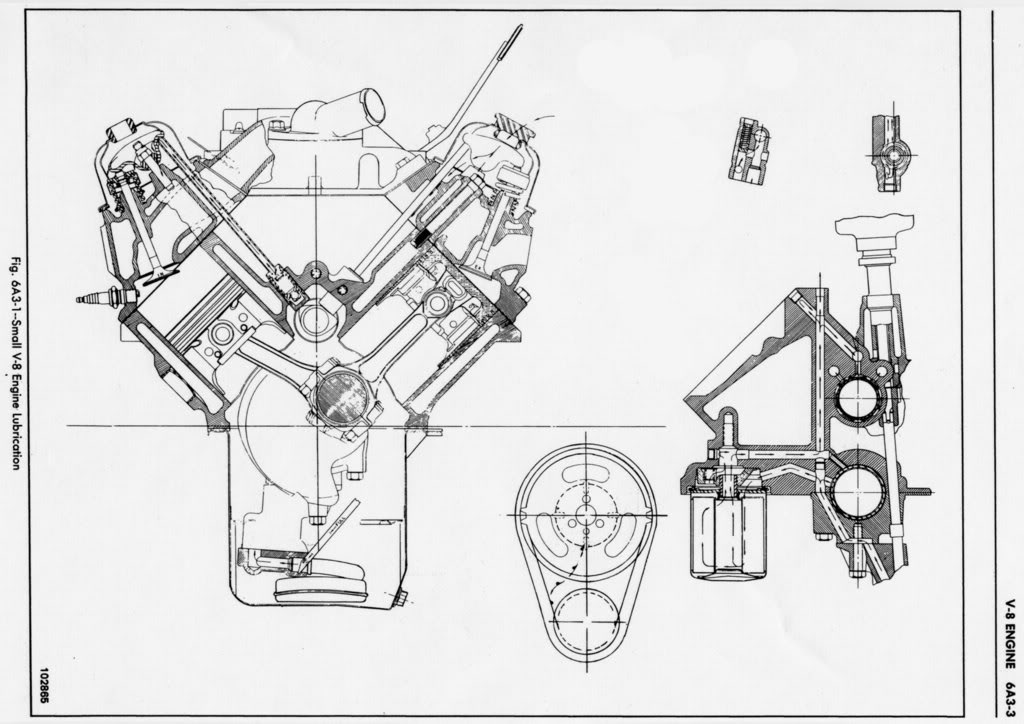

Id suggest two quick checks first, replace your oil filter, as they can be defective and block oil flow, and while its off, inspect the spin on oil filter adapter plate, to verify its not busted

and then verify your oil levels at the correct level on the dipstick,

then loosen ALL the rocker arms until they are loose enough to click at idle,

DON,T OVER LOOK THIS!

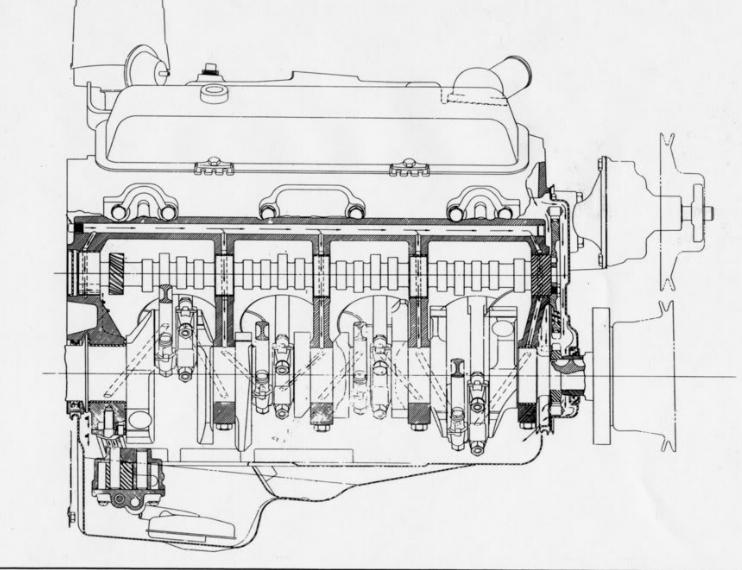

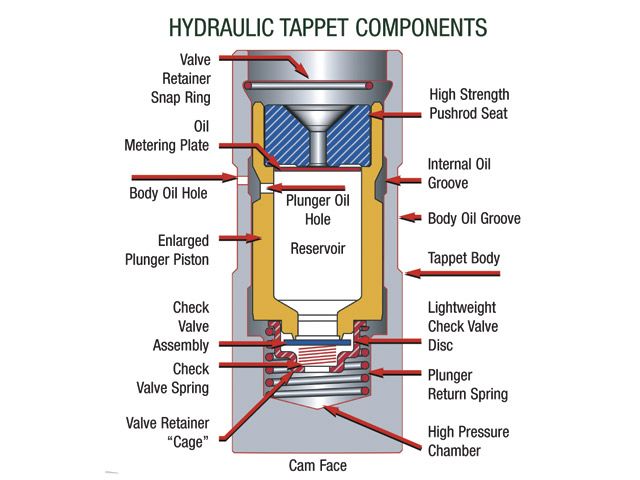

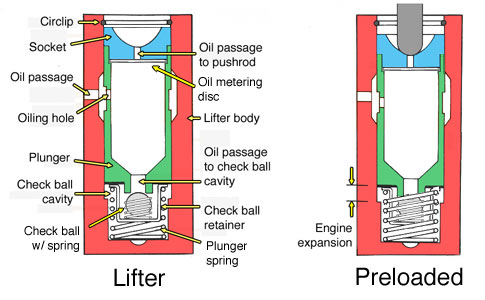

did you do what I suggested and loosen every rocker until it clicks, the reason is that its entirely possible to cold adjust rockers so the lifter seat can,t move far enough up to fill the lifter with oil,when its on the base of the cam lobe when the rockers not placing spring loads on the lifter seat so that no or darn little oil gets under the push rod seat consequentially, no-or very little oil moves up the push rods

and use a pre-luber

http://www.summitracing.com/parts/SUM-901010/?rtype=10

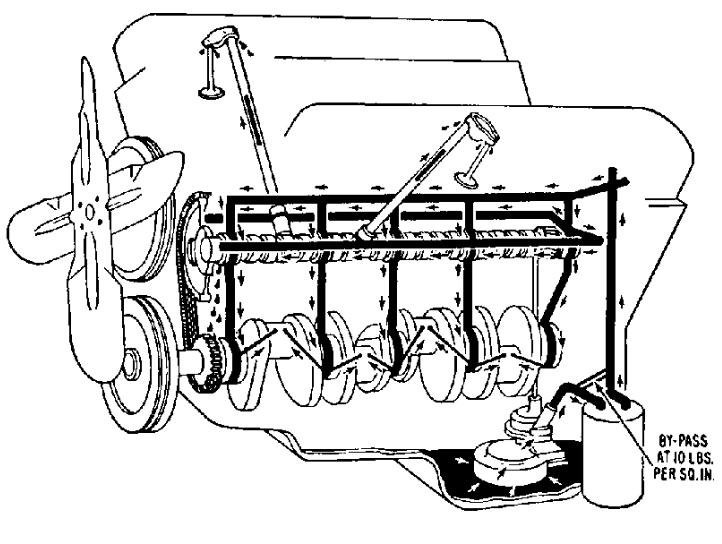

to furnish the oil pressure without putting any wear on the bearings as you slowly rotate the crank to allow oil to flow easily

a 1/2" drive air ratchet

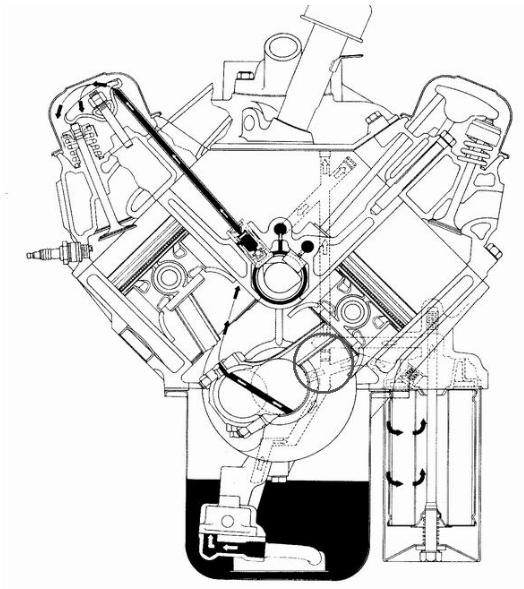

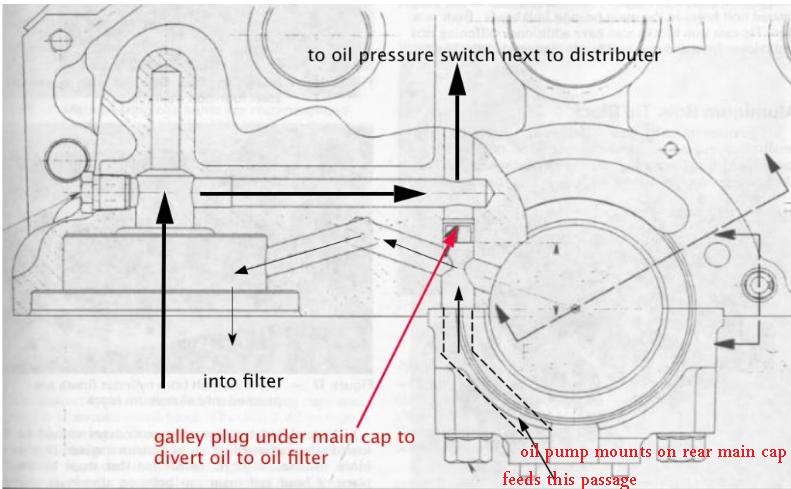

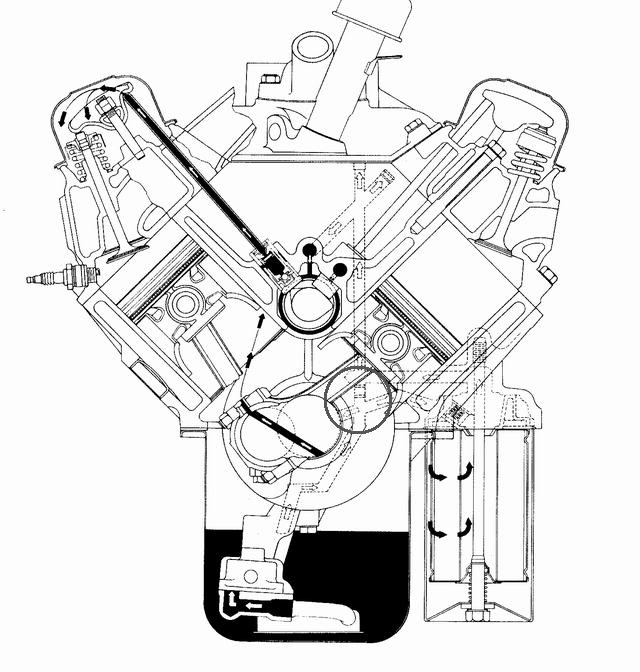

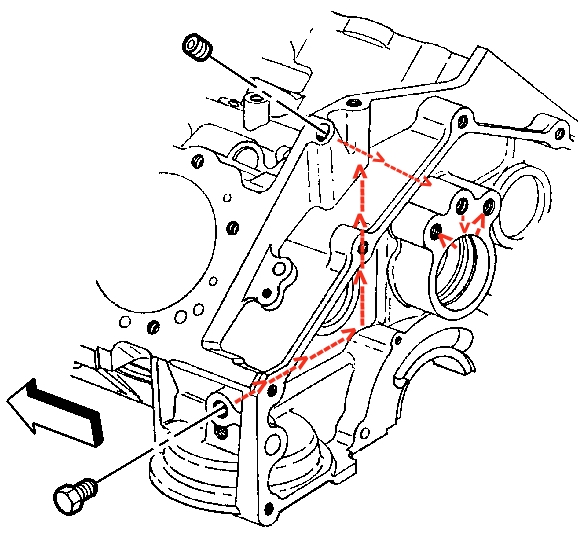

you DO REALIZE THAT THE BASE OF THE DISTRIBUTOR OR PRE_OILER , MUST look like the one above

because it FORMS a wall in the lower lifter gallery oil passage

the correct oil pump primer tool duplicates the distributor body and seals the oil passages.

you MUST manually rotate the crank , a MINIMUM of at least two full revolutions while priming the oil passages to insure all the lifters and push rods get full acess to presurized oil flow

if you use a pre-oiler or oil pump drive like this below, theres a huge internal leak and youll never get much oil flow

will not heat up like an electric drill if your using either to spin the pre-lube tool.

(THE BREAK-IN PROCESS,IS WHERE A NEW ENGINES PARTS MOVING SURFACES LAP INTO A COMPATIBLE,MATCHING SURFACE FINNISH)

the standard 10w 30 oils either synthetic or mineral base can be used, the synthetics have a reputation for taking longer for the components to seat correctly but the new corvettes are shipped full of synthetic oil so its hardly likely the manufacturer would do that if it would become a major problem.

OBVIOUSLY you need to use a good moly assembly lube on the bearings and cam and lifters in a flat tappet engine,

if you want to pay extra for a couple of quarts of oil and a filter that you should run, drain and replace within a few hundred miles use be my guest, but the standard HAVOLINE,VALVOLINE,TEXACO,SHELL, ETC 10w30 oil and a qt of MARVEL MYSTERY OIL and a CAN OF G.M. E. O.S. and a new oil filter, has worked just fine for hundreds of engines IVE built or seen broken in, now IN sure the break-in oil has more friction reducers added, like zinc, & phosphorus but that's a double edge sword, in that it will help cam lobe life but slow rings seating to the cylinder walls, and the E.O.S. has that in large amounts, the MARVEL MYSTERY OIL has solvents and detergents to remove crud quickly,if your running a flat tappet cam you should be running a oil with those in the formula like most diesel oils and the MOLY assembly lube you use on the cam and lifters has other friction reducers

Ive almost always used about 90% of a good brand of synthetic oil and 10% marvel mystery oil in my engines for MANY years, I generally change both the oil and oil filters in the 3500-5000 mile range and they always come apart during inspections looking like new, what many guys don,t realize is that M.M.O. is just a high quality light oil with a high percentage of solvents and detergents, its not an oil additive in the common sense of the word, just an oil that tends to dissolve crud effectively

BTW a few magnets, placed in the oil pan sump to trap metallic dust mixed in the oil is a big advantage, changing the oil and oil filter during the first 300 miles helps for the long engine life.

you really need to read thru these threads, and the sub linked info provided carefully, look at the oil heat ranges, zinc content and what moly assembly lube does to protect moving surfaces, what filters work, etc.

viewtopic.php?f=52&t=282&hilit=+break

http://www.bobistheoilguy.com/index.php ... &Itemid=62

http://people.msoe.edu/~yoderw/oilfilte ... study.html

http://www.hotrod.com/pitstop/hrdp_0702 ... index.html

http://micapeak.com/info/oiled.html

viewtopic.php?f=44&t=799&p=2048&hilit=+procedure#p2048

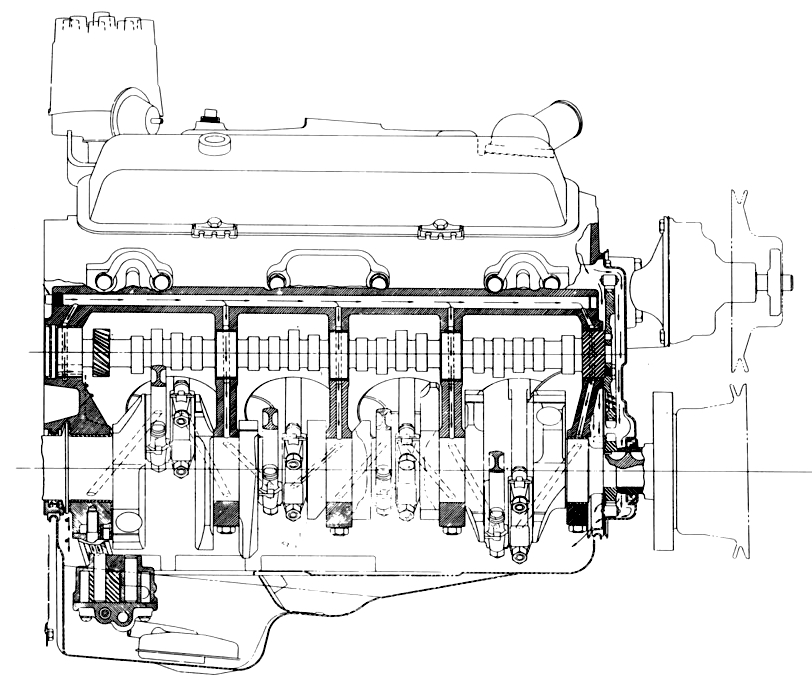

IT should be obvious that you'll need to pre-prime the blocks oil passages and adjust the rockers so oil flows from the rockers with the engine being pre-primed with a priming tool being used BEFORE trying to start any engine with a new cam to insure oil flow begins instantly on the engines start-up,you WON,T get oil to all lifters equally unless the engines crank & cam are spinning,(so during testing spin the engine slowly with a breaker bar or ratchet), because the oil passages feeding the lifters aligns differently at different lifts,your oil leak at the distributor base is normal, but the clearances and flow may be excessive, with a priming tool, some are not nearly to spec. ID measure the diam. of the oil pump primer and then measure the distributor base, Id bet the distributor base is larger and fits better, which reduces the potential for leakage.

those bottom two bands form a wall on the oil passage, some guys cut a rounded grove and install an O-RING so the upper band seals too the block, you don,t want to do that to the lower band simply because that's the oil flow source to the distributor /cam gear

20 psi is about normal for your typical 3/8 drill,max pressure is not nearly as important as checking flow, and for leaks where there should not be leaks, with an engine primer tool,Ive brazed a socket to the top of my oil pump primer and use the 1/2" drive air ratchet to drive it, it won,t heat up and burn up like a electric drill will.

don,t get alarmed if you get zero pressure or flow for a few seconds,(the oil filter and passages need to fill first) that's one reason WHY your pre-priming, to get oil flow to the bearings instantly on start up , you don,t want them running without oil flow if you can prevent it even for 20 seconds

READ THESE

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=3376

viewforum.php?f=54&start=25

ok

step one is verify you've got oil in the oil pan reading on the dipstick and that you've got oil pressure from the oil pump,registering in the oil passages in the block, when you hit the starter registering on the gauge., if not you need to locate the problem as its before the lifters,a oil pump pick-up that was not brazed may have dropped down onto the oil pan floor drastically restricting oil flow into the oil pump.

IF you don,t see at least 20 psi on the gauge cranking the engine on the starter ID suggest pulling the distributor and use of an oil pump primer and checking where the problems located

if your oil filter might be clogged, or have a defective drain back valve ID suggest changing it for a name brand and adding a quart of marvel mystery oil as its got extra solvents

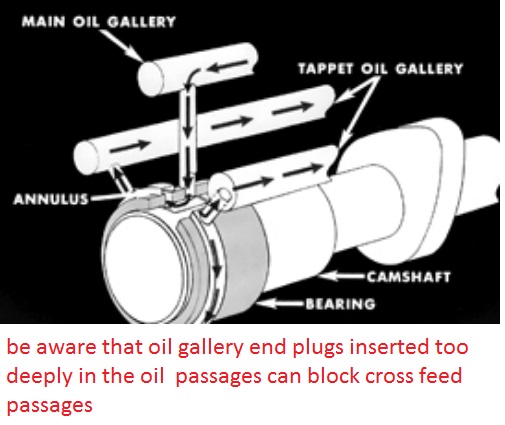

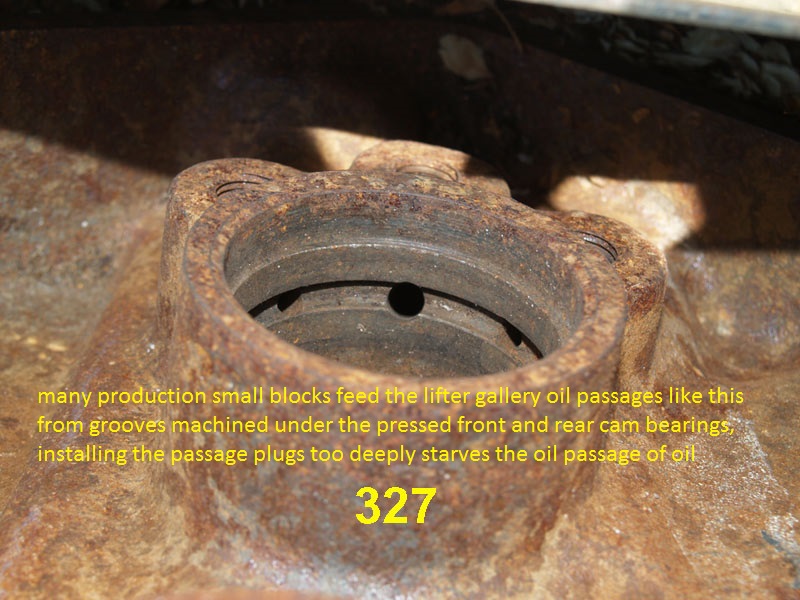

Remember if you adjust lifters too tight they pump very little oil. if you install the cam bearings wrong it restricts oil flow,

step two

if your reading oil pressure on the gauge try backing off each rocker nut a full turn,or more until the rockers click rhythmically, first, the rockers SHOULD click,until properly adjusted slowly inward on the lock nut to about 1/4 turn in from the point they stop clicking at idle. because the hydraulic lifter seat should move up to take up the slack in the valve train, so that the lifter seat compresses a larger volume of oil as it compresses thus sending more up thru the lifter seat and forcing more up the push-rods, the less the seat in the lifters pre-compressed the greater the oil flow forced up the push-rod as the lifter rides over the cam lobe and the greater the volume trapped under the lifter seat as the lifter returns to the cam lobes base circle as the oil pressure flow in the lifter gallery refills and takes up the lifter to push-rod clearance in the valve train

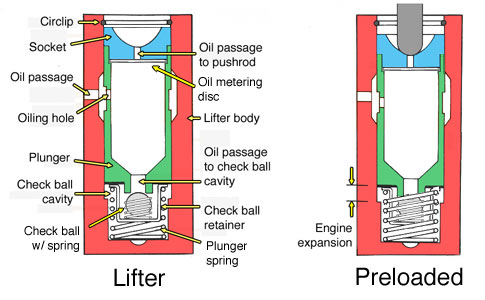

keep in mind roller lifters are very similar to flat tappet lifters internally , its the roller wheel at the base of the roller lifter, the non-tapered lobe surface the lifter wheel rides on,the roller lifters need to remain aligned with the cam lobe rotation and the links that keep it aligned that's the biggest difference, between the flat tappet and roller tappet designs

REMINDER

it should be obvious that during the pre-assembly valve train geometry checks that the push rod and rocker oil hole alignment needs to be verified, the push-rods to guide plate clearance and the rocker geometry needs to be checked and high pressure air and solvent should be forced thru each push rod to remove crud and verify the oil can flow thru the push-rods

IF your having oiling issues,

you DO REALIZE THAT THE BASE OF THE DISTRIBUTOR OR PRE_OILER , MUST look like the one above

because it FORMS a wall in the lower lifter gallery oil passage

theres also a plug that can be incorrectly installed

correctly installed oil passage plug

HERE YOU SEE THE PLUG INSERTED TOO DEEPLY , BLOCKING OIL PASSAGE ,which may be your issue

READ THESE THREADS AND SUB LINKS

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=2051

viewtopic.php?f=54&t=53

viewtopic.php?f=52&t=196

viewtopic.php?f=54&t=4580

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=2376&p=7633#p7633

viewtopic.php?f=44&t=799&p=6576&hilit=+priming#p6576