"I swapped my stock 350 engine for a 383 with bigger heads and a bigger cam and re-installed my old TPI intake and stock injectors and its just not running correctly, any ideas ?"?

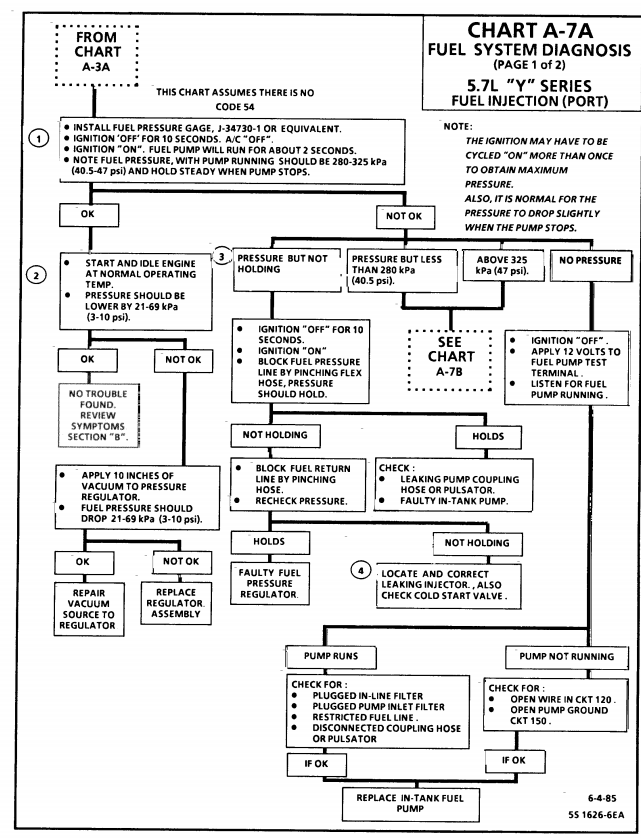

obviously you need to check for vacuum leaks bad electrical connections, faulty ignition timing curves a badly adjusted CPU or low fuel pressure and any mechanical or electrical issues first,and verify every system is working correctly, that theres no mechanical issues like a cam installed incorrectly or a worn cam lobe, low fuel pressure a defective injector, a broken piston ring, a restrictive exhaust,

Id suggest pulling trouble codes and doing a compression check and verifying the ignition advance etc

your horsepower is based on how much fuel/air mix you can efficiently burn per second, you'll burn about 12-15 pounds of air per pound of fuel, all modifications that increase power concentrate either on increasing efficiency like increasing compression or reducing friction , or increasing exhaust scavenging or on burning a greater amount of that fuel/air mix per revolution, such as increased displacement or packing the cylinders with higher pressure like a super charger or a turbo, or increasing the number of power strokes per second, like with longer duration cams,

the most common reason , a new 383 stroker,with a larger duration cam, installed in place of a stock 350 sbc won,t run as expected is failure to realize the new engine combo will need to run at a higher average rpm, and it will require noticeably more air and fuel to make that extra hp,if you just went from 240hp in a stock TPI and built a 470 hp 383 thats a 100% increase in hp it only makes sense that the injector size must jump up to almost double the original flow rate to compensate also,

and the new cam is very likely to require a different ignition advance and CPU tune plus a higher stall converter and a 3.54:1-3.73:1 rear gear should be used so the engine can spend most of its time in the higher average rpm range the cams designed for, all the changes were made so you could burn MORE FUEL and AIR in each power stroke and have MORE power strokes per minute, one of the most common mistakes,is not swapping to a matched rear gear and higher rpm torque converter stall speed,followed buy guys not upgrading the exhaust and understanding the need to upgrade the injector size to supply the higher demands for fuel and air the new engine will maker because its going to need to be supplied with more fuel to maintain the correct fuel/air ratio.the most important and effective performance asset you have is simply your ability to ask yourself questions, the ability to think logically isolate and test components carefully and doing the research if its required to find the best answer's you'll need.

actually 36 lb- 42 lb injectors are very commonly used on the better 383 engine builds, one of the most common problems I see is guys trying to reuse stock 24 lb injectors to build a 400hp plus engine that results in a constant lean upper rpm condition that eventually results in detonation damaging pistons but always results in lower power than expected

ALWAYS TEST ALL YOUR INJECTORS OHMS RESISTANCE, WITH A MULTI METER, IF YOUR ENGINE RUNS BADLY ,INDIVIDUALLY< THEY SHOULD ALL BE VERY CLOSE TO EQUAL, ANY THAT ARE NOT NEED TO BE REPLACED

heres a basic chart on injector size and expected power levels, you should see reached before potential higher rpm lean condition

heres a bit of advice! so many times I get called over to help in some project, only to find the problems the guys hoping I can solve could have been avoided entirely ,

if the guy whos at this point is going partially insane, had only bothered to carefully read the details or installation instructions.

many times youll see the guy ordered the wrong part number, and theres a very similar component that exactly matches the concept ,

hes currently waist deep into, only to find the component he ordered is not compatible with the rest of the parts, hes working with.

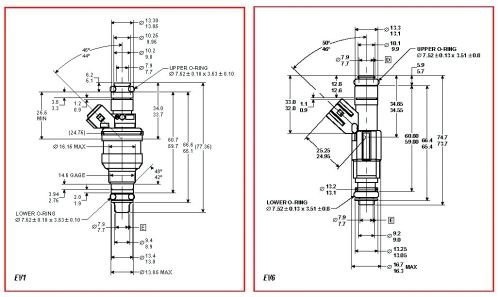

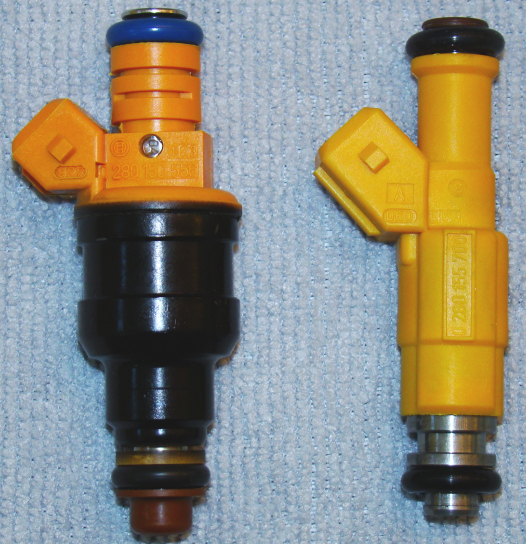

Ive seen guys order high impedance injectors that are installed on a controller designed for low impedance injectors

http://fuelinjectorclinic.com/faqs

You can measure the resistance across the two electrical terminals of the injector. If the resistance is between 1.5 and 4.0 Ohm you have low impedance injectors. If the resistance is between 8 and 16 Ohm you have high impedance injectors.

https://www.hotrod.com/articles/hrdp-1211-low-impedance-vs-high-impedance-fuel-injectors/

Low impedance (peak and hold) injectors have a resistance of between 2 and 4 ohms. High impedance(saturated) injectors have a resistance of between 10 and 14 ohms. Low impedance and high impedance injectors cannot be used interchangeably without modification of the injector drivers.

What are the differences between low impedance/peak & hold and high impedance/saturated injectors?

The older fat body style low impedance injectors (1.5 to 4.0 Ohm) used to have faster open and close times due to the type of electrical signal pattern emitted by an ECU equipped with proper P&H signal transmitters. This “Peak and Hold” injector signal typically uses a high (4 amp) initial current to open the injector, and which reduces to a lower (1 amp) current to keep the injector open until the pulse ends. Since this method put less total current into the coil, the coil heated up less and was therefore more reliable. Since the “hold” or lower current part of the signal has created a weaker magnetic field, the injector will also close more quickly.

High impedance injectors (10 to 16 Ohm) are triggered by a low (typically around 1.2 amps) constant current signal and kept open by the same constant (saturated) current for the entire cycle. Most OEM injectors today are high impedance injectors being driven by saturated injector signals from the ECU since car manufacturers are most interested in the simpler saturated signal which is more cost effective to produce when building ECU’s, especially where there is no apparent loss of drivability or performance.

https://www.summitracing.com/parts/...MIsMryyOf_3gIVjoTICh1o7wzhEAQYAiABEgKO9fD_BwE

https://www.summitracing.com/parts/...MInIGXief_3gIVy-DICh1rpgH3EAYYAiABEgJLafD_BwE

24 lb/hr 326 hp

30 lb/hr 408 hp

32 lb/hr 435 hp

39 lb/hr 530 hp

42 lb/hr 571 hp

https://fuelinjectorclinic.com/flow-calculator

https://www.injectorrx.com/injector-size-calculator/

https://www.witchhunter.com/injectorcalc1.php

http://www.raceworks.com.au/calculators/injector-hp-calculator/

http://www.rcfuelinjection.com/Technical

http://www.enginelabs.com/news/calculating-fuel-demands-and-injector-sizing-with-efi-university/

watch these videos

http://www.youtube.com/watch?v=l2ne6AVn ... re=related

http://www.youtube.com/watch?v=aIUJbTXN ... re=related

http://www.youtube.com/watch?v=49WXmzfO ... e=youtu.be

viewtopic.php?f=32&t=3429&p=9084#p9084

HERES SOME THREADS TO HELP YOU LOCATE YOUR PROBLEM

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1200

viewtopic.php?f=44&t=38

viewtopic.php?f=32&t=596

viewtopic.php?f=44&t=773

viewtopic.php?f=80&t=728

viewtopic.php?f=32&t=168

http://www.hotrod.com/articles/innovate-air-fuel-ratio-meter/

viewtopic.php?f=44&t=5575

obviously you need to check for vacuum leaks bad electrical connections, faulty ignition timing curves a badly adjusted CPU or low fuel pressure and any mechanical or electrical issues first,and verify every system is working correctly, that theres no mechanical issues like a cam installed incorrectly or a worn cam lobe, low fuel pressure a defective injector, a broken piston ring, a restrictive exhaust,

Id suggest pulling trouble codes and doing a compression check and verifying the ignition advance etc

your horsepower is based on how much fuel/air mix you can efficiently burn per second, you'll burn about 12-15 pounds of air per pound of fuel, all modifications that increase power concentrate either on increasing efficiency like increasing compression or reducing friction , or increasing exhaust scavenging or on burning a greater amount of that fuel/air mix per revolution, such as increased displacement or packing the cylinders with higher pressure like a super charger or a turbo, or increasing the number of power strokes per second, like with longer duration cams,

the most common reason , a new 383 stroker,with a larger duration cam, installed in place of a stock 350 sbc won,t run as expected is failure to realize the new engine combo will need to run at a higher average rpm, and it will require noticeably more air and fuel to make that extra hp,if you just went from 240hp in a stock TPI and built a 470 hp 383 thats a 100% increase in hp it only makes sense that the injector size must jump up to almost double the original flow rate to compensate also,

and the new cam is very likely to require a different ignition advance and CPU tune plus a higher stall converter and a 3.54:1-3.73:1 rear gear should be used so the engine can spend most of its time in the higher average rpm range the cams designed for, all the changes were made so you could burn MORE FUEL and AIR in each power stroke and have MORE power strokes per minute, one of the most common mistakes,is not swapping to a matched rear gear and higher rpm torque converter stall speed,followed buy guys not upgrading the exhaust and understanding the need to upgrade the injector size to supply the higher demands for fuel and air the new engine will maker because its going to need to be supplied with more fuel to maintain the correct fuel/air ratio.the most important and effective performance asset you have is simply your ability to ask yourself questions, the ability to think logically isolate and test components carefully and doing the research if its required to find the best answer's you'll need.

actually 36 lb- 42 lb injectors are very commonly used on the better 383 engine builds, one of the most common problems I see is guys trying to reuse stock 24 lb injectors to build a 400hp plus engine that results in a constant lean upper rpm condition that eventually results in detonation damaging pistons but always results in lower power than expected

ALWAYS TEST ALL YOUR INJECTORS OHMS RESISTANCE, WITH A MULTI METER, IF YOUR ENGINE RUNS BADLY ,INDIVIDUALLY< THEY SHOULD ALL BE VERY CLOSE TO EQUAL, ANY THAT ARE NOT NEED TO BE REPLACED

heres a basic chart on injector size and expected power levels, you should see reached before potential higher rpm lean condition

heres a bit of advice! so many times I get called over to help in some project, only to find the problems the guys hoping I can solve could have been avoided entirely ,

if the guy whos at this point is going partially insane, had only bothered to carefully read the details or installation instructions.

many times youll see the guy ordered the wrong part number, and theres a very similar component that exactly matches the concept ,

hes currently waist deep into, only to find the component he ordered is not compatible with the rest of the parts, hes working with.

Ive seen guys order high impedance injectors that are installed on a controller designed for low impedance injectors

http://fuelinjectorclinic.com/faqs

You can measure the resistance across the two electrical terminals of the injector. If the resistance is between 1.5 and 4.0 Ohm you have low impedance injectors. If the resistance is between 8 and 16 Ohm you have high impedance injectors.

https://www.hotrod.com/articles/hrdp-1211-low-impedance-vs-high-impedance-fuel-injectors/

Low impedance (peak and hold) injectors have a resistance of between 2 and 4 ohms. High impedance(saturated) injectors have a resistance of between 10 and 14 ohms. Low impedance and high impedance injectors cannot be used interchangeably without modification of the injector drivers.

What are the differences between low impedance/peak & hold and high impedance/saturated injectors?

The older fat body style low impedance injectors (1.5 to 4.0 Ohm) used to have faster open and close times due to the type of electrical signal pattern emitted by an ECU equipped with proper P&H signal transmitters. This “Peak and Hold” injector signal typically uses a high (4 amp) initial current to open the injector, and which reduces to a lower (1 amp) current to keep the injector open until the pulse ends. Since this method put less total current into the coil, the coil heated up less and was therefore more reliable. Since the “hold” or lower current part of the signal has created a weaker magnetic field, the injector will also close more quickly.

High impedance injectors (10 to 16 Ohm) are triggered by a low (typically around 1.2 amps) constant current signal and kept open by the same constant (saturated) current for the entire cycle. Most OEM injectors today are high impedance injectors being driven by saturated injector signals from the ECU since car manufacturers are most interested in the simpler saturated signal which is more cost effective to produce when building ECU’s, especially where there is no apparent loss of drivability or performance.

https://www.summitracing.com/parts/...MIsMryyOf_3gIVjoTICh1o7wzhEAQYAiABEgKO9fD_BwE

https://www.summitracing.com/parts/...MInIGXief_3gIVy-DICh1rpgH3EAYYAiABEgJLafD_BwE

24 lb/hr 326 hp

30 lb/hr 408 hp

32 lb/hr 435 hp

39 lb/hr 530 hp

42 lb/hr 571 hp

https://fuelinjectorclinic.com/flow-calculator

https://www.injectorrx.com/injector-size-calculator/

https://www.witchhunter.com/injectorcalc1.php

http://www.raceworks.com.au/calculators/injector-hp-calculator/

http://www.rcfuelinjection.com/Technical

http://www.enginelabs.com/news/calculating-fuel-demands-and-injector-sizing-with-efi-university/

watch these videos

http://www.youtube.com/watch?v=l2ne6AVn ... re=related

http://www.youtube.com/watch?v=aIUJbTXN ... re=related

http://www.youtube.com/watch?v=49WXmzfO ... e=youtu.be

viewtopic.php?f=32&t=3429&p=9084#p9084

HERES SOME THREADS TO HELP YOU LOCATE YOUR PROBLEM

http://forum.grumpysperformance.com/viewtopic.php?f=55&t=1200

viewtopic.php?f=44&t=38

viewtopic.php?f=32&t=596

viewtopic.php?f=44&t=773

viewtopic.php?f=80&t=728

viewtopic.php?f=32&t=168

http://www.hotrod.com/articles/innovate-air-fuel-ratio-meter/

viewtopic.php?f=44&t=5575

Last edited by a moderator: