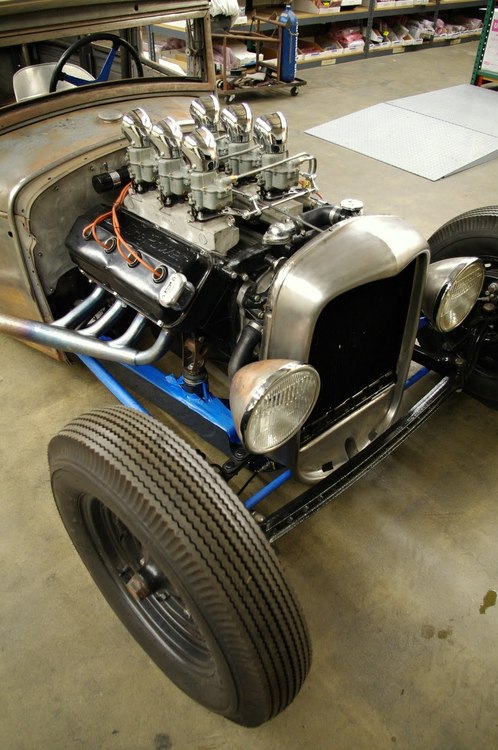

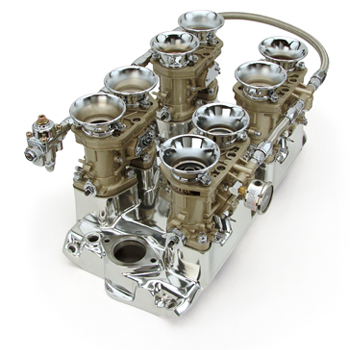

hey grumpy? how about 6 duces?, I found an intake and carbs at a yard sale priced reasonably, should I pick it up?

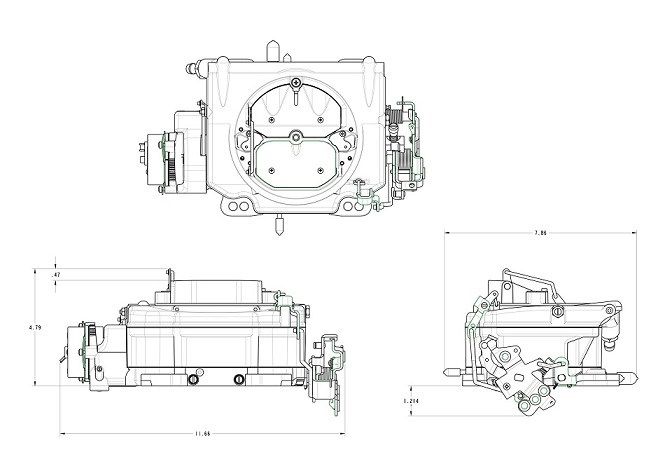

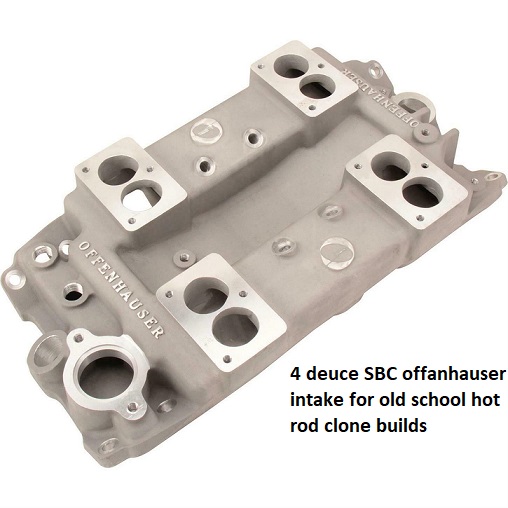

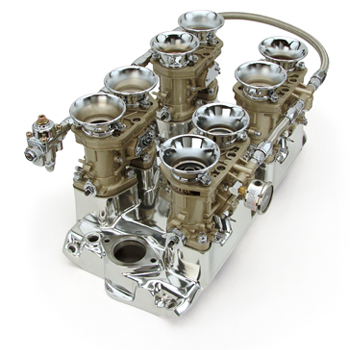

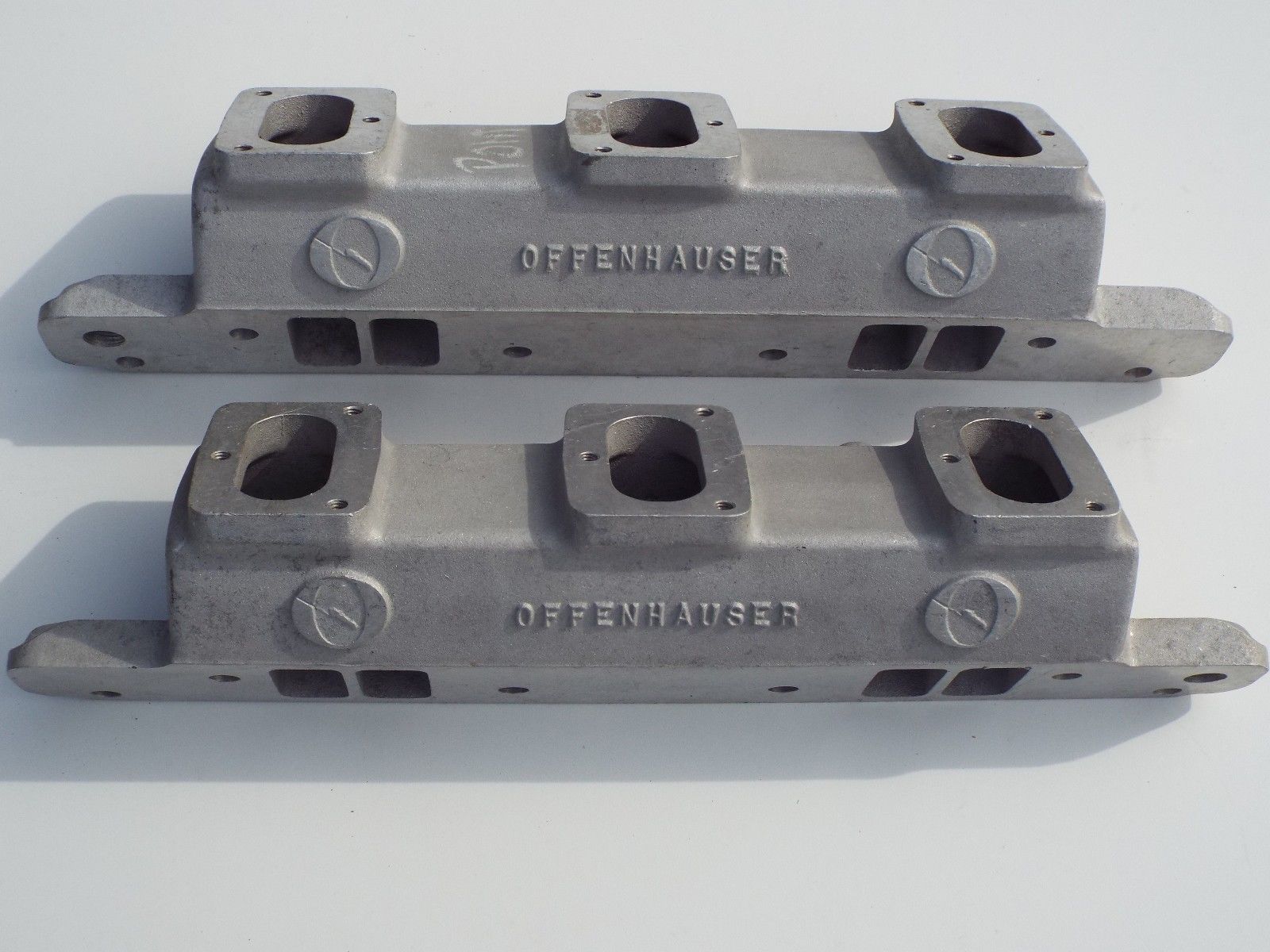

the carbs are available,for the multi 2 barrel intake manifolds of various designs, but they are expensive and theres NO PERFORMANCE ADVANTAGE TO USING THEM, as the more modern carbs atomize fuel far more effectively ,they might be fine on a show car for looks, but I don,t think its a good idea on anything you want to drive regularly, EDELBROCK,MAN-A-FRE AND OFFANHAUSER ALL USED TO SELL THESE STYLE INTAKES, THEY don,t generally produce nearly the hp a good dual quad or single quad intake can and require far more effort to tune, by todays standards the older designs are archaic and for period correct show cars only

yes they can be made to run surprisingly well IF you understand how and want to take the effort to do in correctly

READ THIS LINK

http://garage.grumpysperformance.co...-x-1-how-do-you-set-this-up.11688/#post-54747

http://www.jenvey.co.uk/

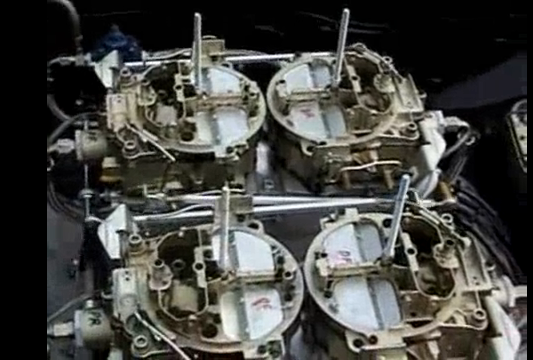

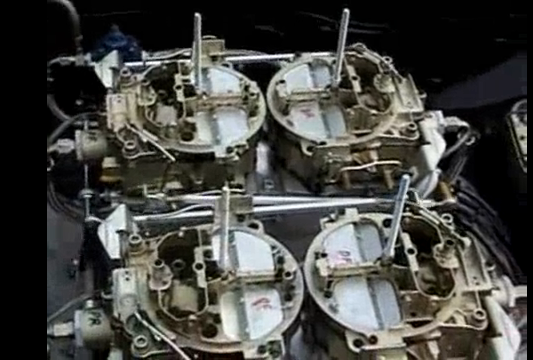

BTW IF YOU THINK OVER CARBING AN ENGINES A HUGE CONCERN,HERES A VIDEO OF A GUY RUNNING 4 750 quadrajet 4 barrel carbs on a car engine, and once tunned for the application it seems to run decently

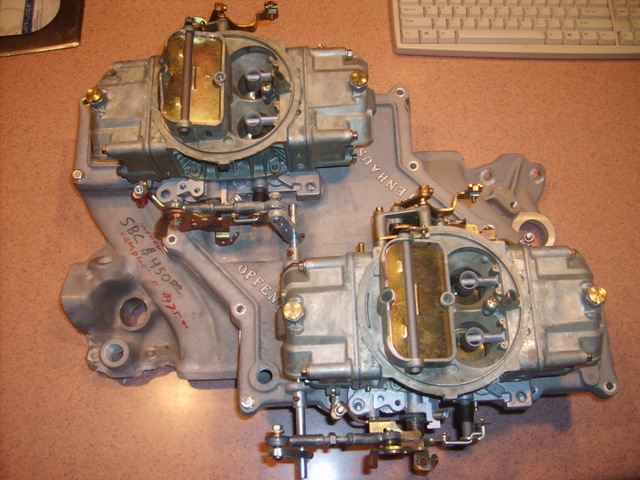

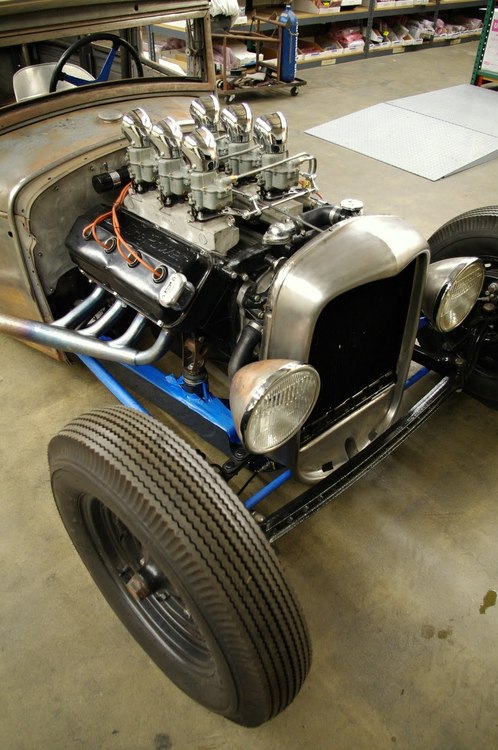

the old 4 deuce and 6 deuce intakes look impressive but rarely run as well as dual quads, dual quads on a well designed tunnel ram intake , or if you must have multi carburetors Id suggest the newer 4 weber intakes which are all far easier to tune

even the older constant flow mechanical fuel injections far better

RELATED THREAD

viewtopic.php?f=55&t=4302&p=12406&hilit=intakes#p12406

viewtopic.php?f=32&t=3916&p=10420&hilit=intakes#p10420

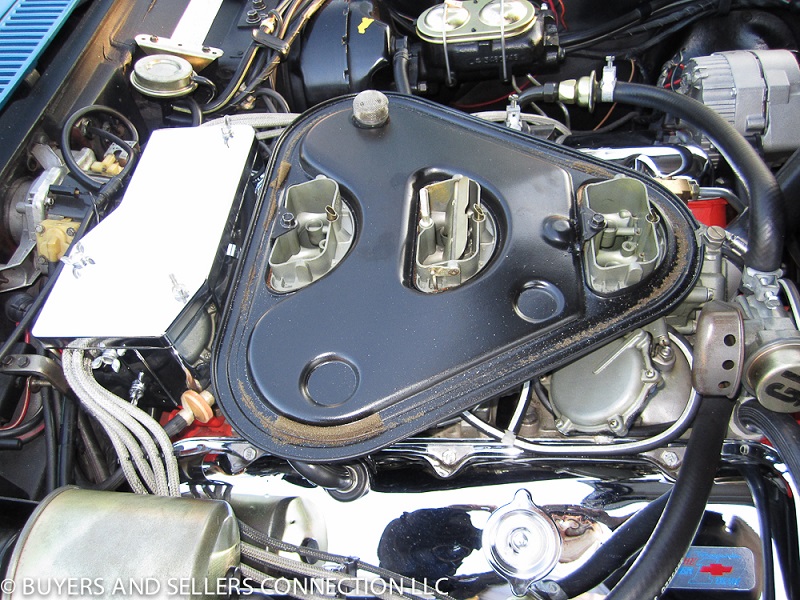

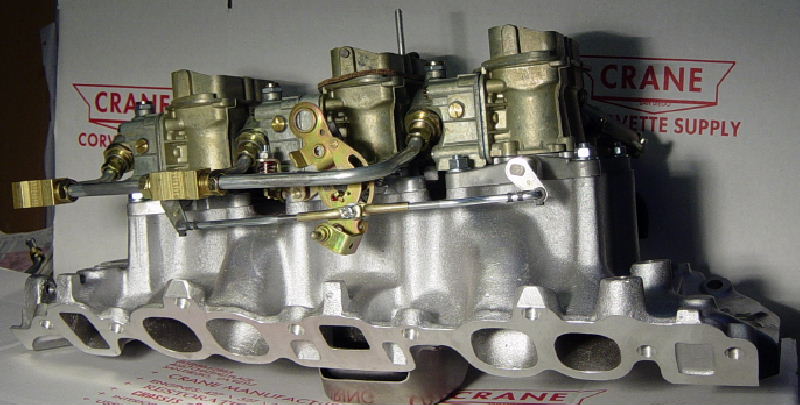

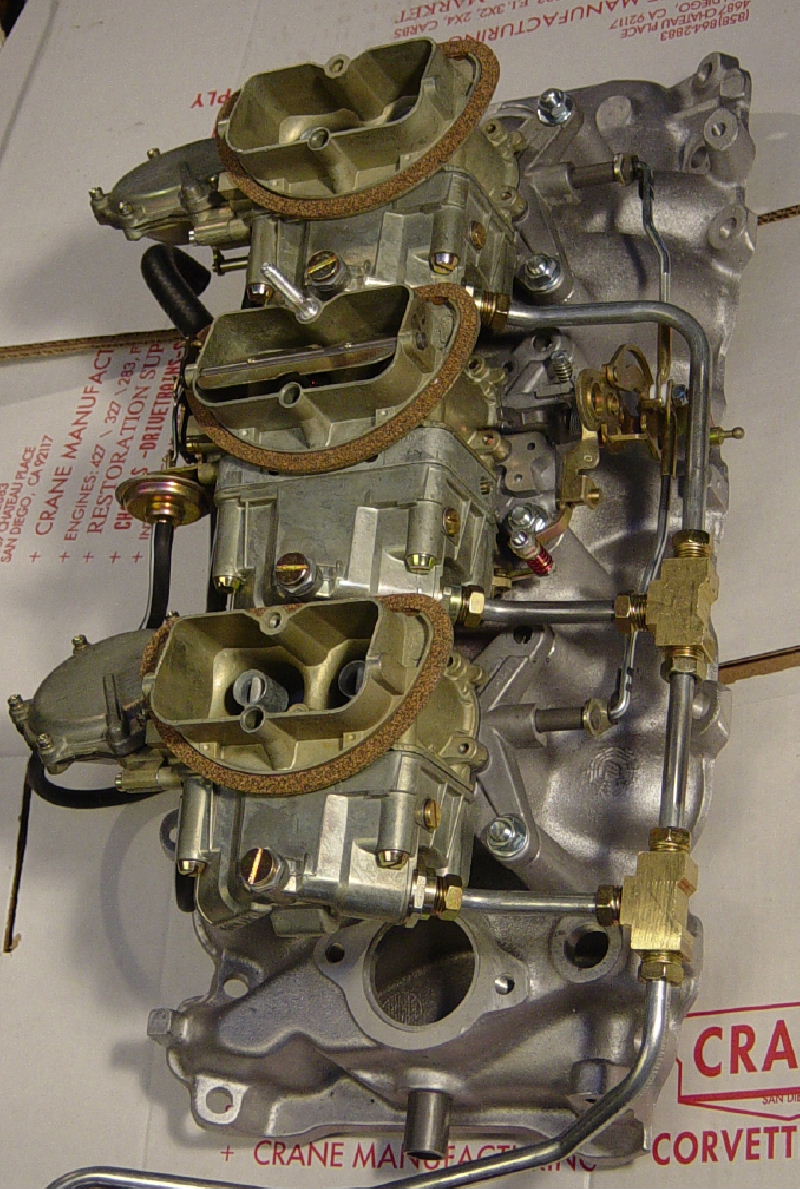

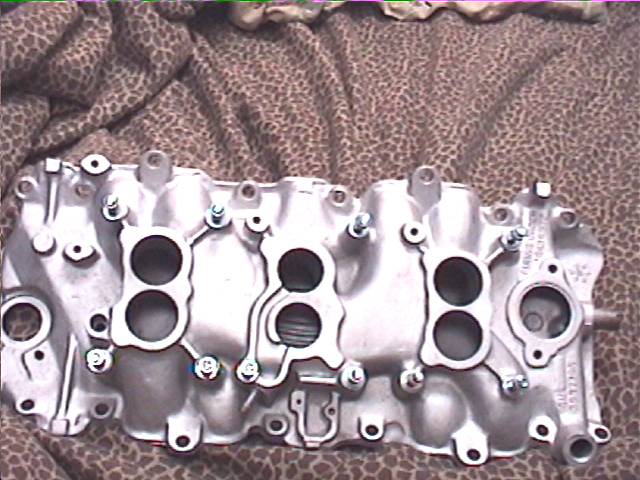

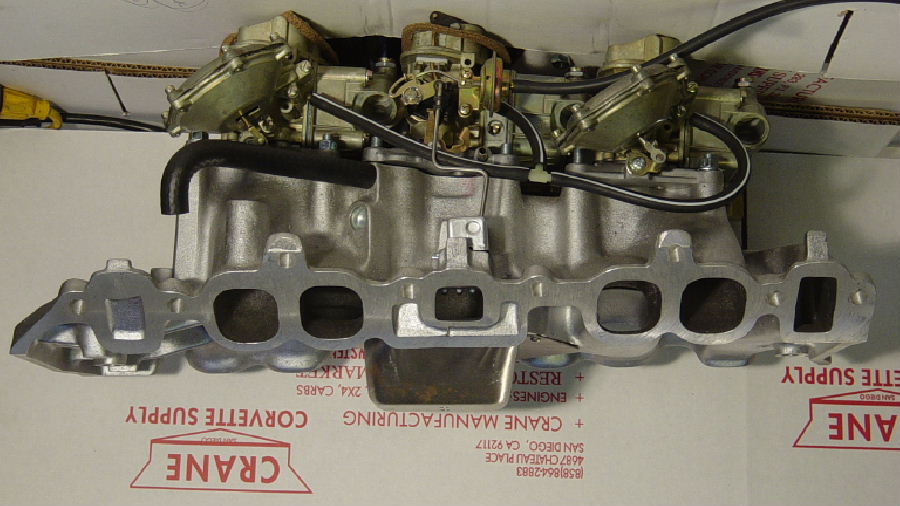

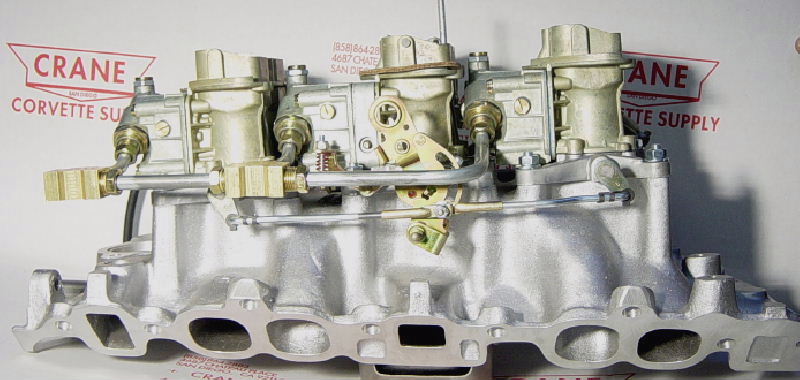

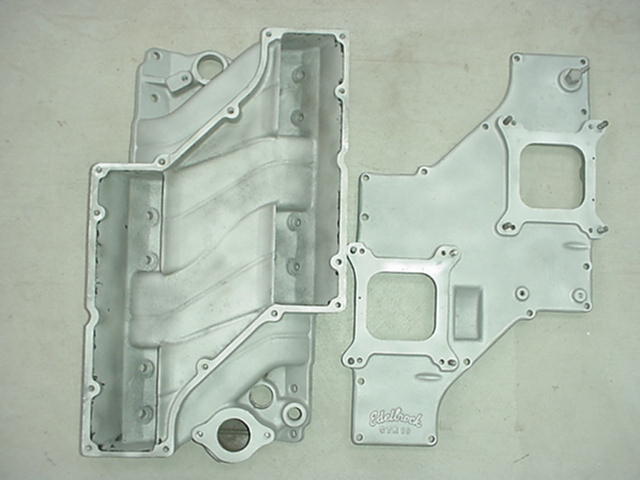

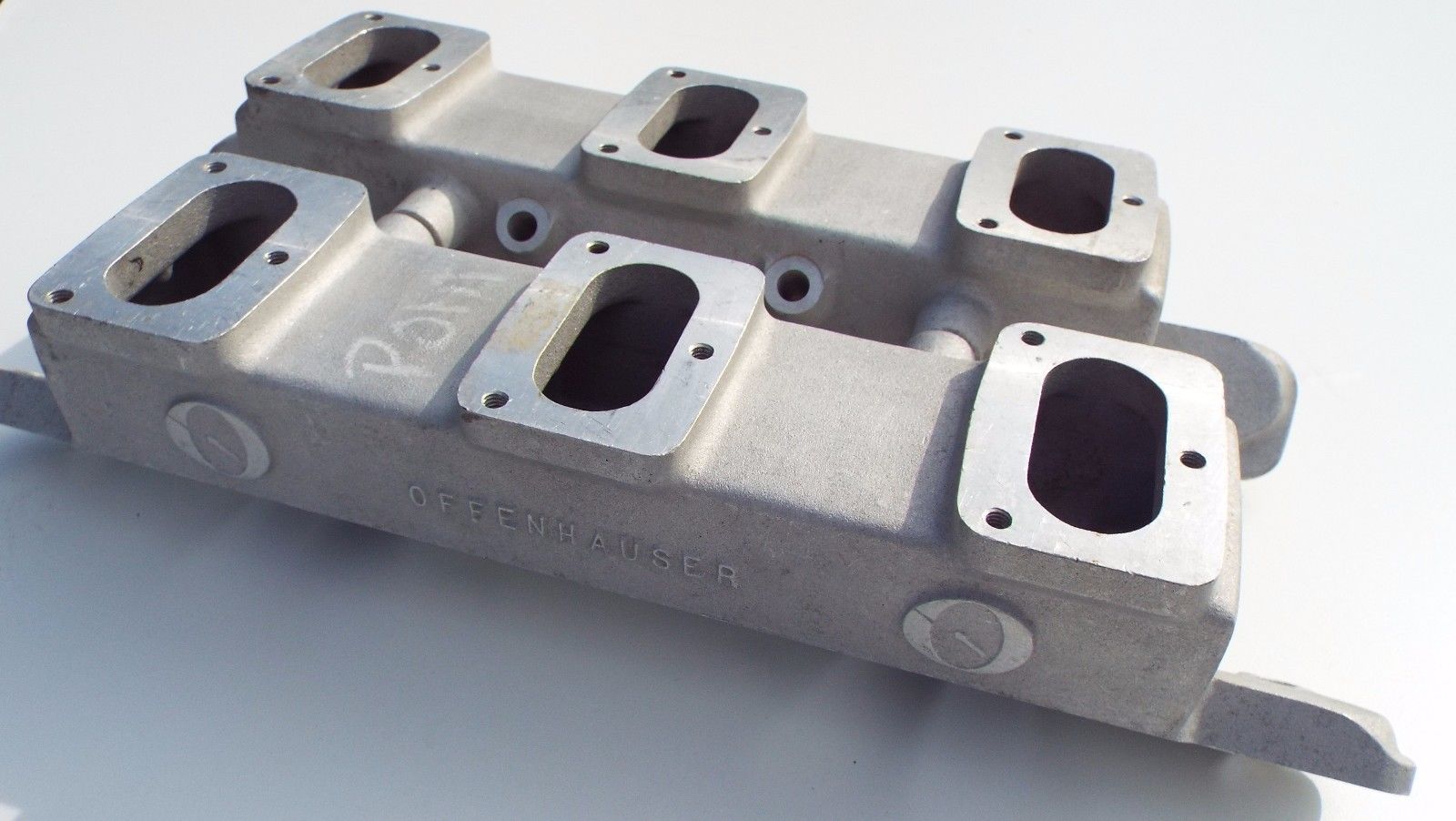

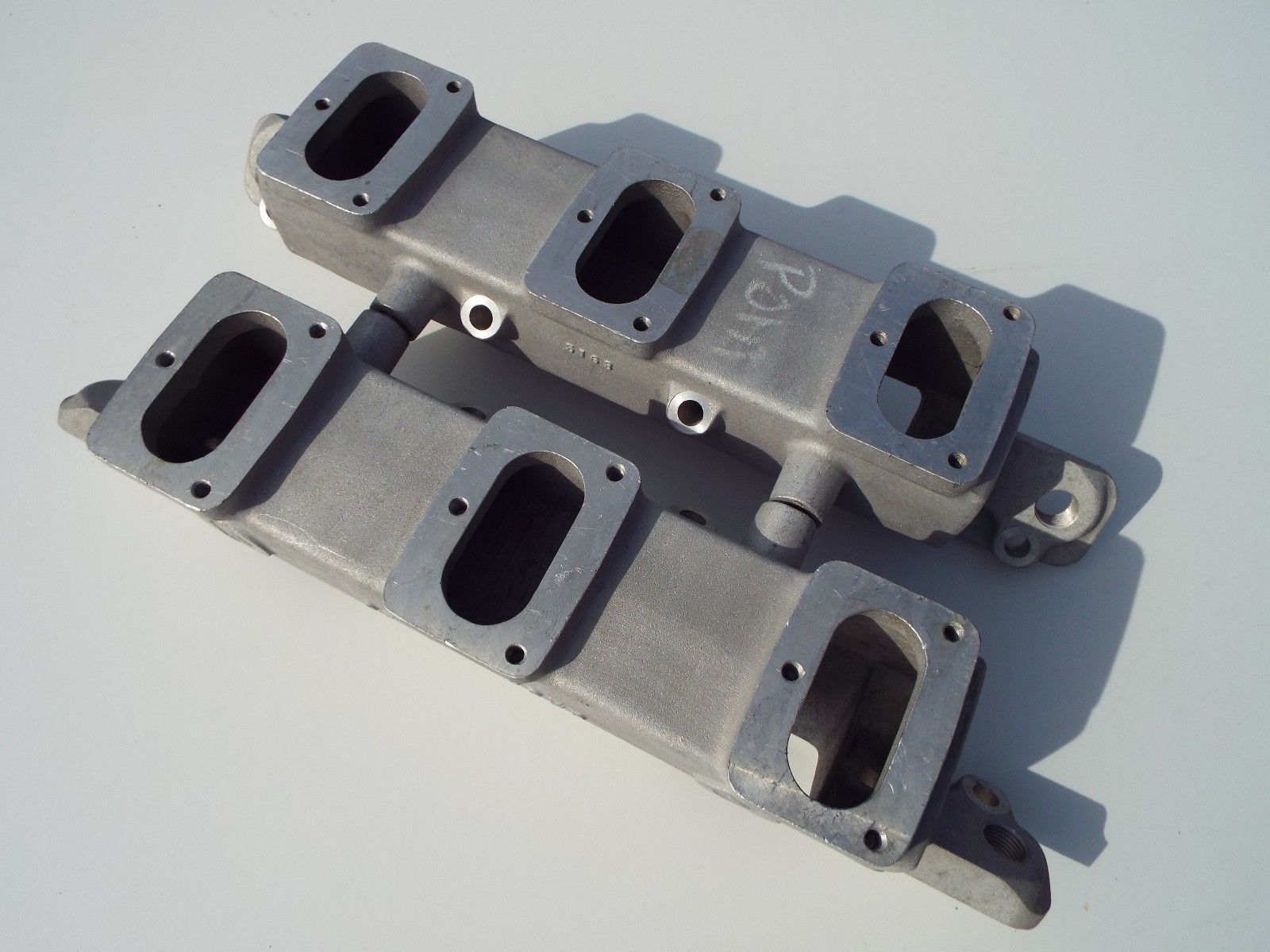

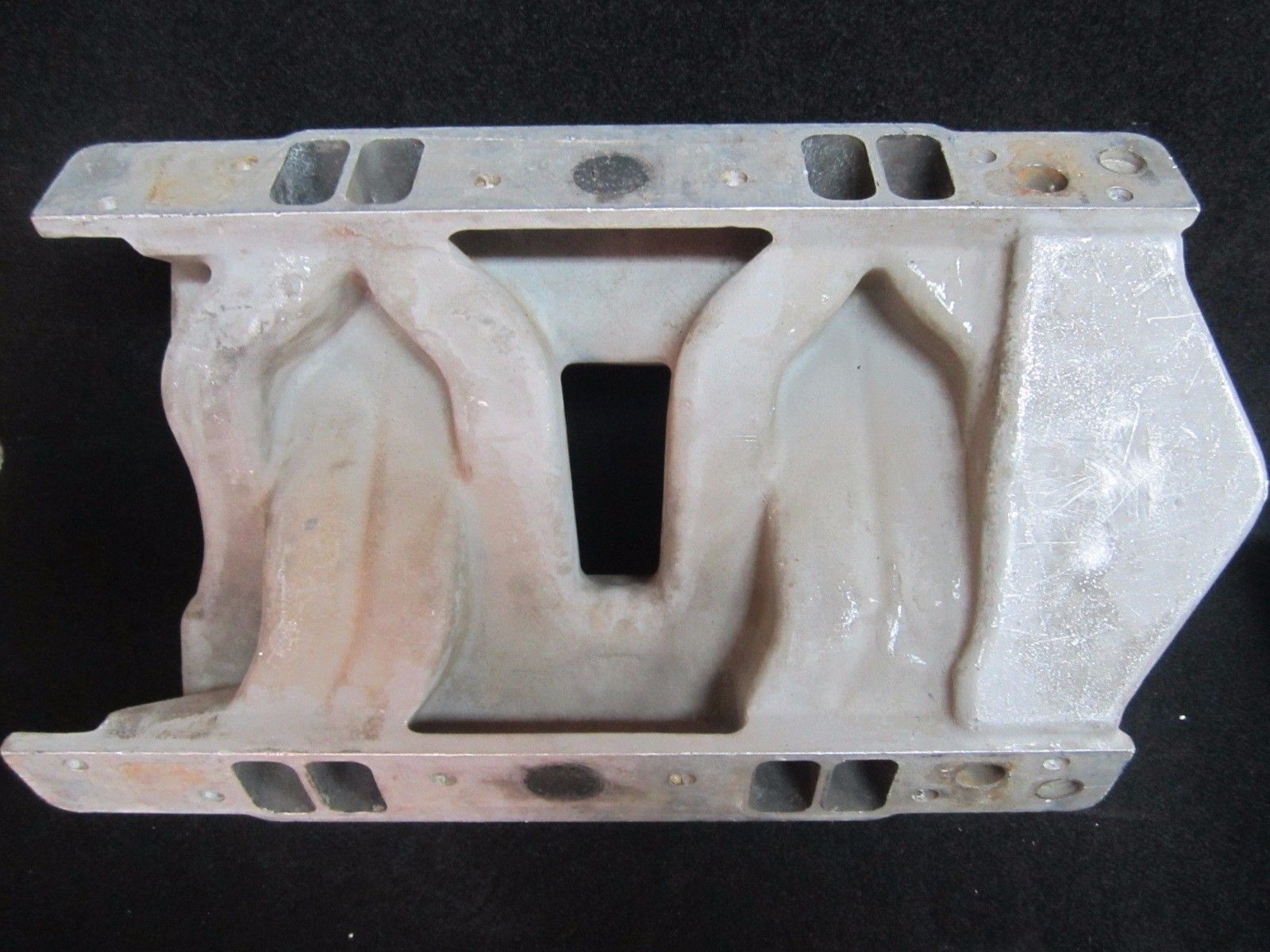

Pontiac 6 deuce intakes were manufactured in several versions, like the two design,s posted below, the log style manifolds were also made for caddy oldsmobile and ford

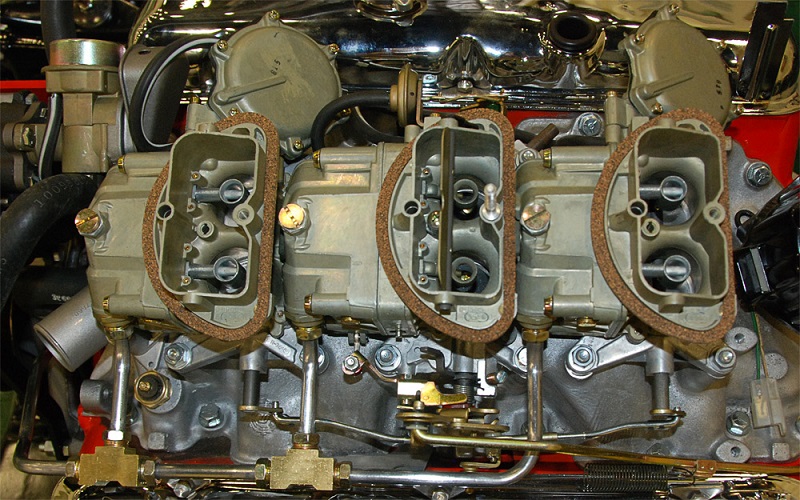

the early log single bank design was common but rarely worked very well as the runner length was very short

the later cross ram versions worked far better

IF YOU KNEW HOW TO TUNE

http://www.thecarburetorshop.com/

yes they can be made to run surprisingly well IF you understand how and want to take the effort to do in correctly

READ THIS LINK

http://garage.grumpysperformance.co...-x-1-how-do-you-set-this-up.11688/#post-54747

http://www.jenvey.co.uk/

BTW IF YOU THINK OVER CARBING AN ENGINES A HUGE CONCERN,HERES A VIDEO OF A GUY RUNNING 4 750 quadrajet 4 barrel carbs on a car engine, and once tunned for the application it seems to run decently

the old 4 deuce and 6 deuce intakes look impressive but rarely run as well as dual quads, dual quads on a well designed tunnel ram intake , or if you must have multi carburetors Id suggest the newer 4 weber intakes which are all far easier to tune

even the older constant flow mechanical fuel injections far better

RELATED THREAD

viewtopic.php?f=55&t=4302&p=12406&hilit=intakes#p12406

viewtopic.php?f=32&t=3916&p=10420&hilit=intakes#p10420

Pontiac 6 deuce intakes were manufactured in several versions, like the two design,s posted below, the log style manifolds were also made for caddy oldsmobile and ford

the early log single bank design was common but rarely worked very well as the runner length was very short

the later cross ram versions worked far better

IF YOU KNEW HOW TO TUNE

http://www.thecarburetorshop.com/

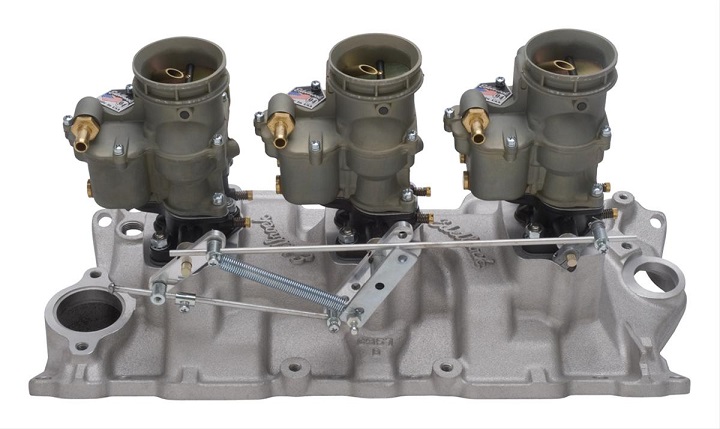

Addition of tripower to a V-8 engine

General

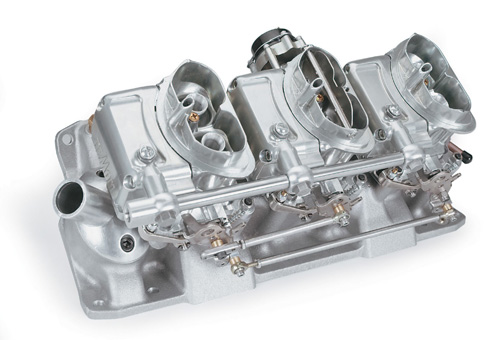

One common “accessory” to a “hot rod” engine set-up is tripower. This is generally done for “looks”, although a few misguided individuals still make the addition for performance. In truth, a “perfect” tripower will never compete (on an 8 cylinder engine) with a properly sized single four-barrel, or better yet, a properly sized dual four-barrel setup. But the reason for the article is not to discuss performance, rather as an attempt to help those who wish to add tripower to their engine.

There are basically 4 methods of adding tripower to an engine. From easiest to most difficult, these are:

(1) If available, install a complete original factory tripower

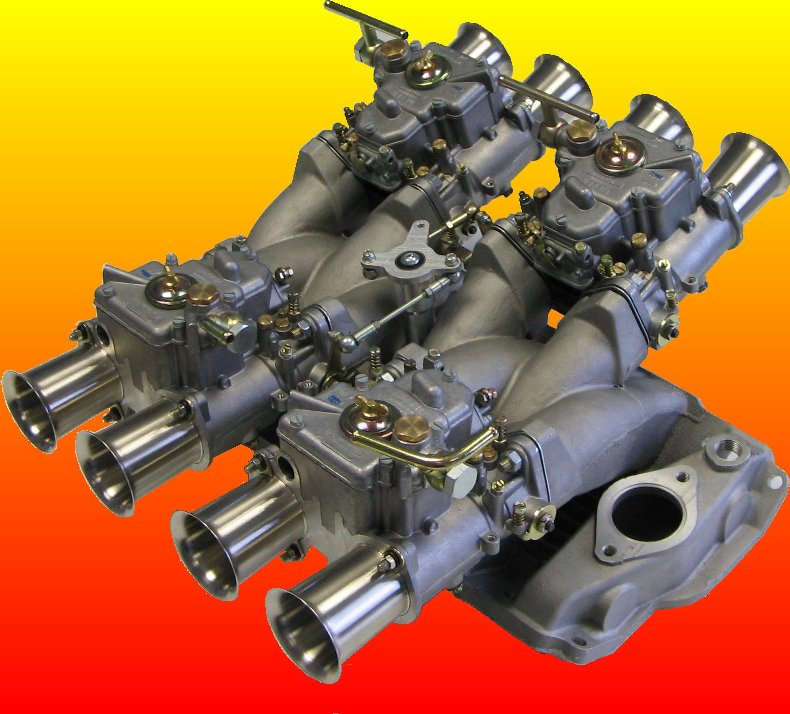

(2) Install an aftermarket intake with original factory tripower carbs from a similar displacement engine

(3) Install an aftermarket intake and non-tripower carbs with solid linkage

(4) Install an aftermarket intake and non-tripower carbs with progressive linkage.

Unless you opt for option 1, the enjoyment of your tripower will probably be in proportion to the amount and quality of research you do PRIOR to its purchase!

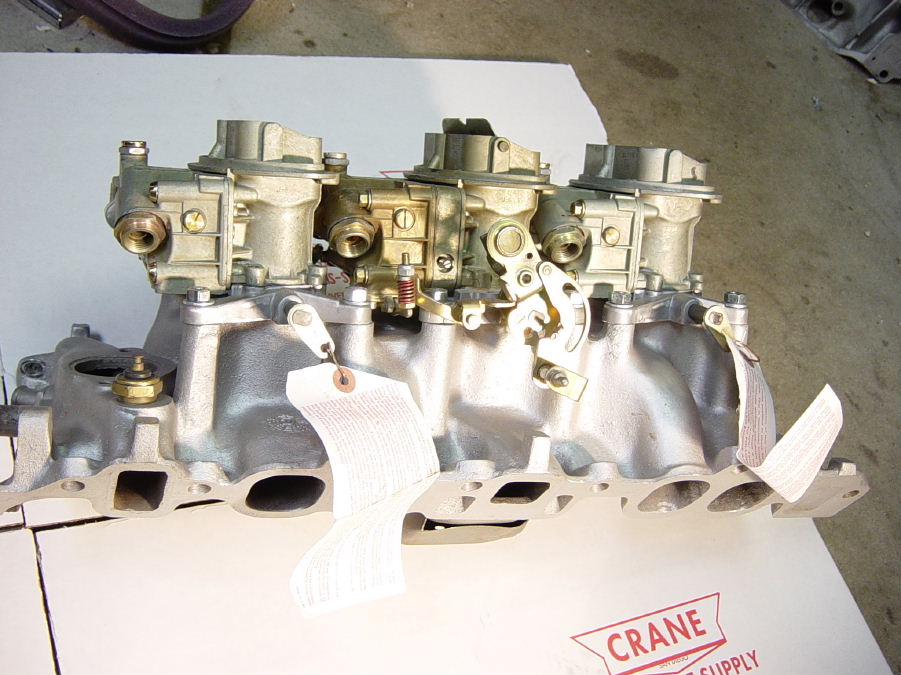

Installing a complete original factory tripower

This is the easiest method of acquiring tripower. All it requires is money. BUT, all of the engineering has been done for you. Simply find a good reference on your engine, and make certain that you have updated the entire engine to the tripower engine specifications. This could include cylinder heads, camshaft, distributor, and exhaust manifolds. If all components are updated, simply find a reliable source for the complete tripower, rebuild it if used, and bolt it on.

Installing aftermarket manifold/original tripower carbs

This is the second easiest installation. BUT some engineering is necessary. One should select a factory unit from a very similar in displacement engine. Thus if one has a 350 Chevrolet, a factory Chevrolet 348 tripower would make a good donor. If one has a 390 Ford, then original tripower carbs from a 389 Pontiac would be a good choice.

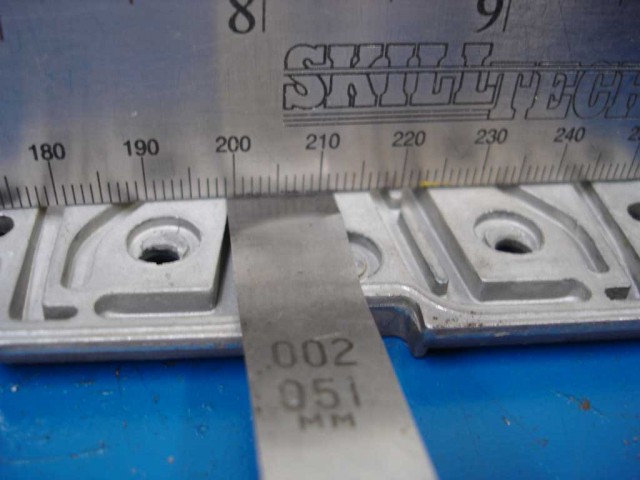

Assuming you acquire carburetors of the proper size; your most difficult issue now will be linkage. Many original equipment tripowers used vacuum linkage, simply because it was much more reliable FOR NON RACE APPLICATIONS than mechanical linkage. However, vacuum linkage today can be difficult to obtain, and incredibly expensive. Thus, many will opt for mechanical linkage due to financial consideration. If you should decide to use mechanical linkage; TAKE A LOOK AT THE WAY THE FACTORIES PRODUCED MECHANICAL LINKAGE! Since these units were originally designed for progressive linkage, progressive is what you will need to use. The big issue is with how the links are affixed to the throttle arms. Take a look at a typical Pontiac link from the front carb to the rear carb. The arm on the rear carb will have a round hole in which to attach the link. The front carb has a horizontal slot. This slot is necessary to compensate for the coefficient of linear expansion. When installing the link, the link should be placed in the round hole of the rear carb and the retaining clip installed. The link should now be installed into the horizontal slot of the front carburetor, and the link bent as necessary such that the link is installed in the center of the slot. The retaining clip should now be installed. FAILURE TO MAKE THIS ADJUSTMENT WILL RESULT IN ONE OR THE OTHER OF THE END CARBS ALWAYS CRACKED OPEN, AND EITHER A POOR OR IRRATIC IDLE CONDITION!

Next comes fabrication of fuel lines. At various times, different manufacturers have used steel, aluminum, and copper. We would suggest using steel. Make sure you double flare the tubes when fabricating the lines. Aluminum or copper may be used, however consider that flaring will “work harden” the tubes, and vibration can result in failure at these locations. Also, tightening the lines adds stress to the flares. We suggest NEVER reusing aluminum or copper lines. Thus should you need to rebuild the carbs, you should replace the lines.

Aftermarket air cleaners can be challenging; however, the reproduction Ford air cleaner can be purchased with the bottom unpunched, and a ready supply of filters is available. Should you go this route NEVER punch the bottom until the unit is installed on the engine (or consider the position of every other item in the engine compartment so you don’t punch in the wrong place). The last unit I did had to be offset approximately 1 inch to clear a coil bracket.

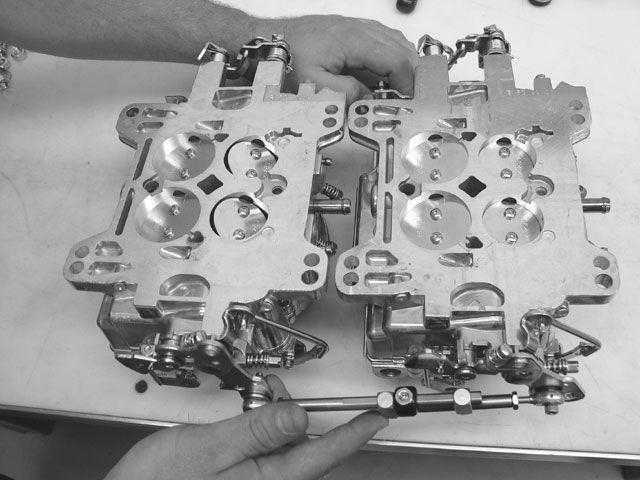

Installing aftermarket intake/non-tripower carbs with solid linkage

This installation is much more difficult than the section above but MUCH EASIER THAN THE INSTALLATION IN THE SECTION TO FOLLOW!

The first AND MOST IMPORTANT issue here is selection of the carburetors. Contrary to popular belief, three 250 CFM carburetors will not flow 750 CFM. What they will flow will depend on a multitude of variables, including the size of the carburetors, the size of the engine, and the efficiency (or lack thereof) of the intake manifold. What carbs to use? This becomes a matter of experience; but generally three from an engine of approximately three quarters size of your engine should work. Thus, if you have a 400 Ford, three carbs from a Ford 289 or 302 might suffice well. ANOTHER KEY IS ALL THREE CARBS SHOULD BE IDENTICAL BY TAG NUMBER! Just because the carbs fit the manifold is absolutely no guarantee that they will function well.

Linkage will require fabrication. Since all three carburetors will be functioning simultaneously, the paragraph in the above section concerning the coefficient of linear expansion does not apply.

If you need a choke, choke all three carburetors.

Use the idle circuit on all three carburetors.

CARBURETORS MUST BE SYNCHRONIZED.

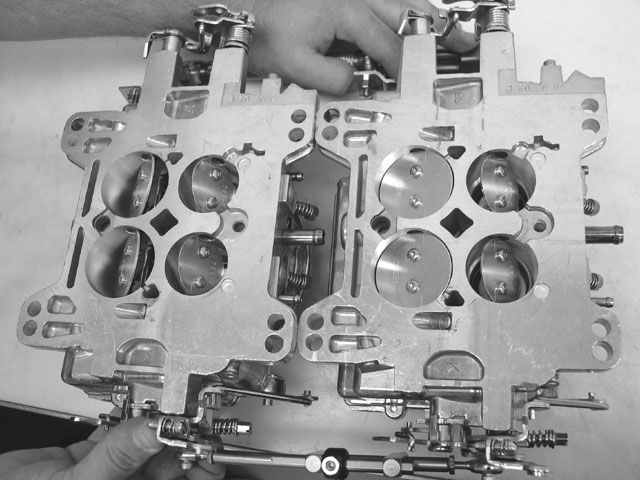

Installing aftermarket intake/non-tripower carb and progressive linkage

This is by far the most difficult installation, and, ironically, the type installation often done by novice mechanics. Because of all of the issues involved in trying to make this setup work, WE WILL NOT BUILD THIS SETUP FOR ANYONE!

For those who have lots of free time, and a good automotive machine shop at their disposal, here are some guidelines on how to proceed:

The first issue is carburetor selection, and the selection of the center carburetor is critical. Since the center carburetor will be responsible for idle fuel, low speed, fuel, and fuel at cruise; THEREFORE, THE CENTER CARBURETOR MUST BE FROM A COMPARABLE SIZED ENGINE. Lets say you are putting a tripower on a 390 Ford. I don’t care what bolt pattern you have, a Stromberg 97 or a Holley 94 is not going to work for the center carburetor. You need an original carburetor from a 390 Ford! Failure to provide the proper sized (internally, not bolt pattern) carburetor will lead to idle and low-speed issues and may lead to a failed engine!

End carbs should be similar in size to the center, and while they may differ in identification number from the center, the front and rear should match each other.

As to the end carbs, MACHINE WORK IS NECESSARY ON VIRTUALLY ANY MODERN CARB!

Why, well, consider this: the throttle plates in end carbs MUST completely close and seal. Throttle plates in a single two-barrel application never completely close. Thus the manufacturer uses a thin throttle plate (to minimize air disturbance) and they close at a very small angle (to maximize adjustment range). To seal the throttle plates, the manufacturer used a much thicker plate on factory end carbs, and closed them at a much greater angle. Trying to force the thin plates to close and seal will result in the plates either not sealing or sticking in the throttle bore, and never opening.

Thus, to make a non-tripower modern carb function as a tripower end, one must first machine thicker throttle plates, and then machine a new throttle shaft to accommodate the thicker plates.

Yes, I am aware that there are some aftermarket throttle bodies available for Rochester 2-barrel carbs. However, the ones I have seen are aluminum. Virtually every carburetor that comes into our shop with an aluminum throttle body REQUIRES bushing. Think about Q-Jets, Stromberg WW’s, Carter BBS and BBD carbs. They all require bushing the first time they are rebuilt. The only exception seems to be the Carter AFB and AVS carbs which have a long bearing surface, and are deliberately set up loose (0.016~0.022 inch) rather than other carbs which are set up at 0.004~0.006. Maybe someone is now producing throttle bodies from cast iron, or installing bushings in the new aluminum throttle bodies, but if so, I am unaware of them.

Also, Rochester used at least 15 different throttle body gaskets on both the two common (large and small) Rochester 2-barrel carbs. This is because 1 size DOESN’T fit all (if you don’t believe me, try walking a mile in your spouse’s shoes)! The aftermarket throttle bodies may (or may not) work with the carbs you selected.

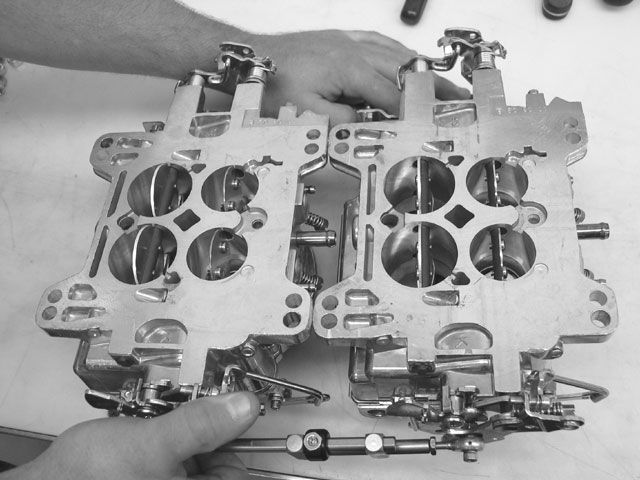

Idle circuits should be completely removed and plugged for end carburetors.

Power valves (if present) should be removed from the end carburetors. Since the end carbs are “dumper” carbs, trying to make the power valve function is just added complexity. Figure the amount of fuel which the power valve adds to the main metering circuit, and increase the main metering jets to provide this fuel.

Chokes are not necessary on end carbs using in progressive linkage setups, and should be removed. If an automatic choke, remember to plug the vacuum port supplying vacuum to the choke. Remove the choke butterfly and shaft. Plug the mounting holes for the shaft using aluminum drive plugs.

Once you have selected the carbs and modified the ends you can refer to previous sections for linkage (see factory progressive), fuel lines, air cleaners, etc.

You still have to calibrate the carbs. To do this, fabricate block off plates for the end plenums of the manifold, and install the plates, not the end carbs. Calibrate the center carb to run the engine up to about 500 RPM more than your normal cruise. Then remove the block off plates, and install the end carbs. Now calibrate for wide-open throttle. If your end carbs are machined properly, there will be no degradation of idle or low speed performance when the end carbs are installed. If degradation occurs, your end carbs need more work.

Good luck.

Last edited by a moderator: