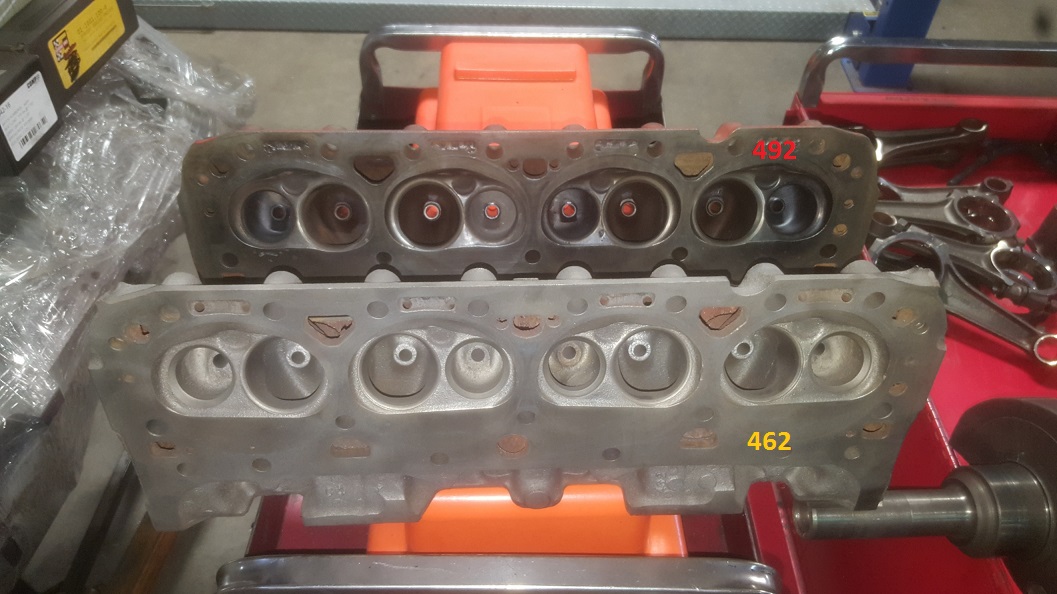

"hey GRUMPYVETTE,I just picked up 492 FUELIE HEADS FOR CHEAP..CAN I GET THEM TO PRODUCE 400 HP!"

SURE you can get those heads to produce 400hp,

but for the same money you could most likely make an additional 40-60 more hp with better aftermarket cylinder heads,TECHNOLOGY HAS ADVANCED A GREAT DEAL SINCE FUELIE HEADS WERE THE HOT TICKET, in fact they are very old outdated tech now!

now Im not saying that the guy selling those fuelie heads may not have even more cash invested in machine work than he's asking for the heads, machine work invested in those heads, can easily get expensive,its just that paying big bucks for fuelie heads , when your goal is making power and not building a period correct numbers matching car restoration is LUDICROUS, as most of the better aftermarket heads easily out perform them, even if you bought them thinking they were a good deal, you would be out looking for better heads within the year, and be out the money you spent, because they flow less than vortec truck heads , there's easily an extra 40-60 hp in better heads.

its easy to spend $500 plus on old heads reconditioning them, but the fact is that the 50 year old technology, small ports and less than ideal design, plus dealing with 40-50 year old castings makes buying those heads as a practical choice a joke compared to better heads currently available.

Look were all on a budget , and I know the $400-$500 range for reworked fuelie heads, spent sounds a good deal better than some of the more expensive options, but in the long run its wasted cash!

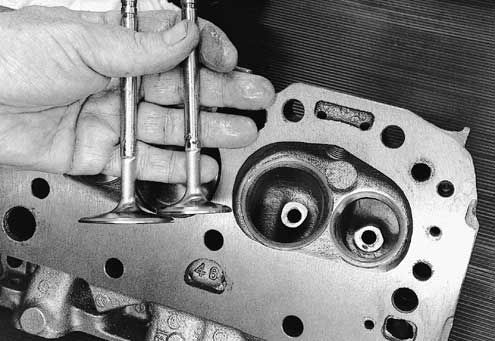

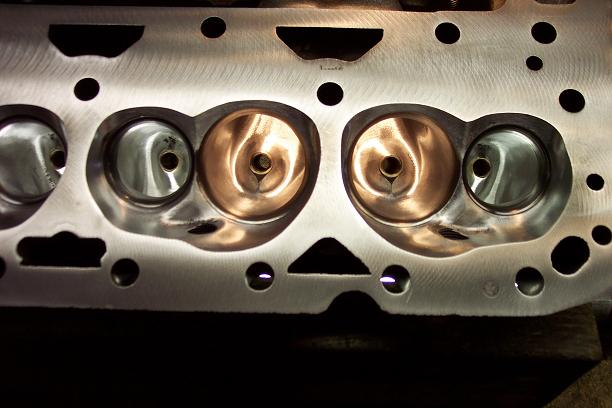

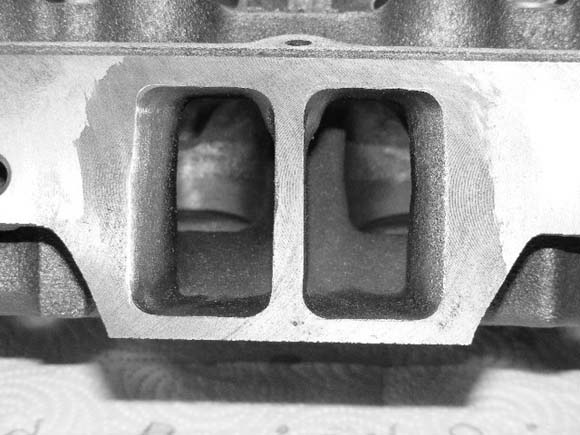

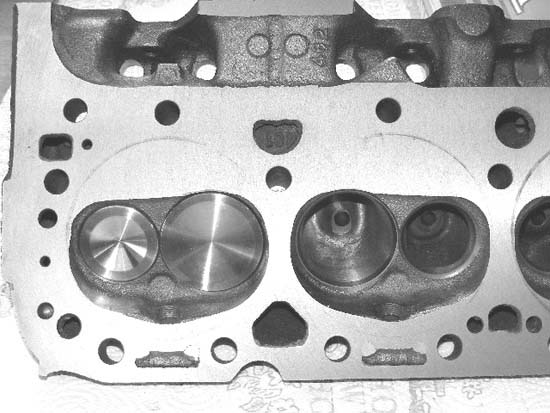

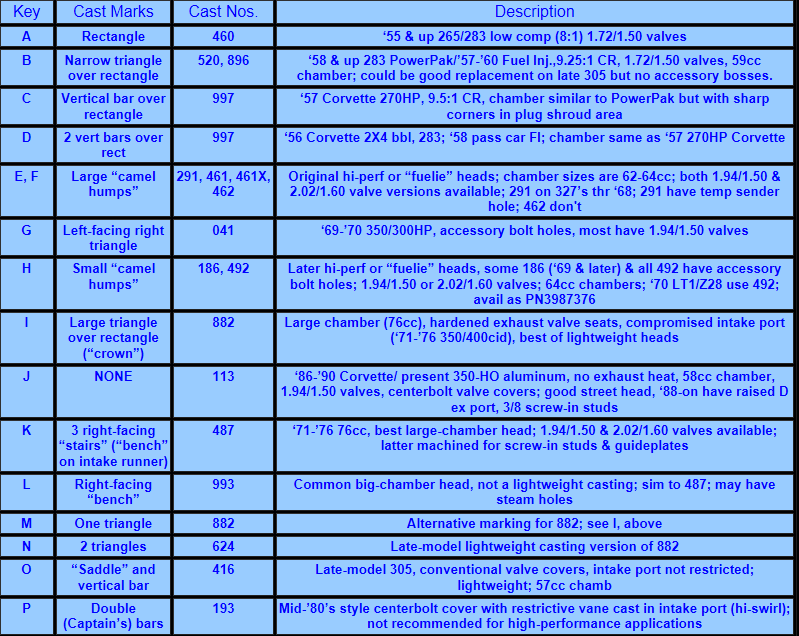

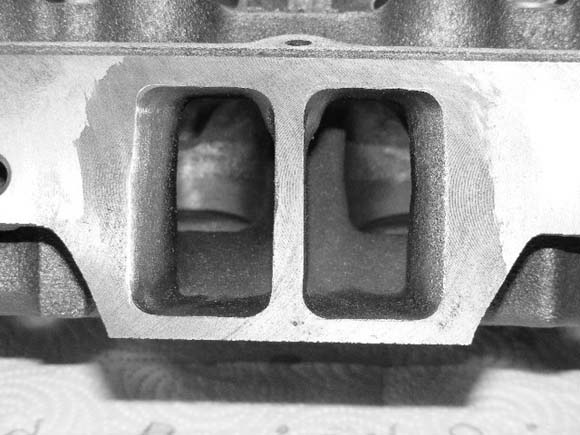

most older FUELIE or camel hump heads are now 45 plus years old and in need of a total rebuild with new hardened valve seats, (needed to run unleaded fuel) new valve guides , (probably new valves ) and certainly a new 3 angle valve job that will be mandatory with the new hardened valve seats, new valve springs , new valve seals etc. and its anyone guess as to the extent of rust damage to the internal coolant passage walls, or stress cracks, or heat warp damage, and even with mild port work they won't flow as well as the newer vortec style ports, with mild port and bowl work, making the cost to value far from ideal, in a performance engine rebuild, you could very easily spend in excess of $600-$700 installing new valve seats, larger valves valve springs and screw in rocker studs in older fuelie heads only to find they flow CONSIDERABLY LESS , air flow and as a result make noticeable less power than a set of out of the box aftermarket cylinder heads, of a more current design.

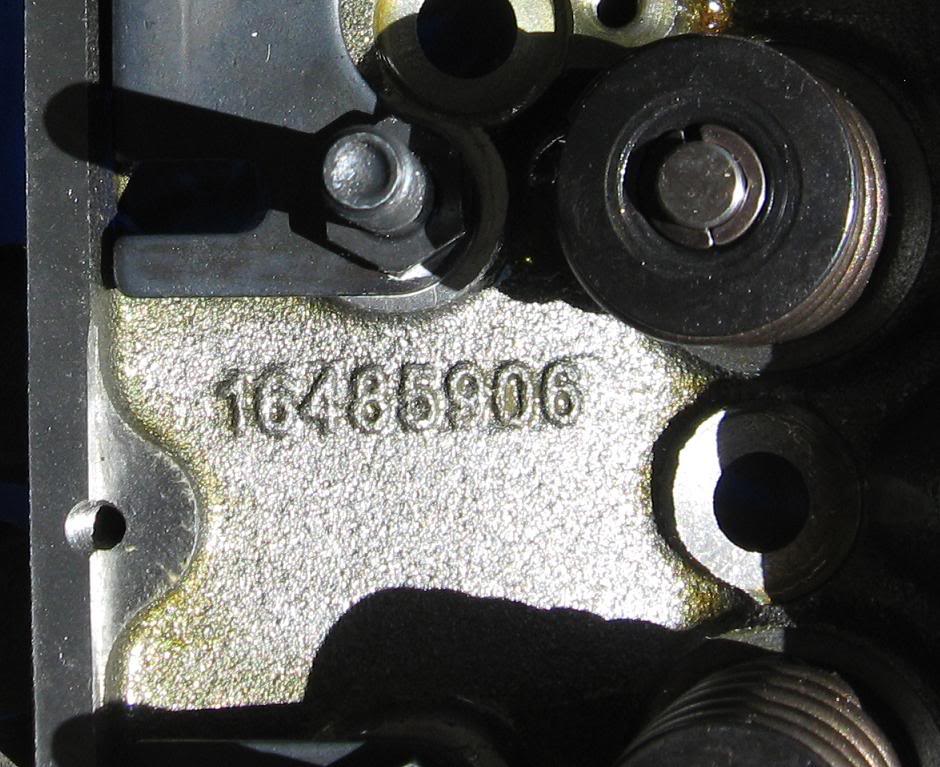

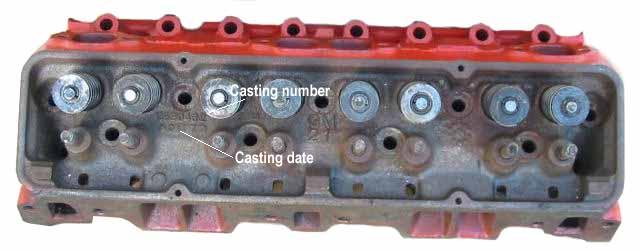

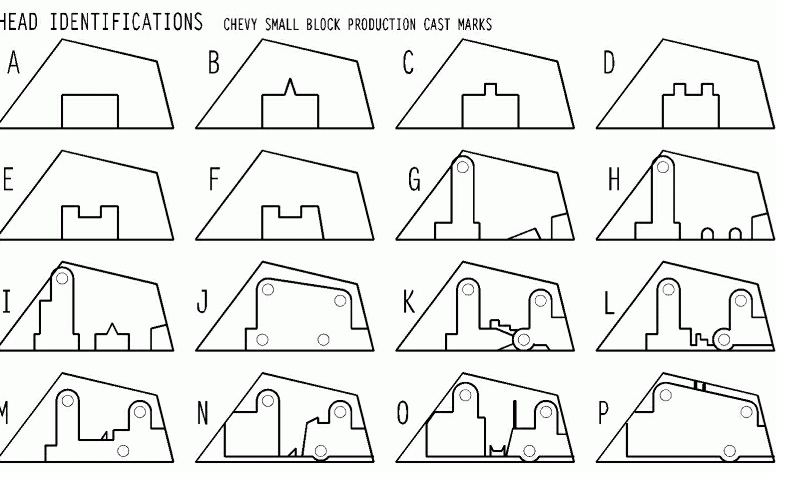

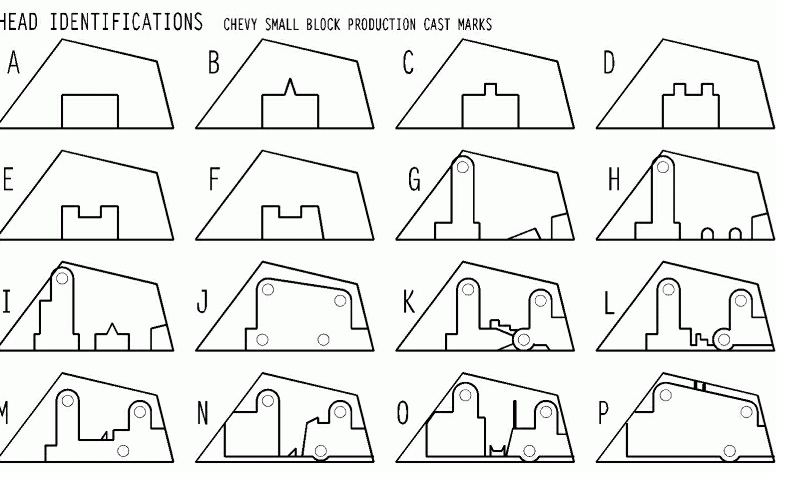

Some of the More Popular Gen I Cast Iron GM Cylinder Heads

http://www.onedirt.com/tech-stories/engine/a-guide-to-vortec-vs-oe-small-block-chevy-heads/

#3767754 – Manufactured from 1959-1961 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3774692 – Manufactured from 1958-1964 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3795896 – Manufactured from 1963-1965 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

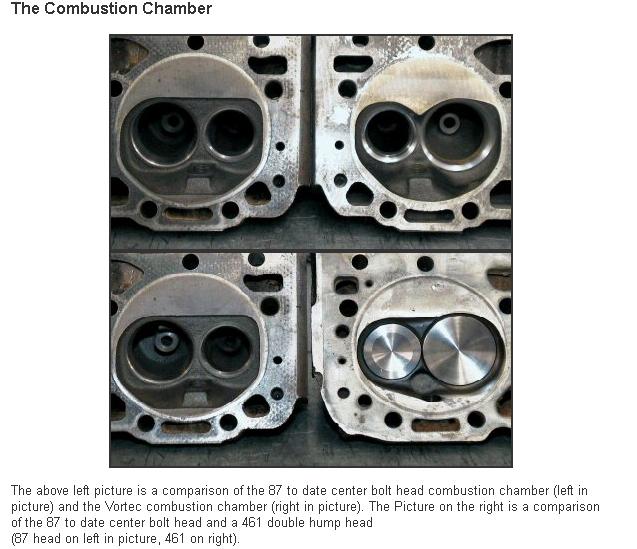

#3782461 – Manufactured from 1964-1966 on 327 Cubic Inch engines. 161/62 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3782461X – Manufactured from 1960-1963 on 283 and 327 Cubic Inch engines. 172/64 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

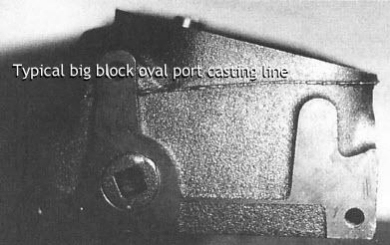

#3890462 – Manufactured from 1966-1967 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol. No accessory mounting holes.

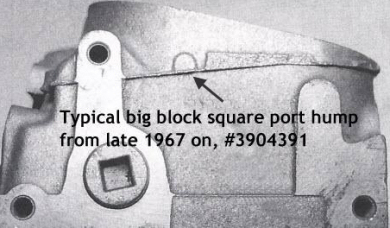

#3917291 – Manufactured from 1967-1968 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol.

#3932441 – Manufactured from 1969-1970 on 350 Cubic Inch engines. 161-165cc intake port. 76cc combustion chamber.

#3932441X – Manufactured from 1969-1970 on 350 and 400 Cubic Inch engines. 161/65cc ports. 80cc combustion chamber. 1.94″ intake/1.5″ exhaust valves.

#333881 – Manufactured from 1974-1975 on 350 Cubic Inch engines. 76cc combustion chamber. 2.02″ intake/1.6″ Exhaust valves.

#3991492 – Manufactured from 1970 on 350 Cubic Inch engines. Available on the LT1 engine and over the counter. 64cc combustion chamber. Either straight or angled plugs.

buying out dated fuelie heads with todays increased tech aftermarket heads available if max performance is your goal is a bad joke, as you can easily put $1200 into machine work and porting and not come close to some of the better current aluminum aftermarket head flow levels

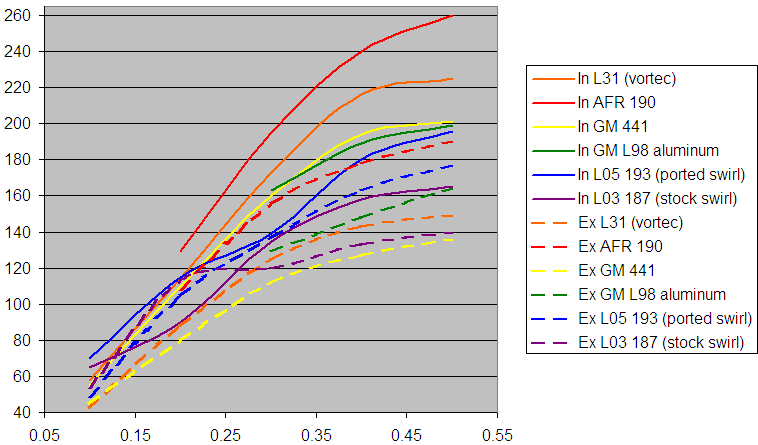

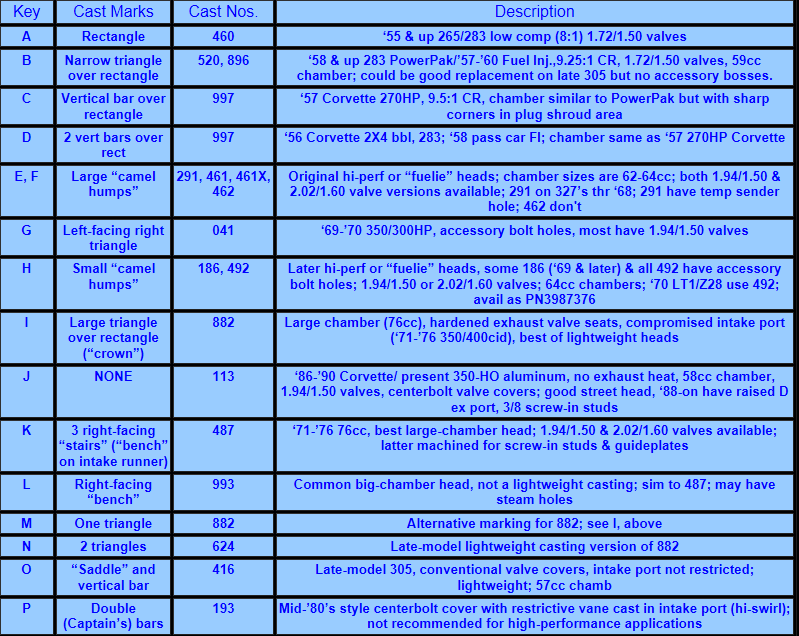

Most Stock “double hump” heads flow in the range of 202 cfm intake and 141 cfm on the exhaust, in the typical lift of a average muscle car era race cam, where valve lift rarely exceeded .550 higher lift and increased duration adds little to flow, mild port work and a multi angle valve job by a skilled & experienced port work job can generally increase peak flow to the 230-237 cfm int 200 ex range.

these were great heads back in the 1960s but current design and testing technology has far surpassed that flow and power level nearly 60 years after they were originally used.

BTW not all fuelie heads had similar potential, or the larger 2.02/1.60 valves ,the 461X head casting was one of the better options , but still required rather extensive mods to perform at its max potential, if your looking for (X) on the fuelie head casting, the 461X head is that the intake port, this head is 170 cc intake port casting where all the other camel hump heads are 155 cc. This was worth 15-35 hp depending on what they allowed you to do with the port work and valves on the heads, and that hp difference was competitively significant.

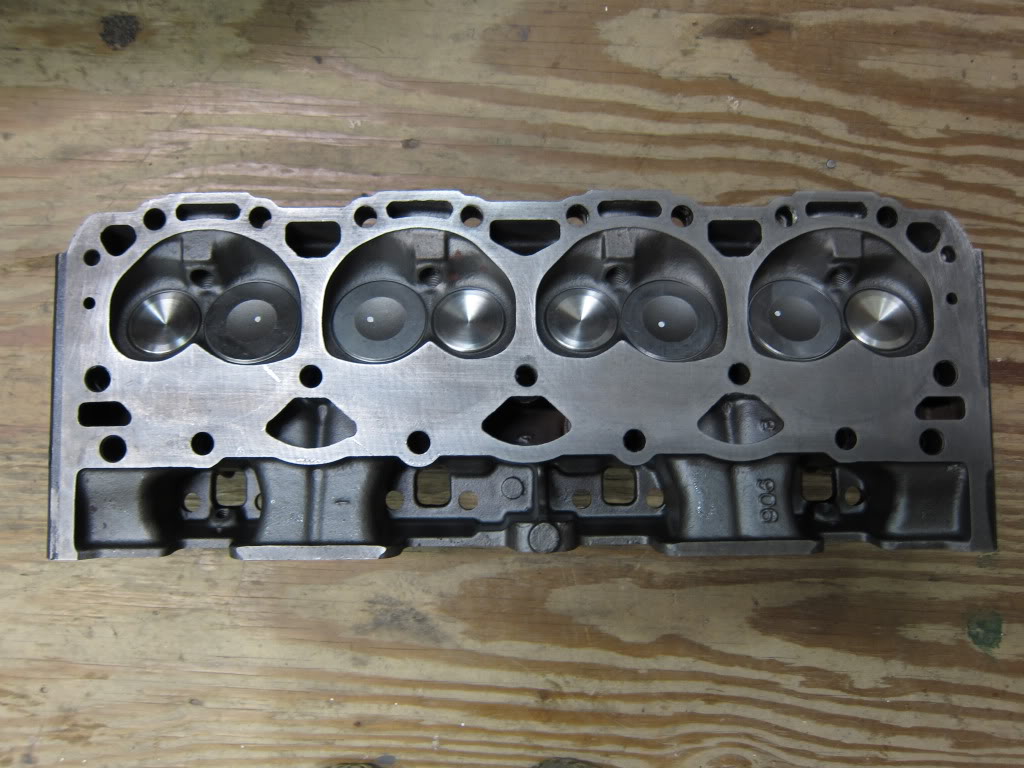

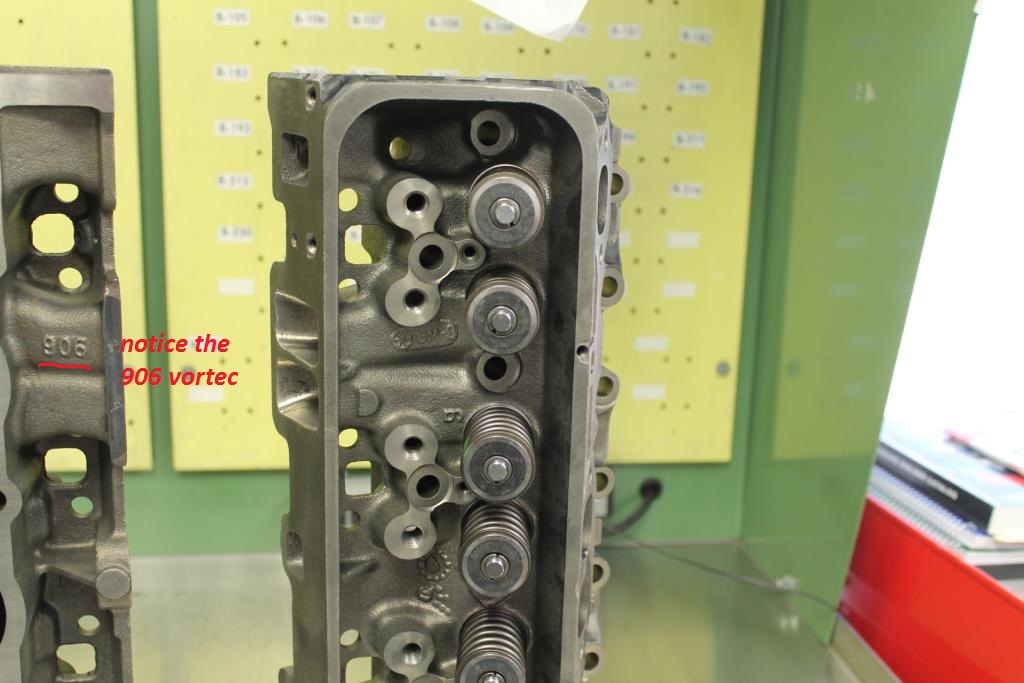

Fast forward to more modern times, the 350 Vortec heads have 170 cc intake ports. That is most of their advantage compared to other cast iron heads also.

A VIDEO DART VS 882 chevy heads TO WATCH

http://www.youtube.com/watch?annotation ... v3ZkqZiMjI

http://www.jegs.com/i/Dart/301/127422/10002/-1?parentProductId=1691309#moreDetails

http://www.airflowresearch.com/index.php?cPath=24_29

http://www.jegs.com/i/Brodix/158/1021001/10002/-1?parentProductId=760699

http://www.profilerperformance.com/raci ... -23-degree

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=2099&p=17024&hilit=FUELIE#p17024

viewtopic.php?f=52&t=3613&p=12743&hilit=fuelie#p12743

http://www.jegs.com/i/GM+Performance/80 ... 6/10002/-1

http://www.summitracing.com/parts/DRT-10311112P/

http://www.summitracing.com/parts/TFS-30400001/

http://www.jegs.com/i/GM+Performance/80 ... 0/10002/-1

http://www.jegs.com/i/Brodix/158/1021004/10002/-1

http://www.profilerperformance.com/sbc-heads-176.html

3991492....70......350..........LT1,Camel hump,accessory holes,64cc, straight plug

3991492....70-up................over the counter,Camel hump,64cc, straight or angle plug

ALMOST ALL the FUELIE heads CAN support 400 plus flywheel hp IF THE OTHER COMPONENTS USED are well matched, and you do a port & bowl area clean up on the heads,clearance them for a .600 valve lift add the right springs and screw in rocker studs and make sure the displacement and compression ratio, and cam timing are carefully matched to the cars gearing, but your dealing with heads that are about 40 year old technology and in questionable condition,

want a combo that easily gets there,

build a balanced /correctly clearanced 10.5:1 cpr 383 sbc with

this cam

http://www.crower.com/misc/cam_spec/cam_finder.php?part_num=00351&x=36&y=7

this intake

http://www.summitracing.com/parts/HLY-300-110/

full length 1 5/8" tuned headers and a decent 750cfm carb and a good ignition

matched to a 4.11:1 rear gear and a manual transmission, and feed it race octane gas

its going to be a P.I.T.A. on the street but it will get you 400hp at the fly wheel if you do it correctly

"the question usually goes, hey, got a chance to buy fuelie heads for $100- $500, is this a great deal or what?"

thirty years ago FUELIE HEADS were the HOT TICKET

but your dealing with heads that are thirty year old technology, they will most likely need at least a valve job,new valve guides and new springs and port work, by the time you put that much work and money in those heads you'll have more than likely spent more money for worse results than buying the more modern heads that have not had 30 plus years of stress,corrosion,and bad valve jobs

http://www.fastnuf.com/Headguide.html

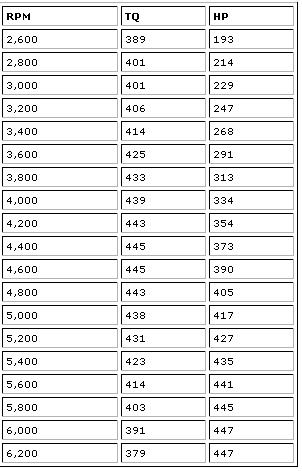

HERES AVERAGE FUELIE HEAD FLOW NUMBERS

http://www.kendrick-auto.com/462_chevy_head.htm

http://www.purplesagetradingpost.com/su ... eads1.html

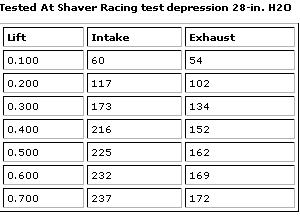

heres two common performance cylinder heads that are available today measured on the same flow bench

http://www.kendrick-auto.com/dart_cs_iron_eagle_215.htm

http://www.kendrick-auto.com/brodix_track_i__cs.htm

THE CAM AND CYLINDER Heads are some of the MOST IMPORTANT PARTS ON YOUR ENGINE AS FAR AS DETERMINING YOUR HP/TQ POTENTIAL

YES THE FUELIE HEADS ARE BETTER THAN MOST STOCK HEADS, YES THEY CAN BE PORTED BY EXPERTS AND MAKE GOOD HP,BUT BY TODAY'S STANDARDS THEY ARE STILL LESS THAN IDEAL.

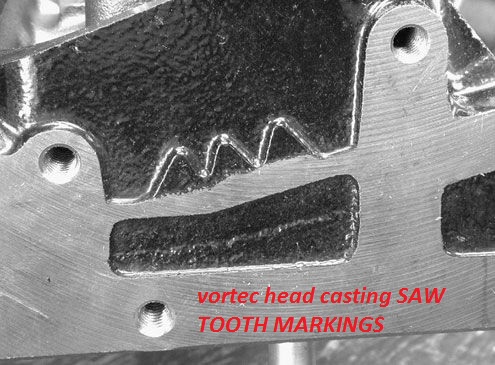

EVEN THE COMMON VORTEC TRUCK HEADS CAN EASILY OUT FLOW THEM,

http://www.kendrick-auto.com/vortec_cs_gm_head.htm

DO YOURSELF A HUGE FAVOR AND IF YOU SPEND MONEY ON ALMOST NO OTHER PARTS BUY GOOD HEADS, LOOK AT THESE ENGINE BUILDS

http://www.ryanscarpage.50megs.com/combos1.html

THE ONE THING YOU'LL FIND OUT IS HIGH HP ENGINES REQUIRE GOOD CYLINDER HEADS AND A MATCHING CAM, I CAN,T THINK OF A MUCH BIGGER OR MORE COMMON MISTAKE THAT TRYING TO BUILD MAX PERFORMANCE WHILE RESTRICTING THE ENGINES POTENTIAL WITH STOCK HEADS

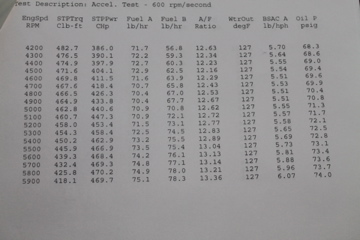

a rough FORMULA/gauge to guess the hp POTENTIAL FROM THE CYLINDER HEADS FLOW NUMBERS is (.257 x flow at max cam lift x 8= potential max hp)

so if you have 225cfm= about 462 hp

if you have 260cfm= 535 hp

now your highly unlikely to reach MAX HP POTENTIAL but the better heads will almost ALWAYS SHOW that 15% or better results. on a 400hp engine running fuelie heads that is likely to mean you would have had 460hp with the better heads (15% improvement)

look over these heads

ALPHABETICAL ORDER

AFR

BRODIX

CANFIELD

DART

EDELBROCK

G.M. PERFORMANCE

PRO ACTION

TRICKFLOW

WORLD PRODUCTS

heads they all have better heads

LINKS WORTH READING

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.circletrack.com/enginetech/c ... index.html

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=240&p=5334&hilit=+numbers#p5334

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=333&p=407#p407

SURE you can get those heads to produce 400hp,

but for the same money you could most likely make an additional 40-60 more hp with better aftermarket cylinder heads,TECHNOLOGY HAS ADVANCED A GREAT DEAL SINCE FUELIE HEADS WERE THE HOT TICKET, in fact they are very old outdated tech now!

now Im not saying that the guy selling those fuelie heads may not have even more cash invested in machine work than he's asking for the heads, machine work invested in those heads, can easily get expensive,its just that paying big bucks for fuelie heads , when your goal is making power and not building a period correct numbers matching car restoration is LUDICROUS, as most of the better aftermarket heads easily out perform them, even if you bought them thinking they were a good deal, you would be out looking for better heads within the year, and be out the money you spent, because they flow less than vortec truck heads , there's easily an extra 40-60 hp in better heads.

its easy to spend $500 plus on old heads reconditioning them, but the fact is that the 50 year old technology, small ports and less than ideal design, plus dealing with 40-50 year old castings makes buying those heads as a practical choice a joke compared to better heads currently available.

Look were all on a budget , and I know the $400-$500 range for reworked fuelie heads, spent sounds a good deal better than some of the more expensive options, but in the long run its wasted cash!

most older FUELIE or camel hump heads are now 45 plus years old and in need of a total rebuild with new hardened valve seats, (needed to run unleaded fuel) new valve guides , (probably new valves ) and certainly a new 3 angle valve job that will be mandatory with the new hardened valve seats, new valve springs , new valve seals etc. and its anyone guess as to the extent of rust damage to the internal coolant passage walls, or stress cracks, or heat warp damage, and even with mild port work they won't flow as well as the newer vortec style ports, with mild port and bowl work, making the cost to value far from ideal, in a performance engine rebuild, you could very easily spend in excess of $600-$700 installing new valve seats, larger valves valve springs and screw in rocker studs in older fuelie heads only to find they flow CONSIDERABLY LESS , air flow and as a result make noticeable less power than a set of out of the box aftermarket cylinder heads, of a more current design.

Some of the More Popular Gen I Cast Iron GM Cylinder Heads

http://www.onedirt.com/tech-stories/engine/a-guide-to-vortec-vs-oe-small-block-chevy-heads/

#3767754 – Manufactured from 1959-1961 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3774692 – Manufactured from 1958-1964 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3795896 – Manufactured from 1963-1965 on 283 Cubic Inch engines. Called the “Power Pack” cylinder heads. 1.72˝ intake valves and 1.50˝ exhaust valves. 60cc Combustion Chambers.

#3782461 – Manufactured from 1964-1966 on 327 Cubic Inch engines. 161/62 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3782461X – Manufactured from 1960-1963 on 283 and 327 Cubic Inch engines. 172/64 cc port volumes, 62cc combustion chamber. Identified by Double Camel hump symbol.

#3890462 – Manufactured from 1966-1967 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol. No accessory mounting holes.

#3917291 – Manufactured from 1967-1968 on 302, 327, and 350 Cubic Inch engines. 64cc combustion chamber. Identified by Camel hump symbol.

#3932441 – Manufactured from 1969-1970 on 350 Cubic Inch engines. 161-165cc intake port. 76cc combustion chamber.

#3932441X – Manufactured from 1969-1970 on 350 and 400 Cubic Inch engines. 161/65cc ports. 80cc combustion chamber. 1.94″ intake/1.5″ exhaust valves.

#333881 – Manufactured from 1974-1975 on 350 Cubic Inch engines. 76cc combustion chamber. 2.02″ intake/1.6″ Exhaust valves.

#3991492 – Manufactured from 1970 on 350 Cubic Inch engines. Available on the LT1 engine and over the counter. 64cc combustion chamber. Either straight or angled plugs.

buying out dated fuelie heads with todays increased tech aftermarket heads available if max performance is your goal is a bad joke, as you can easily put $1200 into machine work and porting and not come close to some of the better current aluminum aftermarket head flow levels

Most Stock “double hump” heads flow in the range of 202 cfm intake and 141 cfm on the exhaust, in the typical lift of a average muscle car era race cam, where valve lift rarely exceeded .550 higher lift and increased duration adds little to flow, mild port work and a multi angle valve job by a skilled & experienced port work job can generally increase peak flow to the 230-237 cfm int 200 ex range.

these were great heads back in the 1960s but current design and testing technology has far surpassed that flow and power level nearly 60 years after they were originally used.

BTW not all fuelie heads had similar potential, or the larger 2.02/1.60 valves ,the 461X head casting was one of the better options , but still required rather extensive mods to perform at its max potential, if your looking for (X) on the fuelie head casting, the 461X head is that the intake port, this head is 170 cc intake port casting where all the other camel hump heads are 155 cc. This was worth 15-35 hp depending on what they allowed you to do with the port work and valves on the heads, and that hp difference was competitively significant.

Fast forward to more modern times, the 350 Vortec heads have 170 cc intake ports. That is most of their advantage compared to other cast iron heads also.

A VIDEO DART VS 882 chevy heads TO WATCH

http://www.youtube.com/watch?annotation ... v3ZkqZiMjI

http://www.jegs.com/i/Dart/301/127422/10002/-1?parentProductId=1691309#moreDetails

http://www.airflowresearch.com/index.php?cPath=24_29

http://www.jegs.com/i/Brodix/158/1021001/10002/-1?parentProductId=760699

http://www.profilerperformance.com/raci ... -23-degree

http://forum.grumpysperformance.com/viewtopic.php?f=44&t=2099&p=17024&hilit=FUELIE#p17024

viewtopic.php?f=52&t=3613&p=12743&hilit=fuelie#p12743

http://www.jegs.com/i/GM+Performance/80 ... 6/10002/-1

http://www.summitracing.com/parts/DRT-10311112P/

http://www.summitracing.com/parts/TFS-30400001/

http://www.jegs.com/i/GM+Performance/80 ... 0/10002/-1

http://www.jegs.com/i/Brodix/158/1021004/10002/-1

http://www.profilerperformance.com/sbc-heads-176.html

3991492....70......350..........LT1,Camel hump,accessory holes,64cc, straight plug

3991492....70-up................over the counter,Camel hump,64cc, straight or angle plug

ALMOST ALL the FUELIE heads CAN support 400 plus flywheel hp IF THE OTHER COMPONENTS USED are well matched, and you do a port & bowl area clean up on the heads,clearance them for a .600 valve lift add the right springs and screw in rocker studs and make sure the displacement and compression ratio, and cam timing are carefully matched to the cars gearing, but your dealing with heads that are about 40 year old technology and in questionable condition,

want a combo that easily gets there,

build a balanced /correctly clearanced 10.5:1 cpr 383 sbc with

this cam

http://www.crower.com/misc/cam_spec/cam_finder.php?part_num=00351&x=36&y=7

this intake

http://www.summitracing.com/parts/HLY-300-110/

full length 1 5/8" tuned headers and a decent 750cfm carb and a good ignition

matched to a 4.11:1 rear gear and a manual transmission, and feed it race octane gas

its going to be a P.I.T.A. on the street but it will get you 400hp at the fly wheel if you do it correctly

"the question usually goes, hey, got a chance to buy fuelie heads for $100- $500, is this a great deal or what?"

thirty years ago FUELIE HEADS were the HOT TICKET

but your dealing with heads that are thirty year old technology, they will most likely need at least a valve job,new valve guides and new springs and port work, by the time you put that much work and money in those heads you'll have more than likely spent more money for worse results than buying the more modern heads that have not had 30 plus years of stress,corrosion,and bad valve jobs

http://www.fastnuf.com/Headguide.html

HERES AVERAGE FUELIE HEAD FLOW NUMBERS

http://www.kendrick-auto.com/462_chevy_head.htm

http://www.purplesagetradingpost.com/su ... eads1.html

heres two common performance cylinder heads that are available today measured on the same flow bench

http://www.kendrick-auto.com/dart_cs_iron_eagle_215.htm

http://www.kendrick-auto.com/brodix_track_i__cs.htm

THE CAM AND CYLINDER Heads are some of the MOST IMPORTANT PARTS ON YOUR ENGINE AS FAR AS DETERMINING YOUR HP/TQ POTENTIAL

YES THE FUELIE HEADS ARE BETTER THAN MOST STOCK HEADS, YES THEY CAN BE PORTED BY EXPERTS AND MAKE GOOD HP,BUT BY TODAY'S STANDARDS THEY ARE STILL LESS THAN IDEAL.

EVEN THE COMMON VORTEC TRUCK HEADS CAN EASILY OUT FLOW THEM,

http://www.kendrick-auto.com/vortec_cs_gm_head.htm

DO YOURSELF A HUGE FAVOR AND IF YOU SPEND MONEY ON ALMOST NO OTHER PARTS BUY GOOD HEADS, LOOK AT THESE ENGINE BUILDS

http://www.ryanscarpage.50megs.com/combos1.html

THE ONE THING YOU'LL FIND OUT IS HIGH HP ENGINES REQUIRE GOOD CYLINDER HEADS AND A MATCHING CAM, I CAN,T THINK OF A MUCH BIGGER OR MORE COMMON MISTAKE THAT TRYING TO BUILD MAX PERFORMANCE WHILE RESTRICTING THE ENGINES POTENTIAL WITH STOCK HEADS

a rough FORMULA/gauge to guess the hp POTENTIAL FROM THE CYLINDER HEADS FLOW NUMBERS is (.257 x flow at max cam lift x 8= potential max hp)

so if you have 225cfm= about 462 hp

if you have 260cfm= 535 hp

now your highly unlikely to reach MAX HP POTENTIAL but the better heads will almost ALWAYS SHOW that 15% or better results. on a 400hp engine running fuelie heads that is likely to mean you would have had 460hp with the better heads (15% improvement)

look over these heads

ALPHABETICAL ORDER

AFR

BRODIX

CANFIELD

DART

EDELBROCK

G.M. PERFORMANCE

PRO ACTION

TRICKFLOW

WORLD PRODUCTS

heads they all have better heads

LINKS WORTH READING

http://www.strokerengine.com/SBCHeadsFlow.html

http://www.circletrack.com/enginetech/c ... index.html

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=240&p=5334&hilit=+numbers#p5334

http://forum.grumpysperformance.com/viewtopic.php?f=52&t=333&p=407#p407

Last edited by a moderator: