"hey I have a cylinder that started missing and a bent push rod, I pulled the head and heres what I found? any idea as to the cause?"

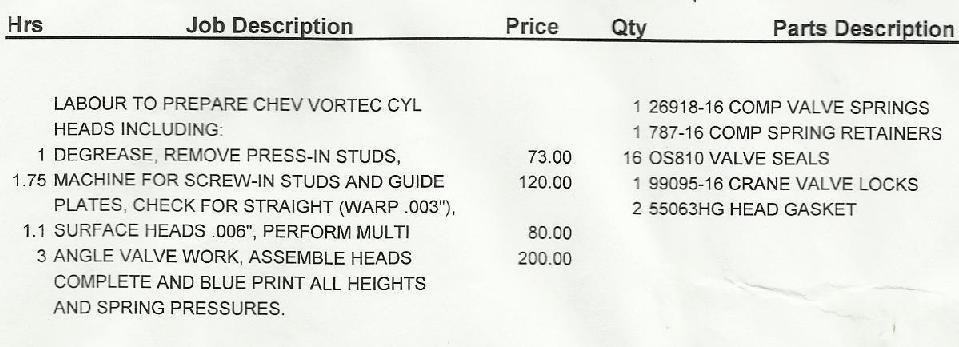

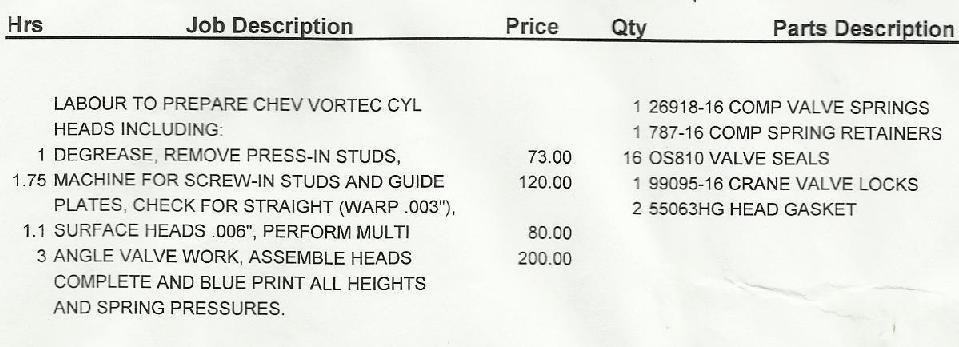

above is a very typical machine shop invoice for reconditioning a set of used vortec heads, notice theres $400 plus in charges and theres a great deal more that could easily be required to recondition used heads, now add the rather typical purchase price of at least $200-$400 for a set of clean used vortec heads and you quickly find you ould buy better head for the cost

a good deal more info on your engine clearances would help a great deal, but actually these are firm indications of clearance issues , most likely AGGRAVATED, or partly caused by improper valve adjustment, or not checking the valve train clearances correctly, since only one cylinder is showing contact,and bending a push rod , and because its takes HUNDREDS OF POUNDS OF FORCE, to bend push rods and damage pistons, you most likely bent a valve in that cylinder , or for some reason the clearances in so check all your valve train related clearances carefully before re-assembly.

I generally see results like this when guys install a performance cam with more lift & duration in a stock engine with-out checking clearances or guys that adjust valves with the engine not running on the engine stand who find they adjusted the valves incorrectly .

the eyebrow marks on the piston obviously indicate valve to piston contact and the fact that the valve contacted the piston outside of the valve relief clearance notch shows a clear indication that valve to piston clearance was most likely never verified

fact

valve train components RARELY just break for no reason

Fact

it takes hundreds of pounds of force to bend push-rods

Fact

IMPROPER CLEARANCES can destroy a valve train or cam in under 30 seconds

Fact

the most common REASON is INCORRECT CLEARANCE OR ROCKER GEOMETRY, or failure to adjust valves properly

FACT

reading links and sub-links helps you isolate the cause, of a failure,... carefully reading through will allow you to avoid having the problem

Fact

In most cases its operator error , or failure to correctly set-up and clearance the valve train that causes problems

Fact

20 minutes -to a couple hours well spent asking questions, and being damn sure you understand the answers, can save you weeks of repairs and machine shop bills

Fact

NO ONE does this the first few times without making SOME mistakes

Fact

having an experienced mentor help guide you through the process tends to reduce the chances of failure

Fact

joining several local corvette or muscle car clubs and helping the older more experienced members work on their cars, and letting them help you on yours, speeds the learning curve

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

http://garage.grumpysperformance.co...ear-articles-you-need-to-read.282/#post-52017

http://garage.grumpysperformance.co...1-6-1-ratio-rockers-and-the-pushrods-rub.198/

http://garage.grumpysperformance.co...lve-springs-loads-and-installed-height.10709/

http://garage.grumpysperformance.co...caused-hydraulic-lifters-to-come-apart.10482/

viewtopic.php?f=44&t=6175&p=19304&hilit=machining+vortec#p19304

viewtopic.php?f=52&t=401&p=6078&hilit=machining+vortec#p6078

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=196

above is a very typical machine shop invoice for reconditioning a set of used vortec heads, notice theres $400 plus in charges and theres a great deal more that could easily be required to recondition used heads, now add the rather typical purchase price of at least $200-$400 for a set of clean used vortec heads and you quickly find you ould buy better head for the cost

a good deal more info on your engine clearances would help a great deal, but actually these are firm indications of clearance issues , most likely AGGRAVATED, or partly caused by improper valve adjustment, or not checking the valve train clearances correctly, since only one cylinder is showing contact,and bending a push rod , and because its takes HUNDREDS OF POUNDS OF FORCE, to bend push rods and damage pistons, you most likely bent a valve in that cylinder , or for some reason the clearances in so check all your valve train related clearances carefully before re-assembly.

I generally see results like this when guys install a performance cam with more lift & duration in a stock engine with-out checking clearances or guys that adjust valves with the engine not running on the engine stand who find they adjusted the valves incorrectly .

the eyebrow marks on the piston obviously indicate valve to piston contact and the fact that the valve contacted the piston outside of the valve relief clearance notch shows a clear indication that valve to piston clearance was most likely never verified

fact

valve train components RARELY just break for no reason

Fact

it takes hundreds of pounds of force to bend push-rods

Fact

IMPROPER CLEARANCES can destroy a valve train or cam in under 30 seconds

Fact

the most common REASON is INCORRECT CLEARANCE OR ROCKER GEOMETRY, or failure to adjust valves properly

FACT

reading links and sub-links helps you isolate the cause, of a failure,... carefully reading through will allow you to avoid having the problem

Fact

In most cases its operator error , or failure to correctly set-up and clearance the valve train that causes problems

Fact

20 minutes -to a couple hours well spent asking questions, and being damn sure you understand the answers, can save you weeks of repairs and machine shop bills

Fact

NO ONE does this the first few times without making SOME mistakes

Fact

having an experienced mentor help guide you through the process tends to reduce the chances of failure

Fact

joining several local corvette or muscle car clubs and helping the older more experienced members work on their cars, and letting them help you on yours, speeds the learning curve

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/adjusting-valves.196/

http://garage.grumpysperformance.co...ear-articles-you-need-to-read.282/#post-52017

http://garage.grumpysperformance.co...1-6-1-ratio-rockers-and-the-pushrods-rub.198/

http://garage.grumpysperformance.co...lve-springs-loads-and-installed-height.10709/

http://garage.grumpysperformance.co...caused-hydraulic-lifters-to-come-apart.10482/

viewtopic.php?f=44&t=6175&p=19304&hilit=machining+vortec#p19304

viewtopic.php?f=52&t=401&p=6078&hilit=machining+vortec#p6078

viewtopic.php?f=52&t=399

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=196

Last edited by a moderator: