I had the valve covers off of my Mark IV big block and noticed some coolant in the oil laying in the top of the heads.

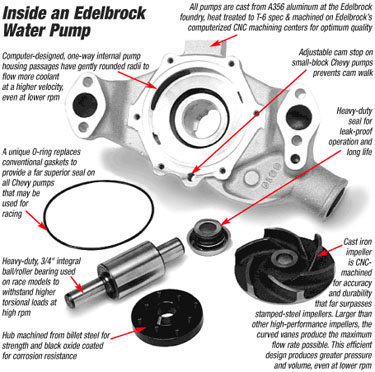

I pressurized the radiator and it held 16psi for 2 hrs. What am I missing? Could the thermostat and the water pump keep the pressure from getting to the intake and block? My thermostat has the float in it that lets the air out and floats and seals when water hits it. I would think 16 psi would sink the float and let the pressure through.

Also, I don't see any oil in the radiator. It should be easy to see since it would go to the top. I thought about just changing the oil and seeing if it happens again, but I need to see where it came from, there was a pretty good amount.

I actually had just driven it for about 30 minutes prior to pressurizing it.

I'll fix whatever it is, I just hate to aimlessly throw parts at it. I'd like to figure out a way to find the leak. If I change intake gaskets I might as well change head gaskets. The right head hits the firewall before it will come over the studs so the motor will have to come out. If I have it that far I might as well tear the whole thing down and have the block and heads magnafluxed. Is there any way to find it before I go that far?

https://www.napaonline.com/en/p/BK_7001006

it may be the result of a crack in the head or block or

just an intake or head gasket leaking, issue, as stated change oil and filter ,

and if the problem returns you darn sure better track down the source before repairs get exponentially more expensive

some cracks won,t leak until the engine heat of the engine thats been running for awhile expands the metal.

if its not up too operating temp, theres no leak.

its not un-common for intake gaskets to leak coolant,

into the lifter gallery if they were not correctly installed or damaged, or intake manifolds to leak coolant

,

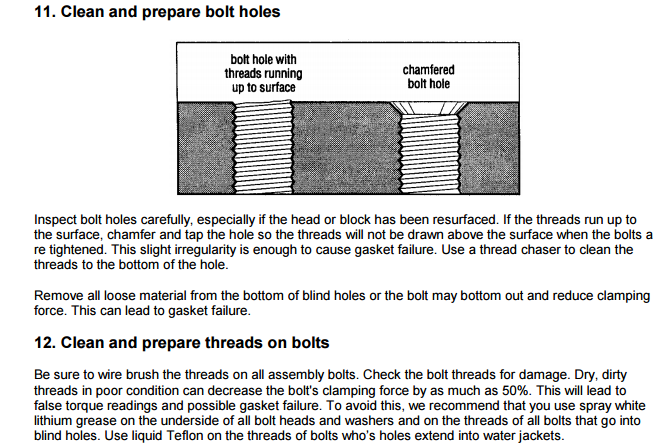

be aware that head bolts enter the block coolant passages,

so if you failed to dip the bolt threads in sealant when they were assembled,

through the heads coolant can seep up along the head bolts,

into the area under the valve cover

btw read this

both of these work great at sealing head bolt threads, IF you forgot to use thread sealant on the head bolt threads, why, not try to eliminate one potential area of concern,why not pull each head bolt one at a time and clean its threads dip the clean bolt in the can of sealant and re-install and re-tighten the individual bolt to the required torque, before removing the next bolt, I've done this in the past when guys failed too seal the bolt threads and its worked and there was no head gasket issues later, the only thing you have to loose by trying this is the cost of a can of thread sealant and an hour or two of your time, and of course you'll more than likely need to re-adjust valves as the rockers will need to be removed at some point in the process..

if the coolant passages are corroded or improperly machined,thats an additional potential issue

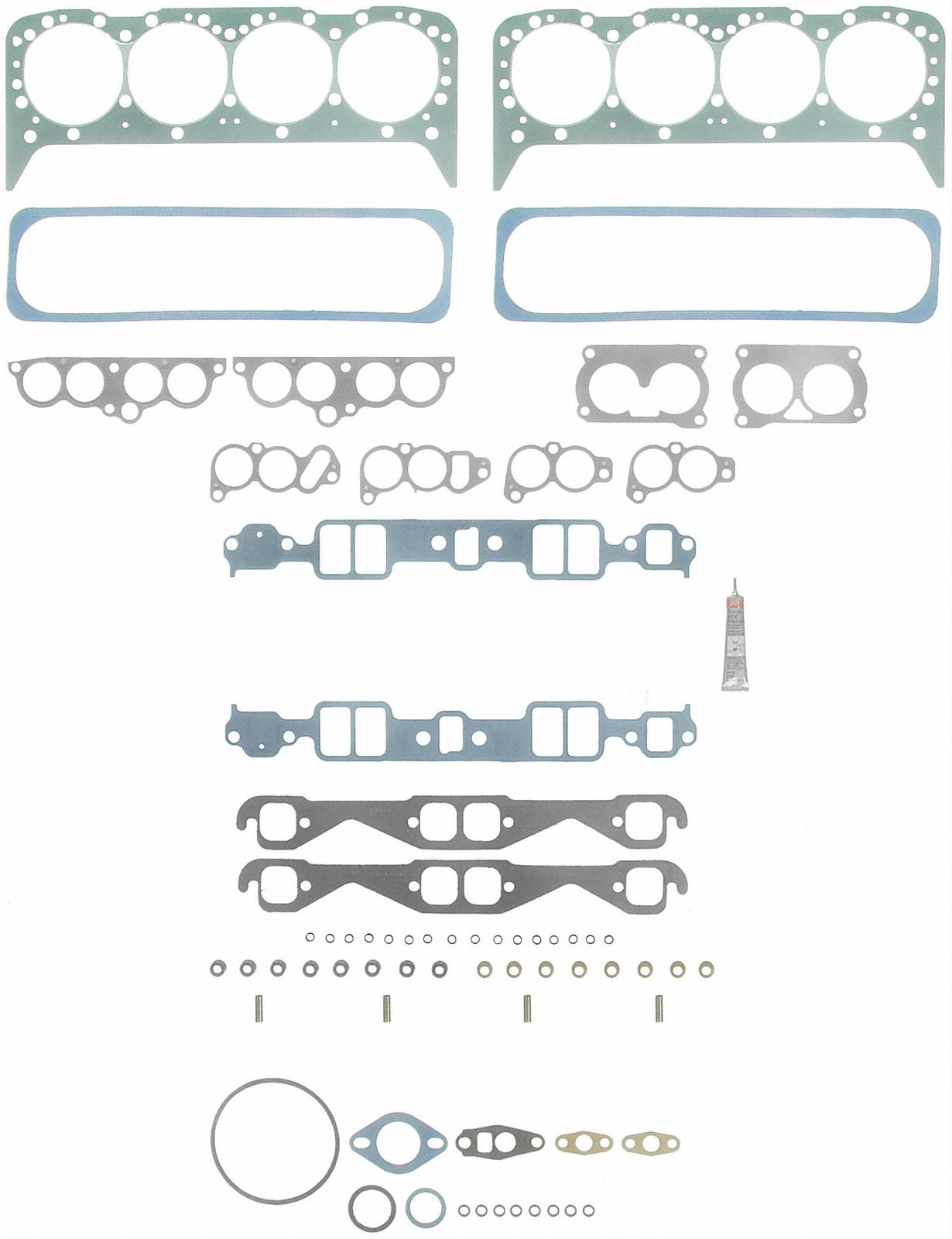

found this gasket over at summit..

using the correct head gasket too match the heads and cylinder heads your using on any big block chevy engine, is critical to prevent coolant loss, and maintain proper cooling

http://www.summitracing.com/parts/FE...2/?image=large

Brand Fel-Pro

Manufacturer's Part Number Q8180PT2

Part Type

Head Gaskets

Product Line Fel-Pro Head Gaskets

Summit Racing Part Number FEL-8180PT-2

Bore (in) 4.370 in.

Bore (mm) 110.998mm

Gasket Material PermaTorqueMLS

Compressed Thickness (in) 0.039 in.

Compressed Volume (cc) 9.700cc

Lock Wire No

Quantity Sold individually.

According to summits apps page

The

gasket your have fits

http://www.summitracing.com/parts/FP...ET&prefilter=1

Make CHEVROLET

Engine Type V8

Liter 6.5

CID 396

Engine Size 6.5L/396

Beginning Year 1966

Ending Year 1970

Engine Family Chevy big block

Mark IV

Make CHEVROLET

Engine Type V8

Liter 6.6

CID 402

Engine Size 6.6L/402

Beginning Year 1970

Ending Year 1972

Engine Family Chevy big block

Mark IV

Make CHEVROLET

Engine Type V8

Liter 7.4

CID 454

Engine Size 7.4L/454

Beginning Year 1970

Ending Year 1990

Engine Family Chevy big block

Mark IV

http://www.superchevy.com/how-to/en...-big-block-casting-changes-through-the-years/

or too find coolant leaks if the wrong head gaskets were used.

Quote:

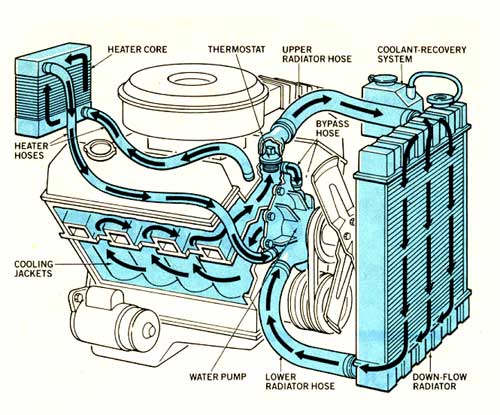

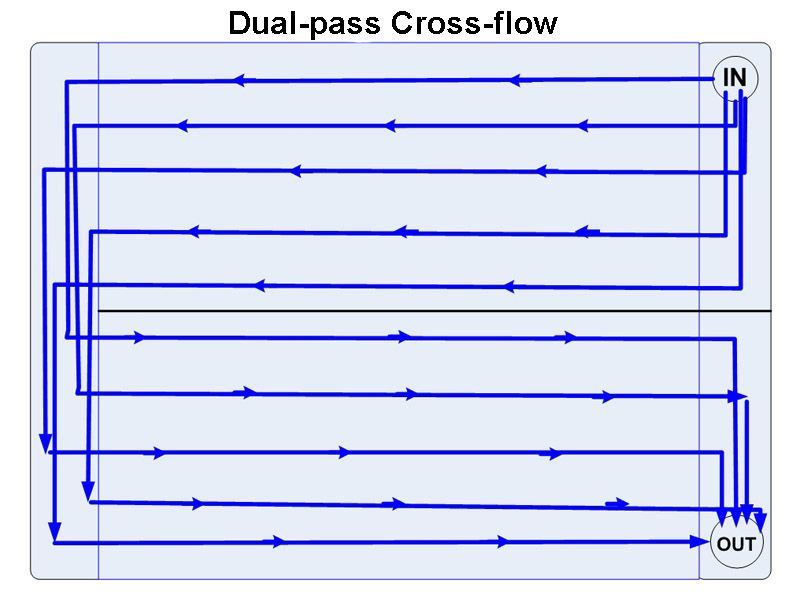

Coolant Routing Mk IV/Gen 5/Gen 6

There are two different ways that coolant can be routed through the engine: series flow and parallel flow. Both ways work just fine. There may be a slight preference for parallel flow, but it is not a big deal. Series flow has the water exiting the water pump, flowing through the block to the rear, it then transfers through the head gasket and into the cylinder head through two large passages on each cylinder bank at the rear of the block. The coolant then travels from the rear of the head, forward to the front of the head, into the intake manifold water passage and out past the thermostat and thermostat housing. The water cools the block first, then it cools the head. The coldest water (coming out of the water pump) is directly below the hottest water (having already picked up the heat of the block and the head) as the hot water transfers into the intake manifold. By contrast, parallel flow has the water exiting from the water pump into the block, where a portion "geysers" up into the head between the first and second cylinder, another portion "geysers" up to the head between the second and third cylinders, another portion geysers up to the head between the third and fourth cylinder, and the remainder transfers to the head at the rear of the block. The coolant temperature inside the engine is more even that way. The differences in coolant routing is having (or not having) the three additional coolant transfer holes in each block deck, and three matching holes in the head gasket. The heads have passages for either system, and are not different based on coolant flow.

Be aware that gaskets that DO have the three extra holes between the cylinders often have restricted coolant flow at the rear--instead of having two large coolant transfer holes at the rear, there is only one, and it's the smaller of the two holes that remains. This is important because if you use a parallel flow head gasket on a series flow block, you can have massive overheating and there's NOTHING that will cure the problem except to replace the head gaskets with ones that don't restrict flow at the rear of the block, or to drill the block decks to allow the coolant to flow into the head between the cylinders. Here's why they can overheat: A series-flow block doesn't have the openings between the cylinders, no coolant can flow up to the head there. The gasket may only have the single, smaller opening at the rear, so the amount of water that gets through that opening is greatly reduced from what the block designers intended. The result is that the coolant flow through the engine is only a fraction of what is needed.

Most, but NOT all Mk IV engines are Series Flow. ALL Gen 5 and Gen 6 engines are Parallel Flow. A series flow block can be converted to parallel flow by drilling 3 holes in each deck surface, and then use parallel flow head gaskets. You can use the parallel flow gaskets as templates for locating the additional holes. It's really easy: Put the parallel flow gaskets on the block, mark the location and size of the three extra holes. Remove the gasket. Grab a 1/2" drill and a drill bit of the correct size, and pop the extra holes in the block. There is NO modification needed on the head castings. Some blocks have one of the holes already, but it needs to be ground oblong to properly match the gasket. Again, very easy with a hand held die grinder and rotary file.

I'd assume the intake gaskets are the source until proven otherwise.

but be aware that miss matched head gaskets, to the heads and block combo in use, can cause several issues

don,t assume the worst, just logically and step by step track down and correct the issue using FACTS.

The Gen V was first installed in the

1991 year models.

The earliest casting I've decoded was a very late (Nov/Dec?) 1989 date.

The Gen VI was first installed in the

1996 year models.

The cams for the Mark IV and Gen V are interchangable for flat tappet lifters.

The Gen VI where the first equiped with Roller Lifters, but the main difference is the machined flats on the lifter bores of this block - you can still install an earlier cam without rollers.

The cam retainer plate holes are verticle on a Gen V~VI, rotated 90deg from the Mark IV's horizontal orientation.

The '91 on trucks with Gen V's had manual transmissions and use a bracket for the pivot, the later medium duty trucks have a hydraulic

clutch.

The Gen blocks use longer main cap bolts than the Mark blocks.

The crank on the Gen engines uses one long key in the keyway slot for the cam drive gear and the damper - the Mark cranks have two short keyway slots and two seperate keys, one for the

cam gear one for the damper.

As he stated, Gen cranks are one-piece seal, Mark are two-piece.

The Flex plates are interchangeable - but Flywheels, for truck and marine applications, are not interchangeable on Mark and Gen engines.

FAILING TO READ THE LINKS WOULD BE A BIG MISTAKE HERE!

http://www.chevydiy.com/gaskets-fasteners-guide-big-block-chevy-engines/

http://www.superchevy.com/how-to/4567-chevrolet-big-block-engine-generations/

http://hotrodenginetech.com/top-10-reasons-to-build-gen-vi-based-big-blocks/

http://garage.grumpysperformance.co...-brief-big-block-chevy-history.951/#post-5878