You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

High Oil Pressure?

- Thread starter bytor

- Start date

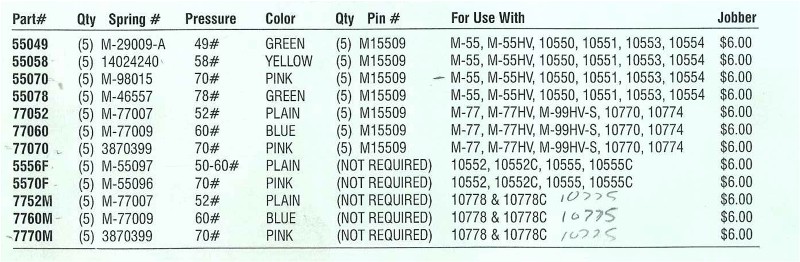

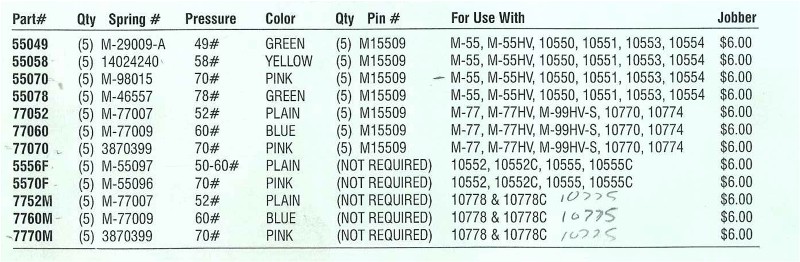

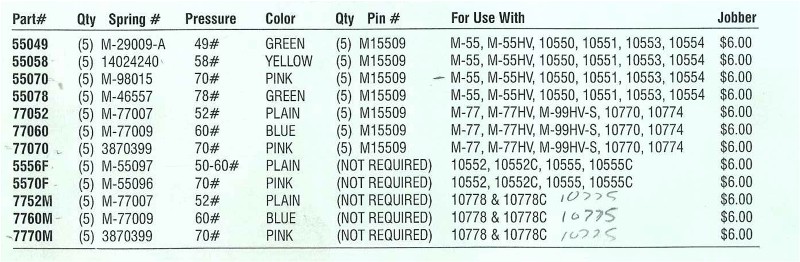

OIL PRESSURE read on the gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but it has zero to do with anything else, if its functioning correctly, your oil pump bye-pass circuit should limit pressure to either 60psi or 70 psi depending on the pump and spring combo,, its a good idea to disassemble and clean and inspect the bye-pass circuit components and don,t ever shim the spring to increase pressure

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

http://www.summitracing.com/search?keyword=5556F&dds=1

(chevy small block oil pump bye-pass springs)

http://www.summitracing.com/parts/mel-77060

(chevy big block oil pump bye-pass springs)

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

your 55 psi at idle serves no purpose as 15psi-25psi is all thats expected in a new engine with tight clearances using a good 10W30 oil, if your using a higher viscosity than 10w30 its reducing oil flow rates and reducing heat transfer rates, Id suggest using a good 10W30 oil. and use of a 7-8 quart, baffled oil pan and windage tray

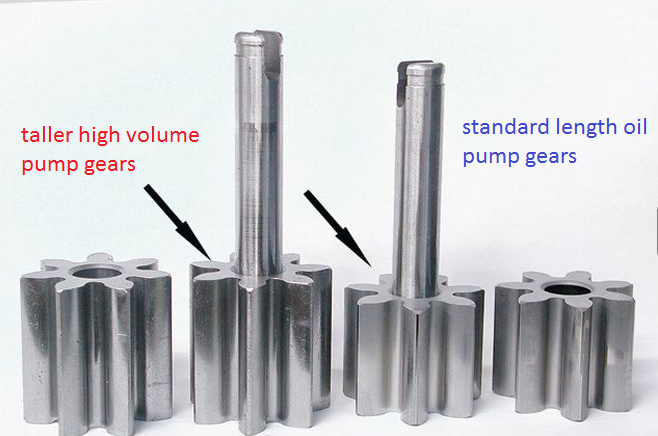

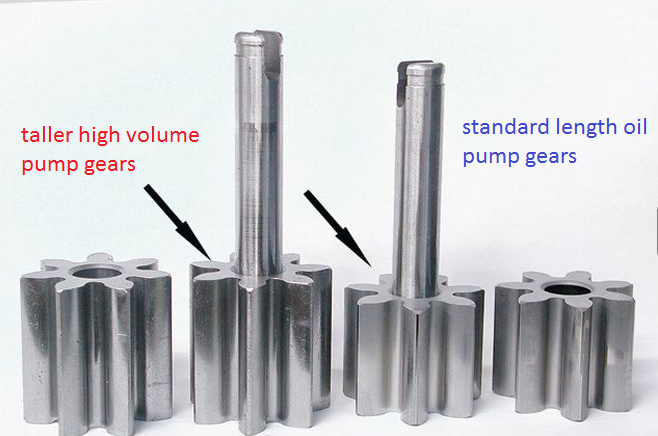

(NOTICE ITS A 4 BOLT small BLOCK HIGH VOLUME OIL PUMP WITH A 5/8" pickup}

10553

10553High pressure performance upgrade for M-55 & M-55A.

Standard volume oil pump.

The 10553 housing and cover are CNC machined and phosphate coated.

Manufactured with pink spring installed for higher pressure (M-55A).

To change pump to lower pressure (M-55) install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10553 uses a 5/8” press in screen.

10552

High volume performance oil pump.

10% increase in volume over stock oil pump.

The 10552 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and phosphate coated.

Includes intermediate shaft with steel guide. Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571.

10778C (Anti-Cavitation)

(NOTICE ITS A 5 BOLT BIG BLOCK HIGH VOLUME OIL PUMP WITH A 3/4" pickup}

http://www.summitracing.com/parts/mel-10778

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The same as the 10778 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571

from chevy high performance mag

you might want to read thru these links and sub links,

as theres a great deal of related useful info contained

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=2102

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=1334

http://garage.grumpysperformance.com/index.php?threads/testing-a-chevy-oil-pump.6479/

hotrod said:For a dual-purpose car, engine oil needs to be at least 220 degrees F to burn off all the deposits and accumulated water vapor. For every pound of fuel burned in an engine, the combustion process also generates a pound of water! If engine sump temperatures rarely exceed 212 degrees (water’s boiling point), the water will mix with sulfur (another combustion by-product) and create acids that can eventually damage bearings.

As for ultimate power potential, the general consensus among most racers is that hot oil and cool water make more power in most engines. Cold engine oil causes excessive frictional drag on the bearings and cylinder walls. A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. The traditional approach is to try to hold oil temperatures between 230 and 260 degrees. Even on a short-duration, drag-only combo where oil is frequently changed, I would not want to routinely see under-200-degree oil temps.

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

http://www.summitracing.com/search?keyword=5556F&dds=1

(chevy small block oil pump bye-pass springs)

http://www.summitracing.com/parts/mel-77060

(chevy big block oil pump bye-pass springs)

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

your 55 psi at idle serves no purpose as 15psi-25psi is all thats expected in a new engine with tight clearances using a good 10W30 oil, if your using a higher viscosity than 10w30 its reducing oil flow rates and reducing heat transfer rates, Id suggest using a good 10W30 oil. and use of a 7-8 quart, baffled oil pan and windage tray

(NOTICE ITS A 4 BOLT small BLOCK HIGH VOLUME OIL PUMP WITH A 5/8" pickup}

10553

10553High pressure performance upgrade for M-55 & M-55A.

Standard volume oil pump.

The 10553 housing and cover are CNC machined and phosphate coated.

Manufactured with pink spring installed for higher pressure (M-55A).

To change pump to lower pressure (M-55) install the supplied yellow spring.

Includes intermediate shaft with steel guide.

The 10553 uses a 5/8” press in screen.

10552

High volume performance oil pump.

10% increase in volume over stock oil pump.

The 10552 is manufactured with the drive and idler shafts extended to allow for additional support in the cover eliminating dynamic shaft deflection at increased RPM levels.

The cover is doweled to the pump housing to assure alignment of the shaft bores.

Screw in plug retains relief valve spring instead of pin.

Relief hole in cover uses screw in plug instead of pressed cup plug.

All bolts are self locking socket heads, with the wrench supplied.

The housing and cover are CNC machined and phosphate coated.

Includes intermediate shaft with steel guide. Uses both 3/4” bolt on or press in screen.

The lower pressure spring is included to reduce pressure if desired.

Patent No. 5,810,571.

10778C (Anti-Cavitation)

(NOTICE ITS A 5 BOLT BIG BLOCK HIGH VOLUME OIL PUMP WITH A 3/4" pickup}

http://www.summitracing.com/parts/mel-10778

High volume performance upgrade for the 10770.

Increase in volume of 25% over stock oil pump.

The same as the 10778 except with the addition of grooves machined in the housing and cover. The grooves reduce cavitation effects in high RPM applications.

Using this oil pump will reduce pressure at idle.

Includes intermediate shaft with steel guide.

Uses 3/4” press in screen.

Racing applications only.

Patent No. 5,810,571

from chevy high performance mag

you might want to read thru these links and sub links,

as theres a great deal of related useful info contained

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=52

viewtopic.php?f=54&t=2102

viewtopic.php?f=54&t=64

viewtopic.php?f=54&t=1334

Last edited by a moderator:

bytor said:Oil pressure question on my recent 383 build. One thing I have noticed is relatively high oil pressure. On cold start, I have 75lb and once warmed up I have around 55lb at idle. Is this excessive? I’m running a Milling 10552 pump.

It would be one hell of a long shot if it happened to you also, but my Melling 10552 oil pump had a couple of spacers that should not be there.

Did you disassemble yours and what did it look like???

I called Melling and talked to George Richmond, the one that does the Melling videos if you have ever watch one. Then I emailed him a picture, this is how it went....

Quoted from my engine build thread on page 42:

I talked with George Richmond at Melling today. After explaining the spacer

sleeves, he said they don't use any spacers. I offered to email him a

picture like the one below. His reply to my email is below in the red text.

I wonder if there is some way to test the pressure at which the valve is going

to regulate my pressure before assembling the engine???

Email response from Melling:

Those sleeves are not anything we use.

The valve and spring looks correct.

George Richmond

Technical Services Manager

ASE Master Automotive Technician

Melling Tool Company

2620 Saradan Drive

Jackson, MI 49202

517-787-8172 Ext 134

On page 43 I tested it with and without spacers in my parts washer using solvent.

1st test with NO spacer - ..... 70 psi

2nd test with one spacer - ...100 psi

3rd test with two spacers - ..150 psi

Attachments

bytor

Well-Known Member

Indycars said:bytor said:Oil pressure question on my recent 383 build. One thing I have noticed is relatively high oil pressure. On cold start, I have 75lb and once warmed up I have around 55lb at idle. Is this excessive? I’m running a Milling 10552 pump.

It would be one hell of a long shot if it happened to you also, but my Melling 10552 oil pump had a couple of spacers that should not be there.

Did you disassemble yours and what did it look like???

Nope, mine did not have those spacers.

I have actually started up a conversation with George as well. Indy, did your pump come with an additional standard pressure spring as well as the pink high pressure spring installed?

Attachments

bytor said:I have actually started up a conversation with George as well. Indy, did your pump come with an additional standard pressure spring as well as the pink high pressure spring installed?

Did you talk with George in person ??? Pretty funny when he says "Never, Never" in the video.

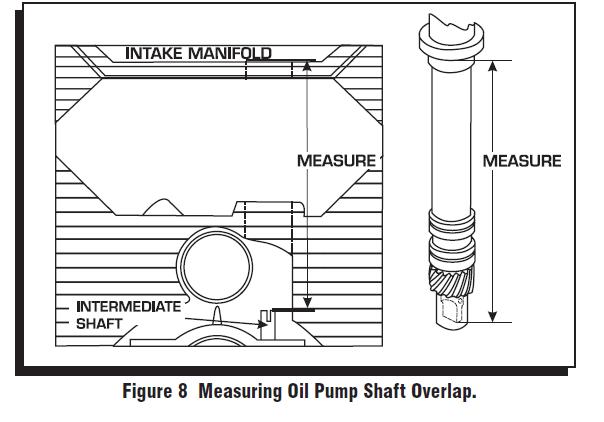

I don't remember an extra spring and I don't show a second spring in any of my photos. Were you able to use the Melling driveshaft with your engine???

bytor

Well-Known Member

Indycars said:bytor said:I have actually started up a conversation with George as well. Indy, did your pump come with an additional standard pressure spring as well as the pink high pressure spring installed?

Did you talk with George in person ??? Pretty funny when he says "Never, Never" in the video.

I don't remember an extra spring and I don't show a second spring in any of my photos. Were you able to use the Melling driveshaft with your engine???

I haven't actually spoke with him yet, just email so far.

Below is the correspondence.

MY Question to Melling:

Oil pressure question on my recent 383 build. One thing I have noticed is relatively high oil pressure. On cold start, I have 75lb and once warmed up I have around 55lb at idle. Is this excessive? I'm running a Milling 10552 pump. I'm wondering if I have too much pump for my set up and a standard pump may be more appropriated. I also noticed in the 10552 description it says that it comes with a standard pressure spring. Mine did not come with an extra spring. I don't think that would help anyway with my issue.

George’s initial response:

Oil pressure is a result of the resistance to the flow of oil . Clearances ,oil viscosity & temp. are the determining factors. You did not say what the pressure was at 2500 RPM. , or if you have a priority oiling block. The lighter spring would help some to reduce the pressure . We can send you a spring if we have your address.

I’m not sure what my pressure is at 2500 RPM so I need to get back with him on that.

I'm using the Melling shaft with no issues.

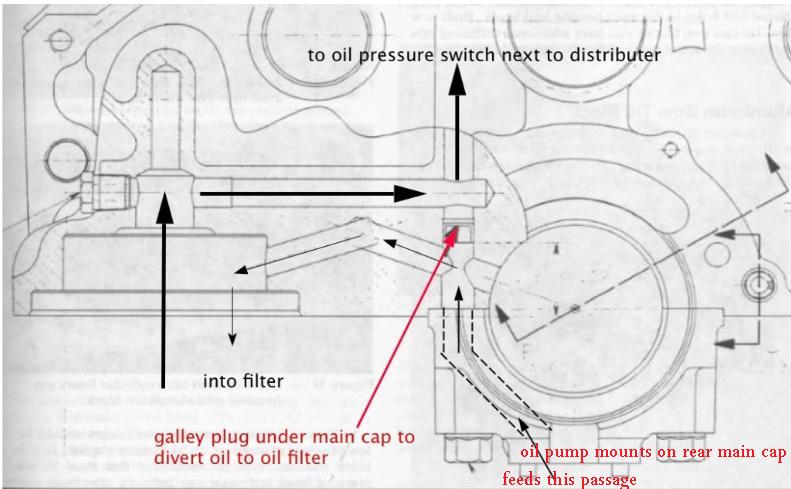

Ask George why he asked " or if you have a priority oiling block." I wonder how that factors into this???

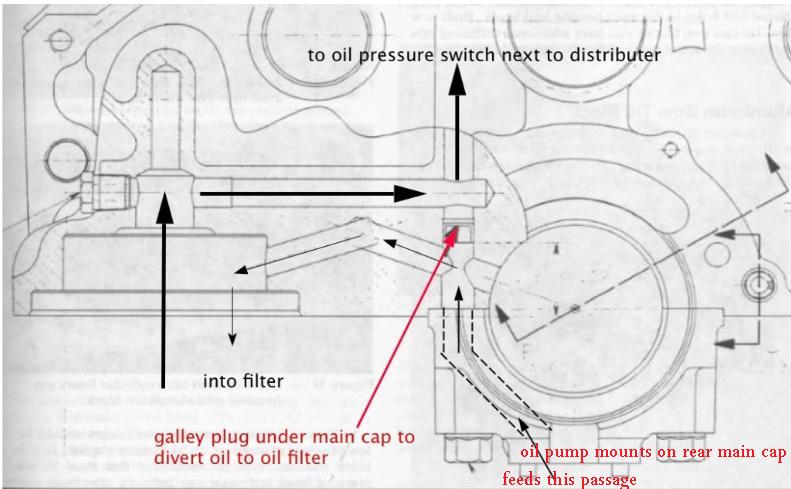

Did you do any of the oil system modification like cutting the distributor, drilling oil galley plug to oil the timing chain or the mod to provide more oil to the rear main thrust bearing surface. Since I did all three, I figured the extra 10% would be just right.

bytor

Well-Known Member

Indycars said:

Did you go any of the oil system modification like cutting the distributor, drilling oil galley plug to oil the timing chain or the mod to provide more oil to the rear main thrust bearing surface. Since I did all three, I figured the extra 10% would be just right.

I just drilled the oil galley plug and not the other 2 mods you did.

bytor

Well-Known Member

George responded that my build is on the tight side and recommended I go with a standard pressure/volume pump. This weekend it did change the oil and put in some 0W20 and it dropped the pressure by 10-15psi. Hot idle went to 45psi and 60psi at 2500RPM

Indy, I asked about the priority oiling comment and his response was "Due to the way a priority block oils the volume requirements are less."

Indycars said:

Ask George why he asked " or if you have a priority oiling block." I wonder how that factors into this???

Indy, I asked about the priority oiling comment and his response was "Due to the way a priority block oils the volume requirements are less."

bytor said:George responded that my build is on the tight side and recommended I go with a standard pressure/volume pump. This weekend it did change the oil and put in some 0W20 and it dropped the pressure by 10-15psi. Hot idle went to 45psi and 60psi at 2500RPM

Indy, I asked about the priority oiling comment and his response was "Due to the way a priority block oils the volume requirements are less."

What are your clearances ???

That pressure is still high, does it max out at 60 psi when you get to 2500 RPM or does it keep climbing ? How hard would it be to drop the pan and put in just the lower half of the bearings using some -0.001 under bearings.

Wish George would have given more details about the priority main oiling, why would it be less?

navygunner08 said:grumpy, I fired up my newest build today and found that I may have too much oil pressure. I have not used an accurate gauge yet, but the vehicles oil pressure sending unit is maxed out well past 80psi. I ensured all my bearing clearances were within spec and I didnt think I was using a high pressure pump, but I guess thats what I actually ordered. Is there such thing as too much pressure? I am thinking I may need to change my oil cooler lines over to -8AN instead of the current -6AN. The motor is a 355 built for a Chevy K1500 for low-end torque and good street manners.

step one,

is obviously using a known to be accurate oil pressure test gauge to verify your true oil pressure , and not relying on what might be a defective gauge or sending unit.

oil pressure can run up to about 120 psi without significant wear or problems so I would not be nearly as concerned with what might seem to be HIGH rather than extremely LOW oil pressure but without verified facts I suspect its a defective or mis- matched or badly connected sending unit, or sensor.

keep in mind the oil pump bye-pass circuit might be stuck, requiring you to drop the oil pan and replace or clearance the spring and piston in the oil pump

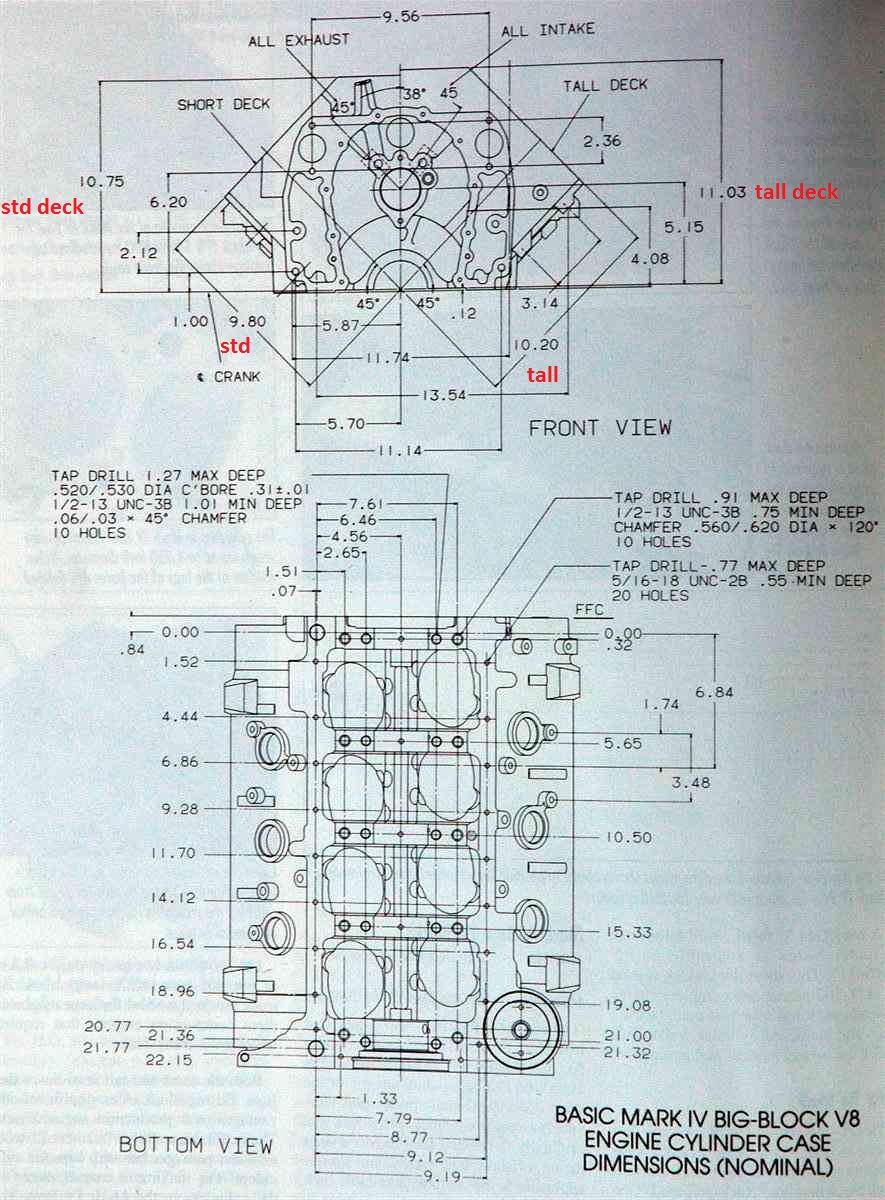

theres several block port locations to check oil pressure or instal sensors, theres several, but different castings vary locations

http://www.harborfreight.com/engine-oil ... 98949.html

you should NEVER shim an oil pumps pressure relief spring as it may prevent the piston it holds from moving down its bore far enough to allow it to open the bay-pass passage, that allows the pressure on the high pressure side of the oil pump from bleeding off back into the intakes side of the oil pump

Many pressure relief springs have one end larger than the other end,the spring always mounts with the larger end facing away from the bypass piston, if installed reversed the piston can,t move far enough to completely open the bypass circuit passage and pressures skyrocket, under some conditions

http://www.summitracing.com/search?keyword=5556F&dds=1

(chevy small block oil pump bye-pass springs)

http://www.summitracing.com/parts/mel-77060

you might want to read thru this thread

viewtopic.php?f=54&t=3536

your current distributor can usually be easily modified by a local machine shop with a lathe for an adjustable slip collar by carefully machining off the current one and adding a slip collar, if you need to make distributor gear to cam gear engagement or oil pump drive shaft length changes

the tall deck block requires a longer reach distributor shaft thats about 0.28 longer thus the need for the adjustable collar on the distributor adding the extra reach to get the oil pump drive and drive gears to properly align and mesh.

Last edited:

8

87vette81big

Guest

High oil pressure cold & hot does not bother me one bit.

I really like the Melling M55A 1967-69 Z-28 Oil pump. High pressure standard volume with 5/8" pickup tube.

80psi cold drive away after 30 second warmup.

60-65 psi hot after 20 minutes driving time.

40Psi idle @700 rpm idle speed.

Casterole GTX 10W30 Oil.

Factory GM Melonized steel distributor gear happy.

No wear issues.

My 1994 K1500 350 TBI Suburban.

Ford 302 5.0 Renagade Racers use 120 - 150psi oil pressure hot.

There turning 9k rpms.

Street driven often some I know.

I really like the Melling M55A 1967-69 Z-28 Oil pump. High pressure standard volume with 5/8" pickup tube.

80psi cold drive away after 30 second warmup.

60-65 psi hot after 20 minutes driving time.

40Psi idle @700 rpm idle speed.

Casterole GTX 10W30 Oil.

Factory GM Melonized steel distributor gear happy.

No wear issues.

My 1994 K1500 350 TBI Suburban.

Ford 302 5.0 Renagade Racers use 120 - 150psi oil pressure hot.

There turning 9k rpms.

Street driven often some I know.