High Velocity Heads’ Incredible Shrinking Combustion Chambers

Written by Jeff Huneycutt on December 21, 2017

New Super C heads from HVH can be a real advantage for flat-top piston classes looking for additional compression.

There are tons of classes in the oval track racing world that require flat-top pistons. The idea is that by eliminating any piston dome, you help put an artificial cap on how much compression the engine can make. For a Chevrolet running 23-degree cylinder heads, that usually mean the chambers are going to be 60 cubic centimeters or so. You can cut that even further by angle milling the heads, but that comes with a whole host of its own problems, including too-thin decks on the exhaust side, slotted bolt holes, and intake manifolds that must be custom cut to fit the new head angles.

Of course, there is a method only the most dedicated will take to shrink the combustion chambers. To do this the engine builder actually extends to the valve seats into the cylinder bores a fraction of an inch. To do this the chambers are shaped as the engine builder likes while leaving the press-in valve seats out. Next, the heads are decided to the absolute extreme. And finally, the seats are pressed in and cut, all the while praying nothing happens to mar up the freshly cut decks so that they will no longer properly seal against the head gaskets.

Of course, it’s also quite expensive. This process is labor intensive, and the hours in machine work adds up. High Velocity Heads (HVH) typically charges $1,400 to do a single head like this.

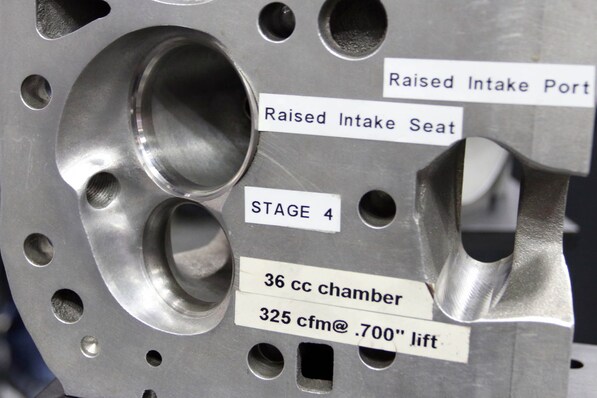

But this year at the PRI trade show, HVH showed us their new Super C process for making maximum-compression cylinder heads. Instead of the usual process, HVH turns everything on its head by finishing the combustion chambers and then cutting the decks on the cylinder heads on an end mill instead of the typical decking apparatus.

There are several advantages to this method, namely significantly smaller chambers at a more reasonable price. HVH showed us a cast iron cylinder head with 45 cc combustion chambers that can be done for $729 instead of the usual $1,400. Second, the heads aren’t angle milled, which is quite often outlawed, avoiding all those issues. There’s no change of water jacket intrusion, the area around the spark plug boss is stronger and less likely to crack, and the process works with both aluminum and cast-iron cylinder heads.

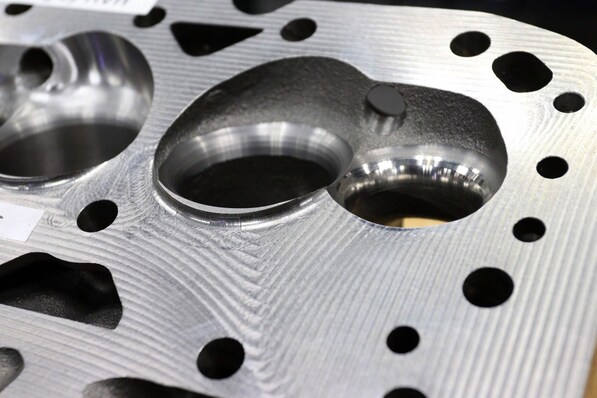

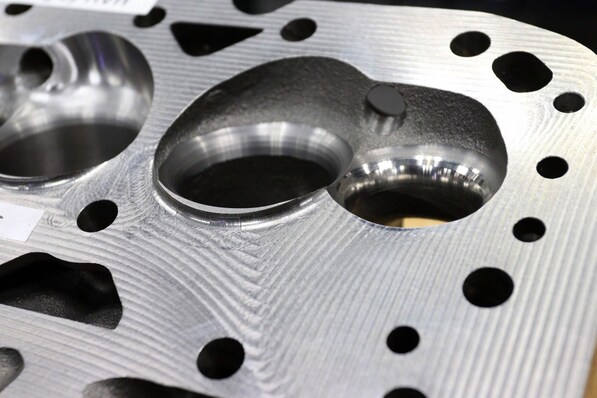

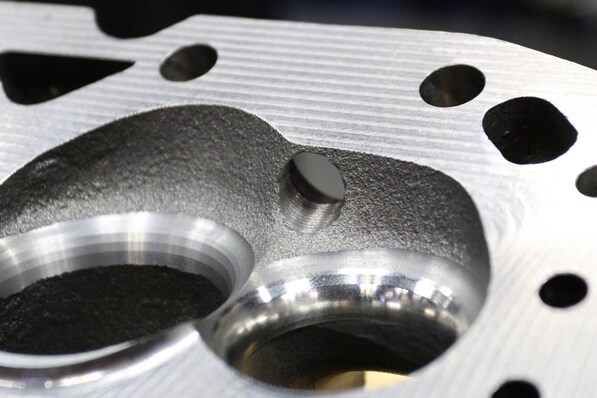

Here’s a cast-iron cylinder head that’s been put through High Velocity Heads (HVH) Super C process. Notice the machine marks on the deck of the head from the innovate engine-milling process.

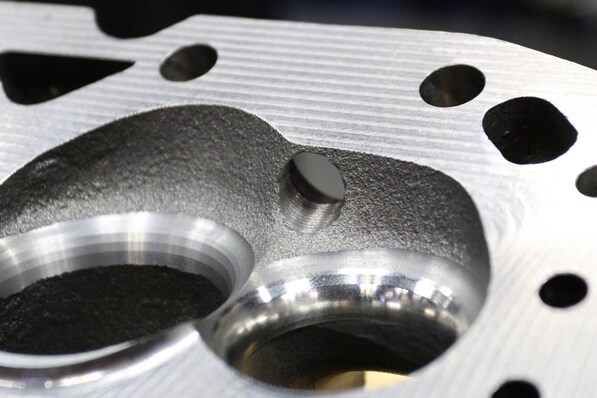

Notice how the valve seat actually extends into the cylinder bore.

Because the small chambers haven’t been achieved by angle milling the decks, there’s still plenty of material around the spark plug bosses.

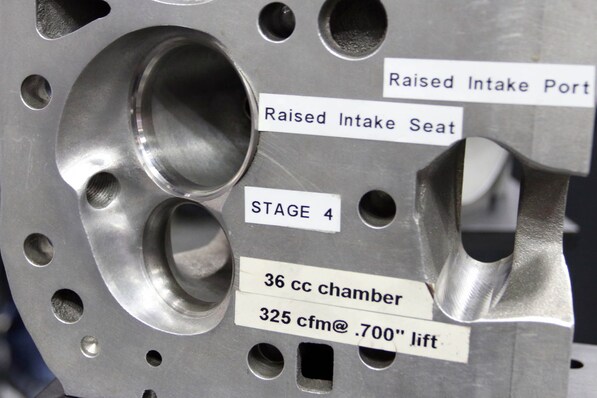

Here’s a head done on the old style. Here, you can see how the valve seat has been pressed in after the deck has been cut.

For more information, check out High Velocity Heads at www.HighVelocityHeads.com

With the Super C heads, you can actually see the tooling marks on the cylinder head decks, but the deck surface is properly smooth and the folks at HVH tell us that the heads will seal with both conventional and multi-layer steel (MLS) head gaskets.

Written by Jeff Huneycutt on December 21, 2017

New Super C heads from HVH can be a real advantage for flat-top piston classes looking for additional compression.

There are tons of classes in the oval track racing world that require flat-top pistons. The idea is that by eliminating any piston dome, you help put an artificial cap on how much compression the engine can make. For a Chevrolet running 23-degree cylinder heads, that usually mean the chambers are going to be 60 cubic centimeters or so. You can cut that even further by angle milling the heads, but that comes with a whole host of its own problems, including too-thin decks on the exhaust side, slotted bolt holes, and intake manifolds that must be custom cut to fit the new head angles.

Of course, there is a method only the most dedicated will take to shrink the combustion chambers. To do this the engine builder actually extends to the valve seats into the cylinder bores a fraction of an inch. To do this the chambers are shaped as the engine builder likes while leaving the press-in valve seats out. Next, the heads are decided to the absolute extreme. And finally, the seats are pressed in and cut, all the while praying nothing happens to mar up the freshly cut decks so that they will no longer properly seal against the head gaskets.

Of course, it’s also quite expensive. This process is labor intensive, and the hours in machine work adds up. High Velocity Heads (HVH) typically charges $1,400 to do a single head like this.

But this year at the PRI trade show, HVH showed us their new Super C process for making maximum-compression cylinder heads. Instead of the usual process, HVH turns everything on its head by finishing the combustion chambers and then cutting the decks on the cylinder heads on an end mill instead of the typical decking apparatus.

There are several advantages to this method, namely significantly smaller chambers at a more reasonable price. HVH showed us a cast iron cylinder head with 45 cc combustion chambers that can be done for $729 instead of the usual $1,400. Second, the heads aren’t angle milled, which is quite often outlawed, avoiding all those issues. There’s no change of water jacket intrusion, the area around the spark plug boss is stronger and less likely to crack, and the process works with both aluminum and cast-iron cylinder heads.

Here’s a cast-iron cylinder head that’s been put through High Velocity Heads (HVH) Super C process. Notice the machine marks on the deck of the head from the innovate engine-milling process.

Notice how the valve seat actually extends into the cylinder bore.

Because the small chambers haven’t been achieved by angle milling the decks, there’s still plenty of material around the spark plug bosses.

Here’s a head done on the old style. Here, you can see how the valve seat has been pressed in after the deck has been cut.

For more information, check out High Velocity Heads at www.HighVelocityHeads.com

With the Super C heads, you can actually see the tooling marks on the cylinder head decks, but the deck surface is properly smooth and the folks at HVH tell us that the heads will seal with both conventional and multi-layer steel (MLS) head gaskets.

Last edited: