8

87vette81big

Guest

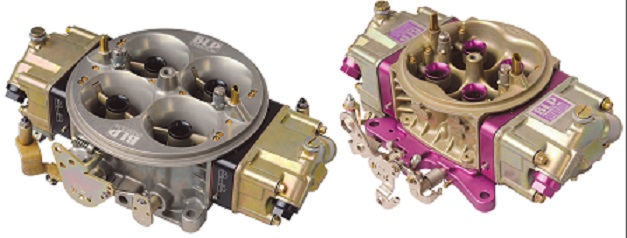

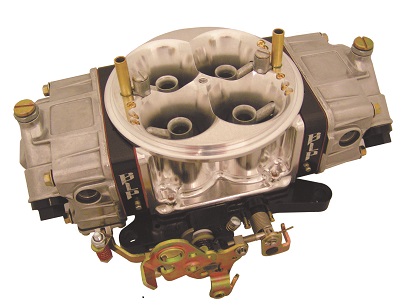

I have a chance to buy a lightly used Holley Street Avenger Carb 770 cfm with electric choke. Vacuum seconday.

Dual external chrome feed lines to the float bowls.

Single pumper.

Primary idle circuit only.

I want to use it on my 1965 Olds 425 A engine Grumpy.

The factory intake is square bore 4150 4-hole flanged.

Are secondary metering block in this carb fixed ?

Or does it use standard Holley brass jets?

What is the stock calibrated jetting out of the box new ?

Value $125-150 ?

Thanks Grumpy.

Dual external chrome feed lines to the float bowls.

Single pumper.

Primary idle circuit only.

I want to use it on my 1965 Olds 425 A engine Grumpy.

The factory intake is square bore 4150 4-hole flanged.

Are secondary metering block in this carb fixed ?

Or does it use standard Holley brass jets?

What is the stock calibrated jetting out of the box new ?

Value $125-150 ?

Thanks Grumpy.