IF YOU DON,T READ THE LINKED INFO YOU'LL MISS A GREAT DEAL

I learned decades ago to swap to a 140 amp-200 amp alternator,

as the stock 75-105 amp alternators on muscle cars and earlier corvettes are marginal at best/

if you shop carefully they can usually be found locally at some alternator re-builders for under $150

both my corvettes have 200 amp versions purchased NEW for under $250

while that may be over-kill to some I find the electric fans on the corvette and ignition and head lights work noticeably better

https://www.dbelectrical.com/alternators/automotive/chevrolet/corvette/5-7-liter/

http://www.ecklerscorvette.com/corvette-alternator-140-amp-chrome-power-master-1969-1982.html

http://garage.grumpysperformance.com/index.php?threads/chasing-a-crazy-electrical-glitch.986/

https://alternatorparts.com/cs144-series-high-output-alternators.html

viewtopic.php?f=36&t=3222&p=8575&hilit=alternator#p8575

http://www.alternatorparts.com/understa ... nators.htm

http://knol.google.com/k/how-to-tell-if ... or-is-bad#

http://autorepair.about.com/od/glossary ... rnator.htm

http://www.madelectrical.com/electrical ... sing.shtml

http://www.madelectrical.com/electrical ... wire.shtml

http://autoparts.lifetips.com/cat/61686 ... index.html

viewtopic.php?f=36&t=1169

http://www.powermastermotorsports.com/charge_wires.html

http://www.powermastermotorsports.com/g ... model.html

http://www.madelectrical.com/electrical ... sing.shtml

http://www.alternatorparts.com/CS-144_Special_offer.htm

http://www.madelectrical.com/electrical ... remy.shtml

http://auto.howstuffworks.com/alternator.htm/printable

http://www.misterfixit.com/alterntr.htm

http://www.powerbase-auto.co.uk/alternators.htm

http://www.nationaltbucketalliance.com/ ... rnator.asp

http://www.youtube.com/watch?v=w5TkStVW ... re=related

https://www.summitracing.com/parts/pwm-67293/overview/make/chevrolet/model/corvette

https://www.summitracing.com/parts/pwm-37293-114/overview/make/chevrolet/model/corvette

http://garage.grumpysperformance.com/index.php?threads/how-altenators-work.355/

https://alternatorparts.com/cs144-series-high-output-alternators.html

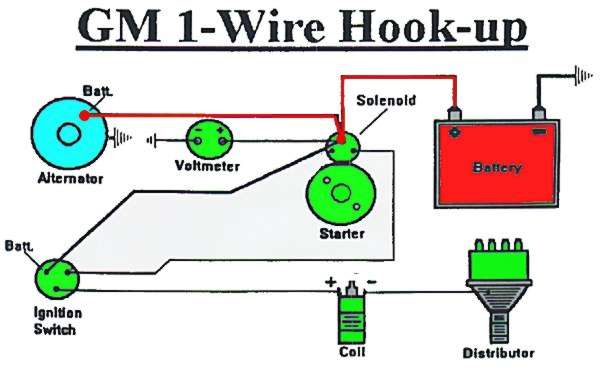

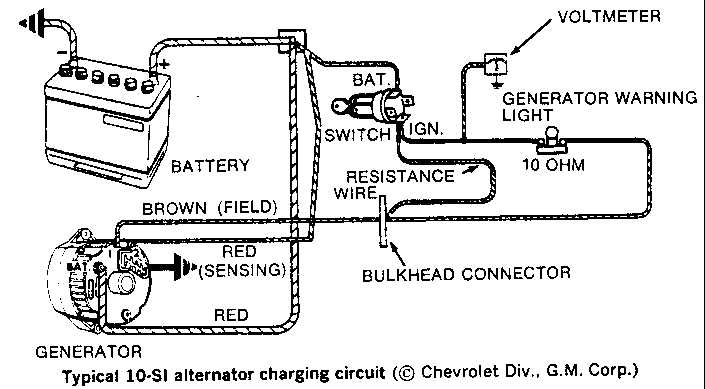

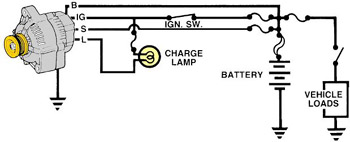

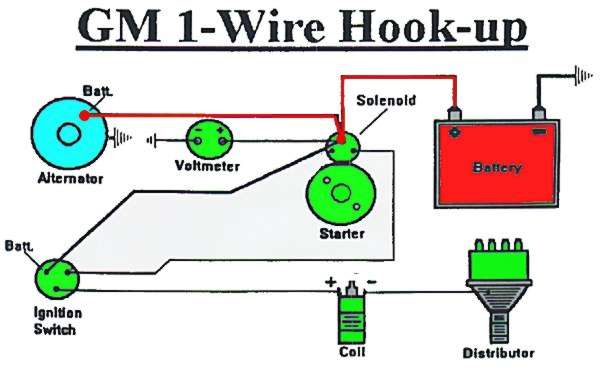

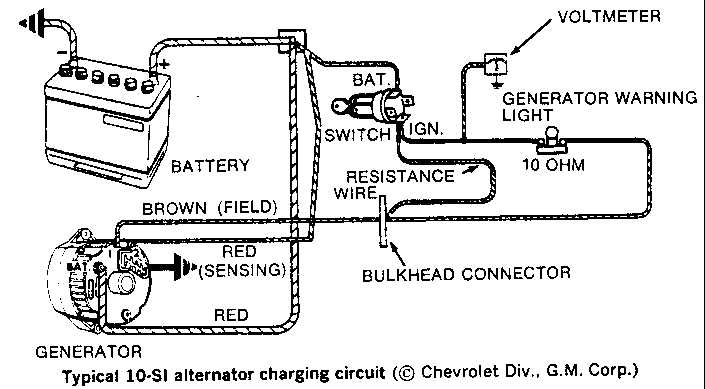

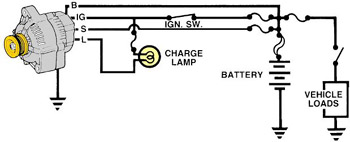

The excitor wire on # 1 terminal of the alternator starts the alternator charging on a 10 or 12si.

If it's a cs130, the "L" terminal is connected to the indicator lamp.

heres a 200 amp alt for the 88-91 vettes

http://cgi.ebay.com/ebaymotors/ws/eBayI ... %26otn%3D4

http://stores.ebay.com/Motor-City-Reman ... ation.html

Disconnecting the battery while the engine is running isn’t a valid test for alternator function and may damage sensitive electronic parts. Instead, use a common voltmeter and the following test procedure. Although some of the steps reference typical GM alternators, the basic methodology is valid for any charging system.

01

Test voltage across the battery terminals with the engine running. A good alternator should maintain battery voltage between 13.9 and 14.8 volts (14.2 is optimum). Even worst-case, with all accessories turned on, there should be at least 13 volts at the battery. Be sure that the engine is running at a high enough rpm for the charging system to function (especially if running a one-wire alternator excited at a specific rpm). If voltage is low, go to Step 02. If voltage is over 15 volts, go to Step 05.

02

Connect the voltmeter between the alternator’s output (BAT) terminal and Ground. If voltage is 13.6–14.6 volts, the alternator is OK, but power isn’t getting to the battery. Go to Step 03. If voltage is under 13.6 volts, go to Step 04.

03

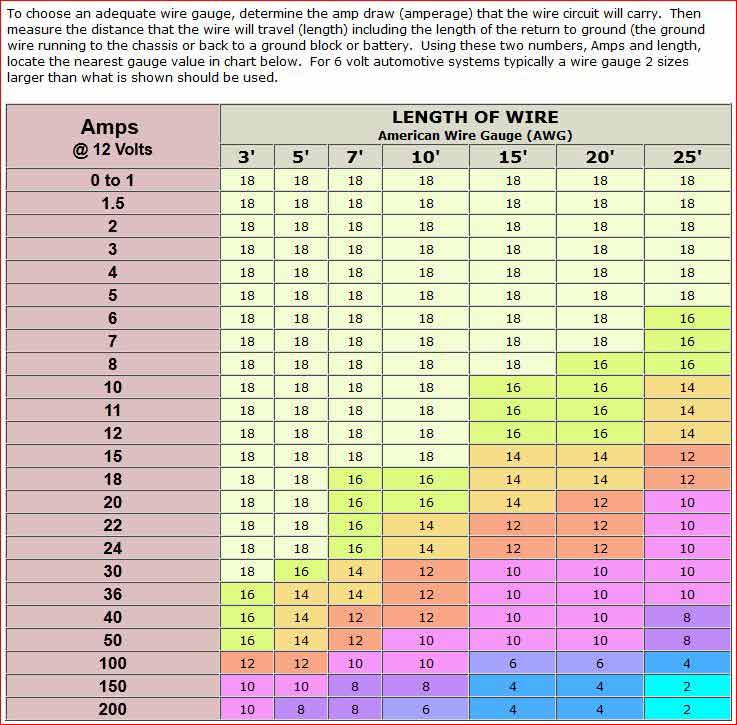

Check the battery cables and alternator charge-wire for bad connections, improper cable and wire size, or corrosion. Repair or replace as needed. Recheck as per Step 02. If voltage is a constant 13.6–14.6, the problem is solved. If voltage is normal, but slowly decreases, go to Step 04.

04

Check the alternator drive-belt. Adjust its tension or replace as needed. On a street car, the crank pulley should be three times larger than the alternator pulley; fix as needed. If voltage is normal but slowly decreases after these repairs, your alternator is OK but can’t keep up with the vehicle’s current demands; upgrade to a higher-output alternator. If you get an immediate under-13.6 volt reading, go to Step 05.

05

Test the voltage regulator. For external regulators, go to Step 06. For internal regulators, go to Step 07.

06

Unplug the harness from the regulator. With the engine running, connect a jumper wire from the connector’s B+ Terminal to the connector’s Field terminal (on most GM cars, that’s respectively the red and blue wires). Only do this for 30 seconds at a time. The engine will bog down. The alternator should have an audible whir and ramp up to max output. If you see a visible arc, repair or replace the regulator. If there’s no arc, the alternator has an open Field circuit or worn-out brushes. Fix or replace as needed.

07

GM SI alternator internal regulators can be checked as shown in the photo. If voltage goes up during this check, repair or replace the internal regulator. If voltage is lower than before, repair or replace the entire alternator. Late-model GM CS alternators don’t have serviceable regulators; the entire unit must be replaced.

as the stock 75-105 amp alternators on muscle cars and earlier corvettes are marginal at best/

if you shop carefully they can usually be found locally at some alternator re-builders for under $150

both my corvettes have 200 amp versions purchased NEW for under $250

while that may be over-kill to some I find the electric fans on the corvette and ignition and head lights work noticeably better

https://www.dbelectrical.com/alternators/automotive/chevrolet/corvette/5-7-liter/

http://www.ecklerscorvette.com/corvette-alternator-140-amp-chrome-power-master-1969-1982.html

http://garage.grumpysperformance.com/index.php?threads/chasing-a-crazy-electrical-glitch.986/

https://alternatorparts.com/cs144-series-high-output-alternators.html

viewtopic.php?f=36&t=3222&p=8575&hilit=alternator#p8575

http://www.alternatorparts.com/understa ... nators.htm

http://knol.google.com/k/how-to-tell-if ... or-is-bad#

http://autorepair.about.com/od/glossary ... rnator.htm

http://www.madelectrical.com/electrical ... sing.shtml

http://www.madelectrical.com/electrical ... wire.shtml

http://autoparts.lifetips.com/cat/61686 ... index.html

viewtopic.php?f=36&t=1169

http://www.powermastermotorsports.com/charge_wires.html

http://www.powermastermotorsports.com/g ... model.html

http://www.madelectrical.com/electrical ... sing.shtml

http://www.alternatorparts.com/CS-144_Special_offer.htm

http://www.madelectrical.com/electrical ... remy.shtml

http://auto.howstuffworks.com/alternator.htm/printable

http://www.misterfixit.com/alterntr.htm

http://www.powerbase-auto.co.uk/alternators.htm

http://www.nationaltbucketalliance.com/ ... rnator.asp

http://www.youtube.com/watch?v=w5TkStVW ... re=related

https://www.summitracing.com/parts/pwm-67293/overview/make/chevrolet/model/corvette

https://www.summitracing.com/parts/pwm-37293-114/overview/make/chevrolet/model/corvette

http://garage.grumpysperformance.com/index.php?threads/how-altenators-work.355/

https://alternatorparts.com/cs144-series-high-output-alternators.html

The excitor wire on # 1 terminal of the alternator starts the alternator charging on a 10 or 12si.

If it's a cs130, the "L" terminal is connected to the indicator lamp.

heres a 200 amp alt for the 88-91 vettes

http://cgi.ebay.com/ebaymotors/ws/eBayI ... %26otn%3D4

http://stores.ebay.com/Motor-City-Reman ... ation.html

Disconnecting the battery while the engine is running isn’t a valid test for alternator function and may damage sensitive electronic parts. Instead, use a common voltmeter and the following test procedure. Although some of the steps reference typical GM alternators, the basic methodology is valid for any charging system.

01

Test voltage across the battery terminals with the engine running. A good alternator should maintain battery voltage between 13.9 and 14.8 volts (14.2 is optimum). Even worst-case, with all accessories turned on, there should be at least 13 volts at the battery. Be sure that the engine is running at a high enough rpm for the charging system to function (especially if running a one-wire alternator excited at a specific rpm). If voltage is low, go to Step 02. If voltage is over 15 volts, go to Step 05.

02

Connect the voltmeter between the alternator’s output (BAT) terminal and Ground. If voltage is 13.6–14.6 volts, the alternator is OK, but power isn’t getting to the battery. Go to Step 03. If voltage is under 13.6 volts, go to Step 04.

03

Check the battery cables and alternator charge-wire for bad connections, improper cable and wire size, or corrosion. Repair or replace as needed. Recheck as per Step 02. If voltage is a constant 13.6–14.6, the problem is solved. If voltage is normal, but slowly decreases, go to Step 04.

04

Check the alternator drive-belt. Adjust its tension or replace as needed. On a street car, the crank pulley should be three times larger than the alternator pulley; fix as needed. If voltage is normal but slowly decreases after these repairs, your alternator is OK but can’t keep up with the vehicle’s current demands; upgrade to a higher-output alternator. If you get an immediate under-13.6 volt reading, go to Step 05.

05

Test the voltage regulator. For external regulators, go to Step 06. For internal regulators, go to Step 07.

06

Unplug the harness from the regulator. With the engine running, connect a jumper wire from the connector’s B+ Terminal to the connector’s Field terminal (on most GM cars, that’s respectively the red and blue wires). Only do this for 30 seconds at a time. The engine will bog down. The alternator should have an audible whir and ramp up to max output. If you see a visible arc, repair or replace the regulator. If there’s no arc, the alternator has an open Field circuit or worn-out brushes. Fix or replace as needed.

07

GM SI alternator internal regulators can be checked as shown in the photo. If voltage goes up during this check, repair or replace the internal regulator. If voltage is lower than before, repair or replace the entire alternator. Late-model GM CS alternators don’t have serviceable regulators; the entire unit must be replaced.

Last edited: