"GRUMPY? , how do you know when you have enough roll crimp? "

basically a crimp on the case is designed to prevent the bullets movement from any recoil generated by the recoil a gun generates as its fired, as its sitting in a magazine or a revolvers cylinder, or during chambering of the cartridge,in auto pistol.

your bullets need to have nearly identical resistance to movement until the pressure of the ignited powder forces them out of the case. none of your bullets should move until the cartridge actually is fired,so your over all cartridge length doesn,t change, which is what your trying to do, the problem is that under hard recoil an unfired cartridge almost acts like its in a kinetic bullet puller if the crimps not got a really good grip and the bullet moves a bit forward in its case, this can and does lock up a revolvers cylinder and the lack of resistance can and does prevent consistent powder ignition.

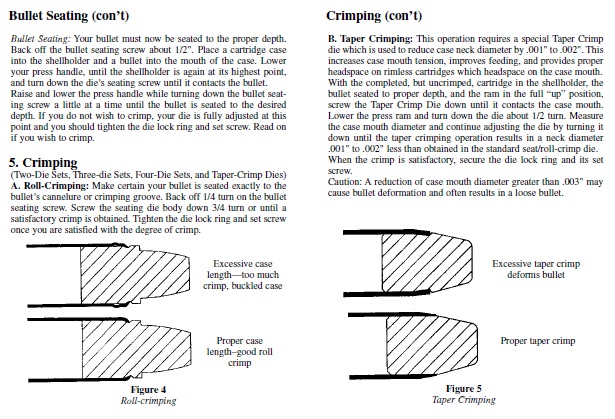

youll get the idea real fast if you screw it up, theres two common types of crimp a roll crimp which is usually used in revolvers that head space on a cartridge rim, and a taper crimp usually used with automatics that head space on the case mouth

You must crimp all cartridges intended to be used in a revolver. The main reason is: upon recoil the unfired bullets want to back out of their cases. They have this tendency because they are obeying one of Newton's laws... "a body at rest wants to remain at rest" etc. When a bullet backs out sufficiently from its case, it renders the revolver USELESS! The cylinder will not rotate because of the bullet(s) protruding from out in front...hitting the sides of the frame as the cylinder rotates

The reason you want to crimp is to increase neck tension. Neck tension will add resistance as the bullet starts its movement out of the case allowing pressure to build and ensuring complete combustion of the powder.

A roll crimp is the most common type of crimp for a revolver cartridge. A semi-auto round normally uses a taper crimp to keep the bullet form being pushed back into the casing. This is the exact opposite of a revolver where an un-crimped bullet may be pulled out of the casing. A crimp will also ensure reliable feeding in a semi-auto.

reads these

http://membres.multimania.fr/shooter/re ... chargt.htm

http://www.exteriorballistics.com/reloa ... /crimp.cfm

http://projects.nfstc.org/firearms/modu ... t09_04.htm

http://www.thefirearmsforum.com/showthread.php?t=76154

http://www.dave-cushman.net/shot/bullet ... mping.html

basically a crimp on the case is designed to prevent the bullets movement from any recoil generated by the recoil a gun generates as its fired, as its sitting in a magazine or a revolvers cylinder, or during chambering of the cartridge,in auto pistol.

your bullets need to have nearly identical resistance to movement until the pressure of the ignited powder forces them out of the case. none of your bullets should move until the cartridge actually is fired,so your over all cartridge length doesn,t change, which is what your trying to do, the problem is that under hard recoil an unfired cartridge almost acts like its in a kinetic bullet puller if the crimps not got a really good grip and the bullet moves a bit forward in its case, this can and does lock up a revolvers cylinder and the lack of resistance can and does prevent consistent powder ignition.

youll get the idea real fast if you screw it up, theres two common types of crimp a roll crimp which is usually used in revolvers that head space on a cartridge rim, and a taper crimp usually used with automatics that head space on the case mouth

You must crimp all cartridges intended to be used in a revolver. The main reason is: upon recoil the unfired bullets want to back out of their cases. They have this tendency because they are obeying one of Newton's laws... "a body at rest wants to remain at rest" etc. When a bullet backs out sufficiently from its case, it renders the revolver USELESS! The cylinder will not rotate because of the bullet(s) protruding from out in front...hitting the sides of the frame as the cylinder rotates

The reason you want to crimp is to increase neck tension. Neck tension will add resistance as the bullet starts its movement out of the case allowing pressure to build and ensuring complete combustion of the powder.

A roll crimp is the most common type of crimp for a revolver cartridge. A semi-auto round normally uses a taper crimp to keep the bullet form being pushed back into the casing. This is the exact opposite of a revolver where an un-crimped bullet may be pulled out of the casing. A crimp will also ensure reliable feeding in a semi-auto.

reads these

http://membres.multimania.fr/shooter/re ... chargt.htm

http://www.exteriorballistics.com/reloa ... /crimp.cfm

http://projects.nfstc.org/firearms/modu ... t09_04.htm

http://www.thefirearmsforum.com/showthread.php?t=76154

http://www.dave-cushman.net/shot/bullet ... mping.html