cruiser said:How much boost will Scat pro comp rods & Scat forged crank be reliable to?

SB around a 421.

I use SCAT rotating assembly's almost exclusively in my engine builds.

the rigidity of the block casting the fasteners used, the main cap design,

I have to point out theres a wide variation in the strength and quality of the various rotating assembly's components, and without knowing EXACTLY what parts your referring too, like the block it will be used in, the rigidity of the block casting the fasteners used, the main cap design, the boost pressures, the use or non-use of higher octane fuel, the connecting rods and rod bolt options selected, if it was custom balanced , the basic rpm range you intend to operate in , theres very little real info to base even a WILD GUESS AT BEST ON.

yes I see you listed a Scat pro comp rods & Scat forged crank , but even that changing options like rod bolts , bearings, use of main cap studs or bolts, use of splayed main caps , in something like a DART block vs an OEM block,

7/16”ARP 8740 cap screw

7/16” ARP 2000 cap screw

some of the newer stroker rods do in most cases let you avoid the use of a smaller base circle cam, but because there's dozens of different connecting rod designs and different types of rods and rod bolts clearances vary a good deal,

as alway you'll need to check & verify the clearances, once the cam is degreed in, and rods are installed in your particular engine.

Big-Inch Chevy Small-Block Cheat Sheet: Connecting Rods

Big-Inch Chevy Small-Block Cheat Sheet: Connecting Rods- Step by Step How-To Instructions, Images, Examples, and Checklists

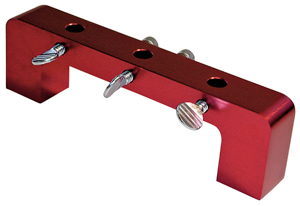

Chevy Small Block Cranks, Rods, and Piston Guide

Chevy Small Block Cranks, Rods, and Piston Guide- How to Build Max Performance Chevy Small Blocks on a Budget

383 Stroker Small Block Chevy - Car Craft Magazine

A 383 Stroker Small Block Chevy is analyzed, assembled and dynoed. Follow along and get every fact and trick you wanted to know about a 383 build. - Car Craft Magazine

should you re-use stock connecting rods?

I get asked all the time, "should you re-use those stock rods, when I rebuild my 350 or when I build my 383 stroker" or "Ive got a 325hp 396 BBC,Im rebuilding, should I upgrade or rebuild the connecting rods" most sbc and many BBC stock rods are designed to be cheap, and dependable in engines...

garage.grumpysperformance.com

the best solution from a performance perspective is to do the required calculations to select the longest length connecting rod and the lowest weight piston,

of a decent design that will reduce the reciprocating mass significantly more.

the tall deck has a 10.2" deck height, a good dual plane aluminum high rise intake manifold will tend to provide the best compromise if you use a low compression and mild cam duration,

while it might seem like a waste of time, now, reading the links and sub-links will provide a good base to work from, later and save you a great deal of wasted time and money

you have a choice, you can slap the components you own together, now and live with what you have built regardless of the results , or you can put some real thought into making the result perform and carefully select parts and significantly boost power... yes that routes more expensive up front, but in the long term it tends to get better results and cost LESS.

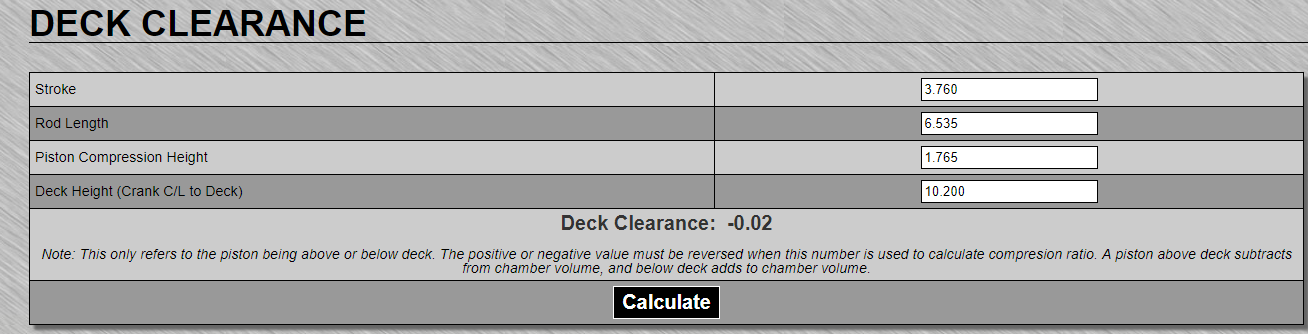

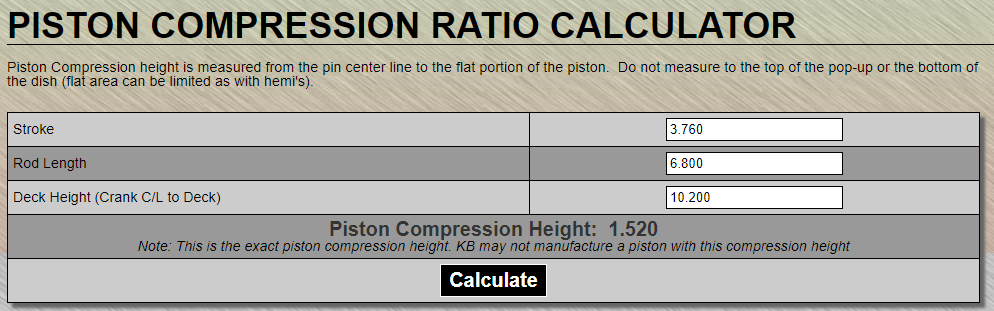

common BB CHEVY piston compression heights are

1.270"

1.395"

1.520"

1.645"

1.765"

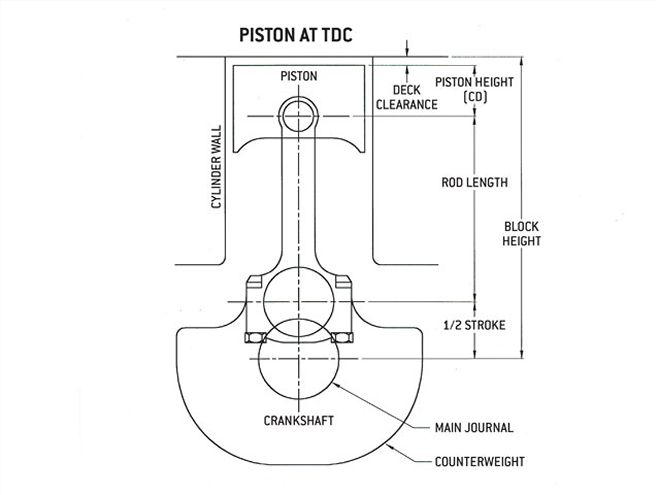

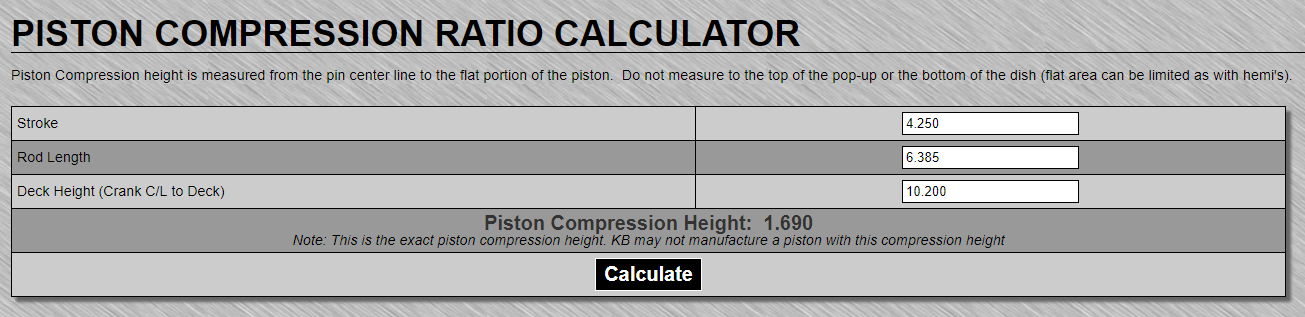

remember the blocks deck height, minus the piston pin height minus 1/2 the crank stroke will equal the required connecting rod length

OR

the blocks deck height, minus the connecting rod length, minus 1/2 the crank stroke. will equal the required piston pin height

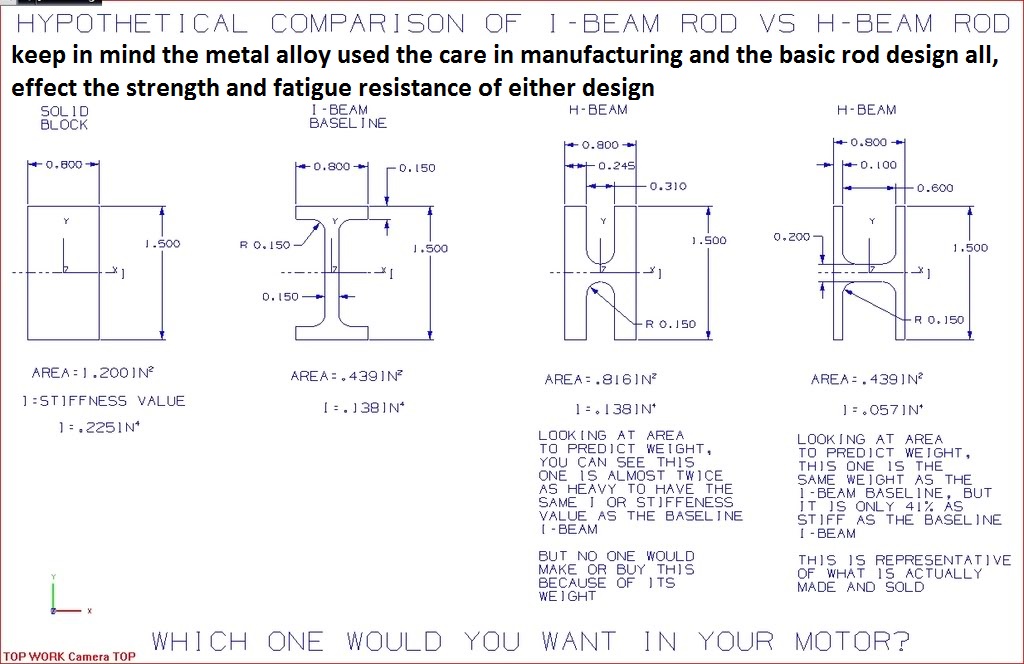

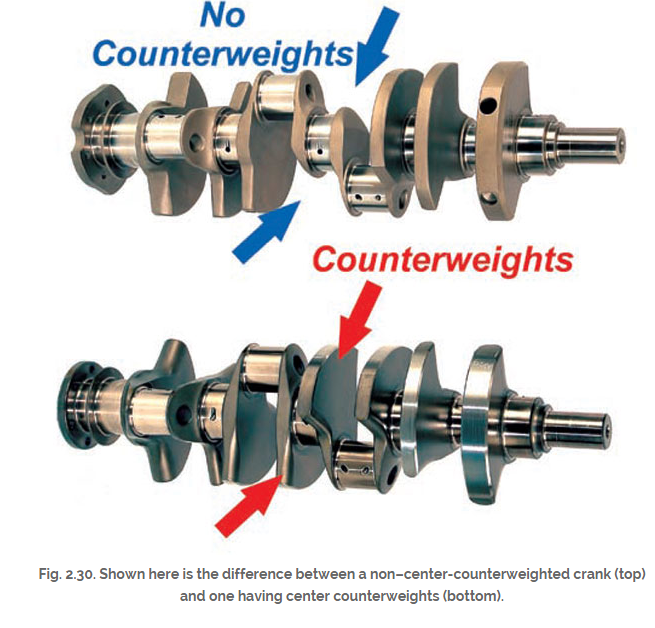

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

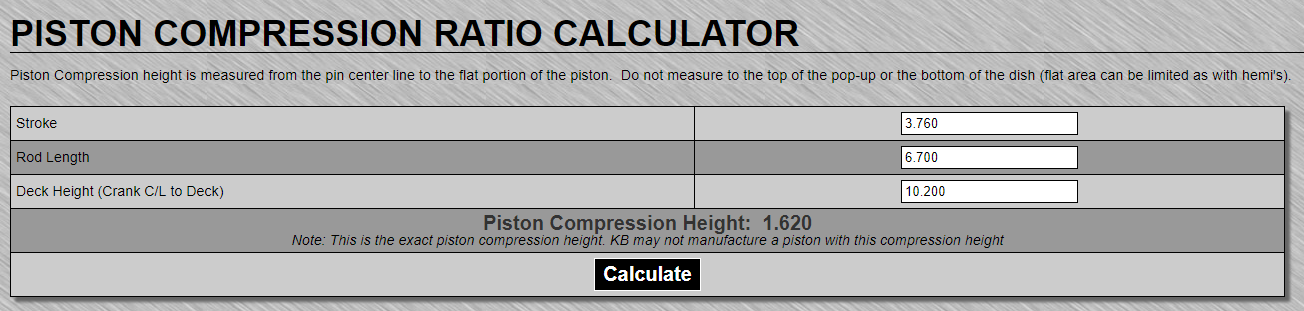

After market performance ,big block connecting rods come in several common lengths

6.7-6.8"

https://www.summitracing.com/parts/esp-67003dl19/overview/make/chevrolet

https://www.summitracing.com/parts/cpi-u16230/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6670022a/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6680022a/overview/make/chevrolet

https://www.summitracing.com/parts/sca-6680022/overview/make/chevrolet

notice the pin height in the pistons pictured above allow a longer or shorter connecting rod length

heres a selection of commonly available big block chevy connecting rod lengths

https://www.uempistons.com/index.php?main_page=calculators&type=deck

https://www.uempistons.com/index.ph...n_comp&zenid=a0b4d1c0899b781e5a1cffb2fe0afe21

your going to want the longer length and 150%-200% stronger aftermarket connecting rods with the much stronger 7/16" ARP rod bolts if your building a tall deck BBC engine,

so if your trying to build the best combo, you should select the longest and strongest connecting rods that allows you to select an off the shelf compression height piston to save money,

keep in mind head gaskets come in head gaskets come in .010 steps from about .020-to-about .80 and blocks generally measure 10.223 if that O.E.M. block has not previously machined, try too get the quench in the .040-.044 range,

you can get the piston thats compression height is .010-.015, .020 , .025, below or above the deck height, and with a matched head gasket get the quench correct after measuring the deck height, and compression height.

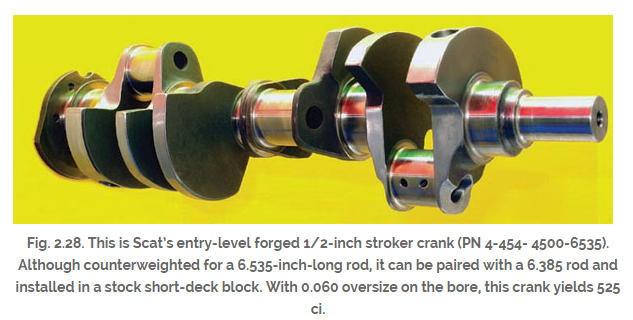

I recently helped one of the local guys assemble a 496 BBC 4.25" stroke

engine using 6.385: SCAT rods with 12.7:1 pistons thats being built

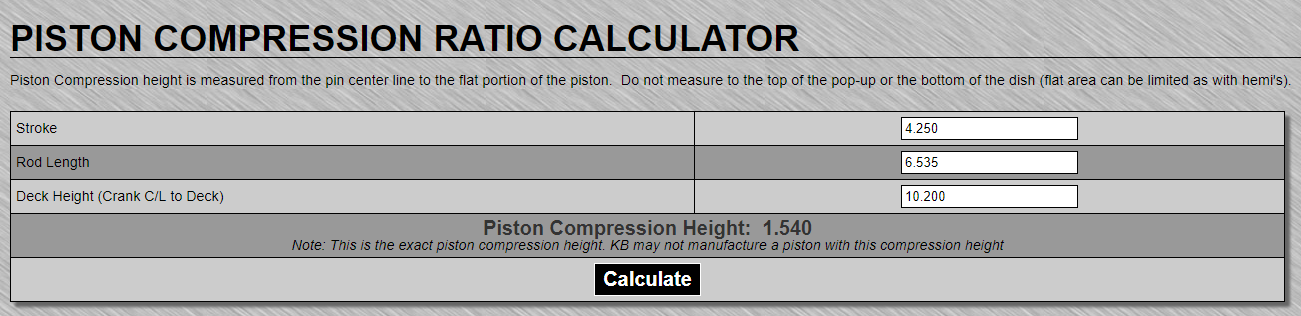

I watched him start to install the first piston with the dome facing the lifter gallery, or upper side of the cylinder... I waited until he had started to install the connecting rod cap on that first rod and asked him to rotate the crank to TDC I handed him a bridge and a dial indicator

https://www.uempistons.com/index.php?main_page=calculators&type=deck

https://www.uempistons.com/index.ph...n_comp&zenid=a0b4d1c0899b781e5a1cffb2fe0afe21

and asked him to verify the deck height.....honestly I had a real hard time not laughing.....I think most of us realize that we all made similar mistakes.... no harm done (YET).

after a few seconds, I suggested he check the spark plug clearance with the head just laid on the block with an old head gasket...yeah, he caught the mistake then!

https://mobiloil.com/en/article/car...w-to-assemble-an-engine-part-2-the-bottom-end

http://garage.grumpysperformance.co...ed-holes-in-bearings-shells.10750/#post-53298

https://mobiloil.com/en/article/car...w-to-assemble-an-engine-part-2-the-bottom-end

http://garage.grumpysperformance.co...d-side-clearance-dont-assume.4690/#post-12702

http://garage.grumpysperformance.co...nk-durring-short-blk-assembly.852/#post-39417

http://www.hotrod.com/articles/0901phr-less-expensive-big-block-chevy-engine/

http://garage.grumpysperformance.com/index.php?threads/measuring-rod-and-pin-heights.3760/#post-9968

http://garage.grumpysperformance.com/index.php?threads/deck-height-problems.3048/#post-8048

http://garage.grumpysperformance.com/index.php?threads/quench-squish.726/#post-1023

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

http://garage.grumpysperformance.com/index.php?threads/head-gasket-related.1859/#post-50617

https://www.uempistons.com/index.ph...e=deck&zenid=823ce2c9e2ffa691864d832c10107df0

https://www.uempistons.com/index.php?main_page=calculators&zenid=823ce2c9e2ffa691864d832c10107df0

heres the catalog

http://www.scatcrankshafts.com/downloads/14scat_catalog_10-13.pdf

http://www.scatcrankshafts.com/rotating-assemblies/rotating-assembly-product-search/

Phone: 310 370 5501

http://www.summitracing.com/parts/sca-440072lw

https://www.summitracing.com/search...Default&SortOrder=Ascending&autoview=SKU&ar=1

a 4" stroke SBC should be limited to about 6500 rpm even with good forged pistons and 7/16" ARP rod bolts, but as a WILD GUESS BASED ON SOME LIMITED EXPERIENCE, ID suspect a properly built 421 SBC spinning at a max of 6500rpm, under boost, with a stable roller cam valve train, thats tuned to avoid detonation, in a DART block would have reasonable durability under 750 hp

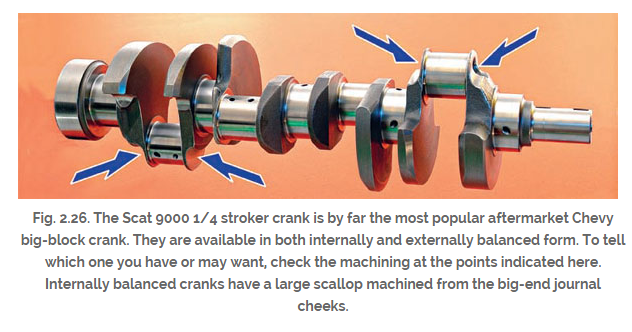

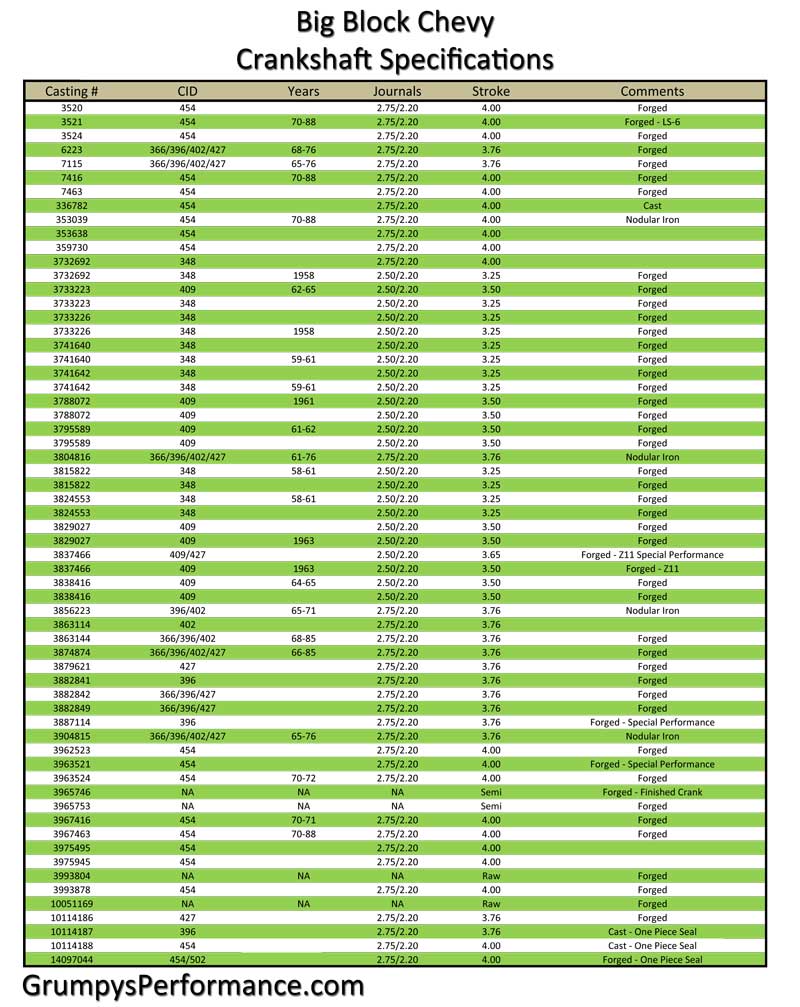

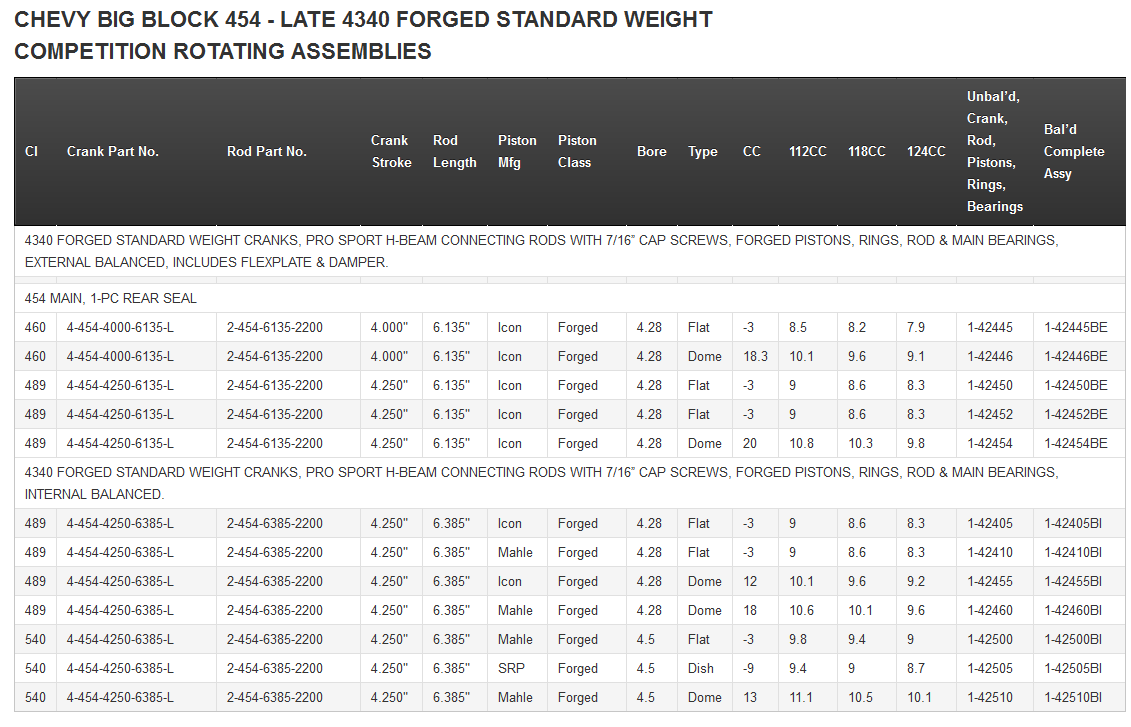

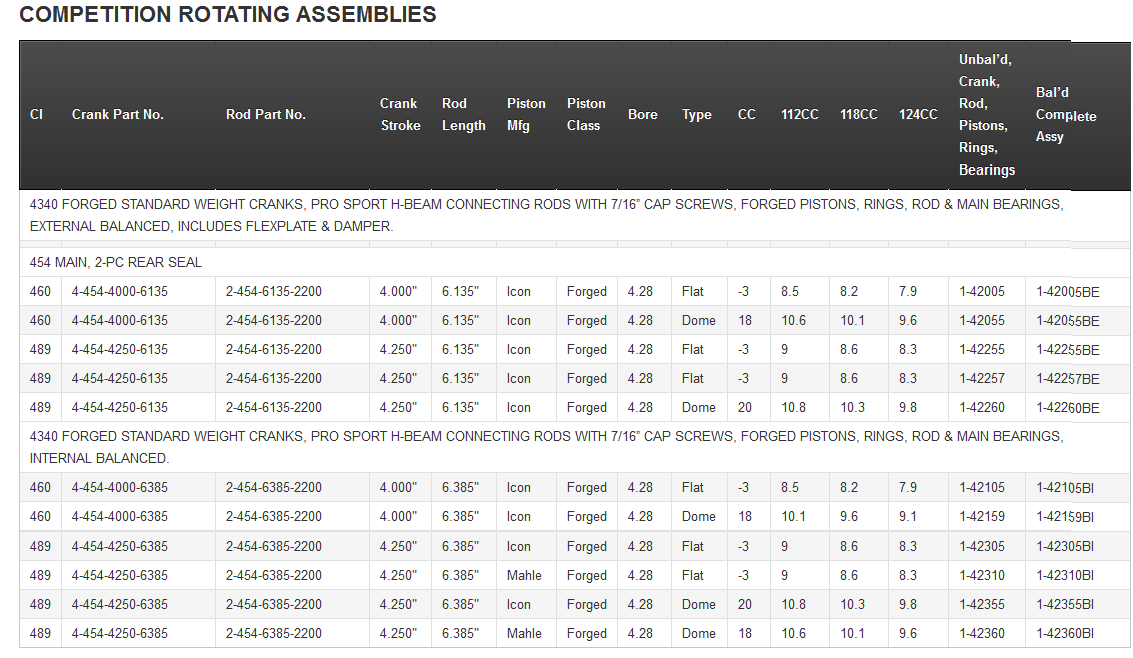

CHEVY BIG BLOCK 454 - LATE 4340 FORGED STANDARD WEIGHT

COMPETITION ROTATING ASSEMBLIES

CI Crank Part No. Rod Part No. Crank Stroke Rod Length Piston Mfg Piston Class Bore Type CC 112CC 118CC 124CC Unbal’d, Crank, Rod, Pistons, Rings, Bearings Bal’d Complete Assy

4340 FORGED STANDARD WEIGHT CRANKS, PRO SPORT H-BEAM CONNECTING RODS WITH 7/16” CAP SCREWS, FORGED PISTONS, RINGS, ROD & MAIN BEARINGS, EXTERNAL BALANCED, INCLUDES FLEXPLATE & DAMPER.

heres the catalog

http://www.scatcrankshafts.com/downloads/14scat_catalog_10-13.pdf

http://www.scatcrankshafts.com/rotating-assemblies/rotating-assembly-product-search/

Phone: 310 370 5501

http://garage.grumpysperformance.com/index.php?threads/496-bb-with-internal-balance.10743/

http://garage.grumpysperformance.com/index.php?threads/468-vs-496-stroker-question.9460/

http://garage.grumpysperformance.co...hy-not-a-4-375-or-4-5-big-block-stroker.6430/

http://www.chevydiy.com/1955-1996-chevy-small-block-performance-guide-crankshafts-manual-part-2/#

http://garage.grumpysperformance.com/index.php?threads/why-not-a-short-6-135-rod-496.5563/

http://garage.grumpysperformance.com/index.php?threads/why-6-385-connecting-rods.5328/

http://garage.grumpysperformance.com/index.php?threads/repair-or-replace-350-crank.14181/

http://garage.grumpysperformance.co...piston-to-bore-clearance-on-your-block.14251/

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68850

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/

http://garage.grumpysperformance.com/index.php?threads/468-build.11794/

http://garage.grumpysperformance.com/index.php?threads/cheaper-454-chevy-build.4620/

http://www.mre-books.com/chevy/engines/parts_interchange/crankshaft.html

http://www.scatcrankshafts.com/rotating-assembies/chevy-rotating-assemblies/

don,t assume the bearing journal diameters are correct, on any crankshaft,

, ( while they are almost certainly correct on a SCAT crank)

its good practice and certainly smart to measure carefully to be 100% sure, and that youve purchased and matched them to the correct matched bearing set!

I find it really amazing how often I see guys get 1/2 way into an engine assembly process and they suddenly want to change or modify some major component,

now in most cases that get expensive and the change will result in having to make corresponding matching changes in other

components

you could have saved a great deal of time and money,

by taking extra time in the research, phase of the engine build,

by simply shopping carefully,for each component and calculating how it will match the other selected components and it generally helps if you deal with a well known major name brand manufacturer and ask lots of carefully thought out questions and know exactly what your trying to accomplish and what your options are that you would want or prefer to have, especially in major components like the rotating assembly, and valve train components ,

ordering custom made 2618 forged aluminum, pistons with,

light weight tool steel wrist pins,

gas ports,

and thermal coated domes,

and friction reducing skirts,

a BALANCED 4340 forged steel rotating assembly,

with connecting rods that use ARP 7/16" rod bolts of the correct for the application strength rating.

Piston Alloy Comparison

4032........................... ................................2618

High silicon ......................................... ...........No silicon

Low expansion ................................... .........High expansion

Tighter piston-to-wall clearance . ...........More Piston-to-wall clearance needed

Quiet Operation .................................Noise when cold

Less ductile ........................................... More ductile

More stable & consistent.................... ...... Higher resistance to detonation

Longer life cycle.............................................. Shorter life cycles

Harder .................................................... ........Softer

http://www.venolia.com/

RELATED LINKED INFO

http://garage.grumpysperformance.com/index.php?threads/snap-ring-pliers.11029/#post-48839

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/

http://garage.grumpysperformance.com/index.php?threads/piston-suppliers.2208/#post-19329

http://garage.grumpysperformance.com/index.php?threads/piston-related-info.110/#post-31943

http://garage.grumpysperformance.com/index.php?threads/types-of-crankshaft-steel.204/#post-240

http://garage.grumpysperformance.co...ore-clearance-on-your-block.14251/#post-72471

http://garage.grumpysperformance.co...lling-connecting-rods-pistons.247/#post-57737

http://garage.grumpysperformance.co...y-in-building-a-good-engine.11682/#post-54682

http://garage.grumpysperformance.co...a-scat-rotating-assembly-be.11495/#post-52962

http://garage.grumpysperformance.co...-calculators-and-basic-math.10705/#post-46582

http://garage.grumpysperformance.com/index.php?threads/recipe-for-my-91-vette.14530/

http://garage.grumpysperformance.com/index.php?threads/rod-bolts-rpm-vs-stress.341/#post-68856

http://garage.grumpysperformance.com/index.php?threads/rotating-assembly-bearings.9527/#post-70329

http://garage.grumpysperformance.com/index.php?threads/piston-to-bore-clearance.4630/#post-12417

http://garage.grumpysperformance.co...n-you-plan-for-quench.11298/page-2#post-51613

http://garage.grumpysperformance.co...-displacement-street-engine.10961/#post-48185

http://garage.grumpysperformance.com/index.php?threads/piston-coating-deburring.4516/#post-16279

http://garage.grumpysperformance.com/index.php?threads/engine-balancing.3900/#post-10338

http://garage.grumpysperformance.co...ns-one-really-over-looked-part.978/#post-1711

Last edited: