Project K1500: Electric Fan Install

Keeping your Engine and Tranny Cool without Emptying your Wallet

Mar. 24, 2008By Jarred Meyer

If you are like me, you may have noticed that when getting a bit rough with your truck on the trails the engine quickly starts to build up heat. So you stop and let the truck run in idle hoping it will cool down. To your surprise, after waiting a few minutes it hasn’t begun to cool. You pop the hood to find that the fan is barely moving. This is because the stock mechanical clutch-driven fan is only designed to move at the speed of the engine and is not built to keep up with the slow speed, high power demands of crawling up rocks or through the mud. After searching far and wide I finally found a solution for keeping my engine running cool. Through some searching on the internet I found that you can prevent this problem by switching to an electric cooling fan.

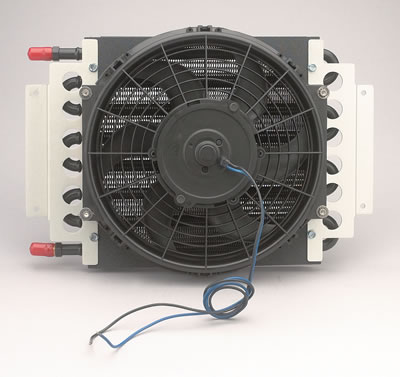

There are multiple benefits to using an

electric cooling fan over a

mechanical fan. First of all, when you are using the fan on a rig designed for riding through the mud or on the trails, you can have the fan running at full speed while the engine is running low RPMs. Another benefit to switching from a clutch-driven fan to an

electric fan is the gain in horsepower you get by taking the added strain off of the engine.

Some people say that where you gain HP by removing the mechanical fan you end up losing it again by adding strain on the alternator and electrical system. I can tell you first hand that the only strain I notice is just the initial start-up of the fan. Beyond that the truck has a noticeable gain in power. Another point to this debate is that the mechanical fanis almost always adding strain to the engine, even when it is cool. The electric fan, on the other hand, can be switched on only when it is needed. I have been running this setup through the winter and have actually only needed to turn the fan on once, which was due to a steep climb up a snow covered road in two-wheel drive.

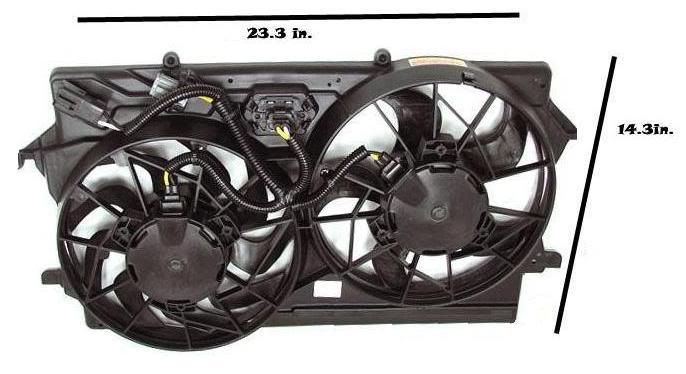

Once I decided on an electric fan I had to figure out which one to get. There is a countless number of possibilities on the market, in a wide range of prices. Initially I was going to cough up around $500 for a high-end dual fan set-up - but then one of my friends (who spends a lot of time in junkyards) came to me with an electric fan out of a Lincoln Mark VIII. Although I could not confirm it, he told me that this fan puts out around 4300 CFMs, which is more than just about any other stock cooling fan out there. He also told me that this particular fan can be found in any Mark VIII between the years '92-'96 which makes it an easy-to-find part at the junkyard. I bought it from him for $20.

The electric fan I used was stock from a 92-96 Lincoln Mark VIII.

Now that I finally had a fan, I needed to figure out a way to mount it in place of the existing fan and shroud. At first glance, the task appeared to be a rather difficult one. However, once I removed the old fan shroud I was able to develop a plan. While the existing fan is in place, you have to remove the old fan shroud in two pieces.

Once removed, you realize that you will be able to use the existing fan shroud in conjunction with the electric fan.

After I removed the fan shroud and set it aside, I then removed the old fan and clutch assembly from the pulley. Be sure you reinstall the four bolts onto the pulley that held the fan/clutch assembly or you will end up losing the belt and pulley down the road.

Remove the existing fan/clutch assembly by backing off the four nuts from the fan stem to the pulley.

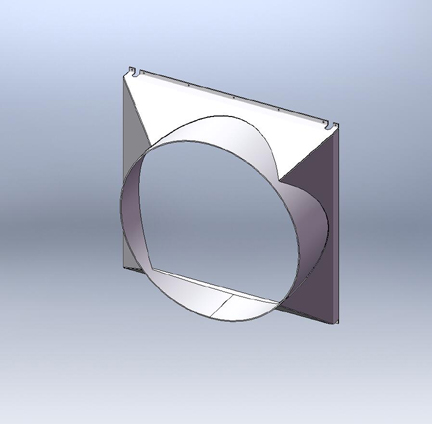

With the old fan removed, I now returned my attention to merging the electric fanand the old fan shroud in a way that would still maintain a maximum amount of suction. To do this I first bolted the two halves of the fan shroudback together and test fitted into the truck to make sure I could slide it back in its place without any conflicts. The only problem I ran into was the lower radiator hose and lower tranny cooler line. To allow the fan shroud to easily pass by these, I simply cut notches into the bottom corners of the shroud.

Slight modifications were made to the 2 existing fan shroudhalves to allow it to be reused in the installation of the electric fan.

Installing the electric faninto the existing shroud also turned out to be pretty easy. The only modifications I had to make were to cut the left and right side flanges off and clip off one of the lower corners. Then, with a little bit of persuasion, I was able to get the modified electric fanassembly to fit right inside of the old shroud. I drilled some holes through the top and bottom flanges of the electric fan assembly and old shroud and simply installed some bolts to hold the two together. This allowed for the maximum amount of air flow through the radiator and tranny cooler without losing too much suction through any holes.

A few modifications to the electric fan assembly allowed it to be installed easily into the old fan shroud.

That completed the merging of the fan shroud and Mark VIII electric fan and it was now time to install the new fan assembly into the truck, wire it up and test it out.

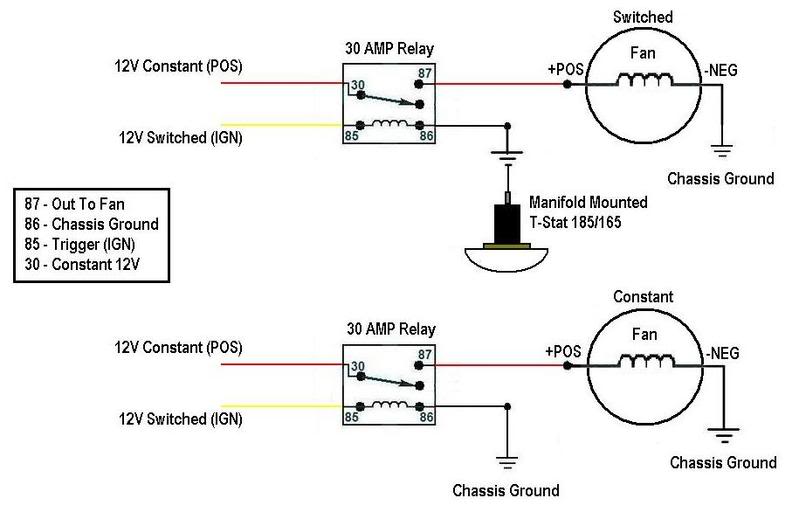

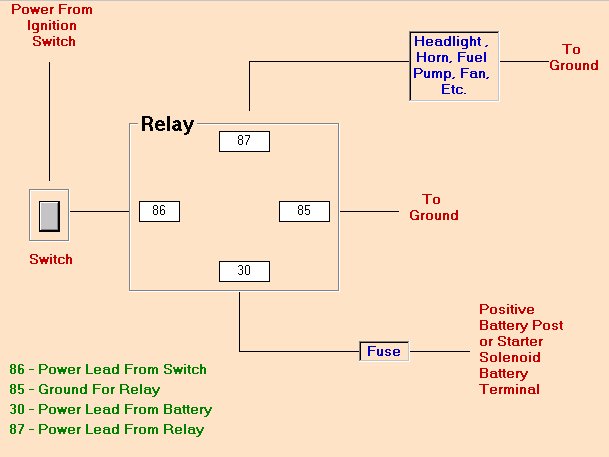

Now, like many of my other wiring projects, I cut a few corners knowing that I will be rewiring the truck in the near future anyway. Besides, I was anxious to see how well the fan worked! Using a few relays and grounding the assembly to the closest bolt, I could just about completed the wiring side of the fan. I ran a wire into the cab and hooked it up to one of my auxiliary switches and I was ready to go. It is possible to get a thermostat to use with the electric fan so that you don’t have to be continually monitoring the temp gauge, but as I found out driving around a bit, you will know when the fan needs to be running. Another advantage to running the fan on a switch is that you can turn it off if you are going to run through some deep water to avoid damaging the fan.

Now that the installation was complete I jumped into the cab and switched the fan on to make sure it worked. The fan started up instantly and sounded similar to a jet powering its engines up for takeoff. It was a very reassuring sound, and I could tell this fan was definitely moving more air than the stock mechanical fan ever could. I turned the fan back off and started to drive around to get the temperature up higher than normal so I could see how quickly the fan would recover. As I pulled up to a stop light I watched as the temperature gauge climb up to around 240. I quickly switched the fan on and to my amazement the rising temperature was instantly put into check and began to fall back down. On the way home I did it again and timed it to see how quickly it recovered. I was amazed to see the temperature back to normal within 60 seconds.

Using the electric fanfrom the Mark VIII turned out to be a complete success!

Replacing the stock cooling fan on Project ’93 K1500 has been one of the most effective low-budget projects I have done. (Maybe minus the snorkelof course. I will get the truck into some deeper water once the interior and wiring will handle it.) I got the truck out to a local mud fest a few weekends ago and was really working it hard - it never came close to overheating the engine. I would definitely recommend this project to anyone who wants to use their truck for even the lightest off-road driving.

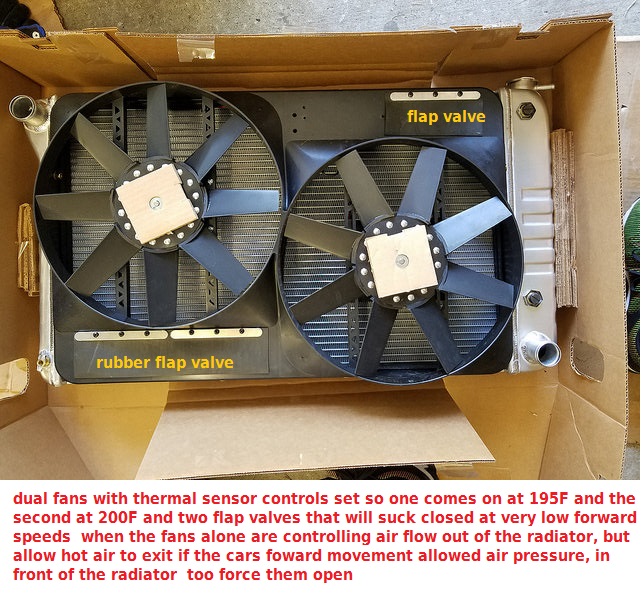

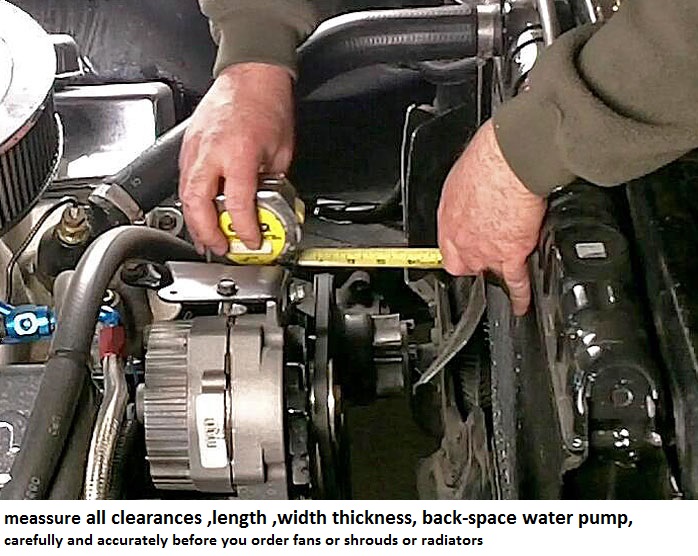

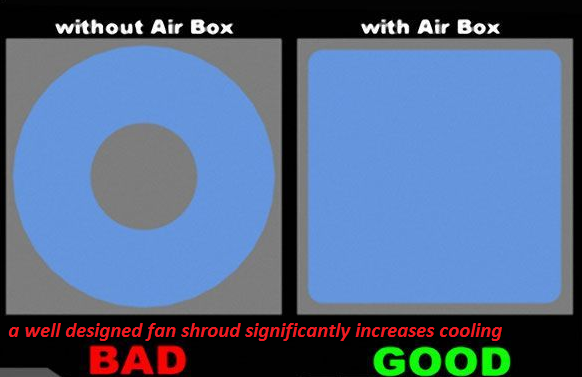

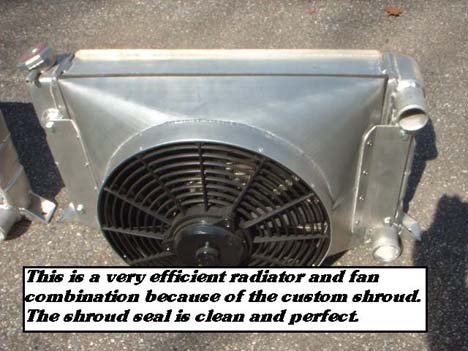

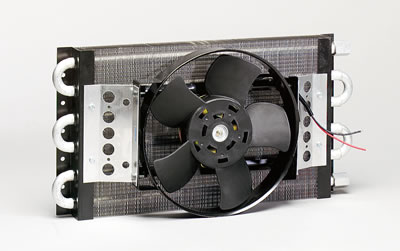

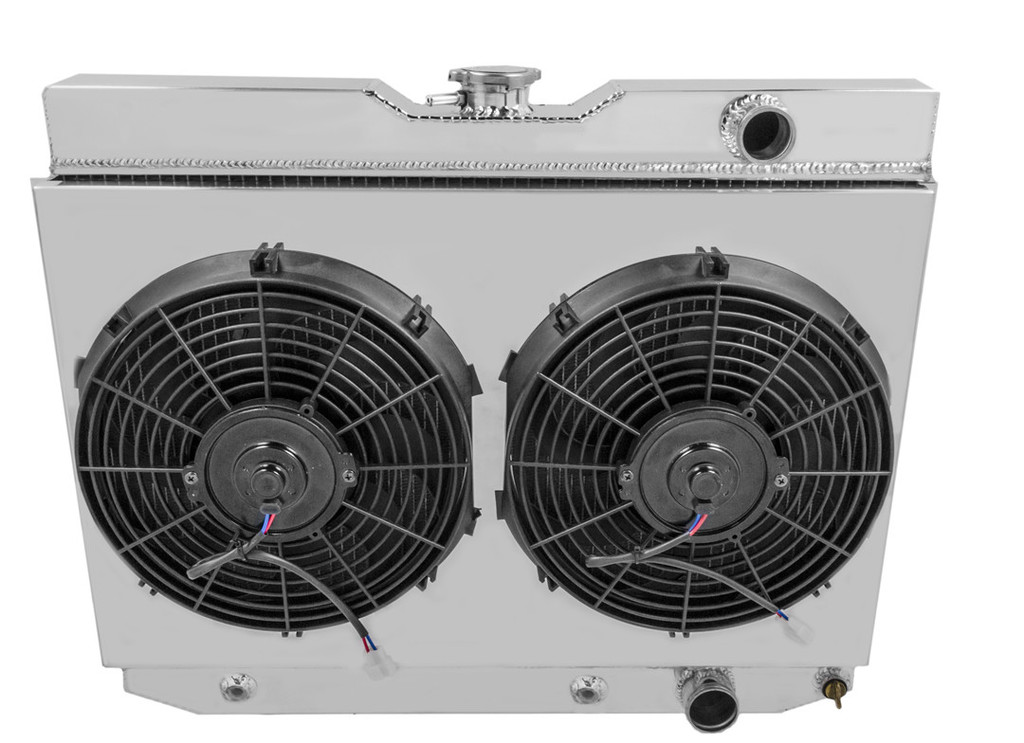

if coolant in the engine gets hotter faster at idle than when your cruising the cause is frequently related to either a lack of air flow (not the correct fan or shroud)

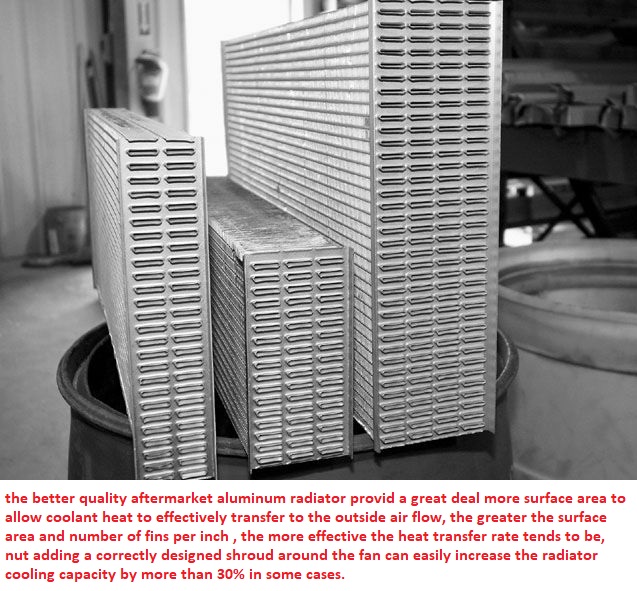

or not enough functional radiator surface area,as the car speed increases it obviously has the effect of increased air flow that results in more efficient heat transfer rates

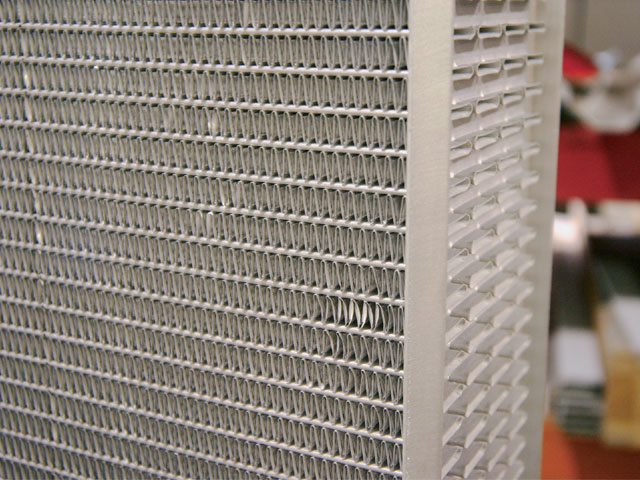

yes the idea of a larger radiator with increased surface area helps.

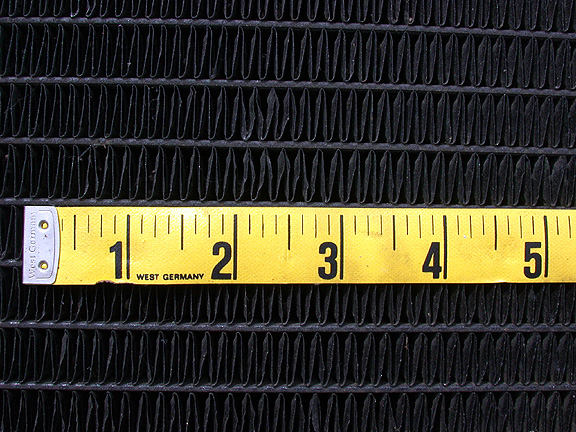

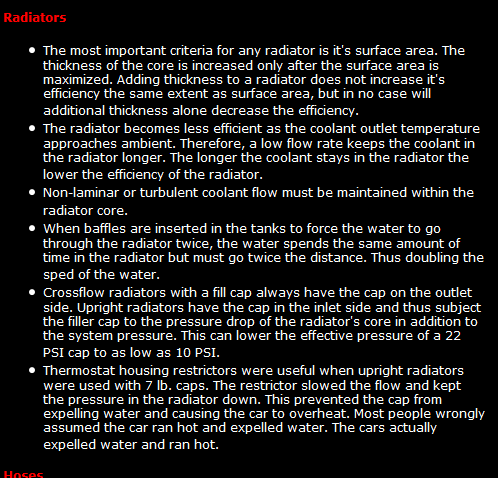

most of us are forced due to clearance limitations to select a radiator with specific width and height limitations you can frequently select a radiator thats a bit thicker,

or has a higher fin count per square inch of surface or more efficient inner coolant tube designs.

reading links helps

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/2-row-vs-3-row.5160/

http://garage.grumpysperformance.co...roving-engine-cooling-system-capability.6888/

http://garage.grumpysperformance.com/index.php?threads/do-i-need-the-fan-shroud.13847/