I got ask, (whats the difference between the one and two, piece rear seal cranks)

viewtopic.php?f=71&t=584&p=757&hilit=lakewood#p757

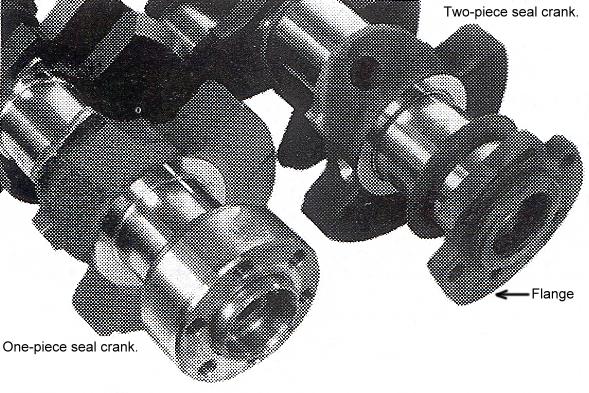

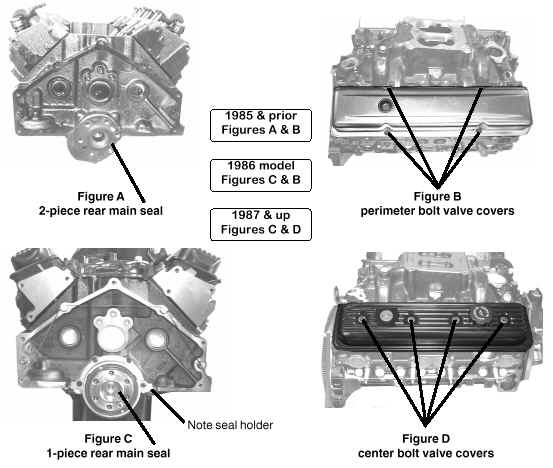

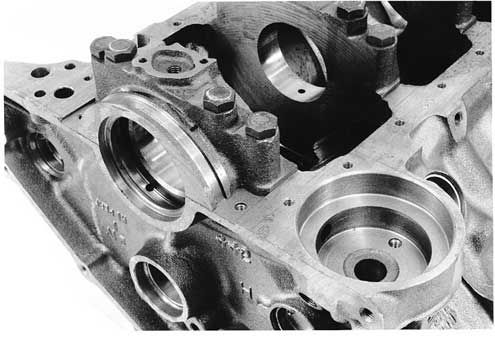

older TWO PIECE REAR SEAL CRANK

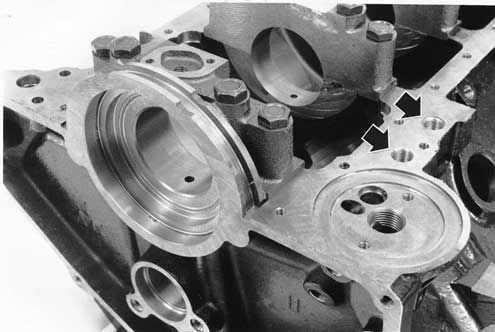

NEWER ONE PIECE REAR CRANK SEAL DESIGN

http://www.mortec.com/journal.htm

(look at the lower chart)

Gen.I, "Small Journal"

265...Mains-2.30"-Rods-2.00"

283...Mains-2.30"-Rods-2.00"

302...Mains-2.30"-Rods-2.00"

327...Mains-2.30"-Rods-2.00"

Gen.I, "Medium Journal", includes "Vortec" 305 and 350 thru '98

262...Mains-2.45"-Rods-2.10"

267...Mains-2.45"-Rods-2.10"

302...Mains-2.45"-Rods-2.10"

305...Mains-2.45"-Rods-2.10"

307...Mains-2.45"-Rods-2.10"

327...Mains-2.45"-Rods-2.10"

350...Mains-2.45"-Rods-2.10"

Gen.I, "Large Journal"

400...Mains-2.65"-rods-2.10"

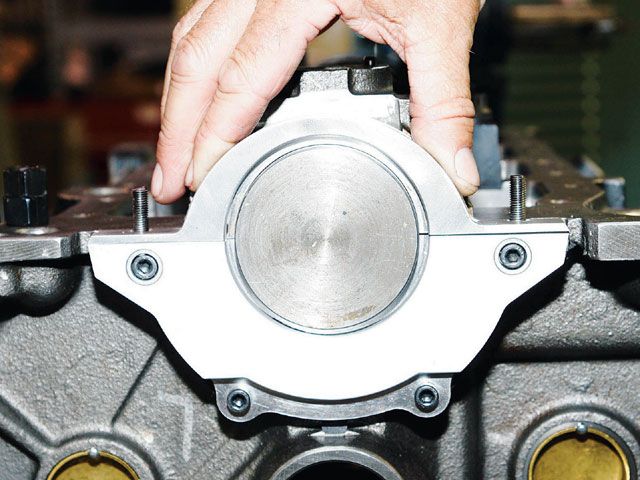

Be sure the lip seal is positioned leaning inward towards the front of the engine, and the rear seals off-set from the main cap parting line by about 1/4" to reduce the tendency to leak oil

MORE USEFUL INFO

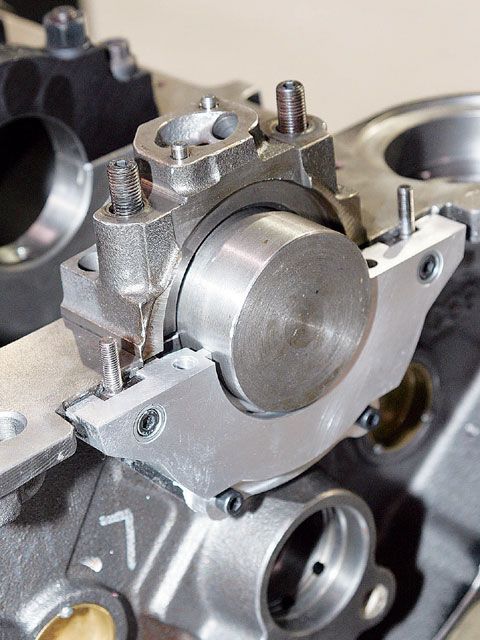

BE 100% SURE that the oil pump bolt or STUD doesn,t protrude past the inner main cap surface , because if it bears on the rear main bearing shell it will almost always result in a quickly failed rear bearing

failure to use the correct stud, bolt or nut or check clearances when mounting an oil pump can cause problems

ONE RATHER COMMON MISTAKE IS USING THE WRONG OIL PUMP STUD OR BOLT TO MOUNT THE OIL PUMP AS IF EITHER EXTENDS THRU THE REAR MAIN CAP IT CAN AND WILL BIND ON THE BEARING AND LOCK OR RESTRICT, SMOOTH ROTATION

BTW, , on BIG BLOCKS the oil pumps and oil filter adapters are different due to the block oil filter recess and rear seals being different

roller blocks have taller lifter bores, because roller lifters are taller, and a provision to bolt the lifter retainer spring, but they can be very easily used for the earlier flat tappet lifters if desired by simply removing the spider(SPRING RETAINER), keep in mind most roller blocks use one piece rear seals

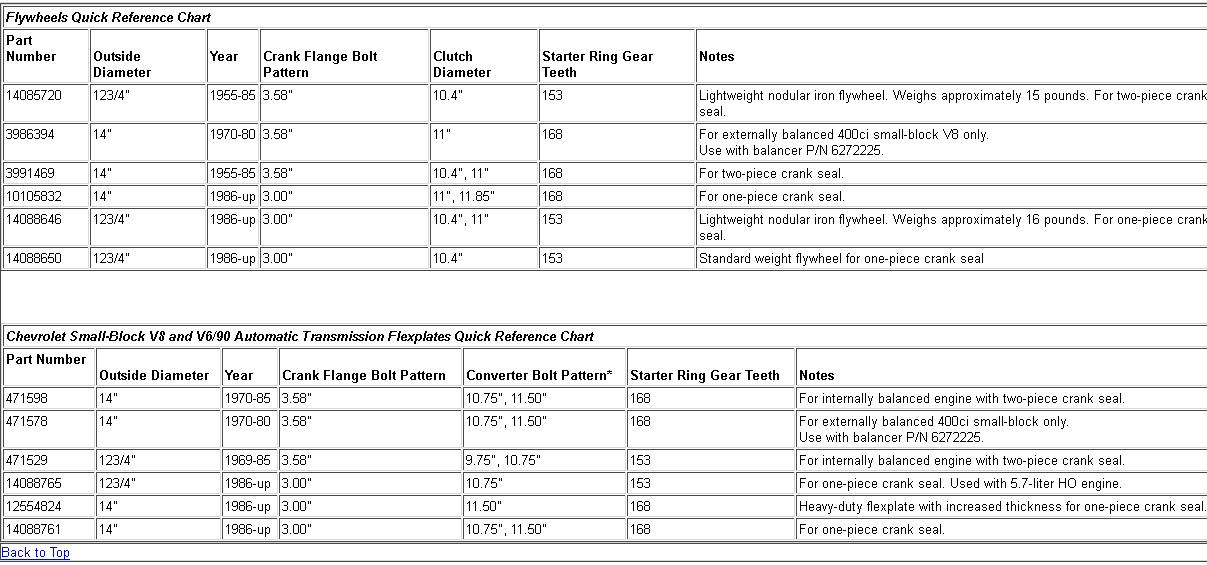

the flywheel must match the crank hub design, a first gen 283-327- 350 will have a two piece rear seal crank up to about 1987, or so, they look completely different so you should have zero problem telling what your dealing with, and most of those engine are usually internally balanced, the later1987 and up engine is usually a one piece rear seal design that most likely will not work with the older style hub crank and flywheel parts and your bell housing may or may not fit the larger 168 tooth flywheel design , and may require the smaller 153 tooth design, some of the newer sbc engines take a different damper like the LT1 , one piece rear seal crank designs and the BIG BLOCK engines can be EXTERNALLY or INTERNALLY balanced, most of the engines larger than 427 cubic inches were EXTERNALLY BALANCED

read these

viewtopic.php?f=38&t=3900&p=13058&hilit=balancing#p13058

viewtopic.php?f=71&t=447

older TWO PIECE REAR SEAL CRANK

don't forget the rear surface of the rear seal to block and main cap needs to be sealed, oil tight

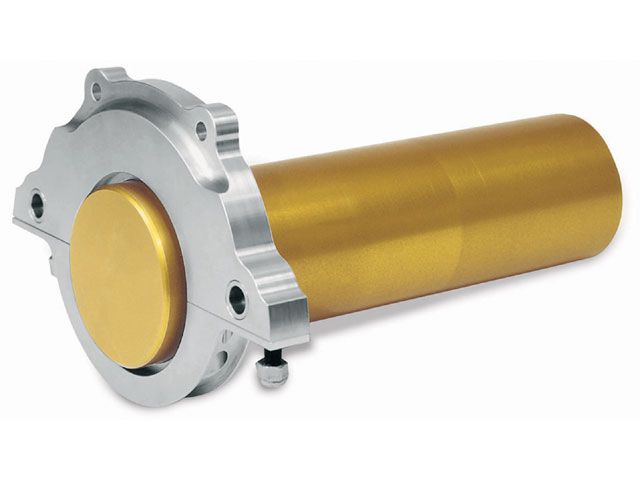

NEWER ONE PIECE REAR CRANK SEAL DESIGN

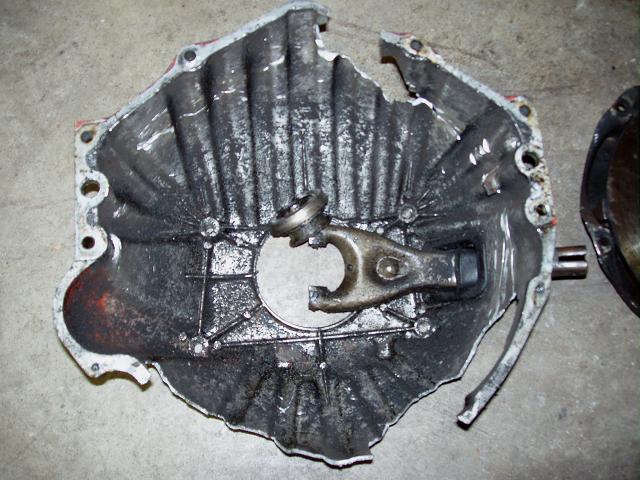

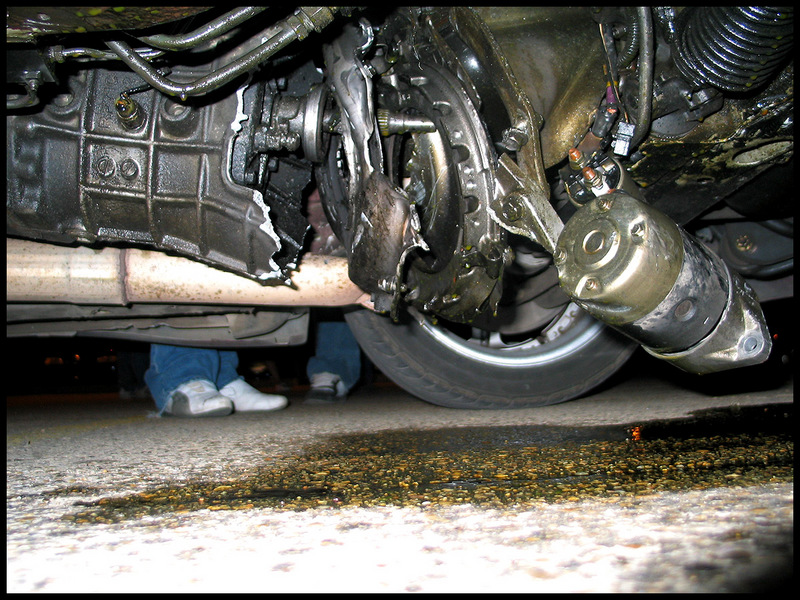

keep in mind a SFI SCATTER SHIELD to protect your feet is almost mandatory, on a high performance engine combo

a stock bell housing provides almost zero protection if a flywheel or clutch comes apart at high rpms, and getting your feet cut off in the process is not unheard of as a result

cheap iron

http://www.summitracing.com/parts/ZZZ-50-6516/

if you like having FEET!

http://www.summitracing.com/parts/RAM-1511/