I added this post to the milling machine thread, but because it won,t show Im posting it here for those few guys with heavy drill presses and mills that might benefit from the info, if you want more info do a search on "MILLING MACHINES" on the site, and reading the links will provide you with a great deal of related info... yes I know some people would rather cut their own throats than read links and sub-links but for those willing to learn , heres a good bit of useful info

http://www.use-enco.com/CGI/INSRHI?PMSECT=0000000996

A GOOD DEAL MORE RELATED INFO IN THE LINKS, and SUB LINKS

http://its.fvtc.edu/MachShop1/coolant/cutfluids.htm

http://en.wikipedia.org/wiki/Cutting_fluid

http://www.liquidicecoolant.com/

http://www.micromark.com/MICROFLOW-COOL ... ,8474.html

http://www.machinetoolhelp.com/Applicat ... fluid.html

viewtopic.php?f=27&t=2198&p=8385&hilit=mill#p8385

viewtopic.php?f=50&t=8340&p=30801&hilit=larger+tools#p30801

http://www.littlemachineshop.com/produc ... us=Coolant

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68876

http://garage.grumpysperformance.com/index.php?threads/mill-and-lathe-info-you-might-need.2198/

http://garage.grumpysperformance.co...hine-tools-like-a-mill-lathe.8340/#post-67349

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-59253

http://garage.grumpysperformance.co...s-you-need-tools-and-skills.11379/#post-52068

http://garage.grumpysperformance.co...op-needs-a-decent-drill-press.970/#post-50726

http://garage.grumpysperformance.co...-are-you-looking-to-acquire.10920/#post-47935

http://garage.grumpysperformance.co...-in-vs-threaded-rocker-studs.2746/#post-43539

http://garage.grumpysperformance.co...luid-chip-filter-for-my-mill.6093/#post-18813

well the milling machine arrived,and as most machinists know you need cutting fluid and cooling oil to keep the tooling bit edges cool or the cutting bits burn up almost instantly when cutting metal, and that cutting oil is not a great rust preventative, so if your asking what oil you need ,are you asking about protecting them from rust or cooling the cutting edge of the bit while cutting steel or aluminum ?

WD40 will work for cooling the bit, on a common drill press but its not what you want with a mill that will use a constantly recirculating cutting fluid pumped to the cutting bit while in use.you can use automotive oil to protect tooling while its stored in zip loc bags or air tight boxes like tupper ware but real water based cutting oils preferable to use while machining parts

http://www.amazon.com/CRC-SL2512-Solubl ... r+drilling

I got my sons to unpack and install it, in the shop which was difficult as it weights 2400lbs, then after carefully reading the instructions its obvious we needed , to order a few accessories like bit holders and cutting bits, coolant pumps, coolant, table clamps, vises,etc.

(easily an extra $500, but that was kind of expected)

but my sons should be able to use the machine once all those components arrive!

this should allow them to do a good deal more

the guys at the grizzly site (tech guys) were friendly and helpful , and understanding)

http://www.grizzly.com/

anyone with a drill press or a mill quickly finds that drilling steel builds heat and your better off with a constant flow of cooling cutting fluid which obviously requires both a pump and method to keep it flowing to the drilled components and a tray and drain pan or some way to collect and recirculate the cutting fluid, and a realization that the fluid will of necessity be both reusable, water soluble oil base cutting fluid that prevents rust, and not cause rust on the tools.

as most guy know,combining fairly slow rpms and constant flow of cutting oil over the bit, contact area and moderate pressure are pretty much required on most metal drill jobs, leaning on the drill and spinning it as fast as you can are a sure recipe for a burn,busted, bent or dull drill bit

http://www.grizzly.com/products/Rustlic ... llon/H9240

looking at coolants for the cutting operation, any info is appreciated from experienced mill operators??

rust prevention? aid to cutting? tool life? any info at all??

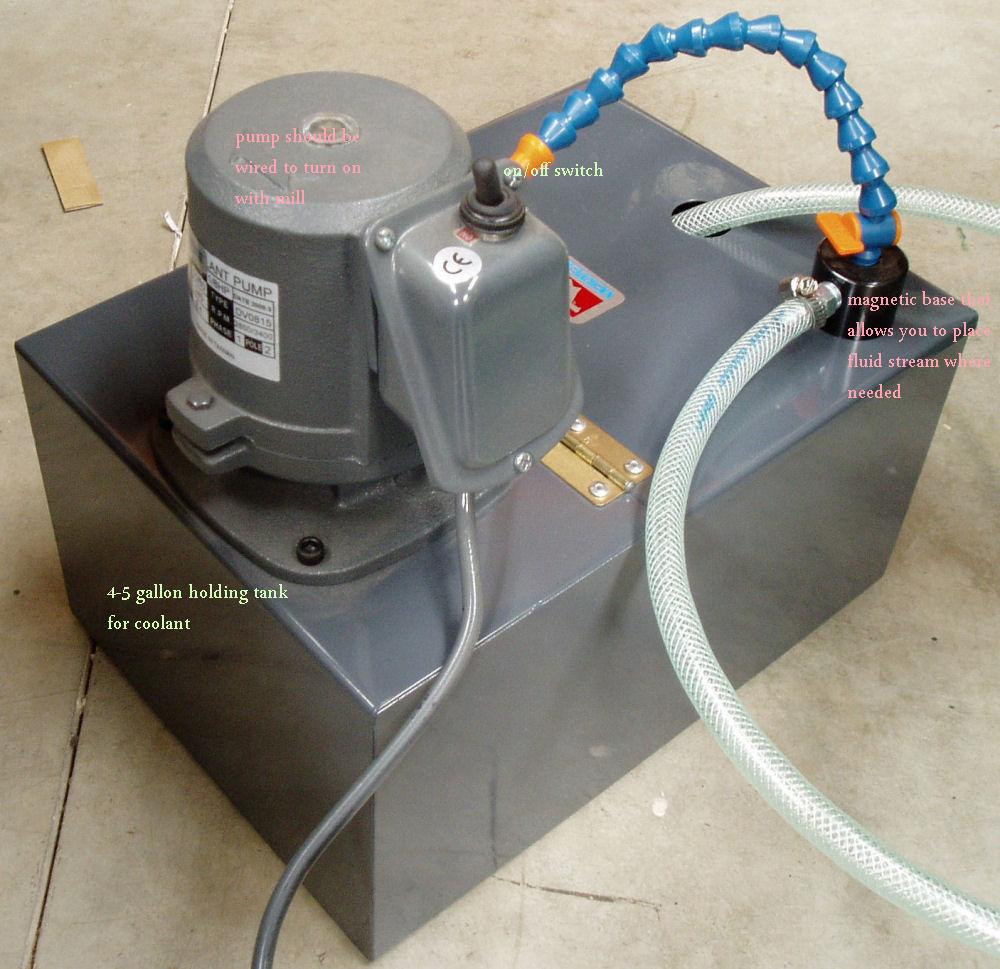

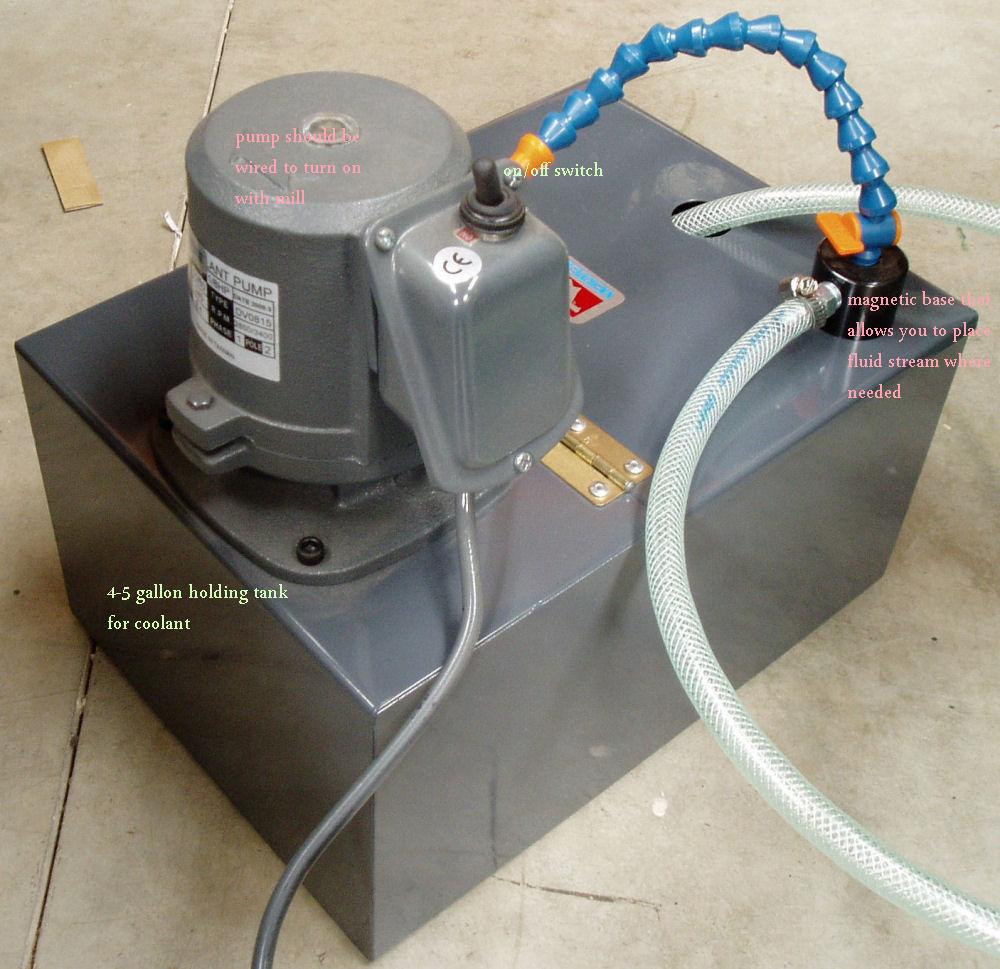

I purchased this coolant pump and tank combo for use on my drill press and mill

I purchased a fox milling machine several years ago when I got frustrated at local shops absurdly over billing me for darn simple milling machine work, I may or may not have made the smartest financial move as the cost of the mill is only a small part as you need rather extensive accessories and tooling before the machines useful and I'll admit I was not expecting those components to cost almost as much as the mill. I took several classes in college, and learned the basics, but you really learn more once your hands-on and youll find you always need to do more research, watch videos and occasionally pay some local machinist to show you how to do something correctly.. and of course theres an expensive and endless list of new tooling to be purchased , on the plus side the tooling and mill cost is partly offset by the savings in work your not sending out.

Weighing in at over 2400 lbs of cast iron and hardened precision ground steel, Model M1003 has the size and stability to handle the toughest jobs. With a 2 HP motor driving 8 speeds from 78 to 2400 RPM, 3 speed quill feed with a micrometer depth stop and auto reverse, and a variable speed longitudinal power feed, this machine has the ability to do the most complex and precise jobs. This brute has both power and finesse!

One-shot pump lubrication

Auto down feed

Quill feeds/spindle rev.: .0019", .0035", .0058" Auto stop with micro adjustable stop

R-8 spindle Longitudinal power feed

Hardened and ground table surface Chrome plated, precision-ground quill

Adjustable micrometer quill depth stop

Motor: 2 HP, 110V/220V, single-phase, TEFC, prewired to 220V

Spindle travel: 5"

Table size: 9" x 49"

Table travel (longitudinal): 27"

Table travel (cross): 12"

Max. dist. spindle to table: 18-3/4"

Max. dist. spindle to column: 18-1/2"

Knee travel: 16"

Head tilt: 45° both ways

Head swivel: 90° both ways

T-slots: 3 on 2-1/2" centers, 1/2" studs

Speeds: 8 Range of speeds: 78, 98, 197, 278, 670, 850, 1700 and 2400 RPM

Approximate shipping weight: 2405 lbs.

http://www.grizzly.com/products/h9240

http://www.grizzly.com/products/7-Gallo ... stem/H8140

or is this better or worse??

you need constant coolant flow over a cutting tool on a mill or the bit burns up

http://www.littlemachineshop.com/produc ... 1229644699

well I purchased this along with the mill and it works good so far

but I got to thinking that all the extra fine metallic chips that get carried by the coolant back to the coolant pump might cause damage so I purchased a few simple components and built a cutting oil filter, to prevent crap from entering the coolant reservoir and pump.

I purchased 2 ft of 1.5" pvc two threaded reducer end caps three 90 degree elbows, two threaded hose barbs and a package of brass scrub pads to act as a rough filter medium inside the pvc . the hose barbs screw into the end caps, the end caps glue into the pvc and the brass scrub pads inserted inside the pvc acting as a metallic chip barrier that easily allows liquids but not metallic debris to pass, correctly assembled you have an (L) shaped section of 1.5" pvc pipe with each leg about 12" long , and two reducer end caps that face vertically with hose connections and a basic course filter internally by use of a couple brass or stainless mazes for coolant to flow thru that will trap most of the chips in the fluid.

its not designed to trap or filter out everything but it will cause almost any of the larger chips to fail to reach the coolant tank and pump for recirculation,back to the coolant sprayed on the cutting bit location. this at least in theory should reduce the chances of the coolant pump ingesting metallic crap , like small cuttings and flakes thats bound to eventually damage the pump

http://www.use-enco.com/CGI/INSRHI?PMSECT=0000000996

http://its.fvtc.edu/MachShop1/coolant/cutfluids.htm

http://en.wikipedia.org/wiki/Cutting_fluid

http://www.liquidicecoolant.com/

http://www.micromark.com/MICROFLOW-COOL ... ,8474.html

http://www.machinetoolhelp.com/Applicat ... fluid.html

viewtopic.php?f=27&t=2198&p=8385&hilit=mill#p8385

viewtopic.php?f=50&t=8340&p=30801&hilit=larger+tools#p30801

http://www.littlemachineshop.com/produc ... us=Coolant

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68876

http://garage.grumpysperformance.com/index.php?threads/mill-and-lathe-info-you-might-need.2198/

http://garage.grumpysperformance.co...hine-tools-like-a-mill-lathe.8340/#post-67349

http://garage.grumpysperformance.com/index.php?threads/finding-a-machine-shop.321/#post-59253

http://garage.grumpysperformance.co...s-you-need-tools-and-skills.11379/#post-52068

http://garage.grumpysperformance.co...op-needs-a-decent-drill-press.970/#post-50726

http://garage.grumpysperformance.co...-are-you-looking-to-acquire.10920/#post-47935

http://garage.grumpysperformance.co...-in-vs-threaded-rocker-studs.2746/#post-43539

http://garage.grumpysperformance.co...luid-chip-filter-for-my-mill.6093/#post-18813

well the milling machine arrived,and as most machinists know you need cutting fluid and cooling oil to keep the tooling bit edges cool or the cutting bits burn up almost instantly when cutting metal, and that cutting oil is not a great rust preventative, so if your asking what oil you need ,are you asking about protecting them from rust or cooling the cutting edge of the bit while cutting steel or aluminum ?

WD40 will work for cooling the bit, on a common drill press but its not what you want with a mill that will use a constantly recirculating cutting fluid pumped to the cutting bit while in use.you can use automotive oil to protect tooling while its stored in zip loc bags or air tight boxes like tupper ware but real water based cutting oils preferable to use while machining parts

http://www.amazon.com/CRC-SL2512-Solubl ... r+drilling

I got my sons to unpack and install it, in the shop which was difficult as it weights 2400lbs, then after carefully reading the instructions its obvious we needed , to order a few accessories like bit holders and cutting bits, coolant pumps, coolant, table clamps, vises,etc.

(easily an extra $500, but that was kind of expected)

but my sons should be able to use the machine once all those components arrive!

this should allow them to do a good deal more

the guys at the grizzly site (tech guys) were friendly and helpful , and understanding)

http://www.grizzly.com/

anyone with a drill press or a mill quickly finds that drilling steel builds heat and your better off with a constant flow of cooling cutting fluid which obviously requires both a pump and method to keep it flowing to the drilled components and a tray and drain pan or some way to collect and recirculate the cutting fluid, and a realization that the fluid will of necessity be both reusable, water soluble oil base cutting fluid that prevents rust, and not cause rust on the tools.

as most guy know,combining fairly slow rpms and constant flow of cutting oil over the bit, contact area and moderate pressure are pretty much required on most metal drill jobs, leaning on the drill and spinning it as fast as you can are a sure recipe for a burn,busted, bent or dull drill bit

http://www.grizzly.com/products/Rustlic ... llon/H9240

looking at coolants for the cutting operation, any info is appreciated from experienced mill operators??

rust prevention? aid to cutting? tool life? any info at all??

I purchased this coolant pump and tank combo for use on my drill press and mill

I purchased a fox milling machine several years ago when I got frustrated at local shops absurdly over billing me for darn simple milling machine work, I may or may not have made the smartest financial move as the cost of the mill is only a small part as you need rather extensive accessories and tooling before the machines useful and I'll admit I was not expecting those components to cost almost as much as the mill. I took several classes in college, and learned the basics, but you really learn more once your hands-on and youll find you always need to do more research, watch videos and occasionally pay some local machinist to show you how to do something correctly.. and of course theres an expensive and endless list of new tooling to be purchased , on the plus side the tooling and mill cost is partly offset by the savings in work your not sending out.

Weighing in at over 2400 lbs of cast iron and hardened precision ground steel, Model M1003 has the size and stability to handle the toughest jobs. With a 2 HP motor driving 8 speeds from 78 to 2400 RPM, 3 speed quill feed with a micrometer depth stop and auto reverse, and a variable speed longitudinal power feed, this machine has the ability to do the most complex and precise jobs. This brute has both power and finesse!

One-shot pump lubrication

Auto down feed

Quill feeds/spindle rev.: .0019", .0035", .0058" Auto stop with micro adjustable stop

R-8 spindle Longitudinal power feed

Hardened and ground table surface Chrome plated, precision-ground quill

Adjustable micrometer quill depth stop

Motor: 2 HP, 110V/220V, single-phase, TEFC, prewired to 220V

Spindle travel: 5"

Table size: 9" x 49"

Table travel (longitudinal): 27"

Table travel (cross): 12"

Max. dist. spindle to table: 18-3/4"

Max. dist. spindle to column: 18-1/2"

Knee travel: 16"

Head tilt: 45° both ways

Head swivel: 90° both ways

T-slots: 3 on 2-1/2" centers, 1/2" studs

Speeds: 8 Range of speeds: 78, 98, 197, 278, 670, 850, 1700 and 2400 RPM

Approximate shipping weight: 2405 lbs.

http://www.grizzly.com/products/h9240

Loading…

www.grumpysperformance.com

Loading…

www.grumpysperformance.com

Loading…

www.grumpysperformance.com

Loading…

www.grumpysperformance.com

Loading…

www.grumpysperformance.com

Loading…

www.grumpysperformance.com

http://www.grizzly.com/products/7-Gallo ... stem/H8140

or is this better or worse??

you need constant coolant flow over a cutting tool on a mill or the bit burns up

http://www.littlemachineshop.com/produc ... 1229644699

well I purchased this along with the mill and it works good so far

but I got to thinking that all the extra fine metallic chips that get carried by the coolant back to the coolant pump might cause damage so I purchased a few simple components and built a cutting oil filter, to prevent crap from entering the coolant reservoir and pump.

I purchased 2 ft of 1.5" pvc two threaded reducer end caps three 90 degree elbows, two threaded hose barbs and a package of brass scrub pads to act as a rough filter medium inside the pvc . the hose barbs screw into the end caps, the end caps glue into the pvc and the brass scrub pads inserted inside the pvc acting as a metallic chip barrier that easily allows liquids but not metallic debris to pass, correctly assembled you have an (L) shaped section of 1.5" pvc pipe with each leg about 12" long , and two reducer end caps that face vertically with hose connections and a basic course filter internally by use of a couple brass or stainless mazes for coolant to flow thru that will trap most of the chips in the fluid.

its not designed to trap or filter out everything but it will cause almost any of the larger chips to fail to reach the coolant tank and pump for recirculation,back to the coolant sprayed on the cutting bit location. this at least in theory should reduce the chances of the coolant pump ingesting metallic crap , like small cuttings and flakes thats bound to eventually damage the pump

Last edited by a moderator: