One of the local guys "LARRY" asked me to help him track down an annoying clicking sound that he was regularly hearing in the newer project car he bought , its a 1995 corvette , that he recently purchased. that looks a great deal similar to my 1996 corvette,

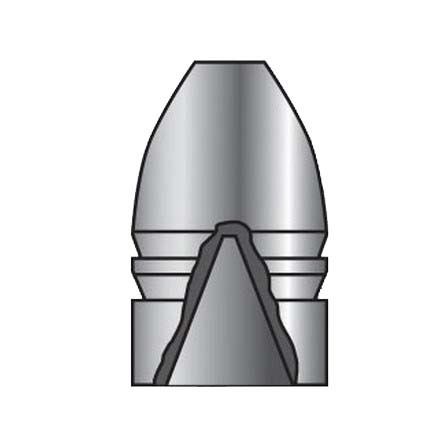

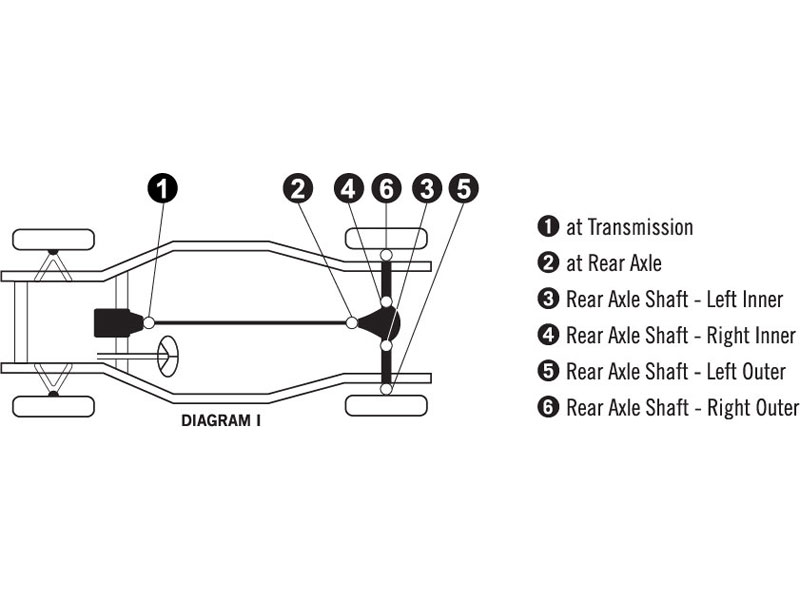

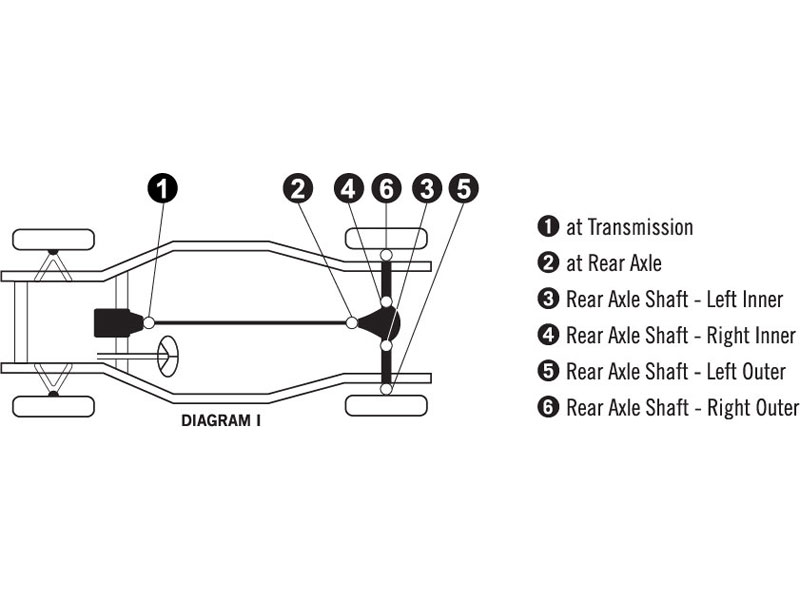

it turned out to be that two of the six u-joints in the car were running dry and were excessively worn,

we put the car up on my lift, isolated the cause and he called the local dealership too ask how much they wanted to replace all 6 u-joints,and ask how long he would have to leave the car, ..... if he drove the car over there to have them work on the car, ....after he almost had a stroke and heart attack after hearing the required time frame and cost too have the dealership do the work, he asked me if that was normal?

when I pointed out that was very common, and that, both all the new parts and a new 20 ton rated hydraulic press could be purchased for less money...

and that we could do the work here in my shop as I already owned a decent hydraulic press .....well.... he was more than willing to run to the local NAPA auto parts to buy the u-joints and he could help me do the u-joint replacement work, provided he helped and would buy both lunch ($23) a couple ham sub sandwiches, and two six packs of apple cider...

consider the U-joints cost about $23 each locally, but you can order them on-line for a bit less

be aware of the quality of the components you select, there are several merchants that advertise a great deal based on lower prices,

who generally deal in the lower and mid range quality products,

and their goal seems too be a low price volume discount supply house.

now Ive seen a few good deals, over the years but keep in mind,

youll generally find discount price parts, use lower quality components or,

less extensive precision machine work, or imported components or a combination of those factors to reduce price.

now I'm not picking on the lower price parts suppliers, they certainly have a place in the economy and hobby.

I use rockauto and advanced auto, walmart and several other suppliers,

if I need too ,but I generally know the parts and use name brands not cheaper import clones.

remember thats frequently a very noticeable difference in quality, in similar components,

you may pay more for name brand parts and at times the higher cost is not justified in my opinion,

but many of the better known brands do tend to have better quality control and R&D

I would suggest you do research and avoid using the lowest cost import parts like bearings, brakes, and suspension parts ,

as Ive seen horrendous quality control on some import component examples

http://www.rockauto.com/en/catalog/...8+ohv,1041376,drivetrain,universal+joint,2392

http://www.rockauto.com/en/moreinfo.php?pk=387687&cc=1041376&jsn=467

http://www.zip-corvette.com/84-96-c4/suspension-drivetrain/corvette-driveshafts-u-joints.html

both lunch and the cider, combined ,which cost well under 10% of what the local dealership quoted for labor and less than 70% of what they quoted for parts vs NAPA

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/u-joint-replacement-info.80/

http://garage.grumpysperformance.com/index.php?threads/replacing-u-joints.227/#post-43685

http://garage.grumpysperformance.com/index.php?threads/should-you-replace-all-6-u-joints.9236/

http://garage.grumpysperformance.co...grading-the-suspension-on-a-c-4.483/#post-597

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/

http://garage.grumpysperformance.co...20-ton-hydraulic-press-of-course-you-do.2735/

http://garage.grumpysperformance.com/index.php?threads/you-need-decent-jack-stands.672/

http://garage.grumpysperformance.co...nsion-related-links-and-info.1025/#post-67816

http://garage.grumpysperformance.co...asuring-for-a-new-drive-shaft.478/#post-67321

http://garage.grumpysperformance.com/index.php?threads/trans-slip-yoke-problem.8765/#post-53682

http://garage.grumpysperformance.com/index.php?threads/u-joints-don-t-fit.10301/#post-41818

https://www.harborfreight.com/ball-joint-service-kit-for-2wd-and-4wd-vehicles-63279.html

https://www.amazon.com/RAM-PRO-Serv...ocphy=9012039&hvtargid=pla-569699011908&psc=1

https://www.walmart.com/ip/Heavy-Du...MIsZ7y14654AIVRuDICh0V4w_lEAQYBCABEgLv1vD_BwE

https://www.amazon.com/exec/obidos/ASIN/B0028QGT86/ezvid02-20

https://www.costway.com/21pcs-ball-...ce-remover-installing-master-adapter-car.html

Safely Jacking a C4

by Wes Burch

Tools Required: 1 Floor Jack (3,000 lb min) and at least 2 Jack Stands. (You really do not want to bet your life on that used ten cent O-Ring in that Floor Jack do you?) Four jack stands is better.

Level of Difficulty: This is far easier than digging a hole under the Corvette so you work on it.

Until you have done this a few times, think about each step before doing it!

(1) Caution: GM did not design the C4 for home maintenance. There are no GM recommended jacking points for a C4 other than those that require a single or dual post lift. So use this procedure at your own risk.

(2) To start you need to be on a solid level surface. Jacking the car on grass will most likely result in sinking either the jack or jack stand into the sand. Better to dig the hole. If the car is an automatic verify the transmission is in park. With a manual make sure the transmission is in gear. Engaging the parking brake is also a good idea.

(3) Because the C4 chassis is remarkably flexible you should pop the hood release while the car is still on the ground. I've seen a few C4s that once they are on jack stands the hood will not release. Do not fully open the hood until you are finished jacking and supporting the car on jack stands.

(4) A strong point for the C4 chassis is the pinch weld joint that runs just behind the lip at the bottom of the sill. But because of the fiberglass floor kick-down; that area is not wide enough to center your jack pad under the pinch weld. I catch two of the "teeth" from my floor jack behind the pinch joint. (Photo 1) That will help prevent the pad from slipping out from under the car while jacking. (As you can see in the photo from my car it is HIGHLY LIKELY that you will chip a bit of paint from the lower edge of the sill.) ALSO BE CAREFUL TO NOT GET THE FLOOR JACK UNDER THE FLOOR! YOU CAN MAKE A NEAT INTERIOR DRAIN HOLE IF YOU DO. THE FLOOR WILL NOT SUPPORT THE WEIGHT OF THE CAR.

Photo 1

(5) Place the floor jack just behind the outside rear view mirror. (Photo 2) That is very near the center of weight for the car. The front and rear of the car should raise more or less evenly as you pump the jack.

Photo 2

(6) I believe the best place to support the rear of the car is where several pinch joints come together just ahead of the rear tire. (Photo 3) Note the shims on the top of the jack stand (more on that later).

Photo 3

(7) There are two places to support the front of the car. Just behind the front tire is a nice flat part of the chassis. Just be sure the jack is on the metal frame and not the plastic that constitutes part of the inner fender. (Photo 4) I have also placed a jack stand under the full-of-holes bar that connects the end links of the lower control arm. (Photo 5)

Photo 4

Photo 5

(8) If you are jacking all four corners of the car, before you place your valuable body parts under the car, verify all the jack stands are supporting the car. I use a small hammer and tap each jack stand. If the jack stand has weight on it the result is a dull thunk. If not, it will sound more like a bell and the jack stand may even move. If a jack has no weight on it I use some shims (photo 3) so that jack is supporting weight. Afterwards, I also walk around the car and gently push each corner to make sure the load is stable.

(9) Now you can safely perform maintenance on the car….enjoy. If your maintenance includes changing fluids, be sure you close the drain before adding fresh fluid. If the wheels were removed be sure to torque the wheels after the car is back on the ground (100 lb-ft for aluminum wheels).

(10) Getting the car back on the ground is just a reverse of the above steps. Just be sure to lower the car slowly so it does not slip on the floor jack on the opposite side.

it turned out to be that two of the six u-joints in the car were running dry and were excessively worn,

we put the car up on my lift, isolated the cause and he called the local dealership too ask how much they wanted to replace all 6 u-joints,and ask how long he would have to leave the car, ..... if he drove the car over there to have them work on the car, ....after he almost had a stroke and heart attack after hearing the required time frame and cost too have the dealership do the work, he asked me if that was normal?

when I pointed out that was very common, and that, both all the new parts and a new 20 ton rated hydraulic press could be purchased for less money...

and that we could do the work here in my shop as I already owned a decent hydraulic press .....well.... he was more than willing to run to the local NAPA auto parts to buy the u-joints and he could help me do the u-joint replacement work, provided he helped and would buy both lunch ($23) a couple ham sub sandwiches, and two six packs of apple cider...

consider the U-joints cost about $23 each locally, but you can order them on-line for a bit less

be aware of the quality of the components you select, there are several merchants that advertise a great deal based on lower prices,

who generally deal in the lower and mid range quality products,

and their goal seems too be a low price volume discount supply house.

now Ive seen a few good deals, over the years but keep in mind,

youll generally find discount price parts, use lower quality components or,

less extensive precision machine work, or imported components or a combination of those factors to reduce price.

now I'm not picking on the lower price parts suppliers, they certainly have a place in the economy and hobby.

I use rockauto and advanced auto, walmart and several other suppliers,

if I need too ,but I generally know the parts and use name brands not cheaper import clones.

remember thats frequently a very noticeable difference in quality, in similar components,

you may pay more for name brand parts and at times the higher cost is not justified in my opinion,

but many of the better known brands do tend to have better quality control and R&D

I would suggest you do research and avoid using the lowest cost import parts like bearings, brakes, and suspension parts ,

as Ive seen horrendous quality control on some import component examples

http://www.rockauto.com/en/catalog/...8+ohv,1041376,drivetrain,universal+joint,2392

http://www.rockauto.com/en/moreinfo.php?pk=387687&cc=1041376&jsn=467

http://www.zip-corvette.com/84-96-c4/suspension-drivetrain/corvette-driveshafts-u-joints.html

both lunch and the cider, combined ,which cost well under 10% of what the local dealership quoted for labor and less than 70% of what they quoted for parts vs NAPA

RELATED INFO

http://garage.grumpysperformance.com/index.php?threads/u-joint-replacement-info.80/

http://garage.grumpysperformance.com/index.php?threads/replacing-u-joints.227/#post-43685

http://garage.grumpysperformance.com/index.php?threads/should-you-replace-all-6-u-joints.9236/

http://garage.grumpysperformance.co...grading-the-suspension-on-a-c-4.483/#post-597

http://garage.grumpysperformance.com/index.php?threads/under-car-safety.26/

http://garage.grumpysperformance.co...20-ton-hydraulic-press-of-course-you-do.2735/

http://garage.grumpysperformance.com/index.php?threads/you-need-decent-jack-stands.672/

http://garage.grumpysperformance.co...nsion-related-links-and-info.1025/#post-67816

http://garage.grumpysperformance.co...asuring-for-a-new-drive-shaft.478/#post-67321

http://garage.grumpysperformance.com/index.php?threads/trans-slip-yoke-problem.8765/#post-53682

http://garage.grumpysperformance.com/index.php?threads/u-joints-don-t-fit.10301/#post-41818

https://www.harborfreight.com/ball-joint-service-kit-for-2wd-and-4wd-vehicles-63279.html

https://www.amazon.com/RAM-PRO-Serv...ocphy=9012039&hvtargid=pla-569699011908&psc=1

https://www.walmart.com/ip/Heavy-Du...MIsZ7y14654AIVRuDICh0V4w_lEAQYBCABEgLv1vD_BwE

https://www.amazon.com/exec/obidos/ASIN/B0028QGT86/ezvid02-20

https://www.costway.com/21pcs-ball-...ce-remover-installing-master-adapter-car.html

Safely Jacking a C4

by Wes Burch

Tools Required: 1 Floor Jack (3,000 lb min) and at least 2 Jack Stands. (You really do not want to bet your life on that used ten cent O-Ring in that Floor Jack do you?) Four jack stands is better.

Level of Difficulty: This is far easier than digging a hole under the Corvette so you work on it.

Until you have done this a few times, think about each step before doing it!

(1) Caution: GM did not design the C4 for home maintenance. There are no GM recommended jacking points for a C4 other than those that require a single or dual post lift. So use this procedure at your own risk.

(2) To start you need to be on a solid level surface. Jacking the car on grass will most likely result in sinking either the jack or jack stand into the sand. Better to dig the hole. If the car is an automatic verify the transmission is in park. With a manual make sure the transmission is in gear. Engaging the parking brake is also a good idea.

(3) Because the C4 chassis is remarkably flexible you should pop the hood release while the car is still on the ground. I've seen a few C4s that once they are on jack stands the hood will not release. Do not fully open the hood until you are finished jacking and supporting the car on jack stands.

(4) A strong point for the C4 chassis is the pinch weld joint that runs just behind the lip at the bottom of the sill. But because of the fiberglass floor kick-down; that area is not wide enough to center your jack pad under the pinch weld. I catch two of the "teeth" from my floor jack behind the pinch joint. (Photo 1) That will help prevent the pad from slipping out from under the car while jacking. (As you can see in the photo from my car it is HIGHLY LIKELY that you will chip a bit of paint from the lower edge of the sill.) ALSO BE CAREFUL TO NOT GET THE FLOOR JACK UNDER THE FLOOR! YOU CAN MAKE A NEAT INTERIOR DRAIN HOLE IF YOU DO. THE FLOOR WILL NOT SUPPORT THE WEIGHT OF THE CAR.

Photo 1

(5) Place the floor jack just behind the outside rear view mirror. (Photo 2) That is very near the center of weight for the car. The front and rear of the car should raise more or less evenly as you pump the jack.

Photo 2

(6) I believe the best place to support the rear of the car is where several pinch joints come together just ahead of the rear tire. (Photo 3) Note the shims on the top of the jack stand (more on that later).

Photo 3

(7) There are two places to support the front of the car. Just behind the front tire is a nice flat part of the chassis. Just be sure the jack is on the metal frame and not the plastic that constitutes part of the inner fender. (Photo 4) I have also placed a jack stand under the full-of-holes bar that connects the end links of the lower control arm. (Photo 5)

Photo 4

Photo 5

(8) If you are jacking all four corners of the car, before you place your valuable body parts under the car, verify all the jack stands are supporting the car. I use a small hammer and tap each jack stand. If the jack stand has weight on it the result is a dull thunk. If not, it will sound more like a bell and the jack stand may even move. If a jack has no weight on it I use some shims (photo 3) so that jack is supporting weight. Afterwards, I also walk around the car and gently push each corner to make sure the load is stable.

(9) Now you can safely perform maintenance on the car….enjoy. If your maintenance includes changing fluids, be sure you close the drain before adding fresh fluid. If the wheels were removed be sure to torque the wheels after the car is back on the ground (100 lb-ft for aluminum wheels).

(10) Getting the car back on the ground is just a reverse of the above steps. Just be sure to lower the car slowly so it does not slip on the floor jack on the opposite side.

Last edited: