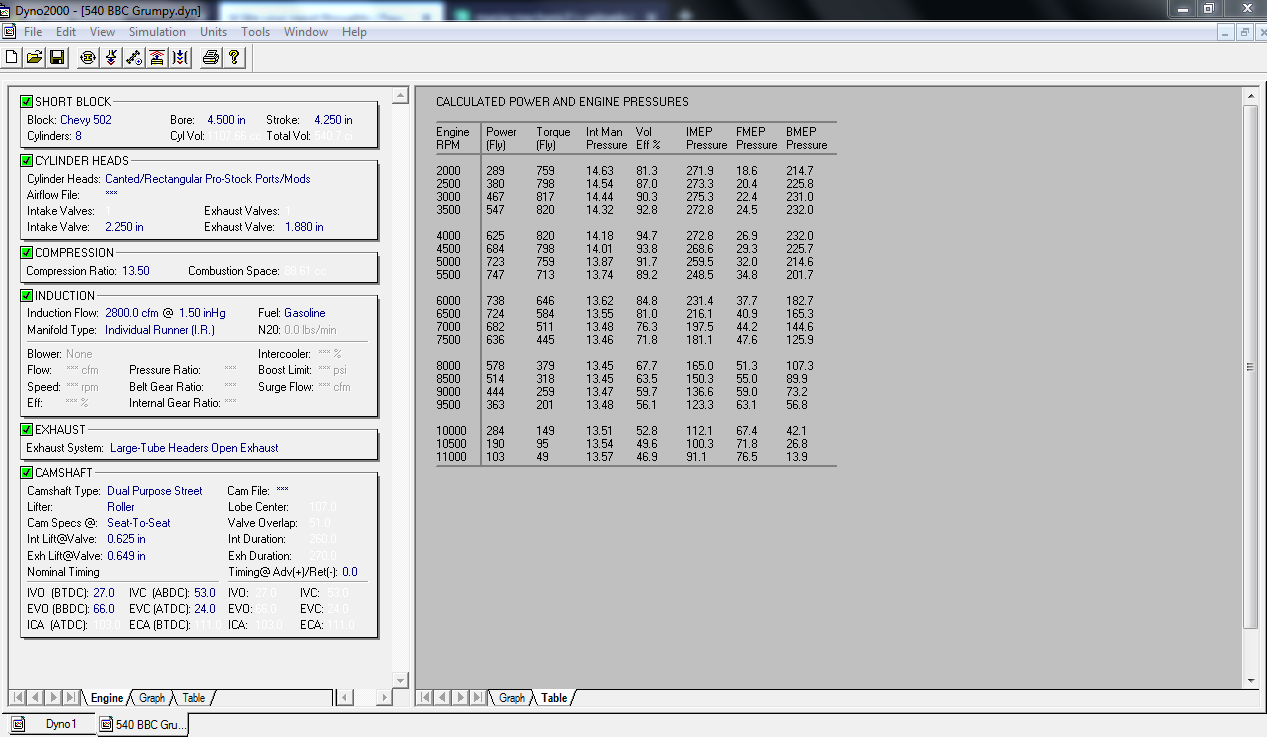

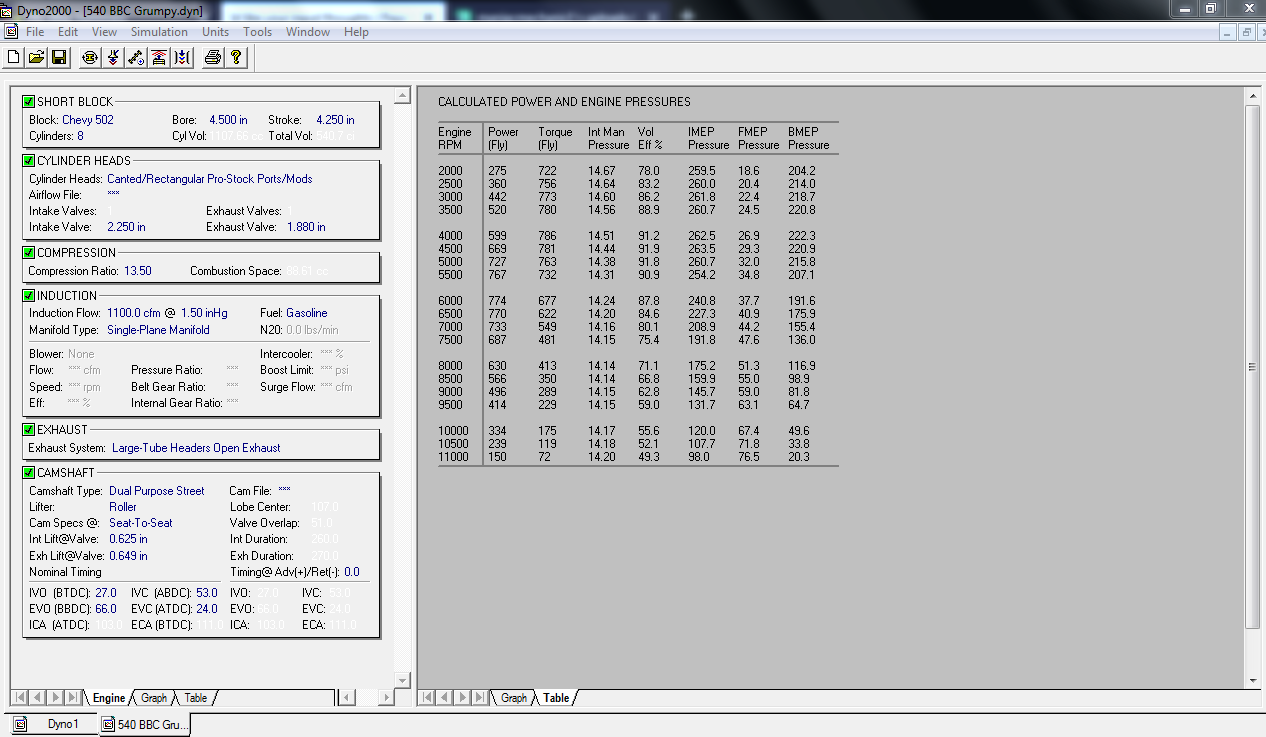

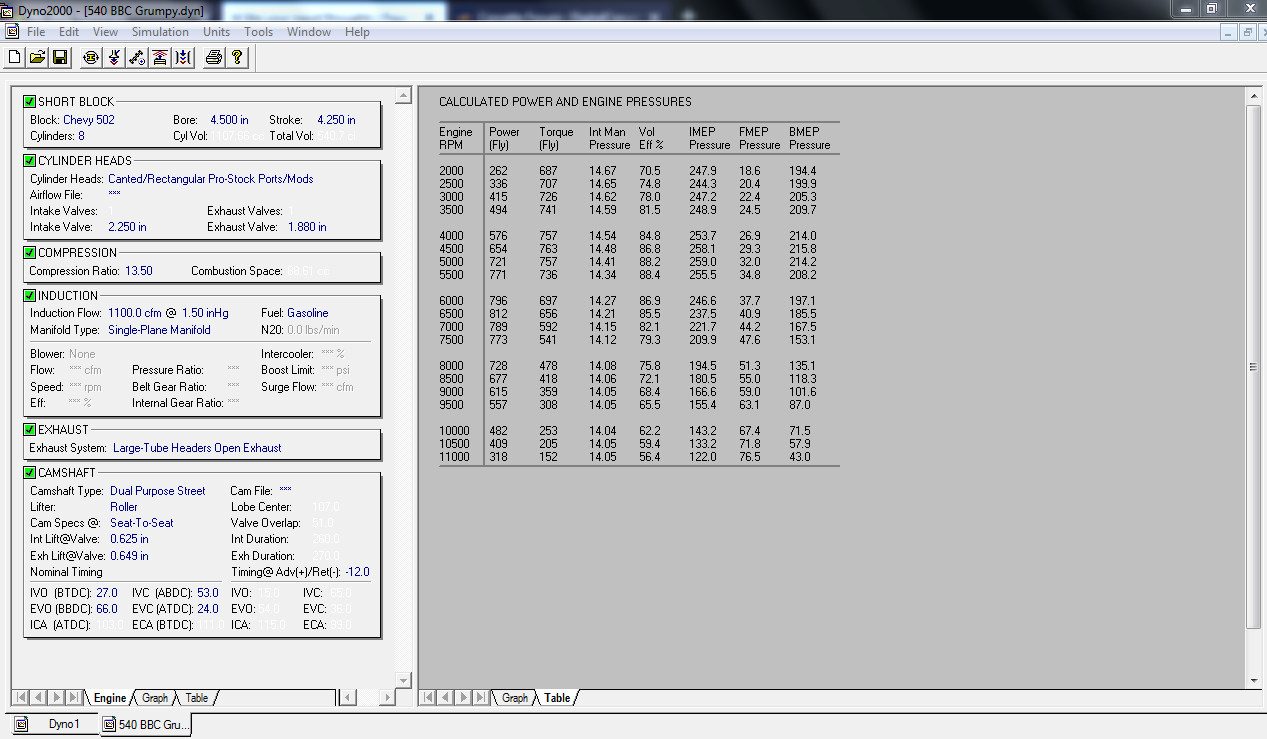

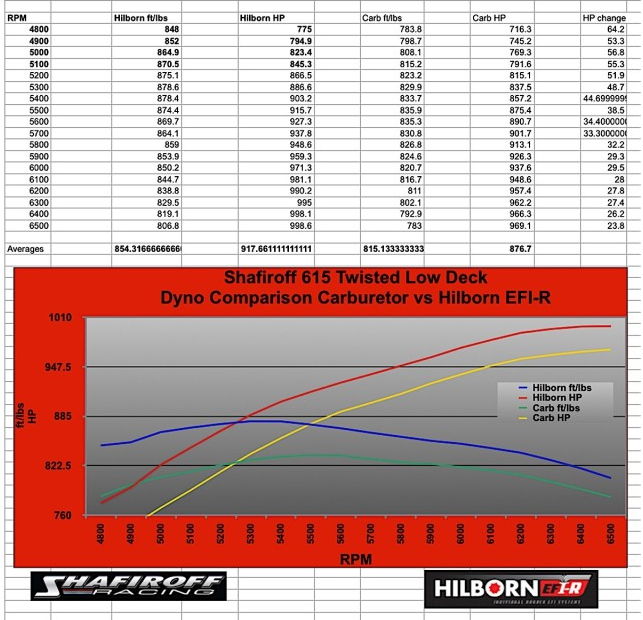

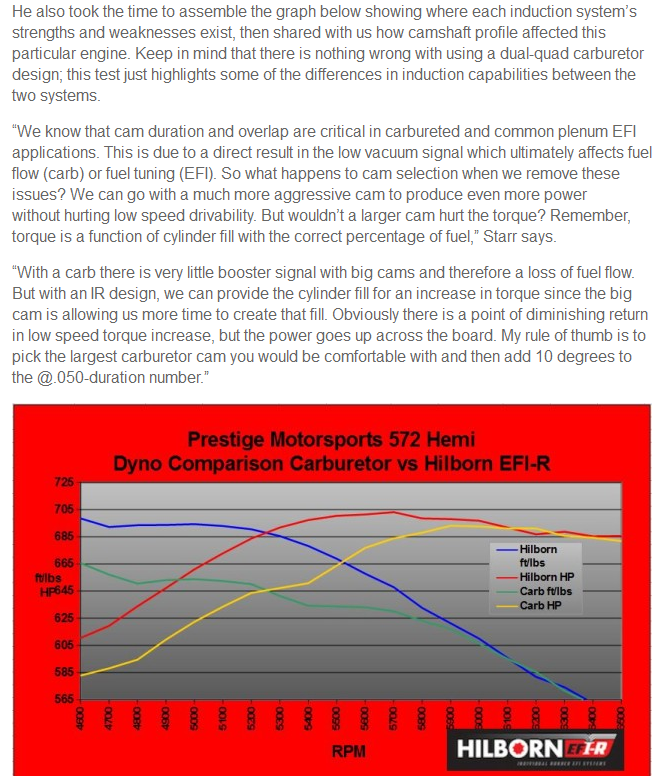

what your overlooking and the software dyno is overlooking and can,t show properly is that stack injectors are air flow rated at a steady flow similar to how they measure carb flow rates

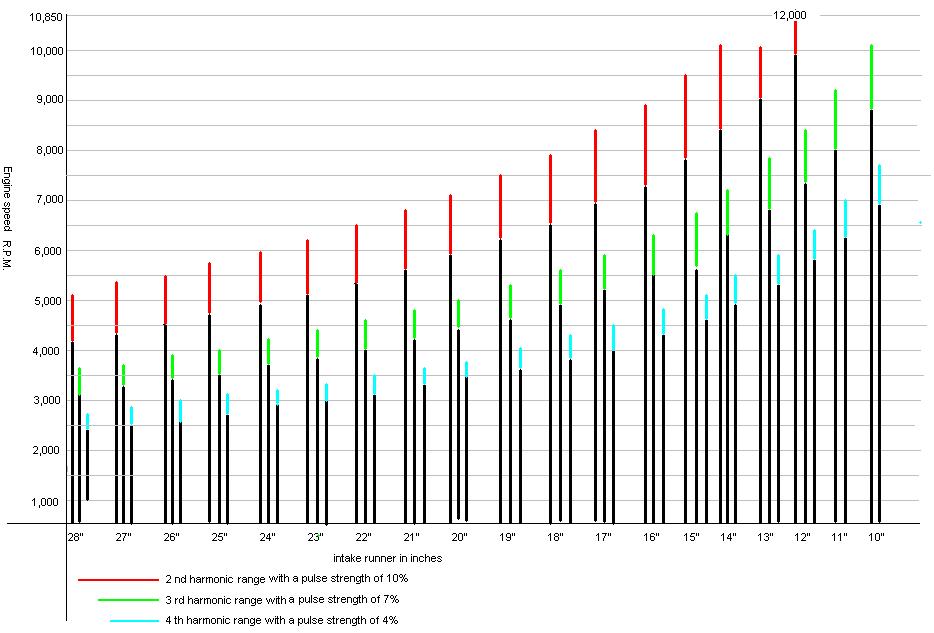

, but stack injection has a long individual column of air suspended over each individual intake runner, once the rpms increase at some point ram tuning is induced and that column of air has weight and inertia,

the flow rate, just like a carb increases to match the demand and its not limited to the rated flow its artificially assigned or rated at, I don,t know any software that adequately shows the true effect.

Id also point out that exhaust scavenging works far more effectively with stack injection

https://www.hotrod.com/articles/hrdp-9907-ram-tuning-guide/

http://garage.grumpysperformance.com/index.php?threads/mechanical-constant-flow-injection.4502/