One of the differences between, being young and in a hurry and older and having a great deal more experience in building engines ,

is that with experience and

a long memory of previous screw ups,

is that over time you get a bit more cautious ,

if you happen to run into an un-expected issue STOP THINK THINGS THROUGH!

now most of this thread are related too todays issue,

but theres hundreds of times when youll find some part won,t fit,

or function as you intend or expect..

always step back mentally and ask yourself WHY?

and what CHANGED?, what can I do to rectify or change this ,

rather than thinking ,you can force the parts too fit,

and function through brute force!

in most cases stopping and thinking things through,

is going to be FAR cheaper than blindly pushing on.

DON,T simply assume the use a bigger breaker bar and forcing the bolts too line up approach,

may work, at the first indication somethings not working as expected..

stop, and find out what changed, and/or what needs to be clearanced, aligned or replaced.!

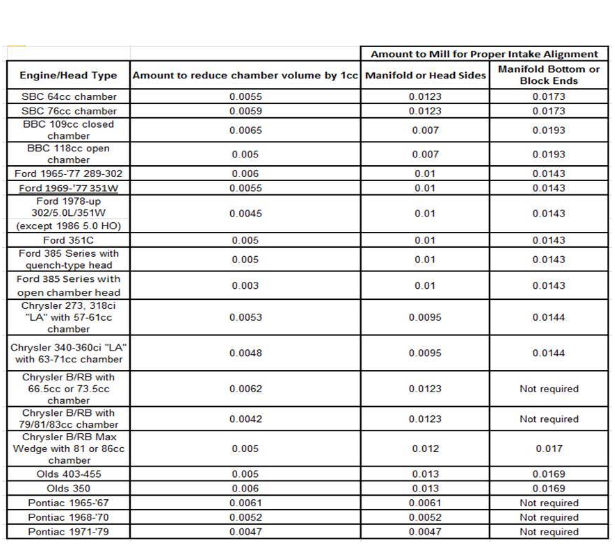

I was helping a local guy install an intake manifold on his car after he had had his cylinder heads ,

back from a local machine-shop,where he had a valve job done to correct minor damage that was the result of a blown head gasket.

the heads had been decked a few thousands and as a result the intake manifold bolts and the location of the cylinder head threaded holes.

that the manifold used to secure that manifold to the heads had changed just enough to no longer allow the manifold to sit on the engine,

and still allow proper mounting bolt alignment.

the solution was rather simple, the manifold mounting bolt holes must be marginally lengthened, to prevent the sides of the manifold mounting bolts from bearing on the holes that were previously more or less rather more correctly aligned.

this was a rather simple modification, but it was mandatory if the intake manifold was to seat properly,

on the heads after they were previously milled a few thousands.

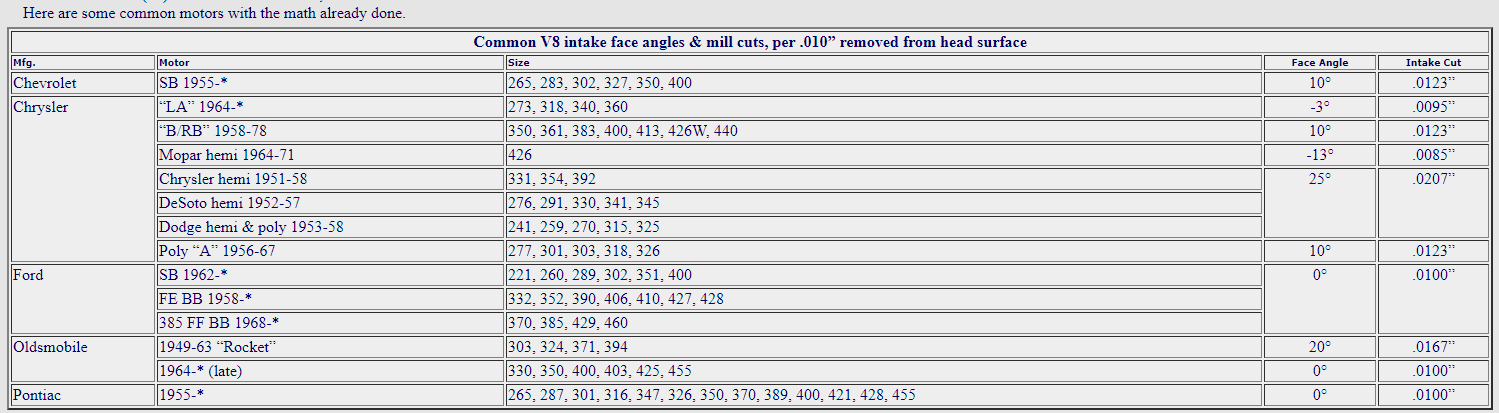

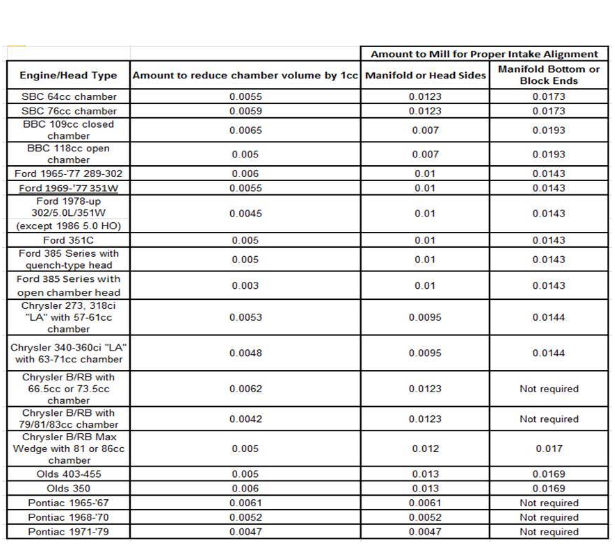

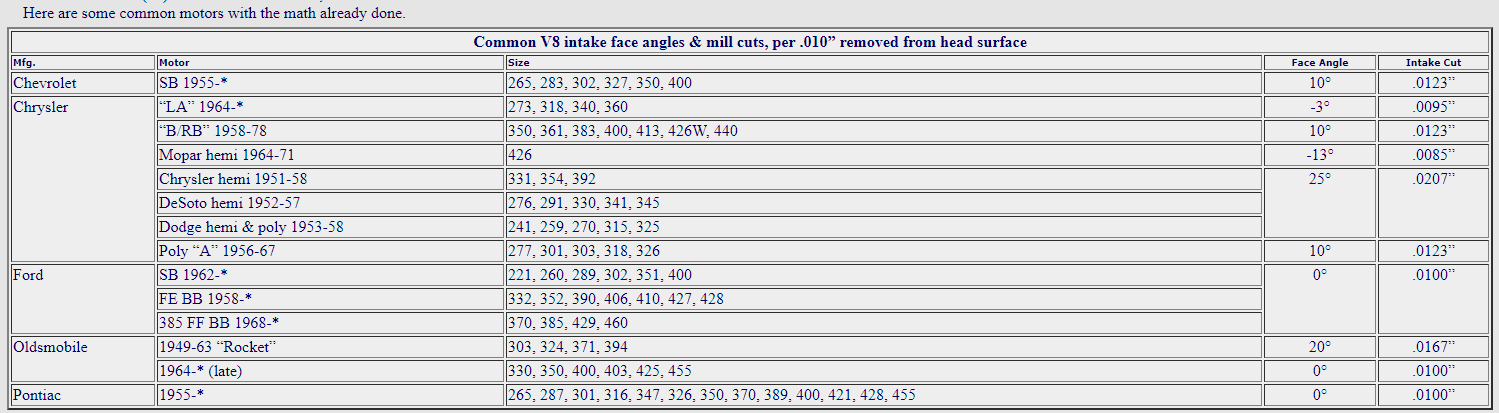

milling the heads a few thousands of an inch seems too be a minor and rather minimal change but you effectively moved the bolt holes a bit lower and closer to the block deck surface,

this effectively results in the manifold moving marginally higher in relation to the heads and even though its hard to envision,

the milled heads on the block effectively make the intake manifold sit a tiny bit higher on the cylinder head mounting face,

thus the intake port alignment is also now changed marginally.

obviously the amount the heads were milled will make milling the matched intake mounting surfaces mandatory at some point so accurate measurements are essential,

if your going to restore proper intake manifold port alignment,

and if much of the heads were milled the block end walls will also interfere with proper manifold alignment,

thus in some cases the ends of the intake manifold might also require modifications in clearance.

http://garage.grumpysperformance.com/index.php?threads/milling-heads-and-intakes.2988/#post-9055

https://www.onallcylinders.com/2016...ics-of-head-milling-to-gain-more-compression/

http://www.victorylibrary.com/mopar/intake-mill-c.htm

is that with experience and

a long memory of previous screw ups,

is that over time you get a bit more cautious ,

if you happen to run into an un-expected issue STOP THINK THINGS THROUGH!

now most of this thread are related too todays issue,

but theres hundreds of times when youll find some part won,t fit,

or function as you intend or expect..

always step back mentally and ask yourself WHY?

and what CHANGED?, what can I do to rectify or change this ,

rather than thinking ,you can force the parts too fit,

and function through brute force!

in most cases stopping and thinking things through,

is going to be FAR cheaper than blindly pushing on.

DON,T simply assume the use a bigger breaker bar and forcing the bolts too line up approach,

may work, at the first indication somethings not working as expected..

stop, and find out what changed, and/or what needs to be clearanced, aligned or replaced.!

I was helping a local guy install an intake manifold on his car after he had had his cylinder heads ,

back from a local machine-shop,where he had a valve job done to correct minor damage that was the result of a blown head gasket.

the heads had been decked a few thousands and as a result the intake manifold bolts and the location of the cylinder head threaded holes.

that the manifold used to secure that manifold to the heads had changed just enough to no longer allow the manifold to sit on the engine,

and still allow proper mounting bolt alignment.

the solution was rather simple, the manifold mounting bolt holes must be marginally lengthened, to prevent the sides of the manifold mounting bolts from bearing on the holes that were previously more or less rather more correctly aligned.

this was a rather simple modification, but it was mandatory if the intake manifold was to seat properly,

on the heads after they were previously milled a few thousands.

milling the heads a few thousands of an inch seems too be a minor and rather minimal change but you effectively moved the bolt holes a bit lower and closer to the block deck surface,

this effectively results in the manifold moving marginally higher in relation to the heads and even though its hard to envision,

the milled heads on the block effectively make the intake manifold sit a tiny bit higher on the cylinder head mounting face,

thus the intake port alignment is also now changed marginally.

obviously the amount the heads were milled will make milling the matched intake mounting surfaces mandatory at some point so accurate measurements are essential,

if your going to restore proper intake manifold port alignment,

and if much of the heads were milled the block end walls will also interfere with proper manifold alignment,

thus in some cases the ends of the intake manifold might also require modifications in clearance.

http://garage.grumpysperformance.com/index.php?threads/milling-heads-and-intakes.2988/#post-9055

https://www.onallcylinders.com/2016...ics-of-head-milling-to-gain-more-compression/

http://www.victorylibrary.com/mopar/intake-mill-c.htm

Last edited: