This is a four part question to those who really know how to buff stainless and chrome - mostly stainless. For a complete answer I will donate $10 to this site. I need to make the trim rings and center hubs (for the early C3s) shine like they never did before.

What is the progression of buffing wheels (cleaning to end of final polishing) Ie: type and firmness.

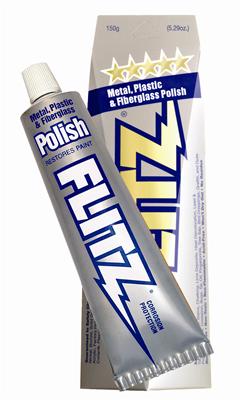

What (sorry don't know what the correct name is) rub do you apply to the wheel?

What speeds?

For repairs (like hammering out dents) what progression of sanding grit from start to finish and with wcompoundpond for buffing out the scratches? Ok, so that was actually 5 questions.

What is the progression of buffing wheels (cleaning to end of final polishing) Ie: type and firmness.

What (sorry don't know what the correct name is) rub do you apply to the wheel?

What speeds?

For repairs (like hammering out dents) what progression of sanding grit from start to finish and with wcompoundpond for buffing out the scratches? Ok, so that was actually 5 questions.