https://philadelphia.craigslist.org/pts/d/chevy-chevroletbolt-main-1/6717266944.html

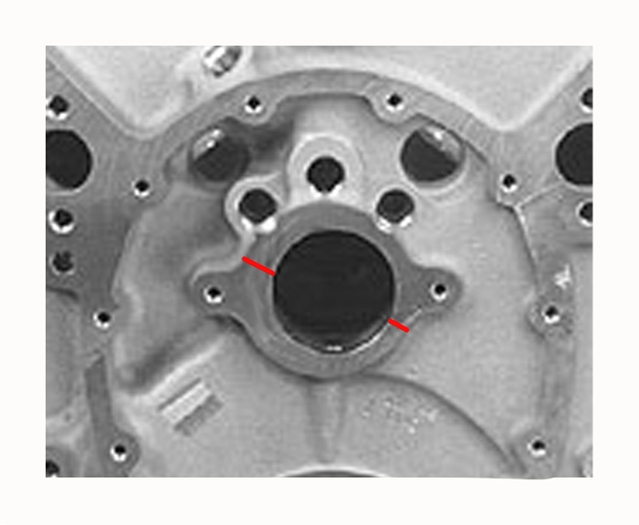

Can someone explain in layman’s terms what makes this block so good? Explain the cam thrust bearing pad feature?

Can someone explain in layman’s terms what makes this block so good? Explain the cam thrust bearing pad feature?