legerwn

Active Member

I'm looking to improve on my fuel system and will start with the fuel pump,

Was looking at the Aeromotive line up but after reading some stuff and input from others that may not be the best selection for the money.

Someone I believe to be knowledgeable in this area has suggested that I look at either a Weldon pump or the Mallory Pro Comp line of pumps.

The Weldon Pumps are out of my price range for now but the Mallory pumps are reasonably priced and have been around for a long time.

I've looked through the posts here but didn't find any info on pump quality or a list of pumps that would be considered top of the line or preferred.

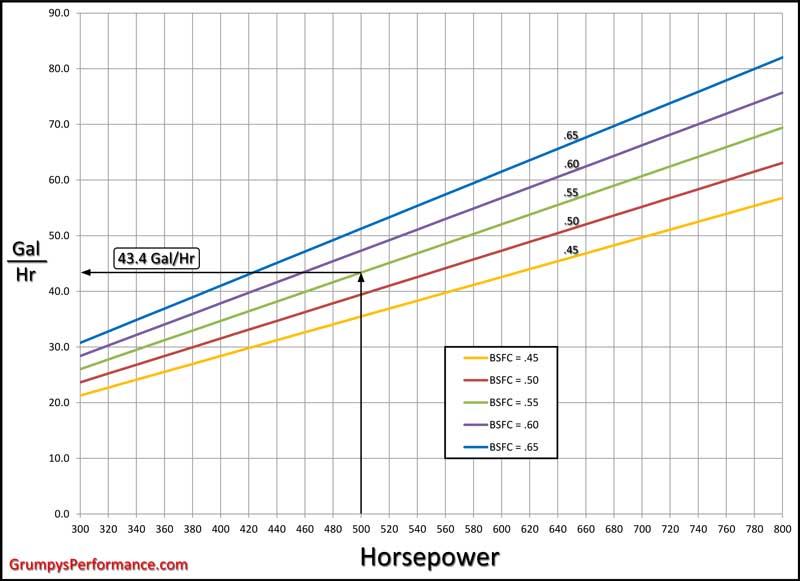

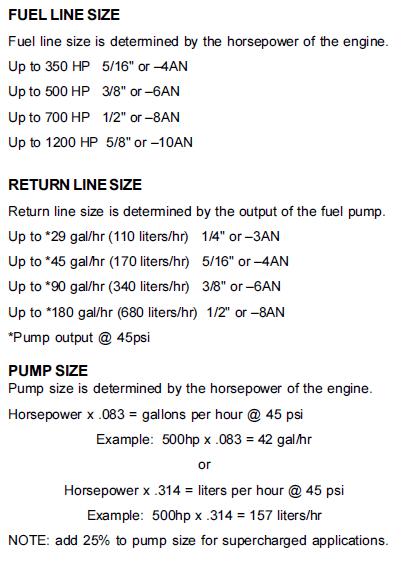

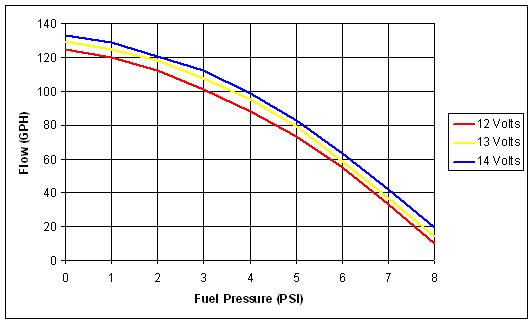

What pump would you suggest for a 700 HP 496BBC (with future upgrades in mind)?

the Mallory pump suggested for my set up was the 5250 Pro Comp pump

thanks Neal

Was looking at the Aeromotive line up but after reading some stuff and input from others that may not be the best selection for the money.

Someone I believe to be knowledgeable in this area has suggested that I look at either a Weldon pump or the Mallory Pro Comp line of pumps.

The Weldon Pumps are out of my price range for now but the Mallory pumps are reasonably priced and have been around for a long time.

I've looked through the posts here but didn't find any info on pump quality or a list of pumps that would be considered top of the line or preferred.

What pump would you suggest for a 700 HP 496BBC (with future upgrades in mind)?

the Mallory pump suggested for my set up was the 5250 Pro Comp pump

thanks Neal