legerwn

Active Member

87vette81big said:The best way would to be use a fuel cell Neal.

15-30 gallons. Or fabricate a fuel cell from scratch.

Not the easiest for the home mechanic to do without prior experience .

Fabrication is not an issue as I worked in that field for 10 years,

My last post is not very clear on what my question is,

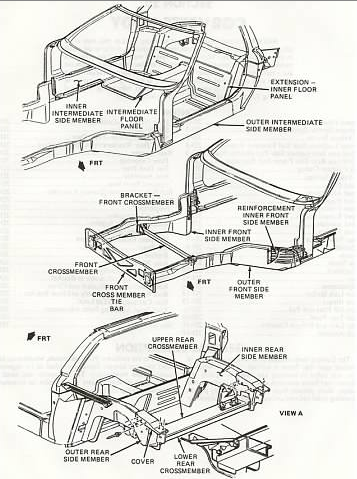

With the fuel pump being behind the half shafts there is no easy path to get the fuel line from the discharge of the pump to the forward side of the half shafts to within the frame rails without passing under the diff or close to the spinning shafts.

I was curious if someone had some insight on this issue?

Neal