heres a picture a guy posted of a snapped off, a ford SCAT 4340 forged crank

keep in mind he was running at 800HP plus,

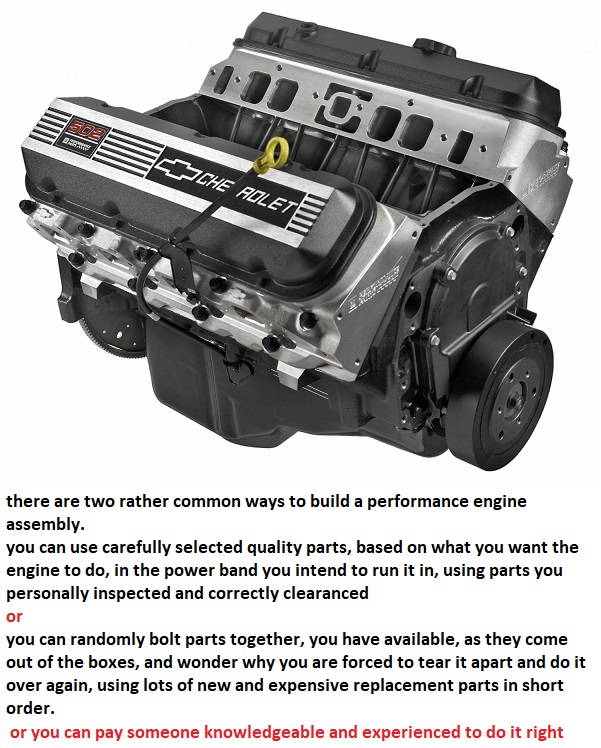

and ANYTHING beat on long enough

will eventually fatigue and break,

looking at the failed area its rather obvious a cyclic stress break ,

now the crank may have been damaged during the install or the wrong balancer may have been installed ,you tend to get what you pay for! and Ive seen a whole lot of guys that never bother to check clearances or get the rotating assembly balanced, they WRONGLY assume that anything they buy can be just bolted together and that if the box says its a standard diam. crank, why theres no reason to do anything but buy standard bearings and bolt it all together and go race!

the concept of just checking bearing clearances with plasti-gauge , using a rod bolt stretch gauge or micrometers, or having the balance checked rather that assuming everything's perfect out of the box is in many guys opinion absurdly expensive and time consuming and a waste of money, and these are the same guys with the deer in the head lights look

when a connecting rod exits the block the first time they hit 7000 rpm, quickly followed by a long tirade about some brand of parts that they improperly installed being crap!

BUT breaks like this are fairly common when you use a big hammer rather than a damper install tool, THERE IS ALWAYS A REASON PARTS FAIL, AT TIMES ITS DEFECTIVE PARTS BUT MOST TIMES ITS IMPROPER INSTALLATION OR MISS MATCHED COMPONENTS, yes theres always a very small percentage of less than perfectly machined parts in and larger run of manufactured parts, but in this case it looks like a bad balance job or wrong damper of bad install.

Just a side note here, you have options in selecting almost all components, I've used several dozen SCAT forged 4340 cranks in both SBC and BBC engine builds

and at least up till this point, in time, I've yet to have any failures and that has been over at least 25 plus years.

I've had the opportunity on several occasions to examine eagle cranks , the ones I've seen are stamped

SICHUAN SUNRAY MACHINERY GROUP CO., LTD (CHINA)

and in the few examples I had the opportunity to examine the consistency of the journal sizes was not quite as consistent as they were on the SCAT cranks (MACHINED IN AMERICA)

I'm fairly sure many of the guys reading through this don,t or have not dealt with, or built enough engines, and been involved with enough of the engine builds to realize the various manufacturers approach building components with a great many different objectives in mind,

component parts vary and careful research and selection is required!

I've always found SCAT and CROWER parts seem to be a good value!

keep in mind the "weakest link in the chain" concept,

Any logical engine builder needs to sellect components with a firm goal in mind and recognize the intended power band and rpm limitations.

need there's not much sense in selecting a rotating assembly that is built to easily handle lets say 1200 hp and 7800 rpm, at 4500 fpm in piston speeds,

if the block main caps walk at much lower stress levels, or if the block your thinking of using it in,will most likely have the caps walk well below that stress level.

nore would it make sense, using such a high dollar rotating assembly if your going to match it with a valve train and hydraulic roller cam that floats valves at 6400 rpm, or heads that reach port stall at 6700 rpm

(labeled as AMERICAN MADE)

SCAT Enterprises, Inc.

1400 Kingsdale Ave.

Redondo Beach, CA 90278

Phone: 310 370 5501

Fax: 310 214 2285

Hours: 8:00 to 4:45 PT Monday – Friday

http://www.scatcrankshafts.com/

http://www.scatcrankshafts.com/rotating-assembies/

http://www.scatcrankshafts.com/rotating-assembies/rotating-assembly-product-search/

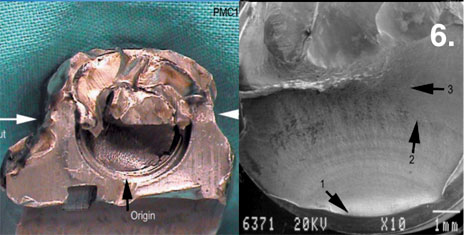

THE DAMAGE SHOWN IS COMMONLY THE RESULT OF AN EXTENDED CYCLIC FLEXING,

THE AREA CIRCLED IS SIMPLY WHERE THE LAST PART SHEARED OFF,

ID SUSPECT THE BALANCE JOB OR THE HARMONIC BALANCE HUB WAS PARTLY AT FAULT

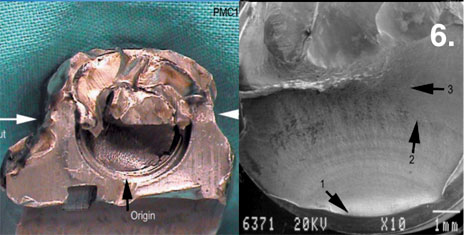

HERES A SIMILAR FAILURE ON AN ARP ROD BOLT

. Cyclic Fatigue Cracks Initiated by Improper Installation Preload

Many connecting rod bolt failures are caused by insufficient preload. When a fastener is insufficiently preloaded during installation the dynamic load may exceed the clamping load resulting in cyclic tensile stress and eventual failure. The first picture is a digital photo of such a failure with the bolt still in the rod. The arrows indicate the location of a cut made to free the bolt. The third arrow shows the origin of the fatigue crack in the second picture – an SEM photo at 30X magnification that clearly shows the origin of the failure (1), and the telltale “thumbprint” or “beach mark” (2). Finally (3) tracks of the outwardly propagating fatigue cracks, and the point where the bolt (unable to carry any further load) breaks-away.

CLOSELY RELATED

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-53734

http://garage.grumpysperformance.com/index.php?threads/damper-tool.223/#post-8024

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68850

http://garage.grumpysperformance.com/index.php?threads/don-t-beat-that-damper.83/#post-14101

http://garage.grumpysperformance.com/index.php?threads/damper-honing.4975/#post-13912

keep in mind he was running at 800HP plus,

and ANYTHING beat on long enough

will eventually fatigue and break,

looking at the failed area its rather obvious a cyclic stress break ,

now the crank may have been damaged during the install or the wrong balancer may have been installed ,you tend to get what you pay for! and Ive seen a whole lot of guys that never bother to check clearances or get the rotating assembly balanced, they WRONGLY assume that anything they buy can be just bolted together and that if the box says its a standard diam. crank, why theres no reason to do anything but buy standard bearings and bolt it all together and go race!

the concept of just checking bearing clearances with plasti-gauge , using a rod bolt stretch gauge or micrometers, or having the balance checked rather that assuming everything's perfect out of the box is in many guys opinion absurdly expensive and time consuming and a waste of money, and these are the same guys with the deer in the head lights look

when a connecting rod exits the block the first time they hit 7000 rpm, quickly followed by a long tirade about some brand of parts that they improperly installed being crap!

BUT breaks like this are fairly common when you use a big hammer rather than a damper install tool, THERE IS ALWAYS A REASON PARTS FAIL, AT TIMES ITS DEFECTIVE PARTS BUT MOST TIMES ITS IMPROPER INSTALLATION OR MISS MATCHED COMPONENTS, yes theres always a very small percentage of less than perfectly machined parts in and larger run of manufactured parts, but in this case it looks like a bad balance job or wrong damper of bad install.

Reasons why not to buy scat 4340 crank 800 hp na snapped in front of first counter weight on dart 4 bolt block... They are blaming everything but the crank, balancer, alternator, vacuum pump, fule pump belt drive BS... We will give you 1/2 off another one... NOT......

They can keep their chinese swing set metal cranks..

Just a side note here, you have options in selecting almost all components, I've used several dozen SCAT forged 4340 cranks in both SBC and BBC engine builds

and at least up till this point, in time, I've yet to have any failures and that has been over at least 25 plus years.

I've had the opportunity on several occasions to examine eagle cranks , the ones I've seen are stamped

SICHUAN SUNRAY MACHINERY GROUP CO., LTD (CHINA)

and in the few examples I had the opportunity to examine the consistency of the journal sizes was not quite as consistent as they were on the SCAT cranks (MACHINED IN AMERICA)

I'm fairly sure many of the guys reading through this don,t or have not dealt with, or built enough engines, and been involved with enough of the engine builds to realize the various manufacturers approach building components with a great many different objectives in mind,

component parts vary and careful research and selection is required!

I've always found SCAT and CROWER parts seem to be a good value!

keep in mind the "weakest link in the chain" concept,

Any logical engine builder needs to sellect components with a firm goal in mind and recognize the intended power band and rpm limitations.

need there's not much sense in selecting a rotating assembly that is built to easily handle lets say 1200 hp and 7800 rpm, at 4500 fpm in piston speeds,

if the block main caps walk at much lower stress levels, or if the block your thinking of using it in,will most likely have the caps walk well below that stress level.

nore would it make sense, using such a high dollar rotating assembly if your going to match it with a valve train and hydraulic roller cam that floats valves at 6400 rpm, or heads that reach port stall at 6700 rpm

(labeled as AMERICAN MADE)

SCAT Enterprises, Inc.

1400 Kingsdale Ave.

Redondo Beach, CA 90278

Phone: 310 370 5501

Fax: 310 214 2285

Hours: 8:00 to 4:45 PT Monday – Friday

http://www.scatcrankshafts.com/

http://www.scatcrankshafts.com/rotating-assembies/

http://www.scatcrankshafts.com/rotating-assembies/rotating-assembly-product-search/

THE DAMAGE SHOWN IS COMMONLY THE RESULT OF AN EXTENDED CYCLIC FLEXING,

THE AREA CIRCLED IS SIMPLY WHERE THE LAST PART SHEARED OFF,

ID SUSPECT THE BALANCE JOB OR THE HARMONIC BALANCE HUB WAS PARTLY AT FAULT

HERES A SIMILAR FAILURE ON AN ARP ROD BOLT

. Cyclic Fatigue Cracks Initiated by Improper Installation Preload

Many connecting rod bolt failures are caused by insufficient preload. When a fastener is insufficiently preloaded during installation the dynamic load may exceed the clamping load resulting in cyclic tensile stress and eventual failure. The first picture is a digital photo of such a failure with the bolt still in the rod. The arrows indicate the location of a cut made to free the bolt. The third arrow shows the origin of the fatigue crack in the second picture – an SEM photo at 30X magnification that clearly shows the origin of the failure (1), and the telltale “thumbprint” or “beach mark” (2). Finally (3) tracks of the outwardly propagating fatigue cracks, and the point where the bolt (unable to carry any further load) breaks-away.

CLOSELY RELATED

http://garage.grumpysperformance.com/index.php?threads/harmonic-balancer.3554/#post-53734

http://garage.grumpysperformance.com/index.php?threads/damper-tool.223/#post-8024

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-68850

http://garage.grumpysperformance.com/index.php?threads/don-t-beat-that-damper.83/#post-14101

http://garage.grumpysperformance.com/index.php?threads/damper-honing.4975/#post-13912

Last edited: