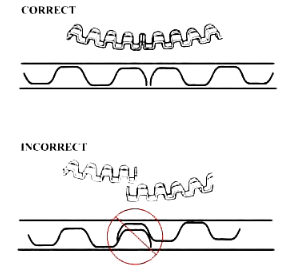

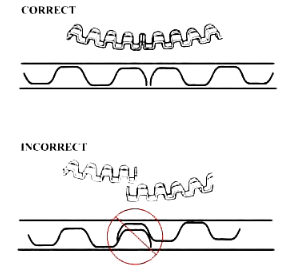

obviously if you've been around engine rebuilds, long enough, your aware that you'll eventually see guys installing rings in piston grooves by spiral twisting them into place, like the picture below depicts, AND YES YOU MIGHT NOT EVEN REALIZE THAT THE RING HAS BEEN SLIGHTLY DISTORTED

http://www.bing.com/videos/search?q...&mid=E76F9F78364354FD222DE76F9F78364354FD222D

the 80MM-120MM tool fits all chevy V8 engines

http://www.aliexpress.com/item/Piston-Ring-Installer-Remover-Engine-Plier-80-120mm/32477002020.html

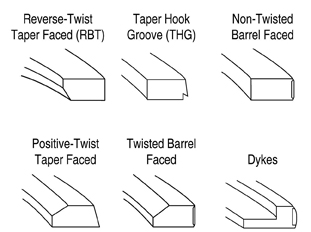

the problem, with that method is that its not at all difficult to leave the piston ring twisted permanently, or warping it to the point it either breaks , or its bent ,OR MORE LIKELY degrading its ability to seal against the bore wall.

so its a good idea to carefully use a expander tool, but only expand the ring enough to install it.

buy and use the correct piston groove cleaning tool, if your one of the guys that think scrapping out crud in a piston ring groove with a broken ring will give good results, I can assure you close detailed inspection will show minor scratches and ring groove damage that reduces the ring seal efficiency

http://www.summitracing.com/parts/shc-94662

http://www.superstreetonline.com/how-to/engine/impp-1110-piston-anatomy-tech-knowledge/

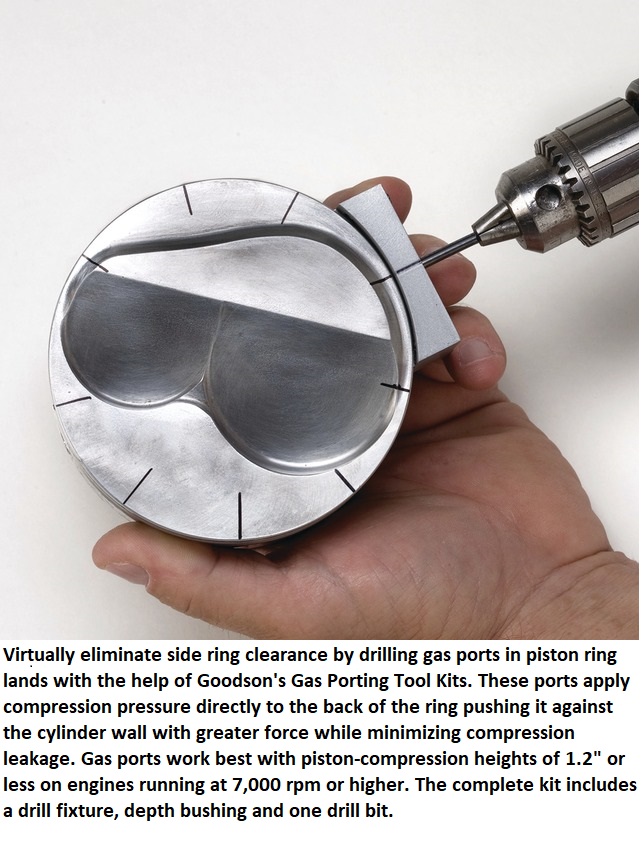

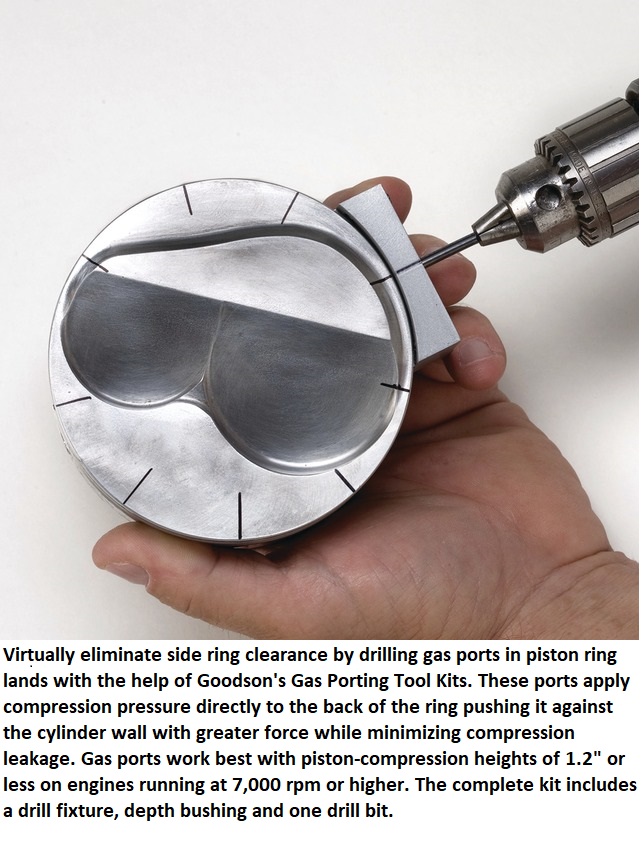

https://goodson.com/products/gas-porting-tools

these tools come in various ring sizes ,(but the various piston diameters are not as critical as ring width, it should be obvious that you MUST USE the tool that places the drilled gas port at the correct place in the upper ring groove roof and you damn sure better not drill deeper than the rear edge of the ring groove or youll destroy the piston

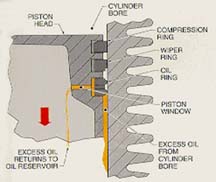

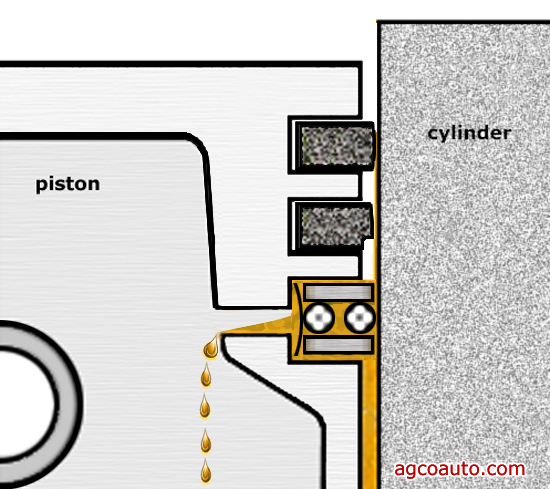

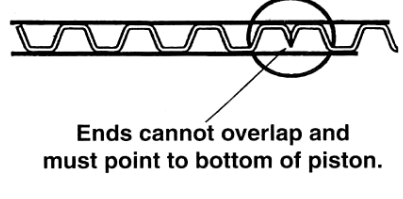

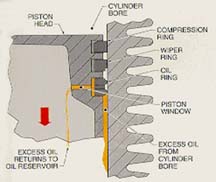

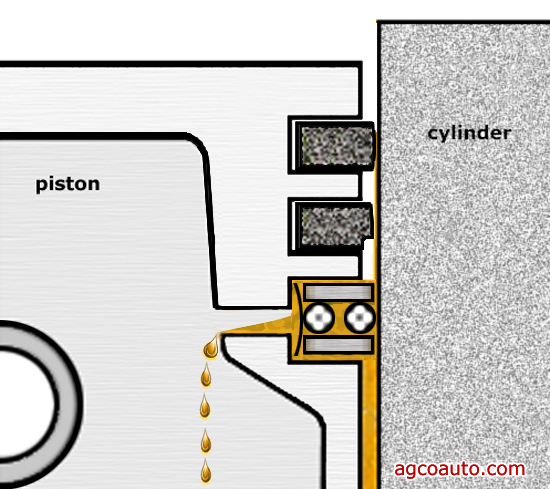

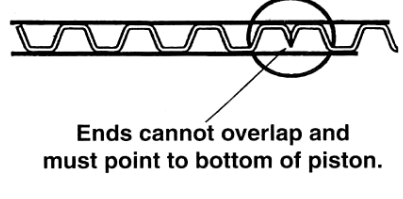

if you have oil ring expanders with the plastic bits,they are there to prevent you from over lapping the ends of the oil ring expander, theres some oil ring expander s that are vertical ,some horizontal, but all have the ends butt , none over-lap

https://www.summitracing.com/parts/sme-90a4000

https://www.summitracing.com/parts/sme-90a4120

https://www.summitracing.com/parts/sme-90a4250

https://www.summitracing.com/parts/tsr-rc4345-4455

https://www.summitracing.com/parts/tsr-rc4455-4575

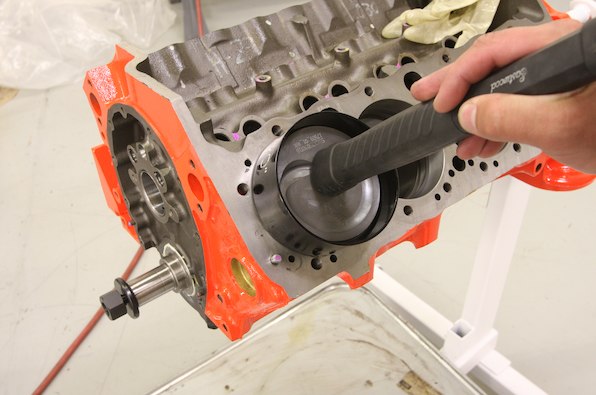

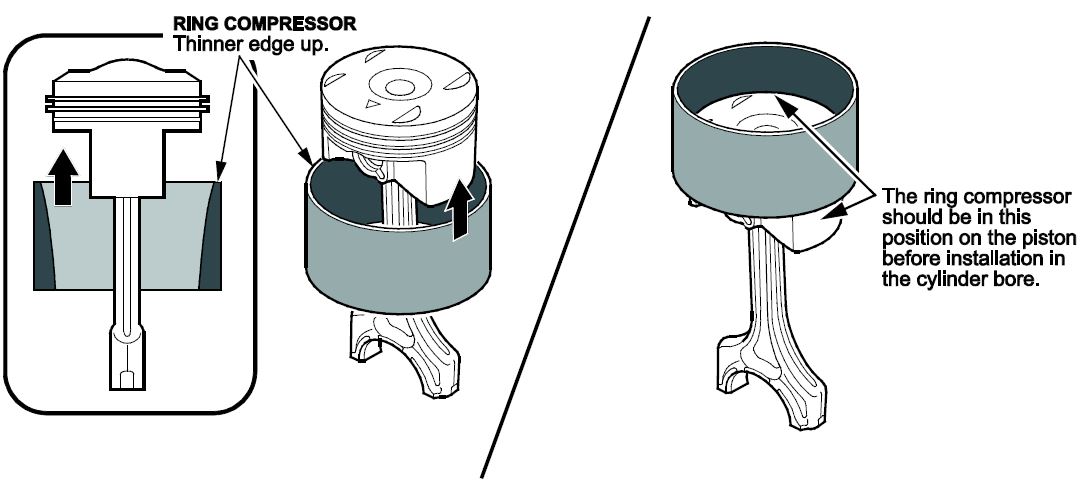

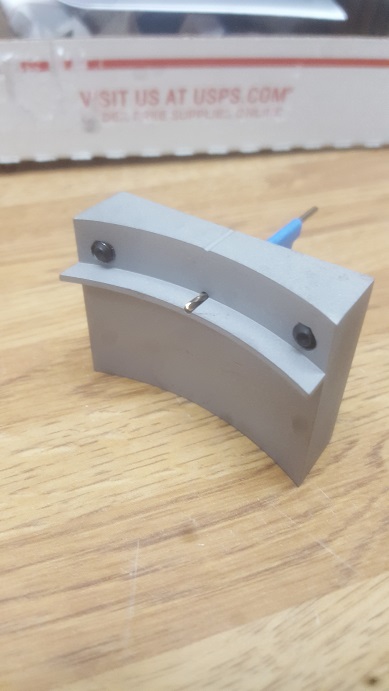

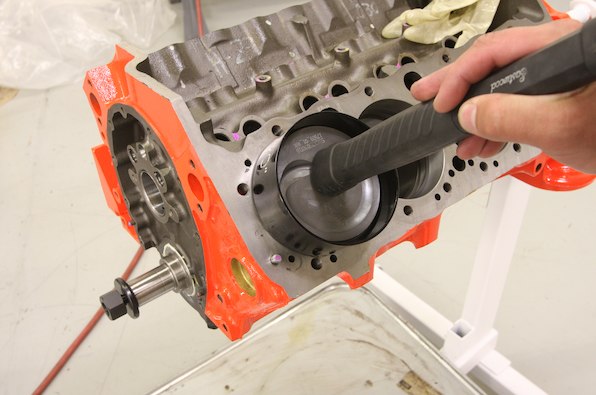

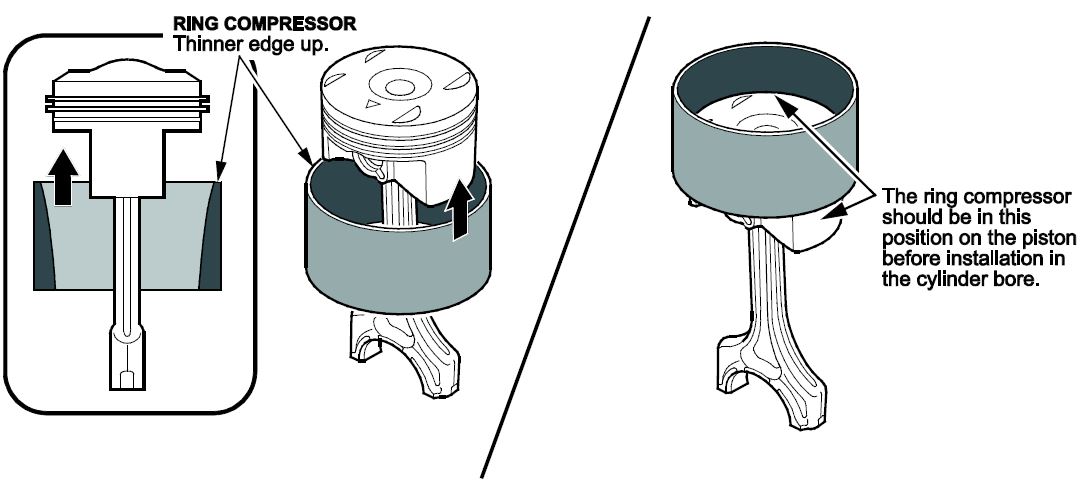

having a decent set of piston ring compressors available in your tool box helps

make engine assembly far easier, using the type posted above makes the job rather easy

using the type below could make a preacher cuss up a blue streak

the #$%%^^& things are just prone to allowing rings too catch and potentially break, as they enter the bore, yeah they work at times but they are not nearly as easy or foolproof

https://www.summitracing.com/parts/lil-20500

related info

http://www.manleyperformance.com/dl/tec ... -rings.pdf

http://www.rosspistons.com/information/ ... lation.pdf

http://www.circletrack.com/enginetech/1 ... education/

http://www.diamondracing.net/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.co...ng-piston-ring-grooves-and-related-info.1797/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.com/index.php?threads/measuring-piston-skirt-clearance.1795/

viewtopic.php?f=53&t=3897

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=5454

viewtopic.php?f=53&t=2795

viewtopic.php?f=50&t=55&p=98&hilit=ring+compressor#p98

https://www.uempistons.com/installation ... lation.pdf

viewtopic.php?f=53&t=247&p=1089&hilit=ring+compressor#p1089

viewtopic.php?f=50&t=8744&p=30912&hilit=cleaning+piston+grooves#p30912

viewtopic.php?f=53&t=509&p=632&hilit=ring+compressor#p632

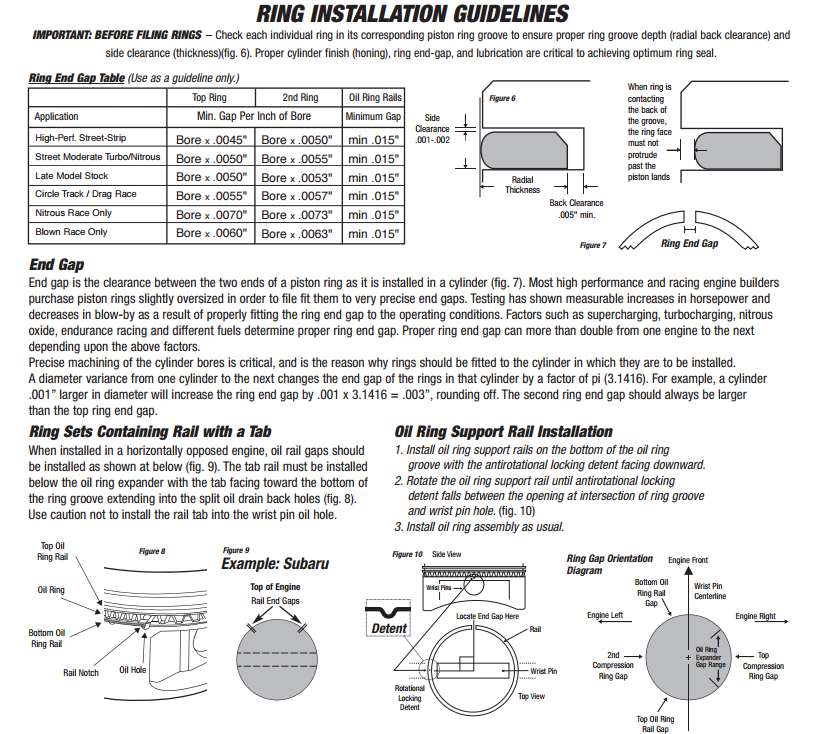

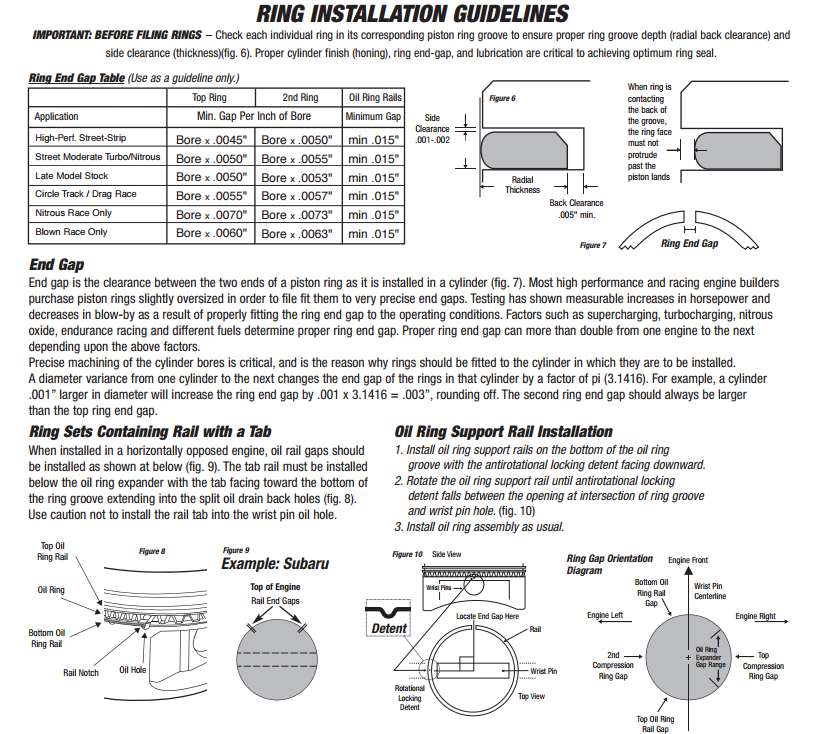

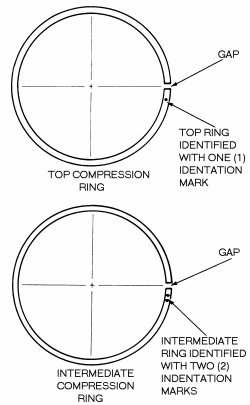

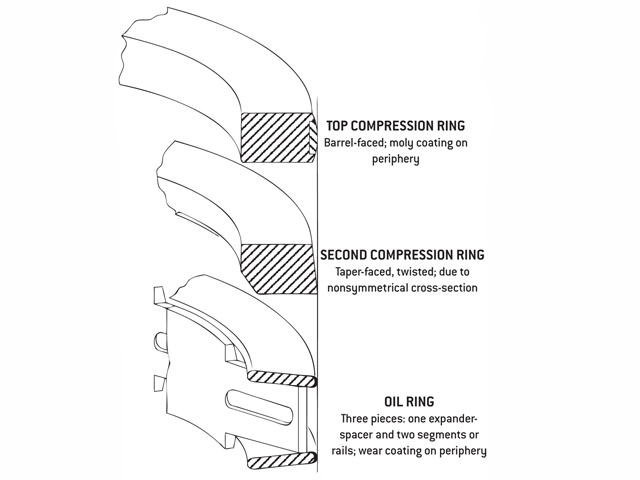

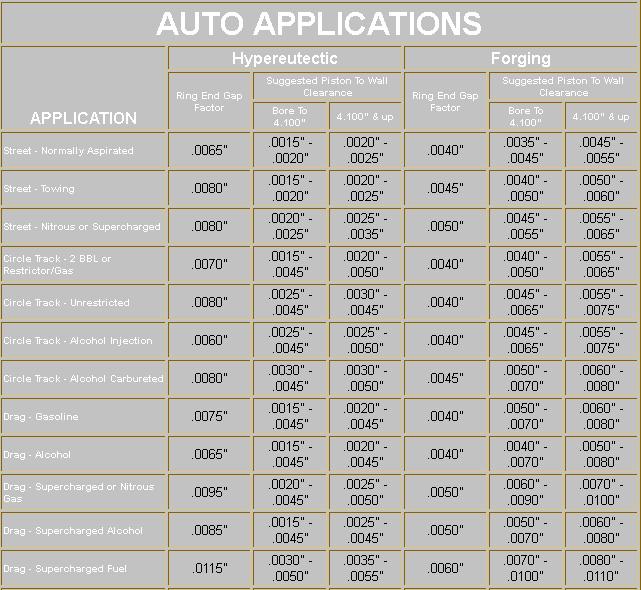

GET THE RING END GAP TOO TIGHT AND WHEN THE RINGS EXPAND WITH ENGINE HEAT THE ENDS TOUCH THE RINGS LOCK IN THE BORE AND THE PISTON LANDS SHEAR OFF

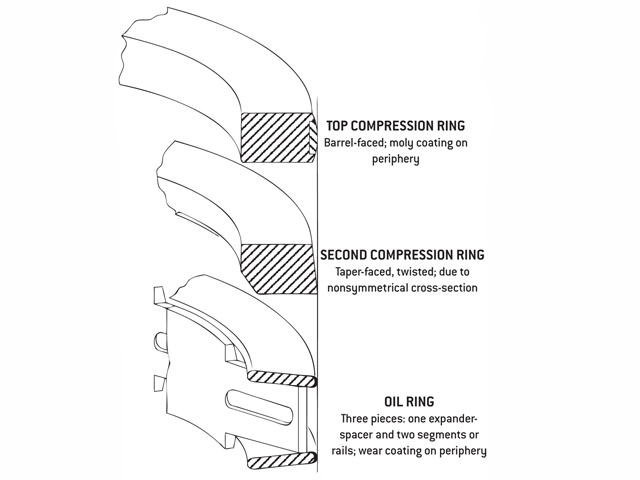

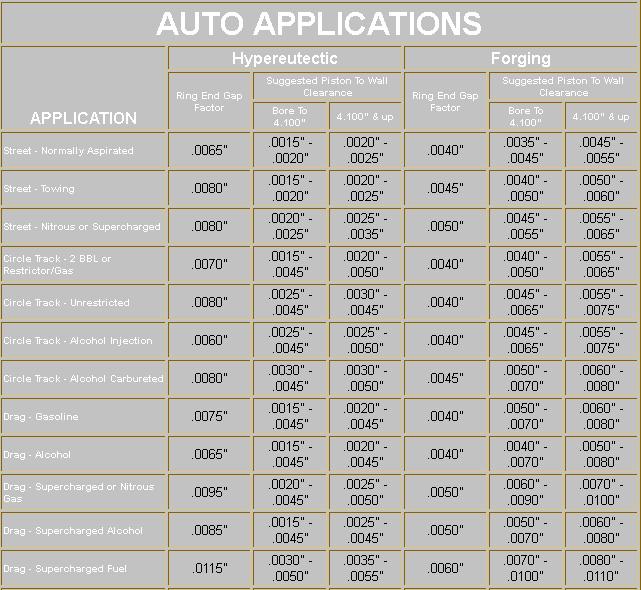

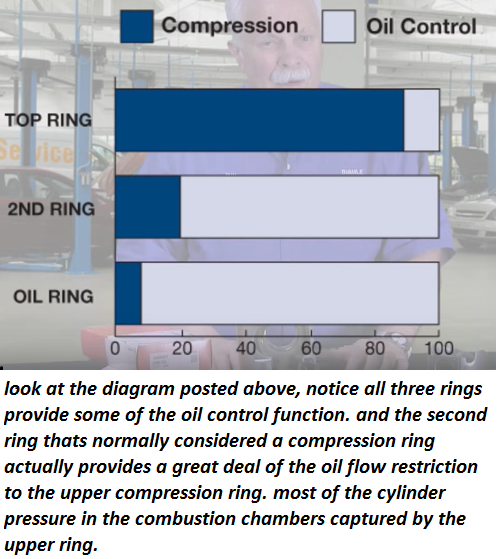

GET THE GAP A BIT TOO LARGE AND YOU MIGHT BURN A BIT MORE OIL OR LOOSE SOME COMPRESSION,BUT YOUR LESS LIKELY TO DAMAGE A PISTON. YOU'LL SEE A CHART LATER IN THE THREAD, BUT GENERALLY YOU'LL WANT .0045-.0065 PER INCH OF BORE DIAM. FOR A RING END GAP

http://www.bing.com/videos/search?q...&mid=E76F9F78364354FD222DE76F9F78364354FD222D

the 80MM-120MM tool fits all chevy V8 engines

http://www.aliexpress.com/item/Piston-Ring-Installer-Remover-Engine-Plier-80-120mm/32477002020.html

the problem, with that method is that its not at all difficult to leave the piston ring twisted permanently, or warping it to the point it either breaks , or its bent ,OR MORE LIKELY degrading its ability to seal against the bore wall.

so its a good idea to carefully use a expander tool, but only expand the ring enough to install it.

buy and use the correct piston groove cleaning tool, if your one of the guys that think scrapping out crud in a piston ring groove with a broken ring will give good results, I can assure you close detailed inspection will show minor scratches and ring groove damage that reduces the ring seal efficiency

http://www.summitracing.com/parts/shc-94662

http://www.superstreetonline.com/how-to/engine/impp-1110-piston-anatomy-tech-knowledge/

https://goodson.com/products/gas-porting-tools

these tools come in various ring sizes ,(but the various piston diameters are not as critical as ring width, it should be obvious that you MUST USE the tool that places the drilled gas port at the correct place in the upper ring groove roof and you damn sure better not drill deeper than the rear edge of the ring groove or youll destroy the piston

if you have oil ring expanders with the plastic bits,they are there to prevent you from over lapping the ends of the oil ring expander, theres some oil ring expander s that are vertical ,some horizontal, but all have the ends butt , none over-lap

https://www.summitracing.com/parts/sme-90a4000

https://www.summitracing.com/parts/sme-90a4120

https://www.summitracing.com/parts/sme-90a4250

https://www.summitracing.com/parts/tsr-rc4345-4455

https://www.summitracing.com/parts/tsr-rc4455-4575

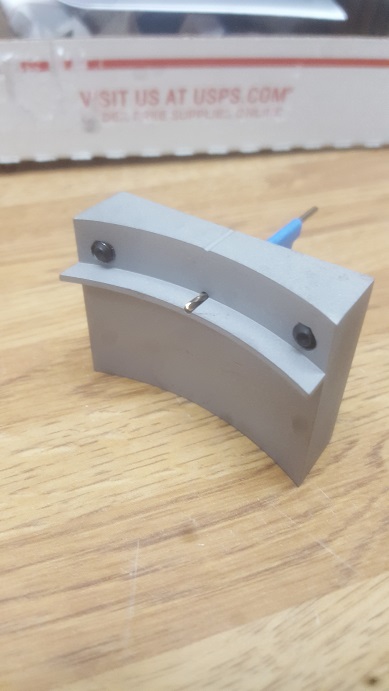

having a decent set of piston ring compressors available in your tool box helps

make engine assembly far easier, using the type posted above makes the job rather easy

using the type below could make a preacher cuss up a blue streak

the #$%%^^& things are just prone to allowing rings too catch and potentially break, as they enter the bore, yeah they work at times but they are not nearly as easy or foolproof

https://www.summitracing.com/parts/lil-20500

related info

http://www.manleyperformance.com/dl/tec ... -rings.pdf

http://www.rosspistons.com/information/ ... lation.pdf

http://www.circletrack.com/enginetech/1 ... education/

http://www.diamondracing.net/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.co...tion-of-crank-durring-short-blk-assembly.852/

http://garage.grumpysperformance.co...ng-and-basic-piston-ring-info-youll-need.509/

http://garage.grumpysperformance.co...ng-piston-ring-grooves-and-related-info.1797/

http://garage.grumpysperformance.com/index.php?threads/maximizing-piston-to-bore-ring-seal.3897/

http://garage.grumpysperformance.com/index.php?threads/measuring-piston-skirt-clearance.1795/

viewtopic.php?f=53&t=3897

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=5454

viewtopic.php?f=53&t=2795

viewtopic.php?f=50&t=55&p=98&hilit=ring+compressor#p98

https://www.uempistons.com/installation ... lation.pdf

viewtopic.php?f=53&t=247&p=1089&hilit=ring+compressor#p1089

viewtopic.php?f=50&t=8744&p=30912&hilit=cleaning+piston+grooves#p30912

viewtopic.php?f=53&t=509&p=632&hilit=ring+compressor#p632

GET THE RING END GAP TOO TIGHT AND WHEN THE RINGS EXPAND WITH ENGINE HEAT THE ENDS TOUCH THE RINGS LOCK IN THE BORE AND THE PISTON LANDS SHEAR OFF

GET THE GAP A BIT TOO LARGE AND YOU MIGHT BURN A BIT MORE OIL OR LOOSE SOME COMPRESSION,BUT YOUR LESS LIKELY TO DAMAGE A PISTON. YOU'LL SEE A CHART LATER IN THE THREAD, BUT GENERALLY YOU'LL WANT .0045-.0065 PER INCH OF BORE DIAM. FOR A RING END GAP

Last edited by a moderator: