Intake Reversion - Enginology

Reversion And How It Can Affect Power

From the August, 2010 issue of Circle Track

By Jim McFarland

Intake Reversion

Depending upon who you might ask, a definition of so-called "reversion" may be compiled in multiple ways. Bottom line, its effects are not necessarily beneficial to efficient combustion, regardless of how it may be defined. Over time, various devices have been construed as helpful in containing reversion, but before we examine how it might be contained, let's review how it develops.

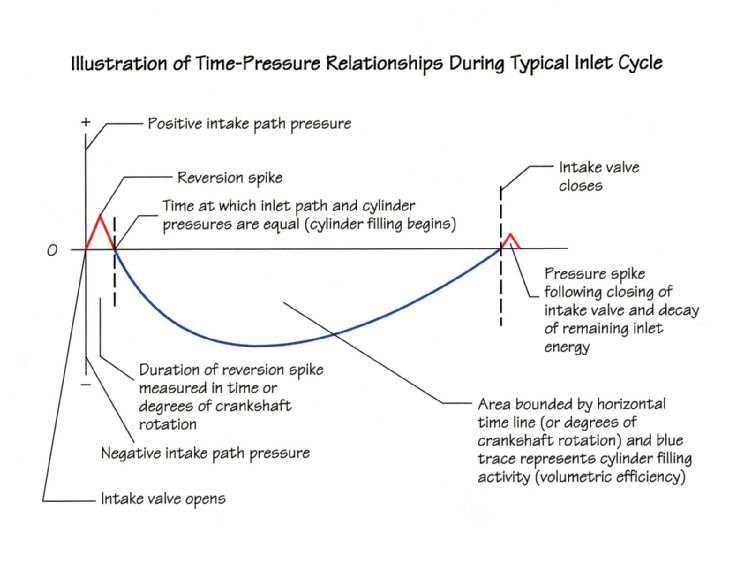

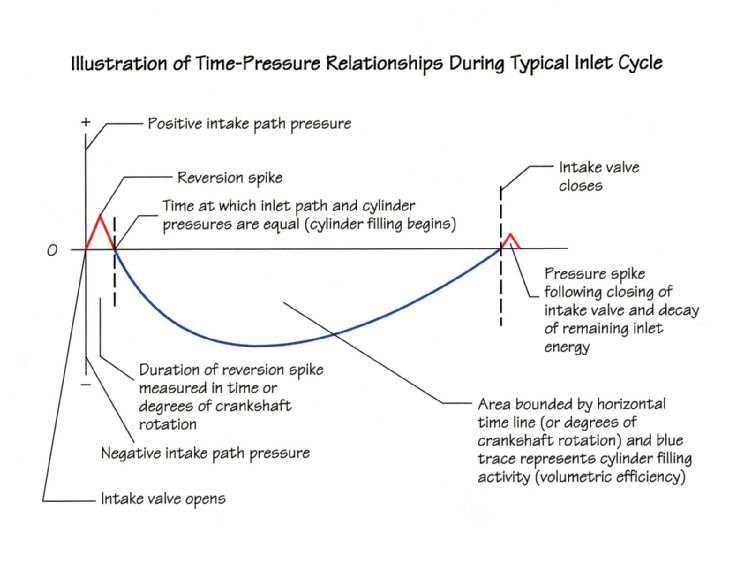

In very slow motion, suppose we break down a typical induction cycle (in a normally aspirated engine) into segments that help identify how reversion is created. You may want to make periodic references to the little illustration we provided this month. It's intended to deliver a graphical image with the following text. In order to simplify an understanding of the phenomenon, we'll focus our description on a single-cylinder, four-stroke cycle engine using a carburetor. That will keep any notions of how a variety of pressure excursions are occurring in a multi-cylinder engine equipped with an intake manifold of single- or dual-plane design can affect the reversion landscape. Including these would rapidly complicate the discussion.

When the intake cycle begins, pressure in the intake manifold is less than atmospheric. At the same time, pressure in the cylinder is higher than atmospheric as exhaust residue is being "pumped" out through the exhaust passage. Now the intake valve begins to open. Since intake events begin before the piston reaches BDC on the exhaust stroke (far ahead of this point in racing engines), a "reverse flow" condition (pulse) is directed back into the intake track and against the direction of normal induction flow. While this condition is counter and disruptive to normal such flow, it also includes gaseous and generally non-combustible material we call exhaust gas.

Depending upon engine speed, the point of pre-BDC intake valve opening, exhaust system efficiency, and related variables, the distance over which this "reversion" pulse (and material) can travel back toward the carburetor will vary. Actually, the higher the rpm, the less penetration it will have into the intake manifold. Stated another way, as rpm increases, reversion activity in the intake manifold becomes contamination to combustion in the cylinders. In severe cases, you'll observe exhaust gas stains on the bottom of the carburetor base. What we do know is that the stronger the pulse, the more time is required to equalize inlet path pressure and cylinder pressure, and the more disruptive reversion becomes.

At this point, cylinder pressure exceeds inlet path pressure. As time passes, cylinder pressure drops to atmospheric, essentially equal to the exhaust. Immediately thereafter, just for an instant, pressure in the inlet path, cylinder, and exhaust path are equal. The exhaust valve then closes and atmospheric pressure begins to force flow into the lower pressure cylinder, beginning the "effective" portion of the intake cycle.

Several consequences of reversion are worth noting. Among them, one is that any combustion residue left in the intake passage and cylinder as a result of reversion, isn't combustible. However, it will occupy some volume in the combustion space, thereby displacing an equal amount of fresh air/fuel charge. The degree of power loss is in direct proportion to the volume of combustion residue present during the next combustion cycle and its effectiveness in reducing flame temperature. After all, this is what EGR (exhaust gas recirculation) does for on-road engines required to meet certain emissions (NOx) standards. In such vehicles, EGR also tends to reduce fuel economy and net power. Despite what might be conventional thinking, this condition is not completely outside the realm of racing engines.

So what are the telltale signs of reversion and what can you do about mitigating the problem? Let's examine some of the more common ones. In extreme cases, a condition often called "stand-off" occurs, during which you will see fuel vapors hovering above the carburetor. Two-plane intake manifolds tend to provide less plenum "damping" of reversion pulses than single-plane versions. In fact, when an engine is fitted with a fuel injection system for which there is no union of runner stacks through a common air chamber that helps dampen such pulses (effectively a plenum function), the problem can be even more acute. If nothing else, the condition further verifies the fact intake flow is bi-directional, under certain circumstances.

By inspection of intake manifold runners at or near their interface with cylinder heads, it's possible to detect traces of exhaust soot on runner walls. If the problem is less severe, intake port coloration becomes the next indicator. Discoloration of a carburetor's base is another spot to inspect. And if you happen to be evaluating engine performance on an engine dyno, watch for the slope of mapped BSFC curves to increase above peak torque rpm. Although there can be other causes of reversion (inadequate exhaust port flow, insufficient exhaust valve duration, mechanical separation of air and fuel at high rpm, ad more), matching this condition with discolorations along the inlet path will separate reversion from other causes of BSFC disruption. At the same time, you may also discover EGTs decreasing below what you'd consider normal for upper rpm power output. Remember, exhaust gas residue tends to cool the combustion process.

Over time, various means have been employed to reduce the impact of reversion on an otherwise efficient combustion process. One particularly effective method is to focus on improving low lift exhaust port flow. This can involve general reduction in exhaust backpressure or shaping exhaust valve seats, pockets and ports that include the backside of exhaust valves. In addition, you can work on reducing airflow in a reverse direction (back toward the combustion space) by valve seat and valve head modifications that promote flow out of the cylinder and not in a back-flow direction. Reverse-flow testing exhaust ports and valves on an airflow bench can be used to determine the effectiveness of such modifications. This technique aids in decreasing cylinder pressure during the last stages of the exhaust cycle, thereby reducing reversion pressure excursions back into the intake path during early opening of the intake valve.

In particular, you may want to study the example time-pressure trace (previously mentioned) that shows positive vs. negative pressure in the inlet path, from intake opening to intake closing. This trace is an example of the pressure history in a single intake path, measured at a point near the junction between the intake manifold and cylinder head. The amplitude and duration of the initial pressure spike is a function of reversion pressure. The area bounded by the horizontal axis and negative pressure part of the trace represents cylinder-filling efficiency (volumetric efficiency), and the smaller spike at the end is created by the kinetic energy decay at the conclusion of the inlet cycle. As you might expect, any successful efforts to reduce the amplitude and duration of the reversion spike nets an increase in the volumetric efficiency area (as previously described).

One final note. Keep in mind that because inlet flow is considered elastic in nature, "negative" pressure spikes created by reversion pulses can affect fuel delivery at the carburetor. Fundamentally, carburetors will deliver fuel based on any pressure differential across its circuitry. Airflow (pulses) delivered to or pressure differentials created across a carburetor will cause a release of fuel, whether the flow is toward or away from the combustion space, thereby upsetting intended carburetor calibrations. The best bet is to address the problem of reversion as not only real but potentially of sufficient significance that it can diminish your best efforts to optimize power.

http://garage.grumpysperformance.com/index.php?threads/oily-crud-on-intake-valves.12083/#post-57903

Reversion And How It Can Affect Power

From the August, 2010 issue of Circle Track

By Jim McFarland

Intake Reversion

Depending upon who you might ask, a definition of so-called "reversion" may be compiled in multiple ways. Bottom line, its effects are not necessarily beneficial to efficient combustion, regardless of how it may be defined. Over time, various devices have been construed as helpful in containing reversion, but before we examine how it might be contained, let's review how it develops.

In very slow motion, suppose we break down a typical induction cycle (in a normally aspirated engine) into segments that help identify how reversion is created. You may want to make periodic references to the little illustration we provided this month. It's intended to deliver a graphical image with the following text. In order to simplify an understanding of the phenomenon, we'll focus our description on a single-cylinder, four-stroke cycle engine using a carburetor. That will keep any notions of how a variety of pressure excursions are occurring in a multi-cylinder engine equipped with an intake manifold of single- or dual-plane design can affect the reversion landscape. Including these would rapidly complicate the discussion.

When the intake cycle begins, pressure in the intake manifold is less than atmospheric. At the same time, pressure in the cylinder is higher than atmospheric as exhaust residue is being "pumped" out through the exhaust passage. Now the intake valve begins to open. Since intake events begin before the piston reaches BDC on the exhaust stroke (far ahead of this point in racing engines), a "reverse flow" condition (pulse) is directed back into the intake track and against the direction of normal induction flow. While this condition is counter and disruptive to normal such flow, it also includes gaseous and generally non-combustible material we call exhaust gas.

Depending upon engine speed, the point of pre-BDC intake valve opening, exhaust system efficiency, and related variables, the distance over which this "reversion" pulse (and material) can travel back toward the carburetor will vary. Actually, the higher the rpm, the less penetration it will have into the intake manifold. Stated another way, as rpm increases, reversion activity in the intake manifold becomes contamination to combustion in the cylinders. In severe cases, you'll observe exhaust gas stains on the bottom of the carburetor base. What we do know is that the stronger the pulse, the more time is required to equalize inlet path pressure and cylinder pressure, and the more disruptive reversion becomes.

At this point, cylinder pressure exceeds inlet path pressure. As time passes, cylinder pressure drops to atmospheric, essentially equal to the exhaust. Immediately thereafter, just for an instant, pressure in the inlet path, cylinder, and exhaust path are equal. The exhaust valve then closes and atmospheric pressure begins to force flow into the lower pressure cylinder, beginning the "effective" portion of the intake cycle.

Several consequences of reversion are worth noting. Among them, one is that any combustion residue left in the intake passage and cylinder as a result of reversion, isn't combustible. However, it will occupy some volume in the combustion space, thereby displacing an equal amount of fresh air/fuel charge. The degree of power loss is in direct proportion to the volume of combustion residue present during the next combustion cycle and its effectiveness in reducing flame temperature. After all, this is what EGR (exhaust gas recirculation) does for on-road engines required to meet certain emissions (NOx) standards. In such vehicles, EGR also tends to reduce fuel economy and net power. Despite what might be conventional thinking, this condition is not completely outside the realm of racing engines.

So what are the telltale signs of reversion and what can you do about mitigating the problem? Let's examine some of the more common ones. In extreme cases, a condition often called "stand-off" occurs, during which you will see fuel vapors hovering above the carburetor. Two-plane intake manifolds tend to provide less plenum "damping" of reversion pulses than single-plane versions. In fact, when an engine is fitted with a fuel injection system for which there is no union of runner stacks through a common air chamber that helps dampen such pulses (effectively a plenum function), the problem can be even more acute. If nothing else, the condition further verifies the fact intake flow is bi-directional, under certain circumstances.

By inspection of intake manifold runners at or near their interface with cylinder heads, it's possible to detect traces of exhaust soot on runner walls. If the problem is less severe, intake port coloration becomes the next indicator. Discoloration of a carburetor's base is another spot to inspect. And if you happen to be evaluating engine performance on an engine dyno, watch for the slope of mapped BSFC curves to increase above peak torque rpm. Although there can be other causes of reversion (inadequate exhaust port flow, insufficient exhaust valve duration, mechanical separation of air and fuel at high rpm, ad more), matching this condition with discolorations along the inlet path will separate reversion from other causes of BSFC disruption. At the same time, you may also discover EGTs decreasing below what you'd consider normal for upper rpm power output. Remember, exhaust gas residue tends to cool the combustion process.

Over time, various means have been employed to reduce the impact of reversion on an otherwise efficient combustion process. One particularly effective method is to focus on improving low lift exhaust port flow. This can involve general reduction in exhaust backpressure or shaping exhaust valve seats, pockets and ports that include the backside of exhaust valves. In addition, you can work on reducing airflow in a reverse direction (back toward the combustion space) by valve seat and valve head modifications that promote flow out of the cylinder and not in a back-flow direction. Reverse-flow testing exhaust ports and valves on an airflow bench can be used to determine the effectiveness of such modifications. This technique aids in decreasing cylinder pressure during the last stages of the exhaust cycle, thereby reducing reversion pressure excursions back into the intake path during early opening of the intake valve.

In particular, you may want to study the example time-pressure trace (previously mentioned) that shows positive vs. negative pressure in the inlet path, from intake opening to intake closing. This trace is an example of the pressure history in a single intake path, measured at a point near the junction between the intake manifold and cylinder head. The amplitude and duration of the initial pressure spike is a function of reversion pressure. The area bounded by the horizontal axis and negative pressure part of the trace represents cylinder-filling efficiency (volumetric efficiency), and the smaller spike at the end is created by the kinetic energy decay at the conclusion of the inlet cycle. As you might expect, any successful efforts to reduce the amplitude and duration of the reversion spike nets an increase in the volumetric efficiency area (as previously described).

One final note. Keep in mind that because inlet flow is considered elastic in nature, "negative" pressure spikes created by reversion pulses can affect fuel delivery at the carburetor. Fundamentally, carburetors will deliver fuel based on any pressure differential across its circuitry. Airflow (pulses) delivered to or pressure differentials created across a carburetor will cause a release of fuel, whether the flow is toward or away from the combustion space, thereby upsetting intended carburetor calibrations. The best bet is to address the problem of reversion as not only real but potentially of sufficient significance that it can diminish your best efforts to optimize power.

http://garage.grumpysperformance.com/index.php?threads/oily-crud-on-intake-valves.12083/#post-57903

Last edited by a moderator: