http://www.popularhotrodding.com/tech/1 ... all_block/

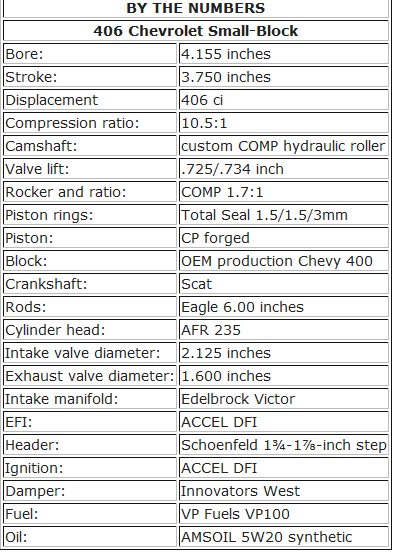

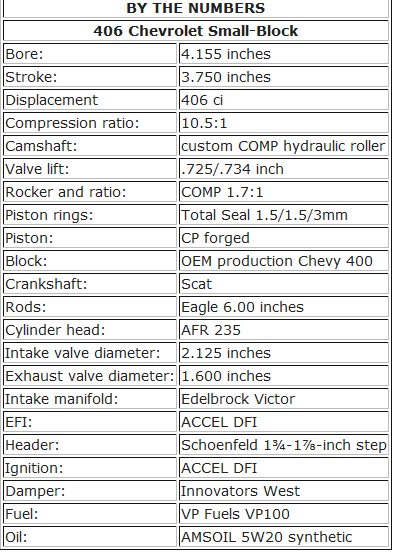

The traditional small-block has been built in just about every configuration you can imagine, but sticking with a proven combination is a surefire path to great results. Take for instance the small-block Chevy featured here. Built by Chris Henderson of Henderson Power Sports, the engine follows a formula that is long established. Using a factory 400 production block as the basis, Henderson didn't alter Chevrolet's basic layout, but instead put together the familiar 406 combination arrived at by retaining the factory 3.75-inch stroke and simply refreshing the OEM 4.125-inch bores with a .030-inch overbore. One of the key advantages of going this route is that aftermarket parts are readily available as off-the-shelf parts, greatly reducing the costs compared to going with a more esoteric combination.

Building Blocks

Production Block As A Base To serve as a foundation, Chris Henderson started with a production block as a base. Pulle

As Henderson tells us, "The block came out of a 1976 Chevy Blazer that was left out in a field so long, a tree was growing out of it. An aftermarket block would have been nice, but the stock GM block probably saved over $1,000 when all was said and done. The GM blocks are plenty strong for this kind of build, and with their siamesed bore there is plenty of meat between the cylinders to keep things stable. We just reinforced the original two-bolt main block with aftermarket billet main caps, and added a partial fill with Hardblock. The two-bolt main blocks are a better starting point than the four-bolt block, since the aftermarket splayed caps are a stronger setup than the factory four-bolt main's." Besides the usual machining, block prep included general cleanup and grinding of the casting flash and adding stand-pipes to direct oil flow to drain back to the rear of the block. Henderson tells us, "I wanted the oil to drain to the rear to keep the oil off the rotating assembly and reduce windage, and off the shallow side at the front of the pan."

While the factory crank measures 3.75 inches in stroke, Henderson opted to go with a Scat aftermarket crank in the same specification. The Scat forged crank is definitely a higher grade material than the OEM piece, but as Henderson points out, "The design of the counterweights and throws is much cleaner and shaped for a reduction in windage, and the surface of the crank is far smoother." Henderson departed from the OEM formula when selecting rods, steering away from the factory short rod arrangement, instead substituting a set of 6.00-inch Eagle H-beam rods. These rods are definitely strong enough to take the punishment, and the added rod length cures the compromised rod angularity problems inherent in the factory Chevy 400. Both the crank and rods are installed with Speed-Pro bearings, specifically coated to gain an extra measure of protection under load.

Owing to the common internal configuration of a stock stroke, 6-inch rod small-block, piston selection for this build was wide open. The .030-inch overbore block's cylinders were readily filled with catalog shelf pistons from CP. Henderson went with CP's Bullet series forged flat-top pistons, which come machined for a 1.5/1.5/3mm ring package. Henderson had the pistons modified by CP with a shallow reverse dome machined into the crown, matching the shape of the engine's AFR cylinder heads. Filling the ring grooves are a set of Total Seal rings, featuring Total Seal's proprietary gapless top design, and a Napier-faced second ring. Henderson remarks, "I like the Total Seal rings because of the superior sealing. Just trying to bar the crank around you'll find that it will practically stop cold at TDC because of the compression seal. There is also a better seal on the induction stroke, which pulls a little harder on that side."

Cam, Heads & Induction

Cp Bullet Unit Pistons Pistons are CP Bullet units, which are readily available stocking items. The pistons were

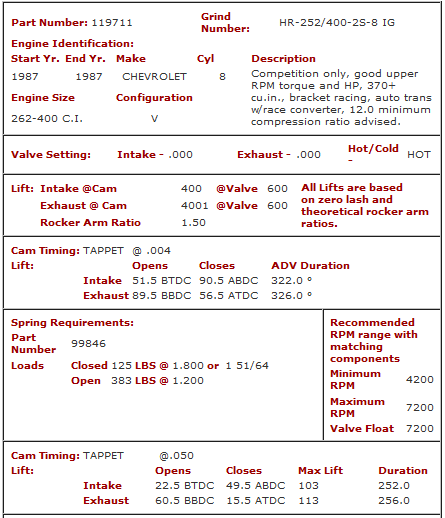

Looking to run in the Street Division of competition in the 2012 AMSOIL Engine Masters Challenge, a hydraulic roller cam was required equipment. Henderson wanted to run aggressive lobe profiles and had a custom camshaft ground using solid roller lobes from COMP Cams. Henderson arrived at the specification of 246/251 degrees duration at .050-inch lift; "I had more duration in the cam than many of the other engines in the competition because I was working with an inline-valve 23-degree head. The cross-sectional area is limited at the pushrods, and the flow is less than you might get from a canted-valve or Hemi engine. The cam puts the power where it needs to be in the rpm range." To work with the cam, Henderson used a set of COMP's limited-travel retrofit hydraulic roller lifters. As Henderson points out, "With a hydraulic roller at this rpm range you do not have to worry too much about lifter pump-up, but there is .160 inch of travel for the lifters to collapse, especially with high spring loads. The limited-travel lifters eliminate that possibility. I set them up at about .006-inch preload, which is very close to zero lash when up to temperature."

Topping the engine is a set of AFR Eliminator 235 cylinder heads. These heads feature the common 60/40 shift, where the intake and exhaust valve are relocated to increase the clearance for larger valves. Henderson tells us, "With this head, an offset rocker provides increased valvetrain clearance, but I was using a standard set of COMP Hi-Tech Stainless rockers in a 1.7:1 ratio. The relatively high ratio delivers .725/.734-inch lift, but the clearance to the intake port was limited with this head and rocker combination. I ended up having to grind for pushrod clearance and also had to use 5/16-inch pushrods. Bigger pushrods would have been better, but I made the 5/16-inch pushrods stiffer by going with a wall thickness of .015 inch."

Afr Heads With the exception of a simple port match, Henderson ran the AFR heads as delivered by AFR

Henderson says the AFR cylinder heads are the best you can get in a conventional 23-degree Chevy small-block head. Henderson ordered the heads with AFR's competition level CNC porting with little further modification: "With these heads you will have a hard time improving the work done by AFR. I know that they invest significant R&D in developing their ports. All I did was a port-match and add the springs and titanium retainers." Henderson went with a COMP Cams dual valvespring assembly delivering 140/500 pounds closed/open load, and found the arrangement worked very well in the operating rpm range of the engine. Henderson disclosed: "I didn't go crazy with the spring loads, but the engine pulled cleanly at high rpm with no sign of valve float or instability."

Feeding the cylinder heads is an Edelbrock Victor single-plane intake manifold converted to fuel injection by the late Jeff Kobylski of Modern Cylinder heads. Henderson details, "The Victor manifold had the cloverleaf Dominator intake flange I wanted, and the runners have a nice taper to them. Modification to the intake was just a basic cleanup and blending, and adding the bungs for the injectors." Working in conjunction with the Victor manifold is a DFI electronic fuel injection system from ACCEL. The Dominator-flanged four-barrel throttle body from ACCEL is nothing short of giant, with an airflow rating of 2,100 cfm. This unit meters the air, while fuel is supplied by ACCEL 55-lb/hr injectors and ACCEL rails, and control is provided by an ACCEL ECU and software. The EFI system incorporates a complete ACCEL ignition system to handle the spark timing requirements.

Henderson spoke enthusiastically about the ACCEL system: "This was my first experience with fuel injection, and the support I got from ACCEL was outstanding. The EFI system allowed very precise control of the fuel and spark, and that helped optimize the power possible from this engine combination. After my experience with ACCEL, I would not run any other fuel injection system."

Dyno Time

Accel Dfi Electronic Control Unit An ACCEL DFI electronic control unit serves as the brain of the injection system controlli

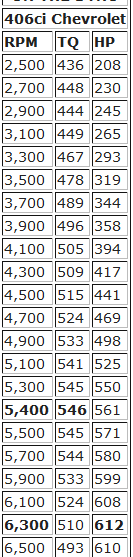

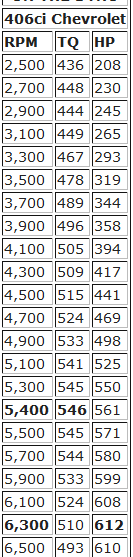

The engine was completed with an Edelbrock mechanical water pump and fitted with a set of Schoenfeld 1¾-1⅞-inch step headers and it was off to meet the SuperFlow/DTS Powermark dyno at the 2012 AMSOIL Engine Masters Challenge hosted at the University of Northwestern Ohio. In discussing this engine with Henderson what got our attention was the broad appeal of such a popular engine combination. It doesn't get much more mainstream than a production-based 406 small-block with 23-degree heads and a hydraulic roller cam, however, watching the engine perform on the dyno showed that the output was anything but common for this kind of arrangement. Henderson's Chevy easily surpassed the 600hp mark, topping out at an impressive 612 hp at 6,300 rpm. In terms of engine speed at peak power, the build was right on target for our competition's 6,500-rpm limit. Delivering 546 lb-ft of torque at 5,400 rpm, there was a peak of 1.34 lb-ft per cubic inch developed, an outstanding accomplishment.

This small-block Chevy from Henderson Power Sports proves that it doesn't take the trick of the week or a reinvention of the small-block to produce impressive results. Careful planning, machining, and assembly, as well as selecting effective components will deliver the goods. No doubt this is one of the main reasons the popularity of Chevy's original small-block continues to endure.

The traditional small-block has been built in just about every configuration you can imagine, but sticking with a proven combination is a surefire path to great results. Take for instance the small-block Chevy featured here. Built by Chris Henderson of Henderson Power Sports, the engine follows a formula that is long established. Using a factory 400 production block as the basis, Henderson didn't alter Chevrolet's basic layout, but instead put together the familiar 406 combination arrived at by retaining the factory 3.75-inch stroke and simply refreshing the OEM 4.125-inch bores with a .030-inch overbore. One of the key advantages of going this route is that aftermarket parts are readily available as off-the-shelf parts, greatly reducing the costs compared to going with a more esoteric combination.

Building Blocks

Production Block As A Base To serve as a foundation, Chris Henderson started with a production block as a base. Pulle

As Henderson tells us, "The block came out of a 1976 Chevy Blazer that was left out in a field so long, a tree was growing out of it. An aftermarket block would have been nice, but the stock GM block probably saved over $1,000 when all was said and done. The GM blocks are plenty strong for this kind of build, and with their siamesed bore there is plenty of meat between the cylinders to keep things stable. We just reinforced the original two-bolt main block with aftermarket billet main caps, and added a partial fill with Hardblock. The two-bolt main blocks are a better starting point than the four-bolt block, since the aftermarket splayed caps are a stronger setup than the factory four-bolt main's." Besides the usual machining, block prep included general cleanup and grinding of the casting flash and adding stand-pipes to direct oil flow to drain back to the rear of the block. Henderson tells us, "I wanted the oil to drain to the rear to keep the oil off the rotating assembly and reduce windage, and off the shallow side at the front of the pan."

While the factory crank measures 3.75 inches in stroke, Henderson opted to go with a Scat aftermarket crank in the same specification. The Scat forged crank is definitely a higher grade material than the OEM piece, but as Henderson points out, "The design of the counterweights and throws is much cleaner and shaped for a reduction in windage, and the surface of the crank is far smoother." Henderson departed from the OEM formula when selecting rods, steering away from the factory short rod arrangement, instead substituting a set of 6.00-inch Eagle H-beam rods. These rods are definitely strong enough to take the punishment, and the added rod length cures the compromised rod angularity problems inherent in the factory Chevy 400. Both the crank and rods are installed with Speed-Pro bearings, specifically coated to gain an extra measure of protection under load.

Owing to the common internal configuration of a stock stroke, 6-inch rod small-block, piston selection for this build was wide open. The .030-inch overbore block's cylinders were readily filled with catalog shelf pistons from CP. Henderson went with CP's Bullet series forged flat-top pistons, which come machined for a 1.5/1.5/3mm ring package. Henderson had the pistons modified by CP with a shallow reverse dome machined into the crown, matching the shape of the engine's AFR cylinder heads. Filling the ring grooves are a set of Total Seal rings, featuring Total Seal's proprietary gapless top design, and a Napier-faced second ring. Henderson remarks, "I like the Total Seal rings because of the superior sealing. Just trying to bar the crank around you'll find that it will practically stop cold at TDC because of the compression seal. There is also a better seal on the induction stroke, which pulls a little harder on that side."

Cam, Heads & Induction

Cp Bullet Unit Pistons Pistons are CP Bullet units, which are readily available stocking items. The pistons were

Looking to run in the Street Division of competition in the 2012 AMSOIL Engine Masters Challenge, a hydraulic roller cam was required equipment. Henderson wanted to run aggressive lobe profiles and had a custom camshaft ground using solid roller lobes from COMP Cams. Henderson arrived at the specification of 246/251 degrees duration at .050-inch lift; "I had more duration in the cam than many of the other engines in the competition because I was working with an inline-valve 23-degree head. The cross-sectional area is limited at the pushrods, and the flow is less than you might get from a canted-valve or Hemi engine. The cam puts the power where it needs to be in the rpm range." To work with the cam, Henderson used a set of COMP's limited-travel retrofit hydraulic roller lifters. As Henderson points out, "With a hydraulic roller at this rpm range you do not have to worry too much about lifter pump-up, but there is .160 inch of travel for the lifters to collapse, especially with high spring loads. The limited-travel lifters eliminate that possibility. I set them up at about .006-inch preload, which is very close to zero lash when up to temperature."

Topping the engine is a set of AFR Eliminator 235 cylinder heads. These heads feature the common 60/40 shift, where the intake and exhaust valve are relocated to increase the clearance for larger valves. Henderson tells us, "With this head, an offset rocker provides increased valvetrain clearance, but I was using a standard set of COMP Hi-Tech Stainless rockers in a 1.7:1 ratio. The relatively high ratio delivers .725/.734-inch lift, but the clearance to the intake port was limited with this head and rocker combination. I ended up having to grind for pushrod clearance and also had to use 5/16-inch pushrods. Bigger pushrods would have been better, but I made the 5/16-inch pushrods stiffer by going with a wall thickness of .015 inch."

Afr Heads With the exception of a simple port match, Henderson ran the AFR heads as delivered by AFR

Henderson says the AFR cylinder heads are the best you can get in a conventional 23-degree Chevy small-block head. Henderson ordered the heads with AFR's competition level CNC porting with little further modification: "With these heads you will have a hard time improving the work done by AFR. I know that they invest significant R&D in developing their ports. All I did was a port-match and add the springs and titanium retainers." Henderson went with a COMP Cams dual valvespring assembly delivering 140/500 pounds closed/open load, and found the arrangement worked very well in the operating rpm range of the engine. Henderson disclosed: "I didn't go crazy with the spring loads, but the engine pulled cleanly at high rpm with no sign of valve float or instability."

Feeding the cylinder heads is an Edelbrock Victor single-plane intake manifold converted to fuel injection by the late Jeff Kobylski of Modern Cylinder heads. Henderson details, "The Victor manifold had the cloverleaf Dominator intake flange I wanted, and the runners have a nice taper to them. Modification to the intake was just a basic cleanup and blending, and adding the bungs for the injectors." Working in conjunction with the Victor manifold is a DFI electronic fuel injection system from ACCEL. The Dominator-flanged four-barrel throttle body from ACCEL is nothing short of giant, with an airflow rating of 2,100 cfm. This unit meters the air, while fuel is supplied by ACCEL 55-lb/hr injectors and ACCEL rails, and control is provided by an ACCEL ECU and software. The EFI system incorporates a complete ACCEL ignition system to handle the spark timing requirements.

Henderson spoke enthusiastically about the ACCEL system: "This was my first experience with fuel injection, and the support I got from ACCEL was outstanding. The EFI system allowed very precise control of the fuel and spark, and that helped optimize the power possible from this engine combination. After my experience with ACCEL, I would not run any other fuel injection system."

Dyno Time

Accel Dfi Electronic Control Unit An ACCEL DFI electronic control unit serves as the brain of the injection system controlli

The engine was completed with an Edelbrock mechanical water pump and fitted with a set of Schoenfeld 1¾-1⅞-inch step headers and it was off to meet the SuperFlow/DTS Powermark dyno at the 2012 AMSOIL Engine Masters Challenge hosted at the University of Northwestern Ohio. In discussing this engine with Henderson what got our attention was the broad appeal of such a popular engine combination. It doesn't get much more mainstream than a production-based 406 small-block with 23-degree heads and a hydraulic roller cam, however, watching the engine perform on the dyno showed that the output was anything but common for this kind of arrangement. Henderson's Chevy easily surpassed the 600hp mark, topping out at an impressive 612 hp at 6,300 rpm. In terms of engine speed at peak power, the build was right on target for our competition's 6,500-rpm limit. Delivering 546 lb-ft of torque at 5,400 rpm, there was a peak of 1.34 lb-ft per cubic inch developed, an outstanding accomplishment.

This small-block Chevy from Henderson Power Sports proves that it doesn't take the trick of the week or a reinvention of the small-block to produce impressive results. Careful planning, machining, and assembly, as well as selecting effective components will deliver the goods. No doubt this is one of the main reasons the popularity of Chevy's original small-block continues to endure.