Eric Weingartner said:I just got back from the Amsoil Engine Masters Challenge. I had a very good time and wished I would have finished better but overall I was pleased. Here is the run down of the engine and how it did.

540bbc

Dart Big M block 4.50 bore

Mahle Pistons 11.4compression ratio with lateral gas ports

Scat 4340 H beam rods with arp 2000 capscrews 6.385

Scat standard weight 4340 crank 4.25stroke

Clevite coated rod bearings

Calico coated King Main bearings.

Total seal gapless rings. (I hate gaping these)

Modified hamburger oil pan

Titan oil pump (I can't believe I spent this much on a pump)

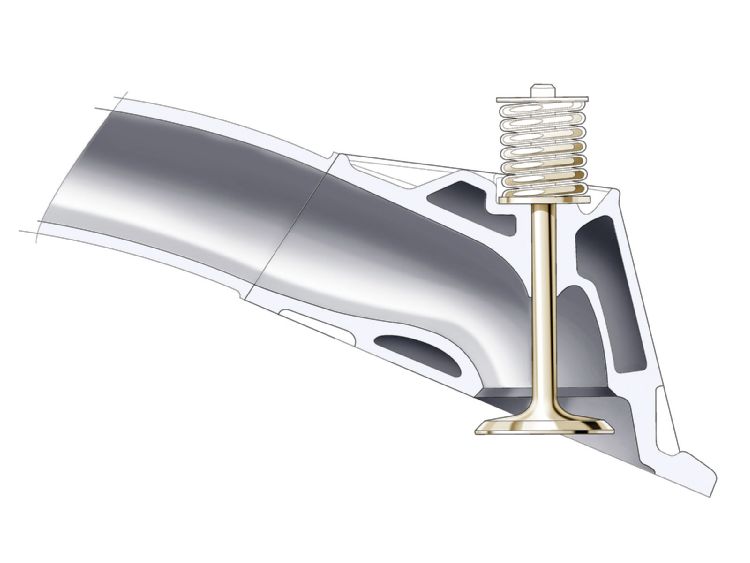

Hydraulic roller camshaft

Straub .904 hydraulic roller lifters

RHS 320cc heads that I heavily ported and had epoxy in. Flowed 442cfm

2.30/1.88 valves

Pac 1.55 springs 275lbs on seat 800open

Pac tool steel retainers

Comp pushrods 3/8 .135 wall

Comp 1.8 XD Ultra Pro magnum rockers intake

Comp 1.7 XD ultra Pro magnum rockers exhaust

Edelbrock Super victor SV 565 intake ported by me with a ton of epoxy in it.

Braswell 4150 carb with 1.75 throttle bores.

ICE ignition

Powerbond dampner

Headman 69camaro 2.25 headers

Dynomax 4.0 merge collectors

At the EMC the best power was 866 Horsepower at 6500 and 757 torque at 5500rpm. It reved to 7200rpm no problems

I was runner up for horsepower king by 4hp to a 572bbf. I was also runner up for torque master.

This engine is going in my car after a different oil pan and a dominator.

I would like to thank the following people for the help this year.

Andy and Donny Key for the initial machine work and dyno session

Dunsworth Machine for opening on a Saturday to dyno

Headman Headers

ICE ignitions

Chris Straub for coming through for a camshaft

http://www.popularhotrodding.com/tech/1 ... ewall.html

theres always a big factor in the selection of engine components ,

for most of us and thats obviously the COST VS potential power gained.

what many guys fail to look at is the valve lift vs flow numbers, and intended application,

I does you darn little good to purchase a killer BBC, set of 360 cfm rectangular port cylinder heads that flow 400- 450 cfm at .800 lift if ,

your cam selected max's out a .650 lift, its not designed to maintain valve control at over 6000 rpm, and your intake port flow stalls at 390 cfm

especially on something like a 9:1 compression 454 BBC, with a typical 750 quadrajet carburetor on a Stock style low rise dual plane intake,

yet I see similar mis-matched components rather frequently , usually from guys that got KILLER DEALS on lightly used race engine parts they picked up at bargain prices at swap meets.

look over the parts your selecting very carefully and use some logic in matching components, if you realistically won,t be running the engine over 6000 rpm, and your displacement is under 427-454 cid, your very unlikely to benefit

lets do some MATH

lets assume you want to build a kick ass 540 BBC

a 540 has a 4.25" stroke and 5200 f.p.m. in piston speed would be a reasonable upper rpm limit (7350 RPM )if you intend to maintain reasonable long term durability.

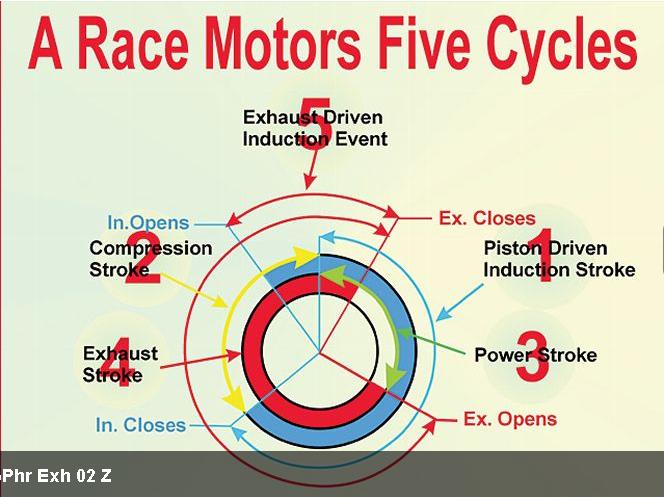

now that would MANDATE a solid lifter cam (ideally a roller solid lifter) valve train to maintain valve train stability in most cases.

at 7350 rpm a 540 will in theory use 1723 cubic feet of air PER MINUTE

thats 215.4 cubic feet of air per minute per cylinder, if divided equally but each cylinder draws

67.5 cubic inches per cylinder x 3675 intake strokes,

thats about 1723 cubic feet of air per port, per minute, and 3675 intake strokes per minute

thats .469 cubic feet per intake stroke ,

(theres 144 cubic inches in a cubic foot) and a cylinder in a 540 has 67.5 cubic inches.

theres 8 cylinders that need 67.5 cubic inches of air volume 3675 times per minute.

Btw heres a tip learned through experience , if your 496 -540 displacement BBC combo includes an engine with at least 10:1 compression and a cam with at least 240 duration at .050 lift, and oval port heads, youll almost always find a single plane intake has some advantages over a dual plane intake.

but remember an intake port and intake valve ,flows air during about 250 degrees in a 720 degree cycle, thats about 35% -40% of the time,the engines intake valve is effectively open and flowing air, and remember the exhaust scavenging,

has a huge effect on intake flow rates.

lets look at an intake port that flows 400 cfm which you might need to allow a 540 to flow enough air because even if the heads potentially flow 400 cfm the intake manifold or some other component may not fully keep up!

flow rates are measured on a flow bench at constant flow rates,

but theres 61.25 intake strokes per minute, per cylinder.

in theory a port that flows 400 cfm will flow about 160 cfm during the 40% of the time its open in the 720 degree cycle. thats 160 CFM x 144 cubic inches,23040 cubic inches

/61.25 intake strokes per minute= 376 cubic inches of rated flow capacity

376 cubic inches x 61.25 intake stroke per minute =23039 cubic inches

http://garage.grumpysperformance.com/index.php?threads/aftermarket-heads-for-a-bbc.12316/

http://garage.grumpysperformance.com/index.php?threads/big-block-head-comparison.319/

http://garage.grumpysperformance.co...n-chamber-big-block-heads-and-casting-s.3960/

Last edited by a moderator: