http://www.hotrod.com/articles/ccrp-0709-aftermarket-parts/

We Test A Pile Of Speed Parts To Discover

‘This was dyno thrash week, and we went through the Summit catalog like kids at Christmastime. The conversation went something like this: “This will be great-test that tunnel-ram against a single four-barrel manifold . . . See that new Edelbrock dual-quad setup? Test that too . . . Hey, Holley’s got three different 750 mechanical secondary carburetors. Which one will make the most power and which one costs the most? Run ’em all and find out . . .” It was like combining stream of consciousness with dyno testing. Before I knew it, I was staring at a 6-foot-tall pile of parts in my shop that took two truckloads to haul to Westech for a marathon dyno session.

The New Buick ® Encore

Get Details on the All New Encore. See Photos, Pricing, and Specs Now. Buick.com/Encore_vs_Ford_Edge

We also enlisted Car Craft’s brand-new JMS-built 383 small-block Chevy for the beatings, which would consume 35 gallons of pump gas and three long days of 6,500-plus-rpm blasts. At the end, we had Westech’s Steve Brul asking, “You’re not coming back again for awhile . . . are you?”

After cleaning the last bit of synthetic oil out from under our fingernails and pondering whether we qualified for the Guinness World Record for the most small-block Chevy intake manifold swaps in a single 48-hour period, we did manage to compile a rather sizeable database for the parts we tested. We discovered all kinds of surprising stuff. We learned that Wilson tapered carburetor spacers rock; that 7,000 rpm can tweak a set of valvesprings in one pull; that tailpipes cost power but not where you think; that Weiand makes a very strong dual-plane Air Strike intake manifold; that an Edelbrock nostalgic dual-quad setup looks pretty cool on any small-block; and finally that Dart’s CNC 227 heads matched with a big cam can make wicked horsepower. All told, the thrash was a total success. And you’re the big winner, because now you have all the information you need on these parts to decide if they’re worth emptying your savings account in the name of horsepower.

First-Ever Buick Envision

Buick.com/Envision_vs_Acura_RDX

Compare Buick ® & The Acura RDX. View Trims, Packages & More Here!

The Power Source

All the tests in this section were performed on the same 383ci small-block Chevy machined and assembled by JMS Racing Engines. Since this small-block was destined for a very hard life on the dyno, it made sense to plug in a rock-solid rotating assembly that could take the abuse, which led us to a complete bottom end from Lunati. One small shift from the norm was to start with a one-piece rear main seal block of ’88-and-later vintage. To give it a fighting chance to survive, JMS added steel four-bolt main caps to the center three main bearings, requiring a careful boring operation to make the bearing housings all round. We opted for the standard 3.75-inch-stroke steel Lunati crank with a one-piece rear main seal, along with Lunati’s forged Pro Mod rods and a set of flat-top, forged Wiseco Pro Tru pistons with two 5.4cc valve reliefs.

Stroker packages, especially the 383 Chevy, often need a little clearancing around the bottom of the cylinders, and this block was no exception. Once the block was cleaned and the forged pistons assembled on the Lunati rods, it all slipped together with the 11/416-inch rings and bearings supplied with the rotator package. We selected a pair of Dart Pro 1 Platinum 215 heads as the starting point for our small-block test mule combined with a Comp Cams Xtreme Energy XR280 mechanical roller cam (cam specs can be found in the Dart cylinder head test sidebar). Compression came in just a hair under 11.0:1, but even with the smaller cam detonation was never a problem. We also planned on testing a larger set of Dart CNC 227 heads combined with a bigger XR292 cam, so Comp supplied 0.080-inch-thick-wall pushrods along with some lash caps we needed to ensure the rocker arms would clear the larger-diameter valvesprings. After that bit of custom engineering, the engine came together very quickly, including a three-piece front timing cover and a Hamburger oil pan from Summit Racing to button everything up with Fel-Pro gaskets and ARP bolts.

The 2017 Buick ® Encore

Add Luxury to Your Daily Commute. Build, Price & Compare Yours Here! See Buick.com/Encore_vs_Ford_Edge

Parts List

DESCRIPTION PN SOURCE PRICE

Lunati 4340 stroker rotator assm. EA62 Summit Racing $3,470.39

Steel main caps SB350C12 JMS 225.00

Hamburger’s oil pan 1088 Summit Racing 239.88

Comp Cams XR280 roller cam 12-771-8 Summit Racing 255.95

Comp Cams lifters, Endurex roller 888-16 Summit Racing 516.99

Comp Cams timing set 3100KT Summit Racing 176.69

Comp Cams pushrods, 0.080 wall 7972-16 Summit Racing 135.95

Comp Cams three-piece cover 210 Summit Racing 229.95

Comp Cams Magnum rockers, 1.5 1305-16 Summit Racing 275.95

Comp Cams billet-timing set 7100 Summit Racing 101.69

Dart 215 Pro 1 Platinum heads, pr. 11611123P Summit Racing 1,439.90

ARP head bolts 134-3601 Summit Racing 59.95

ARP 7¼16 rocker studs 134-7103 Summit Racing 35.95

ARP Perma-Loc 300-8243 Summit Racing 53.95

ARP intake manifold bolt kit 134-2001 Summit Racing 19.95

ARP distributor stud kit 130-1702 Summit Racing 3.88

750-CFM Carb Swap

Carburetor cfm ratings seem to be those magic buttons that everyone wants to push to make more horsepower. The truth is that large carburetors will make more power on most, but not all, combinations. But there’s really a more important story that needs to be told than just the old sneeze that bigger is better. The truth is that not all fuel mixers are created equal.

The trick is matching the fuel-delivery characteristics of a carburetor to the engine it sits atop. Holley has taken a cue from the custom carb tuners and now offers several levels of performance carburetors, each with special features that can create a little more power. For this test, we flogged three different Holley carburetors, all rated at 750 cfm but with different features. A simple test would have been to see which carburetor made the most power while also comparing the prices of all three carbs, but we decided to add a little more data to this comparison by also evaluating the amount of fuel delivered at each rpm point by each carb (see the chart).

As a starting point, all three carbs tested here are mechanical-secondary versions. Our baseline carburetor is the classic Holley 750 mechanical-secondary 0-4779-C. This is based on the original double-pumper design complete with the integral choke housing and fixed air bleeds in both the main body and the metering blocks. The second carb is what Holley calls its Street HP carburetor, an in-between 750 offered in both mechanical- and vacuum-secondary configurations. The Street HP offers most of the features that have made the HP popular but at a more affordable price. The main body has contoured venturi entries, screw-in air bleeds, and a tumble finish, but is only $80 more than the 0-4779-C. As you can see from the dyno results, it does deliver a slight power increase over the standard 750 version with no major tuning required.

The final test utilized the 750 HP carb, which offers all the same advantages of the Street HP along with Dominator-style fuel bowls, notched floats with jet extensions in the secondary side, stainless steel throttle plates for increased durability, and high-flow metering blocks with screw-in main-well bleeds. Each of these carburetors is individually wet-flow tested to ensure the calibration is correct. The HP version is $230 more expensive than the entry-level 750 but with many features that can otherwise only be found on custom carbs costing much more. If you look closely at the overall curve of the three tests, note how the 750 HP tended to deliver more fuel throughout the entire curve yet made more power only from 4,900 rpm and up. It appears that an engine designed to make serious power above 5,000 rpm would really benefit from an HP carb more than a mild, 400hp engine. According to Holley, the metering characteristics are supposed to be very similar between the Street HP and the HP carburetors, which is reinforced by our testing where the fuel curves overlap. From this test the Street HP seems to be a better deal since it made similar power for $150 less than the HP.

Both the HP and Street HP offer the opportunity to really get in depth to dial in the fuel curve on a particular application, and with sufficient time on a chassis dyno using a wide-band air-fuel ratio meter, it’s possible to dial in the carb to fit your engine’s specific fuel-curve requirement. What we’ve learned is that there is benefit to more expensive yet infinitely more tunable HP-style carburetors. Even if you never mess with air bleeds (we didn’t for this test), there are still advantages to selecting these fuel mixers. It comes down to whether the additional power and/or adjustability is worth the additional cost. Now you have the numbers to make a more educated decision.

750 carb test

Note in this comparison that we evaluated overall power with average torque and horsepower, but also fuel use. Note how both HP versions delivered a fatter fuel curve at lower engine speeds that cost power, yet above 5,000 rpm the curve leaned out and the engine made more power. As an example, at 3,900 rpm, the HP delivered 7 more pounds of fuel per hour (lb/hr) than the 750 classic carb. Had we been able to customize the fuel curve in the HP to reduce the fuel flow around that engine speed, it’s possible that power would increase beyond what the classic carb version produced.

TEST 1 TEST 2 TEST 3 DIFFERENCE

750 Classic 750 Street HP 750 HP

RPM TQ HP Fuel TQ HP Fuel TQ HP Fuel TQ Fuel

2,500 392 187 84 395 188 80 392 187 81 0 -3

2,700 384 197 86 384 197 85 383 197 85 -1 0

2,900 381 210 89 384 212 97 381 210 91 0 +2

3,100 393 232 97 400 236 98 396 233 97 +3 0

3,300 411 258 103 419 263 96 417 262 105 -1 +2

3,500 426 284 111 428 285 104 425 283 114 -1 +3

3,700 436 307 121 435 307 118 433 305 124 -3 +3

3,900 444 330 126 439 326 126 441 328 133 -3 +7

4,100 453 354 134 448 350 133 448 350 141 -5 +7

4,300 457 374 146 455 373 144 452 370 149 -5 +3

4,500 458 393 157 456 391 155 457 391 158 -1 +1

4,700 460 412 166 456 408 164 460 411 167 0 +1

4,900 461 430 172 457 426 172 464 433 176 +3 +4

5,100 458 444 182 460 447 180 461 448 182 +3 0

5,300 456 460 194 456 460 184 457 462 189 +6 -5

5,500 449 470 204 448 470 189 452 473 193 +3 -11

5,700 436 473 208 438 476 196 441 479 199 +5 -9

5,900 423 476 205 427 479 201 428 481 206 +5 -1

6,100 413 480 208 416 483 205 418 485 215 +5 +7

6,300 401 481 216 404 485 210 405 486 219 +4 +3

6,500 385 477 227 387 479 222 389 481 220 +4 -7

Peak 461 481 227 460 485 222 464 486 220 +6 —

Avg. 428.5 369.2 154.2 429.4 367.9 150.5 429.8 370.4 154.6 +1.4 +2.4

Note: Averages were taken from the entire dyno run at every 100-rpm data point. The last column is the power difference between Test 1 and Test 3.

Parts List

DESCRIPTION PN SOURCE PRICE

Holley 750-cfm Classic 0-4779-C Summit Racing $429.95

Holley 750-cfm Street HP 0-82751 Summit Racing 509.95

Holley 750 cfm HP 0-80528-1 Summit Racing 659.95

Holley Keith Dorton manifold 300-110 Summit Racing 239.95

Single Four-Barrel Vs. Dual-Quads

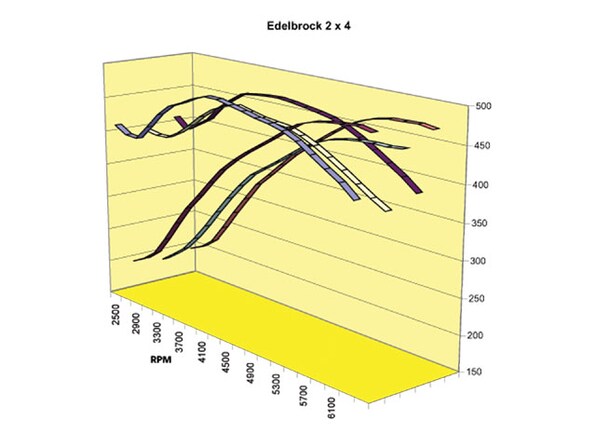

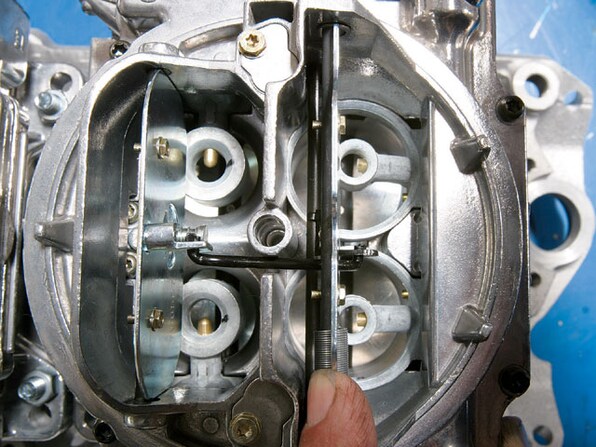

In the early days of horsepower, finding a four-barrel carburetor that flowed more than 400 or 500 cfm was the territory of exotic race-only engines. With limited cfm capability, the natural process was to bolt on multiple carburetors. That’s why ’50s and early ’60s cars like the Hemi and the early GTOs came with multiple carburetors. Older car crafters wishing to duplicate their younger years think a pair of 500-cfm carbs is still pretty cool, as do a few car builders searching for a nostalgic theme. We thought it would be interesting to see just how well this older-style package would perform. In this case, we’re testing the low-slung version rather than the tunnel-ram style, which we test elsewhere in this section. Conventional wisdom holds that a solid, high-flow, single four-barrel system is better than an older dual-quad setup, but we decided to put that theory to the test.

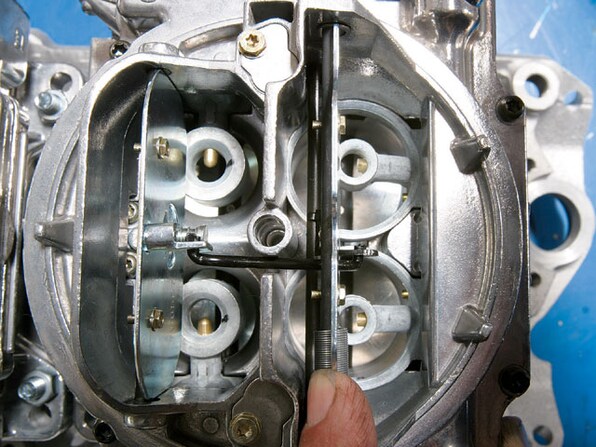

Edelbrock offers two different ways to play in the dual-quad scene with its original (dare we call it ancient?), low-profile manifold for a small-block Chevy, along with a brand new dual-quad Air Gap manifold that is available as a complete kit with specially calibrated 500-cfm Edelbrock Thunder Series AVS (adjustable valve secondary) carbs. Besides small-block, big-block and Gen III Chevy applications, Edelbrock offers these kits for the Chrysler 5.7L Hemi as well as 289/302 small-block Fords and even the 351W. What impressed us was the small-block Chevy kit (PN 2025 in our case), which came with an intake gasket, gasket cement, intake bolts, all the linkage pieces, and even a nice fuel line. It made the installation much smoother and easier. Edelbrock gets major style points for this effort. Just be prepared for a large deduction from your savings account, since this package sells through Summit for just under a grand.

We started our test with a single four-barrel baseline using the Edelbrock Performer RPM Air Gap configured with an Edelbrock 800-cfm EPS carburetor. This set the bar pretty high for the other two dual-planes, making this a worthy test. Our small-block 383ci was configured with its Dart 215cc Platinum heads and the smaller Comp Cams mechanical roller cam along with Westech’s 131/44-inch dyno headers and open exhaust. As you can see from the test numbers, the baseline was no slouch, making 482 lb-ft of torque and 481 hp.

Our second setup was with the older C-26 manifold, to which we also added the Edelbrock finned valve covers to give it a real feel for the old days. To no one’s surprise, this older casting dropped some significant torque (in excess of 26 lb-ft) over the entire power range with horsepower down by 19 hp compared to the single-quad setup. We also tried the air cleaner, but at least here we saw no further loss of power. In defense of the older manifold, bolt this package on a little 327 or 283 and the power differential would probably disappear altogether.

The Air Gap dual-quad was next up, and it fared much better. Average power was down by roughly 6 lb-ft of torque and barely 2.5 hp, which would be hard to feel in the car on the street. Also, much of the power difference we saw could have been improved with tuning since both dual-quad systems tended to run richer than we would have preferred in the midrange. So if you’re searching for that vintage late ’50s Henry Gregor Felson look, you’ve got a couple of great options that will still make great power. In fact, we’ve got a 0.060-over 283 that’s perfect for that older C-26 manifold and those twin 500s.

Dual-Quad Test

TEST 1 TEST 2 TEST 3 DIFFERENCE

Edelbrock Edelbrock Edelbrock

Air Gap1x4 C-26 2×4 Air Gap 2×4

RPM TQ HP TQ HP TQ HP TQ HP

2,500 409 195 394 187 407 194 – 2 – 1

2,700 399 205 391 201 392 203 – 7 – 2

2,900 398 220 392 216 404 218 + 6 – 2

3,100 419 247 403 238 416 245 – 3 – 2

3,300 441 277 418 263 437 274 – 4 – 3

3,500 457 305 435 290 452 301 – 5 – 4

3,700 465 328 449 316 465 328 0 0

3,900 475 353 458 340 468 347 – 7 – 6

4,100 482 376 463 361 470 367 -12 – 9

4,300 482 394 458 375 471 386 -11 – 8

4,500 478 410 454 389 469 402 – 9 – 8

4,700 474 424 452 404 466 417 – 8 – 7

4,900 469 438 450 419 463 432 – 6 – 6

5,100 466 453 443 430 459 446 – 7 – 7

5,300 461 466 434 438 452 456 – 9 -10

5,500 452 473 423 443 442 463 -10 -10

5,700 439 477 411 446 430 467 – 9 -10

5,900 426 479 398 447 417 468 – 9 -11

6,100 414 481 385 447 404 469 -10 -12

6,300 397 477 374 449 388 466 – 9 -11

Peak 482 481 463 449 471 469 -12 -11

Avg. 443.5 379.6 422.5 360.7 437.2 377.0

Note: Averages were taken from the entire dyno run at every 100-rpm data point. The last column is the power difference between Test 1 and Test 3.

Parts List

DESCRIPTION PN SOURCE PRICE

Edelbrock Performer RPM Air Gap 7501 Summit Racing $209.88

Edelbrock EPS 800-cfm carb 1412 Summit Racing 304.95

Edelbrock C-26 dual-quad intake 5425 Summit Racing 259.95

Edelbrock Air Gap dual-plane kit 2025 Summit Racing 999.95

Edelbrock finned valve covers 4145 Summit Racing 155.95

Edelbrock dual-quad air cleaner 4235 Summit Racing 119.95

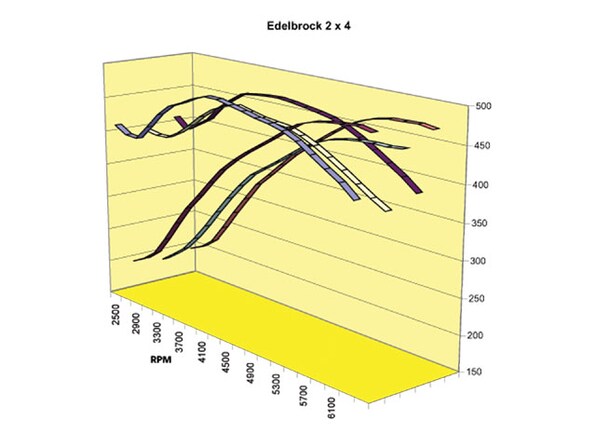

Dual-Plane Vs. Single-Plane Vs. Tunnel-Ram

Much of the action that happens on the street is influenced by dragstrip chic-of-the-week. That includes such audacious displays of horsepower as 8-71 blowers and tunnel-ram intake manifolds protruding through the hood like a real-world version of a Rat Fink cartoon. Much of this is done strictly in the name of fashion, but there are those hard-core car crafters who believe in tall-runner manifolds. We wanted to see for ourselves, so we fashioned a quick comparison test for our Dart-headed Lunati 383. Configured with the Dart Pro 1 Platinum 215 heads and 280 Comp roller cam, this engine was ripe for an intake manifold face-off. Summit has long advertised a budget-based Weiand tunnel-ram intake configured with a pair of 600-cfm Holley carbs at an affordable price, so we tagged that as our eight-barrel heavy-hitter. For comparison purposes, we decided on a good single-plane intake and came up with one of Holley’s Keith Dorton-designed single-planes. Then just to make it even more interesting, we decided to throw down one of Weiand’s new Stealth Air Strike dual-plane intakes as the baseline. This way we would test the entire range of intakes from dual-plane to single-plane to tunnel-ram.

Dual-plane manifolds are known to enhance torque based on a longer intake-runner path compared to the shorter intake length of a single-plane manifold. The tunnel-ram offers the best of both worlds with longer intake runners like a dual-plane combined with a straight shot between the carburetors and the intake ports. The main reason tunnel-rams aren’t more popular for the street is the simple issue of hood clearance. Not everybody wants to carve holes in their hood.

As for our test, theory dictates that the dual-plane should make the most torque, given the smaller plenum and stronger signal to the carburetor. The single-plane should make more peak horsepower than the dual-plane but at the sacrifice of midrange torque. The tunnel-ram should best the single-plane in peak power and in theory generate a solid torque curve as well. The only hiccup in this concept is the size of the tunnel-ram’s pair of carburetors and dialing in a decent fuel curve.

After we were done making all kinds of noise, we immediately noticed that even with a strong 480hp small-block, the dual-plane intake still made the most overall power of all three manifolds. Weiand’s Stealth Air Strike dual-plane beat both the single-plane and the tunnel-ram in torque, and the only place the single-plane intake combo made more power was at the top of the rpm curve. Given that scenario, our money is on the dual-plane every time with a combination like this.

After bolting on the tunnel-ram with a pair of 0-1850 Holley carbs right out of the box, we discovered that perhaps the twin 600-cfm carbs were a bit too much for this engine combination. It became impossible to load the dyno below 3,500 rpm at wide-open throttle, necessitating testing the tunnel-ram system from 3,700 rpm and above. Plus it appeared from the testing that the engine really wasn’t happy until at least 4,500 rpm, where the induction system seemed a bit more stable. But only around peak horsepower did this system show any kind of advantage over the dual-plane, and then only by a couple of horsepower. Part of this disadvantage came from the fact that the 4160-style Holley carbs use metering plates in the secondaries rather than metering blocks. Without additional metering plates, we couldn’t adjust the secondary metering. This is something you should put on your shopping list should you decide to add one of these tunnel-ram kits to your small-block. We couldn’t convert to metering blocks since the fore-aft carbs would then be too long to fit on the tunnel-ram. It would have required placing them sideways, but we didn’t have the proper linkage to accomplish that.

Based on input from guys like Pontiac expert Ken Crocie, a choice of the smaller 450-cfm Holley carburetors would have resulted in a much cleaner-running engine and more powerful dyno curve that would have allowed us to start the test at a lower rpm and generate stronger torque numbers as well. It’s possible that fuel metering was not quite as good as it should be because the flow velocity through the larger 600 carbs was just too slow to accurately meter the fuel. Another advantage of the 450 carbs is that they are slightly less expensive. Since this test was in the midst of our mad dyno thrash, we didn’t have the luxury of time to dial in the carburetors, but with a little tuning time we could have made this combination work much better, especially in the midrange and lower-rpm levels.

Parts List

DESCRIPTION PN SOURCE PRICE

Summit tunnel-ram kit, 600 cfm CWND403S Summit Racing $749.95

Summit tunnel-ram kit, 450 cfm CWND303 Summit Racing 709.95

Weiand tunnel-ram manifold 1984 Summit Racing 279.95

Holley Keith Dorton manifold 300-110 Summit Racing 239.95

Weiand Stealth Air Strike manifold 8501 Summit Racing 209.95

Holley 750-cfm mech. sec. Street HP 0-82751 Summit Racing 509.95

Holley 450-cfm mech. sec. carb 0-9776 Summit Racing 29.95

Manifold Comparison

The baseline used a Weiand Stealth Air Strike dual-plane and 750-cfm Street HP carburetor. The middle test is the same engine with the addition of the Holley-Dorton single-plane intake using the same 750 Street HP carb. The third test converted to the Summit-Weiand tunnel-ram system using a pair of Holley 600-cfm vacuum-secondary carburetors.

TEST 1 TEST 2 TEST 3 DIFFERENCE

Weiand Holley-Dorton

Air Strike 1×4 Holley 1×4 Weiand 2×4

RPM TQ HP Fuel TQ HP Fuel TQ HP Fuel TQ HP

2,500 403 192 101 395 188 80 — — — — —

2,700 386 198 108 384 197 85 — — — — —

2,900 375 207 107 384 212 97 — — — — —

3,100 400 236 110 400 236 98 — — — — —

3,300 441 277 122 419 263 96 — — — — —

3,500 459 306 134 428 285 104 — — — — —

3,700 471 332 146 435 307 118 397 279 155 -74 -53

3,900 481 357 154 439 326 126 404 300 148 -77 –57

4,100 483 377 164 448 350 133 420 328 151 -63 -49

4,300 480 393 174 456 373 144 441 361 155 -39 -32

4,500 478 409 182 456 391 155 450 386 161 28 -23

4,700 473 423 188 456 408 164 456 408 164 17 -15

4,900 467 436 194 457 426 172 462 431 169 -5 -5

5,100 459 446 199 460 447 180 462 449 179 +3 +3

5,300 456 460 206 456 460 184 456 460 194 0 0

5,500 448 469 215 448 470 189 449 470 206 +1 +1

5,700 437 474 222 438 476 196 440 477 217 +3 +3

5,900 425 477 226 427 479 201 427 480 225 +2 +3

6,100 412 479 228 416 483 205 411 477 228 -1 -2

6,300 400 480 238 404 485 210 394 473 238 -6 -3

6,500 387 478 250 387 479 222 378 468 251 -9 -10

Peak 483 480 250 460 485 222 462 480 251

Avg. 440.4 377.8 174.7 429.4 369.7 150.4 — — —

Note: Averages were calculated on the entire power curve every 100 rpm. Averages were not calculated for the tunnel-ram due to an incomplete pull from 2,500 rpm, making any average invalid.The Difference column compares Test 1 and Test 3.

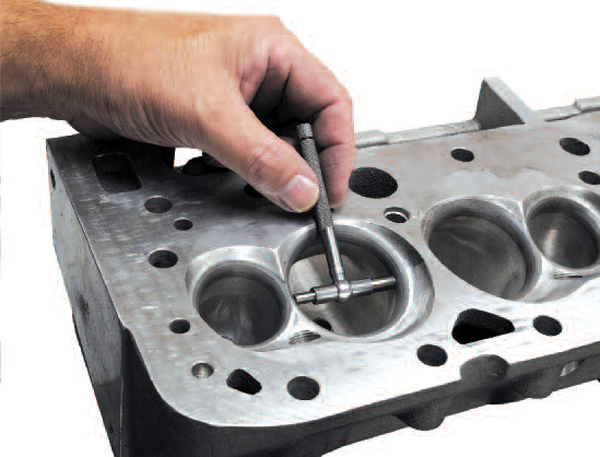

280 VS. 292 Cams, 215CC VS. 227CC Heads

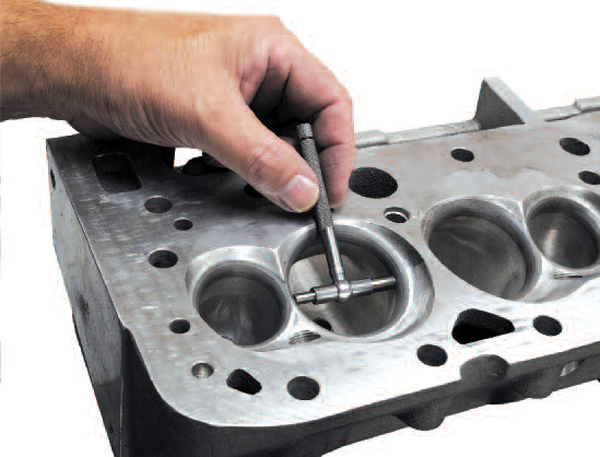

Up until now, we’ve been testing with a set of Dart 215 Pro 1 Platinum heads that have performed very well. These are as-cast heads, and everybody knows that a CNC-ported heads will bring some serious ponies to the party. The computer-ported star in the Dart lineup is the 227cc CNC head, which not only has increased port volume, but also adds a bunch to the flow curve along the way. If you’ve been paying attention to our tech diatribes throughout the years, then you may know about midlift flow. Our contention is that ignoring big head flow numbers at high valve lifts in favor of strong midlift flow numbers will always deliver a stronger overall power package for a street engine. In testament to that, the Dart CNC 227 bumps the 0.400-inch lift flow numbers up over the 215 Platinum on the intake side by a staggering 28 cfm, a 13 percent increase. The 0.300-inch lift numbers are equally as impressive, gaining 26 cfm, a 15 percent bump. Combined, this makes for an impressive midlift one-two punch, and when blended with excellent exhaust flow numbers it’s an outstanding opportunity to make power.

To test that theory, we baselined the engine with the Dart 215 heads, the Holley-Dorton single-plane and 750-cfm Street HP carburetor, and the Comp Cams Xtreme Energy mechanical XR-280 Street Roller cam. For the second test we switched to the bigger XR 292 mechanical roller cam, and then for the final mondo-combo, we bolted on the Dart CNC 227 heads.

As you can see from the dyno chart, this motor loved the combination of lift, duration, and more cylinder head. The addition of the bigger cam in tests 2 and 3 illustrates how more duration trades torque in the low- to midrange portion of the rpm curve for more power above peak torque. But what’s interesting is that the peak torque rpm point didn’t move up as we expected. Note that in all three tests the peak torque hovered between 4,900 and 5,100 rpm. Of course what everyone will latch onto is the stellar power increase. When you can make almost 70 more horsepower from a cam and cylinder head swap, you know the parts are working. This doesn’t come at a discount price, though. The bill for the larger cam and a pair of assembled Dart 227 CNC heads will top $2,800, and that’s assuming the engine is already equipped with a mechanical roller cam. If you have to purchase all the mechanical roller pieces, expect that price tag to exceed $3,400. But we’re also looking at a 383ci small-block Chevy that makes just shy of 550 hp. That, friends, is a solid 1.43 hp per cubic inch. Plug this power and torque into a 3,500-pound street car, and if you can hook it up it will run high 11s all day long. Sounds like fun, doesn’t it?

Cam And Head Comparison

The first test uses Dart 215cc heads with the small XR-280 Comp Cams roller cam, the Holley-Dorton single-plane intake, and a 750 Street HP carburetor. Test 2 employs the same as above except with the larger Comp Cams mechanical XR-292 roller cam. The final test is the same combo as Test 2 except we added the Dart CNC 227 heads.

TEST 1 TEST 2 TEST 3 DIFFERENCE

Dart 215 Dart 215 Dart 227 CNC

Comp XR-280 Comp XR-292 Comp XR-292

RPM TQ HP TQ HP TQ HP TQ HP

2700 384 197 350 180 353 181 -31 -16

2900 384 212 345 190 347 192 -37 -20

3100 400 236 365 215 361 213 -39 -23

3300 419 263 396 249 383 241 -36 -22

3500 428 285 417 278 410 273 -18 -12

3700 435 307 428 302 429 302 -6 -5

3900 439 326 437 325 443 329 +4 +3

4100 448 350 450 351 457 357 +9 +7

4300 456 373 463 379 467 383 +11 +10

4500 456 391 469 402 475 407 +19 +16

4700 456 408 475 425 484 433 +28 +25

4900 457 426 480 448 489 456 +32 +30

5100 460 447 480 466 491 477 +31 +30

5300 456 460 478 482 490 495 +34 +35

5500 448 470 471 493 484 507 +36 +35

5700 438 476 461 500 477 518 +39 +42

5900 427 479 450 505 470 528 +43 +49

6100 416 483 440 511 462 536 +46 +53

6300 404 485 430 516 452 542 +48 +57

6500 387 479 415 514 443 548 +55 +68

6700 — 428 546 — — — — —

Peak 460 485 480 516 491 548

Avg. 431.3 378.9 436.4 387.7 414.7 369.7

Note: The Difference column compares Test 1 with Test 3.

Cam Spec Chart

Cam Duration Duration Lift

(Adv.) (@0.050) Separation Lobe

Comp XR-280, roller Intake 280 242 0.609 110

PN 12-771-8 Exhaust 286 248 0.616

Comp XR-292, roller Intake 292 254 0.622 110

PN 12-773-8 Exhaust 297 260 0.628

Both gross cam valve lifts are calculated using a 1.6:1 rocker ratio. Note that actual (net) valve lift equals gross lift minus lash. Lash was set at 0.016-inch intake and 0.018-inch exhaust for both cams.

Parts List

DESCRIPTION PN SOURCE PRICE

Comp Cams XR-280 roller cam 12-771-8 Summit Racing $255.95

Comp XR-280 mech. roller cam 12-773-8 Summit Racing 255.95

Dart 215 Pro 1 Platinum heads, pr. 11611123P Summit Racing 1,439.90

Dart 27 CNC heads, pr. 11971143 Summit Racing 2,551.90

Dart 27 CNC heads, pr. 11971143 Summit Racing 2,551.90

Cylinder Head Flow Testing

Dart 215 Pro 1 Platinum Dart 227 CNC

Lift Intake Exhaust Intake Exhaust

(w/ pipe) (w/ pipe)

0.100 63 59 65 53

0.200 124 101 145 110

0.300 171 136 197 148

0.400 214 160 242 178

0.500 247 177 272 196

0.600 272 188 283 208

0.700 — — 287 215

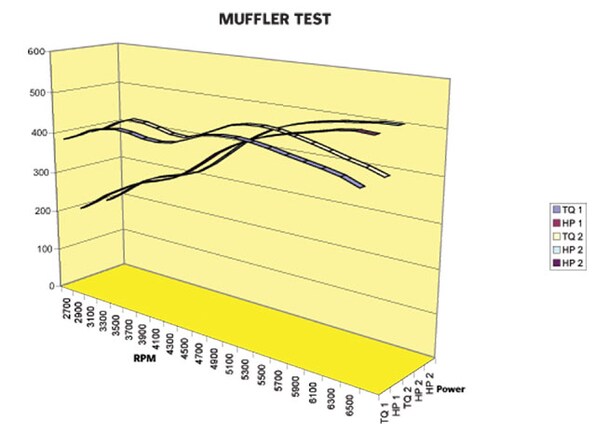

211/42- Vs. 3-Inch Exhaust

What goes in has to go out with any high-horsepower street combination, but for many car builders the question of what to do with the exhaust system is often given afterthought status. For professional engine builders and those attuned to the needs of an engine that moves trainloads of air, exhaust systems can make or break the combination. It’s acknowledged that exhaust systems don’t make horsepower, but a poorly executed exhaust system can cost too much to be blatantly ignored. There are still those who feel that open exhaust is the only avenue to peak horsepower success, and we won’t argue the point. But the reality is that a properly designed exhaust system can minimize the power loss and perhaps even pump up the torque at the same time.

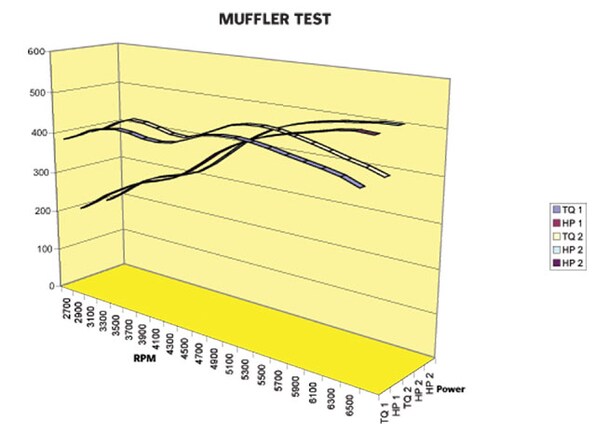

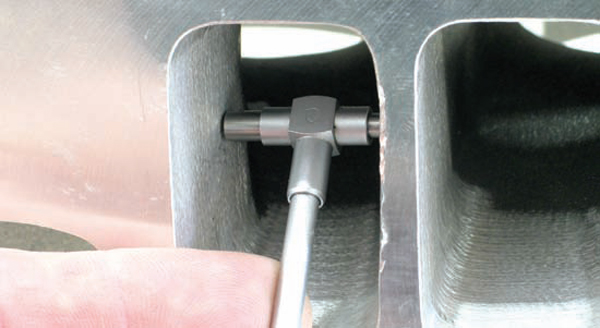

Our test was devised to be as simple as possible: to compare 211/42-inch versus 3-inch-diameter Flowmaster Super 44 mufflers.. There are plenty of 3-inch exhaust systems out there designed to fit many popular musclecar chassis intended for big-cubic-inch engine applications. The engine combination for this test began with the 383ci small-block, with the larger Dart 227 CNC ported heads and the big XR292 Xtreme Energy roller cam combined with the Holley-Dorton intake and 750 Street HP carburetor. Instead of the 131/44 custom dyno headers, we substituted a set of Hedman 131/44-inch chassis headers that offered a three-bolt flange to install the 211/42- and 3-inch exhaust pipes. While the 3-inch system looks massive and flows lots of air, if you are considering one of these systems, the big concern should be sound level. It is inevitable that a 3-inch exhaust will also be the loudest. The large flow area of the 3-inch system represents a 45 percent increase in area, which means the mufflers and tailpipes create a resonance that can be overwhelming, in much the same way that big exhaust tips on import cars resonate (except not as annoying). But beyond the noise factor, there is definitely torque and horsepower to be gained with a 3-inch exhaust system, and we wanted to know how much on our 500 hp 383 small-block.

It was interesting that at the peaks the 2.5-inch mufflers were barely 5 hp shy of the 3-inch ones, but that’s not even half the story. Looking at the entire curve, the 3-inch system delivers substantially more torque virtually throughout the 2,700- 6,500 test sweep. This may be more of a tuning issue than just a question of volume, but there’s no questioning the solid 11 hp gain the 3-inch system delivers between 5,100 and 5,700 rpm. That’s power that will show up on the e.t. slip every time. While we didn’t itemize the power numbers on the chart, we also threw on a pair of 3-inch tailpipes on the 3-inch mufflers. Surprisingly, the tailpipes actually delivered a tiny 1hp gain at 6,500 rpm with 510 hp, but again, looking at the entire curve, the tailpipes cost power almost throughout the entire pull, losing as much as 32 lb-ft of torque at 3,300 rpm. Using an average power evaluation, the tailpipes lost exactly 9 lb-ft of torque and 6.4 hp overall, so clearly tailpipes cost some power, although not at all where you might expect. It’s also possible that carburetor tuning might be able to make up some of this torque loss. Another interesting test would be to add an H- or X-pipe to this test and see what occurs. But that will have to wait for another day. We’ve burned our hands enough times during this test already.

Flowmaster 211/42- Vs. 3-Inch Mufflers

The first test is the baseline, with a pair of Hedman 131/44-inch headers connected to a complete 211/42-inch exhaust system with the Flowmaster Super 44 mufflers and no tailpipes. The second test upgraded to 3-inch inlet and outlet Super 44 mufflers.

TEST 1 TEST 2 DIFFERENCE

Flowmaster

211/42-inch Flowmaster

3-inch

RPM TQ HP TQ HP TQ HP

2,700 385 198 390 200 +5 +2

2,900 400 221 404 223 +4 +2

3,100 418 247 424 250 +6 +3

3,300 427 268 437 274 +10 +6

3,500 433 288 435 290 +2 +2

3,700 430 303 428 301 -2 -2

3,900 423 314 419 311 -4 -3

4,100 421 328 417 326 -4 -2

4,300 426 349 429 351 +3 +2

4,500 440 377 446 382 +6 +5

4,700 455 407 463 414 +8 +7

4,900 461 430 471 439 +10 +9

5,100 462 449 473 460 +11 +11

5,300 459 463 470 474 +11 +11

5,500 453 474 463 485 +10 +11

5,700 445 483 454 493 +9 +10

5,900 438 492 444 499 +6 +7

6,100 431 501 433 503 +2 +2

6,300 422 506 424 508 +2 +2

6,500 407 504 411 509 +4 +4

Peak 462 506 473 509 +11 +11

Avg. 432.8 381.0 437.9 385.7 +5.1 +4.7

Note: The Difference column compares Test 1 with Test 3.

PARTS LIST

DESCRIPTION PN SOURCE PRICE

Flowmaster Super 44 2.5 in/out 942546 Summit Racing $76.39

Flowmaster Super 44 3.0 in/out 943046 Summit Racing 76.39

Flowmaster tailpipes 3.0 15819 Summit Racing 124.39

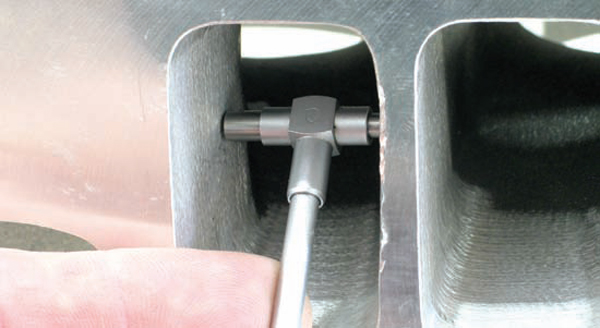

Four-Hole Vs. Tapered Carb Spaces

Sometimes you can find big power in the unlikeliest places. While most enthusiasts are preoccupied with high-fashion power parts like superchargers and nitrous systems, there is reliable power to be found in subtle changes to the induction system. Such is often the case with carburetor spacers. The trick, to quote Kenny Rogers, is to know when to hold ’em and know when to fold ’em. While there are catalog pages full of different designs, certain applications work better than others. Let’s run through three of the most common designs, and then we’ll bolt them on a typical street engine.

The most basic of all carb spacers is the open-chamber design. Here, the idea is to increase plenum volume of the intake manifold while also increasing the distance between the bottom of the carburetor and the manifold floor. The latter gives the incoming air and fuel charge a greater distance to make the change from vertical to horizontal flow path entering the intake port. These spacers are intended to be used on 5,000-rpm-and-up applications where the incoming air from the carburetor has lots of inertia. When you consider that fuel weighs more than air, the fuel will have more trouble making the change in direction at the bottom of the manifold where it transitions into the intake port. Additional carb height helps the fuel make that directional change. Open plenum spacers are generally used on single-plane intake manifolds although they occasionally do show power gains with dual-plane manifolds. These spacers can be made out of aluminum or plastic, which also helps as a heat insulator.

<img src="http://enthusiastnetwork.s3.amazona...6_0709_28_z-aftermarket_parts-spacer_dyno.jpg" alt="Wilson Spacer Comparison

‘The insulating spacers are called “phenolic” spacers, referring to the type of thermostatic plastics used to make them.” class=”wp-image-276059″ />

The second design is appropriately called a four-hole spacer. These are generally intended to extend the length of the carb outlet and tend to improve the signal strength to the carb during part-throttle applications. Our test is only a wide-open-throttle test, so not all of the advantages of a four-hole spacer can be realized. However, if the combination includes a long-duration cam, it’s possible to increase midrange torque with a four-hole spacer since it will improve the signal strength to the carburetor. Often this kind of spacer will affect the fuel curve by using more fuel. Sometimes this is an advantage, but if not, the four-hole spacer may require tuning the carburetor a bit leaner to take full advantage of the spacer’s effect.

The final spacer type is the tapered four-hole from Wilson Manifolds. It is designed to actually increase airflow through the carburetor based on years of experimentation with NASCAR restrictor-plate manifold designs. Prior experience with these spacer plates on single-plane-manifold street engines tend to show horsepower gains from 5,500 rpm and up.

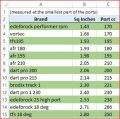

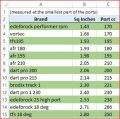

a great deal of the info you may want can be calculated after carefully measuring the intake port and runner length and cross sectional areas.(remember its not the intake port gasket cross sectional opening, cross sectional area, its the smallest part of the port cross sectional area and valve throat areas that limit port flow rates)

if as an example we selected a port with about a 2 sq inch cross sectional area, you'll find max torque on a 350 will fall near 4000-rpm and port stall near 6000-rpm

http://users.erols.com/srweiss/calccsa.htm

http://users.erols.com/srweiss/calcplv.htm

http://users.erols.com/srweiss/calchpaf.htm

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.walmart.com/ip/Texas-Instruments-TI-30X-IIS-Scientific-Calculator/1535939

http://www.summitracing.com/parts/cca-5605/overview/

related info, that you might need

http://garage.grumpysperformance.co...heads-for-small-block-chevys.3293/#post-26213

http://garage.grumpysperformance.com/index.php?threads/what-are-these-heads.4702/#post-12742

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848

http://garage.grumpysperformance.co...ther-efi-intake-manifold-info.431/#post-26322

http://garage.grumpysperformance.com/index.php?threads/porting-can-help.462/page-3#post-59145

http://garage.grumpysperformance.co...ads-tuned-intake-turbulence.12998/#post-67611

Volume (CCs) of Head Gasket

CCs of Head Gasket = Bore x Bore x 12.87 x Thickness of Head Gasket

COMMON SBC INTAKE PORTS

felpro # 1204=Port Size: 1.23" x 1.99"=2.448 sq inches

felpro # 1205=Port Size: 1.28" x 2.09"=2.67 sq inches

felpro # 1206=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1207=Port Size: 1.38" x 2.28"=3.146 sq inches

felpro # 1209=Port Size: 1.38" x 2.38"=3.28 sq inches

felpro # 1255 VORTEC=Port Size: 1.08" x 2.16"-2.33 sq inches

felpro # 1263=Port Size: 1.31" x 2.02"=2.65 sq inches

felpro # 1266=Port Size: 1.34" x 2.21"=2.96 sq inches

felpro # 1284 LT1=Port Size: 1.25 x 2.04''=2.55 sq inches

felpro # 1289 FASTBURN=Port Size: 1.30" x 2.31" 3.00 sq inches

http://users.erols.com/srweiss/calccsa.htm

Your RPM computed from your Cross Sectional Area of 1.95

(the smaller AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,569.12 .

Your RPM computed from your Cross Sectional Area of 2.05

(the Larger AFR HEADS)

and Bore of 4.03 and Stroke of 3.75 is 5,854.72 .

you,ll barely notice the about 300 rpm shift in the power band on the lower part of rpm range but appreciate it much more on the upper edge of that power curve

heres a chart FROM THE BOOK,HOW TO BUILD BIG-INCH CHEVY SMALL BLOCKS with some common cross sectional port sizes

(measured at the smallest part of the ports)

USE THE CALCULATORS

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.hotrod.com/articles/choosing-the-right-camshaft/

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/

We Test A Pile Of Speed Parts To Discover

‘This was dyno thrash week, and we went through the Summit catalog like kids at Christmastime. The conversation went something like this: “This will be great-test that tunnel-ram against a single four-barrel manifold . . . See that new Edelbrock dual-quad setup? Test that too . . . Hey, Holley’s got three different 750 mechanical secondary carburetors. Which one will make the most power and which one costs the most? Run ’em all and find out . . .” It was like combining stream of consciousness with dyno testing. Before I knew it, I was staring at a 6-foot-tall pile of parts in my shop that took two truckloads to haul to Westech for a marathon dyno session.

The New Buick ® Encore

Get Details on the All New Encore. See Photos, Pricing, and Specs Now. Buick.com/Encore_vs_Ford_Edge

We also enlisted Car Craft’s brand-new JMS-built 383 small-block Chevy for the beatings, which would consume 35 gallons of pump gas and three long days of 6,500-plus-rpm blasts. At the end, we had Westech’s Steve Brul asking, “You’re not coming back again for awhile . . . are you?”

After cleaning the last bit of synthetic oil out from under our fingernails and pondering whether we qualified for the Guinness World Record for the most small-block Chevy intake manifold swaps in a single 48-hour period, we did manage to compile a rather sizeable database for the parts we tested. We discovered all kinds of surprising stuff. We learned that Wilson tapered carburetor spacers rock; that 7,000 rpm can tweak a set of valvesprings in one pull; that tailpipes cost power but not where you think; that Weiand makes a very strong dual-plane Air Strike intake manifold; that an Edelbrock nostalgic dual-quad setup looks pretty cool on any small-block; and finally that Dart’s CNC 227 heads matched with a big cam can make wicked horsepower. All told, the thrash was a total success. And you’re the big winner, because now you have all the information you need on these parts to decide if they’re worth emptying your savings account in the name of horsepower.

First-Ever Buick Envision

Buick.com/Envision_vs_Acura_RDX

Compare Buick ® & The Acura RDX. View Trims, Packages & More Here!

The Power Source

All the tests in this section were performed on the same 383ci small-block Chevy machined and assembled by JMS Racing Engines. Since this small-block was destined for a very hard life on the dyno, it made sense to plug in a rock-solid rotating assembly that could take the abuse, which led us to a complete bottom end from Lunati. One small shift from the norm was to start with a one-piece rear main seal block of ’88-and-later vintage. To give it a fighting chance to survive, JMS added steel four-bolt main caps to the center three main bearings, requiring a careful boring operation to make the bearing housings all round. We opted for the standard 3.75-inch-stroke steel Lunati crank with a one-piece rear main seal, along with Lunati’s forged Pro Mod rods and a set of flat-top, forged Wiseco Pro Tru pistons with two 5.4cc valve reliefs.

Stroker packages, especially the 383 Chevy, often need a little clearancing around the bottom of the cylinders, and this block was no exception. Once the block was cleaned and the forged pistons assembled on the Lunati rods, it all slipped together with the 11/416-inch rings and bearings supplied with the rotator package. We selected a pair of Dart Pro 1 Platinum 215 heads as the starting point for our small-block test mule combined with a Comp Cams Xtreme Energy XR280 mechanical roller cam (cam specs can be found in the Dart cylinder head test sidebar). Compression came in just a hair under 11.0:1, but even with the smaller cam detonation was never a problem. We also planned on testing a larger set of Dart CNC 227 heads combined with a bigger XR292 cam, so Comp supplied 0.080-inch-thick-wall pushrods along with some lash caps we needed to ensure the rocker arms would clear the larger-diameter valvesprings. After that bit of custom engineering, the engine came together very quickly, including a three-piece front timing cover and a Hamburger oil pan from Summit Racing to button everything up with Fel-Pro gaskets and ARP bolts.

The 2017 Buick ® Encore

Add Luxury to Your Daily Commute. Build, Price & Compare Yours Here! See Buick.com/Encore_vs_Ford_Edge

Parts List

DESCRIPTION PN SOURCE PRICE

Lunati 4340 stroker rotator assm. EA62 Summit Racing $3,470.39

Steel main caps SB350C12 JMS 225.00

Hamburger’s oil pan 1088 Summit Racing 239.88

Comp Cams XR280 roller cam 12-771-8 Summit Racing 255.95

Comp Cams lifters, Endurex roller 888-16 Summit Racing 516.99

Comp Cams timing set 3100KT Summit Racing 176.69

Comp Cams pushrods, 0.080 wall 7972-16 Summit Racing 135.95

Comp Cams three-piece cover 210 Summit Racing 229.95

Comp Cams Magnum rockers, 1.5 1305-16 Summit Racing 275.95

Comp Cams billet-timing set 7100 Summit Racing 101.69

Dart 215 Pro 1 Platinum heads, pr. 11611123P Summit Racing 1,439.90

ARP head bolts 134-3601 Summit Racing 59.95

ARP 7¼16 rocker studs 134-7103 Summit Racing 35.95

ARP Perma-Loc 300-8243 Summit Racing 53.95

ARP intake manifold bolt kit 134-2001 Summit Racing 19.95

ARP distributor stud kit 130-1702 Summit Racing 3.88

750-CFM Carb Swap

Carburetor cfm ratings seem to be those magic buttons that everyone wants to push to make more horsepower. The truth is that large carburetors will make more power on most, but not all, combinations. But there’s really a more important story that needs to be told than just the old sneeze that bigger is better. The truth is that not all fuel mixers are created equal.

The trick is matching the fuel-delivery characteristics of a carburetor to the engine it sits atop. Holley has taken a cue from the custom carb tuners and now offers several levels of performance carburetors, each with special features that can create a little more power. For this test, we flogged three different Holley carburetors, all rated at 750 cfm but with different features. A simple test would have been to see which carburetor made the most power while also comparing the prices of all three carbs, but we decided to add a little more data to this comparison by also evaluating the amount of fuel delivered at each rpm point by each carb (see the chart).

As a starting point, all three carbs tested here are mechanical-secondary versions. Our baseline carburetor is the classic Holley 750 mechanical-secondary 0-4779-C. This is based on the original double-pumper design complete with the integral choke housing and fixed air bleeds in both the main body and the metering blocks. The second carb is what Holley calls its Street HP carburetor, an in-between 750 offered in both mechanical- and vacuum-secondary configurations. The Street HP offers most of the features that have made the HP popular but at a more affordable price. The main body has contoured venturi entries, screw-in air bleeds, and a tumble finish, but is only $80 more than the 0-4779-C. As you can see from the dyno results, it does deliver a slight power increase over the standard 750 version with no major tuning required.

The final test utilized the 750 HP carb, which offers all the same advantages of the Street HP along with Dominator-style fuel bowls, notched floats with jet extensions in the secondary side, stainless steel throttle plates for increased durability, and high-flow metering blocks with screw-in main-well bleeds. Each of these carburetors is individually wet-flow tested to ensure the calibration is correct. The HP version is $230 more expensive than the entry-level 750 but with many features that can otherwise only be found on custom carbs costing much more. If you look closely at the overall curve of the three tests, note how the 750 HP tended to deliver more fuel throughout the entire curve yet made more power only from 4,900 rpm and up. It appears that an engine designed to make serious power above 5,000 rpm would really benefit from an HP carb more than a mild, 400hp engine. According to Holley, the metering characteristics are supposed to be very similar between the Street HP and the HP carburetors, which is reinforced by our testing where the fuel curves overlap. From this test the Street HP seems to be a better deal since it made similar power for $150 less than the HP.

Both the HP and Street HP offer the opportunity to really get in depth to dial in the fuel curve on a particular application, and with sufficient time on a chassis dyno using a wide-band air-fuel ratio meter, it’s possible to dial in the carb to fit your engine’s specific fuel-curve requirement. What we’ve learned is that there is benefit to more expensive yet infinitely more tunable HP-style carburetors. Even if you never mess with air bleeds (we didn’t for this test), there are still advantages to selecting these fuel mixers. It comes down to whether the additional power and/or adjustability is worth the additional cost. Now you have the numbers to make a more educated decision.

750 carb test

Note in this comparison that we evaluated overall power with average torque and horsepower, but also fuel use. Note how both HP versions delivered a fatter fuel curve at lower engine speeds that cost power, yet above 5,000 rpm the curve leaned out and the engine made more power. As an example, at 3,900 rpm, the HP delivered 7 more pounds of fuel per hour (lb/hr) than the 750 classic carb. Had we been able to customize the fuel curve in the HP to reduce the fuel flow around that engine speed, it’s possible that power would increase beyond what the classic carb version produced.

TEST 1 TEST 2 TEST 3 DIFFERENCE

750 Classic 750 Street HP 750 HP

RPM TQ HP Fuel TQ HP Fuel TQ HP Fuel TQ Fuel

2,500 392 187 84 395 188 80 392 187 81 0 -3

2,700 384 197 86 384 197 85 383 197 85 -1 0

2,900 381 210 89 384 212 97 381 210 91 0 +2

3,100 393 232 97 400 236 98 396 233 97 +3 0

3,300 411 258 103 419 263 96 417 262 105 -1 +2

3,500 426 284 111 428 285 104 425 283 114 -1 +3

3,700 436 307 121 435 307 118 433 305 124 -3 +3

3,900 444 330 126 439 326 126 441 328 133 -3 +7

4,100 453 354 134 448 350 133 448 350 141 -5 +7

4,300 457 374 146 455 373 144 452 370 149 -5 +3

4,500 458 393 157 456 391 155 457 391 158 -1 +1

4,700 460 412 166 456 408 164 460 411 167 0 +1

4,900 461 430 172 457 426 172 464 433 176 +3 +4

5,100 458 444 182 460 447 180 461 448 182 +3 0

5,300 456 460 194 456 460 184 457 462 189 +6 -5

5,500 449 470 204 448 470 189 452 473 193 +3 -11

5,700 436 473 208 438 476 196 441 479 199 +5 -9

5,900 423 476 205 427 479 201 428 481 206 +5 -1

6,100 413 480 208 416 483 205 418 485 215 +5 +7

6,300 401 481 216 404 485 210 405 486 219 +4 +3

6,500 385 477 227 387 479 222 389 481 220 +4 -7

Peak 461 481 227 460 485 222 464 486 220 +6 —

Avg. 428.5 369.2 154.2 429.4 367.9 150.5 429.8 370.4 154.6 +1.4 +2.4

Note: Averages were taken from the entire dyno run at every 100-rpm data point. The last column is the power difference between Test 1 and Test 3.

Parts List

DESCRIPTION PN SOURCE PRICE

Holley 750-cfm Classic 0-4779-C Summit Racing $429.95

Holley 750-cfm Street HP 0-82751 Summit Racing 509.95

Holley 750 cfm HP 0-80528-1 Summit Racing 659.95

Holley Keith Dorton manifold 300-110 Summit Racing 239.95

Single Four-Barrel Vs. Dual-Quads

In the early days of horsepower, finding a four-barrel carburetor that flowed more than 400 or 500 cfm was the territory of exotic race-only engines. With limited cfm capability, the natural process was to bolt on multiple carburetors. That’s why ’50s and early ’60s cars like the Hemi and the early GTOs came with multiple carburetors. Older car crafters wishing to duplicate their younger years think a pair of 500-cfm carbs is still pretty cool, as do a few car builders searching for a nostalgic theme. We thought it would be interesting to see just how well this older-style package would perform. In this case, we’re testing the low-slung version rather than the tunnel-ram style, which we test elsewhere in this section. Conventional wisdom holds that a solid, high-flow, single four-barrel system is better than an older dual-quad setup, but we decided to put that theory to the test.

Edelbrock offers two different ways to play in the dual-quad scene with its original (dare we call it ancient?), low-profile manifold for a small-block Chevy, along with a brand new dual-quad Air Gap manifold that is available as a complete kit with specially calibrated 500-cfm Edelbrock Thunder Series AVS (adjustable valve secondary) carbs. Besides small-block, big-block and Gen III Chevy applications, Edelbrock offers these kits for the Chrysler 5.7L Hemi as well as 289/302 small-block Fords and even the 351W. What impressed us was the small-block Chevy kit (PN 2025 in our case), which came with an intake gasket, gasket cement, intake bolts, all the linkage pieces, and even a nice fuel line. It made the installation much smoother and easier. Edelbrock gets major style points for this effort. Just be prepared for a large deduction from your savings account, since this package sells through Summit for just under a grand.

We started our test with a single four-barrel baseline using the Edelbrock Performer RPM Air Gap configured with an Edelbrock 800-cfm EPS carburetor. This set the bar pretty high for the other two dual-planes, making this a worthy test. Our small-block 383ci was configured with its Dart 215cc Platinum heads and the smaller Comp Cams mechanical roller cam along with Westech’s 131/44-inch dyno headers and open exhaust. As you can see from the test numbers, the baseline was no slouch, making 482 lb-ft of torque and 481 hp.

Our second setup was with the older C-26 manifold, to which we also added the Edelbrock finned valve covers to give it a real feel for the old days. To no one’s surprise, this older casting dropped some significant torque (in excess of 26 lb-ft) over the entire power range with horsepower down by 19 hp compared to the single-quad setup. We also tried the air cleaner, but at least here we saw no further loss of power. In defense of the older manifold, bolt this package on a little 327 or 283 and the power differential would probably disappear altogether.

The Air Gap dual-quad was next up, and it fared much better. Average power was down by roughly 6 lb-ft of torque and barely 2.5 hp, which would be hard to feel in the car on the street. Also, much of the power difference we saw could have been improved with tuning since both dual-quad systems tended to run richer than we would have preferred in the midrange. So if you’re searching for that vintage late ’50s Henry Gregor Felson look, you’ve got a couple of great options that will still make great power. In fact, we’ve got a 0.060-over 283 that’s perfect for that older C-26 manifold and those twin 500s.

Dual-Quad Test

TEST 1 TEST 2 TEST 3 DIFFERENCE

Edelbrock Edelbrock Edelbrock

Air Gap1x4 C-26 2×4 Air Gap 2×4

RPM TQ HP TQ HP TQ HP TQ HP

2,500 409 195 394 187 407 194 – 2 – 1

2,700 399 205 391 201 392 203 – 7 – 2

2,900 398 220 392 216 404 218 + 6 – 2

3,100 419 247 403 238 416 245 – 3 – 2

3,300 441 277 418 263 437 274 – 4 – 3

3,500 457 305 435 290 452 301 – 5 – 4

3,700 465 328 449 316 465 328 0 0

3,900 475 353 458 340 468 347 – 7 – 6

4,100 482 376 463 361 470 367 -12 – 9

4,300 482 394 458 375 471 386 -11 – 8

4,500 478 410 454 389 469 402 – 9 – 8

4,700 474 424 452 404 466 417 – 8 – 7

4,900 469 438 450 419 463 432 – 6 – 6

5,100 466 453 443 430 459 446 – 7 – 7

5,300 461 466 434 438 452 456 – 9 -10

5,500 452 473 423 443 442 463 -10 -10

5,700 439 477 411 446 430 467 – 9 -10

5,900 426 479 398 447 417 468 – 9 -11

6,100 414 481 385 447 404 469 -10 -12

6,300 397 477 374 449 388 466 – 9 -11

Peak 482 481 463 449 471 469 -12 -11

Avg. 443.5 379.6 422.5 360.7 437.2 377.0

Note: Averages were taken from the entire dyno run at every 100-rpm data point. The last column is the power difference between Test 1 and Test 3.

Parts List

DESCRIPTION PN SOURCE PRICE

Edelbrock Performer RPM Air Gap 7501 Summit Racing $209.88

Edelbrock EPS 800-cfm carb 1412 Summit Racing 304.95

Edelbrock C-26 dual-quad intake 5425 Summit Racing 259.95

Edelbrock Air Gap dual-plane kit 2025 Summit Racing 999.95

Edelbrock finned valve covers 4145 Summit Racing 155.95

Edelbrock dual-quad air cleaner 4235 Summit Racing 119.95

Dual-Plane Vs. Single-Plane Vs. Tunnel-Ram

Much of the action that happens on the street is influenced by dragstrip chic-of-the-week. That includes such audacious displays of horsepower as 8-71 blowers and tunnel-ram intake manifolds protruding through the hood like a real-world version of a Rat Fink cartoon. Much of this is done strictly in the name of fashion, but there are those hard-core car crafters who believe in tall-runner manifolds. We wanted to see for ourselves, so we fashioned a quick comparison test for our Dart-headed Lunati 383. Configured with the Dart Pro 1 Platinum 215 heads and 280 Comp roller cam, this engine was ripe for an intake manifold face-off. Summit has long advertised a budget-based Weiand tunnel-ram intake configured with a pair of 600-cfm Holley carbs at an affordable price, so we tagged that as our eight-barrel heavy-hitter. For comparison purposes, we decided on a good single-plane intake and came up with one of Holley’s Keith Dorton-designed single-planes. Then just to make it even more interesting, we decided to throw down one of Weiand’s new Stealth Air Strike dual-plane intakes as the baseline. This way we would test the entire range of intakes from dual-plane to single-plane to tunnel-ram.

Dual-plane manifolds are known to enhance torque based on a longer intake-runner path compared to the shorter intake length of a single-plane manifold. The tunnel-ram offers the best of both worlds with longer intake runners like a dual-plane combined with a straight shot between the carburetors and the intake ports. The main reason tunnel-rams aren’t more popular for the street is the simple issue of hood clearance. Not everybody wants to carve holes in their hood.

As for our test, theory dictates that the dual-plane should make the most torque, given the smaller plenum and stronger signal to the carburetor. The single-plane should make more peak horsepower than the dual-plane but at the sacrifice of midrange torque. The tunnel-ram should best the single-plane in peak power and in theory generate a solid torque curve as well. The only hiccup in this concept is the size of the tunnel-ram’s pair of carburetors and dialing in a decent fuel curve.

After we were done making all kinds of noise, we immediately noticed that even with a strong 480hp small-block, the dual-plane intake still made the most overall power of all three manifolds. Weiand’s Stealth Air Strike dual-plane beat both the single-plane and the tunnel-ram in torque, and the only place the single-plane intake combo made more power was at the top of the rpm curve. Given that scenario, our money is on the dual-plane every time with a combination like this.

After bolting on the tunnel-ram with a pair of 0-1850 Holley carbs right out of the box, we discovered that perhaps the twin 600-cfm carbs were a bit too much for this engine combination. It became impossible to load the dyno below 3,500 rpm at wide-open throttle, necessitating testing the tunnel-ram system from 3,700 rpm and above. Plus it appeared from the testing that the engine really wasn’t happy until at least 4,500 rpm, where the induction system seemed a bit more stable. But only around peak horsepower did this system show any kind of advantage over the dual-plane, and then only by a couple of horsepower. Part of this disadvantage came from the fact that the 4160-style Holley carbs use metering plates in the secondaries rather than metering blocks. Without additional metering plates, we couldn’t adjust the secondary metering. This is something you should put on your shopping list should you decide to add one of these tunnel-ram kits to your small-block. We couldn’t convert to metering blocks since the fore-aft carbs would then be too long to fit on the tunnel-ram. It would have required placing them sideways, but we didn’t have the proper linkage to accomplish that.

Based on input from guys like Pontiac expert Ken Crocie, a choice of the smaller 450-cfm Holley carburetors would have resulted in a much cleaner-running engine and more powerful dyno curve that would have allowed us to start the test at a lower rpm and generate stronger torque numbers as well. It’s possible that fuel metering was not quite as good as it should be because the flow velocity through the larger 600 carbs was just too slow to accurately meter the fuel. Another advantage of the 450 carbs is that they are slightly less expensive. Since this test was in the midst of our mad dyno thrash, we didn’t have the luxury of time to dial in the carburetors, but with a little tuning time we could have made this combination work much better, especially in the midrange and lower-rpm levels.

Parts List

DESCRIPTION PN SOURCE PRICE

Summit tunnel-ram kit, 600 cfm CWND403S Summit Racing $749.95

Summit tunnel-ram kit, 450 cfm CWND303 Summit Racing 709.95

Weiand tunnel-ram manifold 1984 Summit Racing 279.95

Holley Keith Dorton manifold 300-110 Summit Racing 239.95

Weiand Stealth Air Strike manifold 8501 Summit Racing 209.95

Holley 750-cfm mech. sec. Street HP 0-82751 Summit Racing 509.95

Holley 450-cfm mech. sec. carb 0-9776 Summit Racing 29.95

Manifold Comparison

The baseline used a Weiand Stealth Air Strike dual-plane and 750-cfm Street HP carburetor. The middle test is the same engine with the addition of the Holley-Dorton single-plane intake using the same 750 Street HP carb. The third test converted to the Summit-Weiand tunnel-ram system using a pair of Holley 600-cfm vacuum-secondary carburetors.

TEST 1 TEST 2 TEST 3 DIFFERENCE

Weiand Holley-Dorton

Air Strike 1×4 Holley 1×4 Weiand 2×4

RPM TQ HP Fuel TQ HP Fuel TQ HP Fuel TQ HP

2,500 403 192 101 395 188 80 — — — — —

2,700 386 198 108 384 197 85 — — — — —

2,900 375 207 107 384 212 97 — — — — —

3,100 400 236 110 400 236 98 — — — — —

3,300 441 277 122 419 263 96 — — — — —

3,500 459 306 134 428 285 104 — — — — —

3,700 471 332 146 435 307 118 397 279 155 -74 -53

3,900 481 357 154 439 326 126 404 300 148 -77 –57

4,100 483 377 164 448 350 133 420 328 151 -63 -49

4,300 480 393 174 456 373 144 441 361 155 -39 -32

4,500 478 409 182 456 391 155 450 386 161 28 -23

4,700 473 423 188 456 408 164 456 408 164 17 -15

4,900 467 436 194 457 426 172 462 431 169 -5 -5

5,100 459 446 199 460 447 180 462 449 179 +3 +3

5,300 456 460 206 456 460 184 456 460 194 0 0

5,500 448 469 215 448 470 189 449 470 206 +1 +1

5,700 437 474 222 438 476 196 440 477 217 +3 +3

5,900 425 477 226 427 479 201 427 480 225 +2 +3

6,100 412 479 228 416 483 205 411 477 228 -1 -2

6,300 400 480 238 404 485 210 394 473 238 -6 -3

6,500 387 478 250 387 479 222 378 468 251 -9 -10

Peak 483 480 250 460 485 222 462 480 251

Avg. 440.4 377.8 174.7 429.4 369.7 150.4 — — —

Note: Averages were calculated on the entire power curve every 100 rpm. Averages were not calculated for the tunnel-ram due to an incomplete pull from 2,500 rpm, making any average invalid.The Difference column compares Test 1 and Test 3.

280 VS. 292 Cams, 215CC VS. 227CC Heads

Up until now, we’ve been testing with a set of Dart 215 Pro 1 Platinum heads that have performed very well. These are as-cast heads, and everybody knows that a CNC-ported heads will bring some serious ponies to the party. The computer-ported star in the Dart lineup is the 227cc CNC head, which not only has increased port volume, but also adds a bunch to the flow curve along the way. If you’ve been paying attention to our tech diatribes throughout the years, then you may know about midlift flow. Our contention is that ignoring big head flow numbers at high valve lifts in favor of strong midlift flow numbers will always deliver a stronger overall power package for a street engine. In testament to that, the Dart CNC 227 bumps the 0.400-inch lift flow numbers up over the 215 Platinum on the intake side by a staggering 28 cfm, a 13 percent increase. The 0.300-inch lift numbers are equally as impressive, gaining 26 cfm, a 15 percent bump. Combined, this makes for an impressive midlift one-two punch, and when blended with excellent exhaust flow numbers it’s an outstanding opportunity to make power.

To test that theory, we baselined the engine with the Dart 215 heads, the Holley-Dorton single-plane and 750-cfm Street HP carburetor, and the Comp Cams Xtreme Energy mechanical XR-280 Street Roller cam. For the second test we switched to the bigger XR 292 mechanical roller cam, and then for the final mondo-combo, we bolted on the Dart CNC 227 heads.

As you can see from the dyno chart, this motor loved the combination of lift, duration, and more cylinder head. The addition of the bigger cam in tests 2 and 3 illustrates how more duration trades torque in the low- to midrange portion of the rpm curve for more power above peak torque. But what’s interesting is that the peak torque rpm point didn’t move up as we expected. Note that in all three tests the peak torque hovered between 4,900 and 5,100 rpm. Of course what everyone will latch onto is the stellar power increase. When you can make almost 70 more horsepower from a cam and cylinder head swap, you know the parts are working. This doesn’t come at a discount price, though. The bill for the larger cam and a pair of assembled Dart 227 CNC heads will top $2,800, and that’s assuming the engine is already equipped with a mechanical roller cam. If you have to purchase all the mechanical roller pieces, expect that price tag to exceed $3,400. But we’re also looking at a 383ci small-block Chevy that makes just shy of 550 hp. That, friends, is a solid 1.43 hp per cubic inch. Plug this power and torque into a 3,500-pound street car, and if you can hook it up it will run high 11s all day long. Sounds like fun, doesn’t it?

Cam And Head Comparison

The first test uses Dart 215cc heads with the small XR-280 Comp Cams roller cam, the Holley-Dorton single-plane intake, and a 750 Street HP carburetor. Test 2 employs the same as above except with the larger Comp Cams mechanical XR-292 roller cam. The final test is the same combo as Test 2 except we added the Dart CNC 227 heads.

TEST 1 TEST 2 TEST 3 DIFFERENCE

Dart 215 Dart 215 Dart 227 CNC

Comp XR-280 Comp XR-292 Comp XR-292

RPM TQ HP TQ HP TQ HP TQ HP

2700 384 197 350 180 353 181 -31 -16

2900 384 212 345 190 347 192 -37 -20

3100 400 236 365 215 361 213 -39 -23

3300 419 263 396 249 383 241 -36 -22

3500 428 285 417 278 410 273 -18 -12

3700 435 307 428 302 429 302 -6 -5

3900 439 326 437 325 443 329 +4 +3

4100 448 350 450 351 457 357 +9 +7

4300 456 373 463 379 467 383 +11 +10

4500 456 391 469 402 475 407 +19 +16

4700 456 408 475 425 484 433 +28 +25

4900 457 426 480 448 489 456 +32 +30

5100 460 447 480 466 491 477 +31 +30

5300 456 460 478 482 490 495 +34 +35

5500 448 470 471 493 484 507 +36 +35

5700 438 476 461 500 477 518 +39 +42

5900 427 479 450 505 470 528 +43 +49

6100 416 483 440 511 462 536 +46 +53

6300 404 485 430 516 452 542 +48 +57

6500 387 479 415 514 443 548 +55 +68

6700 — 428 546 — — — — —

Peak 460 485 480 516 491 548

Avg. 431.3 378.9 436.4 387.7 414.7 369.7

Note: The Difference column compares Test 1 with Test 3.

Cam Spec Chart

Cam Duration Duration Lift

(Adv.) (@0.050) Separation Lobe

Comp XR-280, roller Intake 280 242 0.609 110

PN 12-771-8 Exhaust 286 248 0.616

Comp XR-292, roller Intake 292 254 0.622 110

PN 12-773-8 Exhaust 297 260 0.628

Both gross cam valve lifts are calculated using a 1.6:1 rocker ratio. Note that actual (net) valve lift equals gross lift minus lash. Lash was set at 0.016-inch intake and 0.018-inch exhaust for both cams.

Parts List

DESCRIPTION PN SOURCE PRICE

Comp Cams XR-280 roller cam 12-771-8 Summit Racing $255.95

Comp XR-280 mech. roller cam 12-773-8 Summit Racing 255.95

Dart 215 Pro 1 Platinum heads, pr. 11611123P Summit Racing 1,439.90

Dart 27 CNC heads, pr. 11971143 Summit Racing 2,551.90

Dart 27 CNC heads, pr. 11971143 Summit Racing 2,551.90

Cylinder Head Flow Testing

Dart 215 Pro 1 Platinum Dart 227 CNC

Lift Intake Exhaust Intake Exhaust

(w/ pipe) (w/ pipe)

0.100 63 59 65 53

0.200 124 101 145 110

0.300 171 136 197 148

0.400 214 160 242 178

0.500 247 177 272 196

0.600 272 188 283 208

0.700 — — 287 215

211/42- Vs. 3-Inch Exhaust

What goes in has to go out with any high-horsepower street combination, but for many car builders the question of what to do with the exhaust system is often given afterthought status. For professional engine builders and those attuned to the needs of an engine that moves trainloads of air, exhaust systems can make or break the combination. It’s acknowledged that exhaust systems don’t make horsepower, but a poorly executed exhaust system can cost too much to be blatantly ignored. There are still those who feel that open exhaust is the only avenue to peak horsepower success, and we won’t argue the point. But the reality is that a properly designed exhaust system can minimize the power loss and perhaps even pump up the torque at the same time.

Our test was devised to be as simple as possible: to compare 211/42-inch versus 3-inch-diameter Flowmaster Super 44 mufflers.. There are plenty of 3-inch exhaust systems out there designed to fit many popular musclecar chassis intended for big-cubic-inch engine applications. The engine combination for this test began with the 383ci small-block, with the larger Dart 227 CNC ported heads and the big XR292 Xtreme Energy roller cam combined with the Holley-Dorton intake and 750 Street HP carburetor. Instead of the 131/44 custom dyno headers, we substituted a set of Hedman 131/44-inch chassis headers that offered a three-bolt flange to install the 211/42- and 3-inch exhaust pipes. While the 3-inch system looks massive and flows lots of air, if you are considering one of these systems, the big concern should be sound level. It is inevitable that a 3-inch exhaust will also be the loudest. The large flow area of the 3-inch system represents a 45 percent increase in area, which means the mufflers and tailpipes create a resonance that can be overwhelming, in much the same way that big exhaust tips on import cars resonate (except not as annoying). But beyond the noise factor, there is definitely torque and horsepower to be gained with a 3-inch exhaust system, and we wanted to know how much on our 500 hp 383 small-block.

It was interesting that at the peaks the 2.5-inch mufflers were barely 5 hp shy of the 3-inch ones, but that’s not even half the story. Looking at the entire curve, the 3-inch system delivers substantially more torque virtually throughout the 2,700- 6,500 test sweep. This may be more of a tuning issue than just a question of volume, but there’s no questioning the solid 11 hp gain the 3-inch system delivers between 5,100 and 5,700 rpm. That’s power that will show up on the e.t. slip every time. While we didn’t itemize the power numbers on the chart, we also threw on a pair of 3-inch tailpipes on the 3-inch mufflers. Surprisingly, the tailpipes actually delivered a tiny 1hp gain at 6,500 rpm with 510 hp, but again, looking at the entire curve, the tailpipes cost power almost throughout the entire pull, losing as much as 32 lb-ft of torque at 3,300 rpm. Using an average power evaluation, the tailpipes lost exactly 9 lb-ft of torque and 6.4 hp overall, so clearly tailpipes cost some power, although not at all where you might expect. It’s also possible that carburetor tuning might be able to make up some of this torque loss. Another interesting test would be to add an H- or X-pipe to this test and see what occurs. But that will have to wait for another day. We’ve burned our hands enough times during this test already.

Flowmaster 211/42- Vs. 3-Inch Mufflers

The first test is the baseline, with a pair of Hedman 131/44-inch headers connected to a complete 211/42-inch exhaust system with the Flowmaster Super 44 mufflers and no tailpipes. The second test upgraded to 3-inch inlet and outlet Super 44 mufflers.

TEST 1 TEST 2 DIFFERENCE

Flowmaster

211/42-inch Flowmaster

3-inch

RPM TQ HP TQ HP TQ HP

2,700 385 198 390 200 +5 +2

2,900 400 221 404 223 +4 +2

3,100 418 247 424 250 +6 +3

3,300 427 268 437 274 +10 +6

3,500 433 288 435 290 +2 +2

3,700 430 303 428 301 -2 -2

3,900 423 314 419 311 -4 -3

4,100 421 328 417 326 -4 -2

4,300 426 349 429 351 +3 +2

4,500 440 377 446 382 +6 +5

4,700 455 407 463 414 +8 +7

4,900 461 430 471 439 +10 +9

5,100 462 449 473 460 +11 +11

5,300 459 463 470 474 +11 +11

5,500 453 474 463 485 +10 +11

5,700 445 483 454 493 +9 +10

5,900 438 492 444 499 +6 +7

6,100 431 501 433 503 +2 +2

6,300 422 506 424 508 +2 +2

6,500 407 504 411 509 +4 +4

Peak 462 506 473 509 +11 +11

Avg. 432.8 381.0 437.9 385.7 +5.1 +4.7

Note: The Difference column compares Test 1 with Test 3.

PARTS LIST

DESCRIPTION PN SOURCE PRICE

Flowmaster Super 44 2.5 in/out 942546 Summit Racing $76.39

Flowmaster Super 44 3.0 in/out 943046 Summit Racing 76.39

Flowmaster tailpipes 3.0 15819 Summit Racing 124.39

Four-Hole Vs. Tapered Carb Spaces

Sometimes you can find big power in the unlikeliest places. While most enthusiasts are preoccupied with high-fashion power parts like superchargers and nitrous systems, there is reliable power to be found in subtle changes to the induction system. Such is often the case with carburetor spacers. The trick, to quote Kenny Rogers, is to know when to hold ’em and know when to fold ’em. While there are catalog pages full of different designs, certain applications work better than others. Let’s run through three of the most common designs, and then we’ll bolt them on a typical street engine.

The most basic of all carb spacers is the open-chamber design. Here, the idea is to increase plenum volume of the intake manifold while also increasing the distance between the bottom of the carburetor and the manifold floor. The latter gives the incoming air and fuel charge a greater distance to make the change from vertical to horizontal flow path entering the intake port. These spacers are intended to be used on 5,000-rpm-and-up applications where the incoming air from the carburetor has lots of inertia. When you consider that fuel weighs more than air, the fuel will have more trouble making the change in direction at the bottom of the manifold where it transitions into the intake port. Additional carb height helps the fuel make that directional change. Open plenum spacers are generally used on single-plane intake manifolds although they occasionally do show power gains with dual-plane manifolds. These spacers can be made out of aluminum or plastic, which also helps as a heat insulator.

<img src="http://enthusiastnetwork.s3.amazona...6_0709_28_z-aftermarket_parts-spacer_dyno.jpg" alt="Wilson Spacer Comparison

‘The insulating spacers are called “phenolic” spacers, referring to the type of thermostatic plastics used to make them.” class=”wp-image-276059″ />

The second design is appropriately called a four-hole spacer. These are generally intended to extend the length of the carb outlet and tend to improve the signal strength to the carb during part-throttle applications. Our test is only a wide-open-throttle test, so not all of the advantages of a four-hole spacer can be realized. However, if the combination includes a long-duration cam, it’s possible to increase midrange torque with a four-hole spacer since it will improve the signal strength to the carburetor. Often this kind of spacer will affect the fuel curve by using more fuel. Sometimes this is an advantage, but if not, the four-hole spacer may require tuning the carburetor a bit leaner to take full advantage of the spacer’s effect.

The final spacer type is the tapered four-hole from Wilson Manifolds. It is designed to actually increase airflow through the carburetor based on years of experimentation with NASCAR restrictor-plate manifold designs. Prior experience with these spacer plates on single-plane-manifold street engines tend to show horsepower gains from 5,500 rpm and up.

a great deal of the info you may want can be calculated after carefully measuring the intake port and runner length and cross sectional areas.(remember its not the intake port gasket cross sectional opening, cross sectional area, its the smallest part of the port cross sectional area and valve throat areas that limit port flow rates)

if as an example we selected a port with about a 2 sq inch cross sectional area, you'll find max torque on a 350 will fall near 4000-rpm and port stall near 6000-rpm

http://users.erols.com/srweiss/calccsa.htm

http://users.erols.com/srweiss/calcplv.htm

http://users.erols.com/srweiss/calchpaf.htm

http://www.wallaceracing.com/chokepoint.php

http://www.rbracing-rsr.com/runnertorquecalc.html

http://www.walmart.com/ip/Texas-Instruments-TI-30X-IIS-Scientific-Calculator/1535939

http://www.summitracing.com/parts/cca-5605/overview/

related info, that you might need

http://garage.grumpysperformance.co...heads-for-small-block-chevys.3293/#post-26213

http://garage.grumpysperformance.com/index.php?threads/what-are-these-heads.4702/#post-12742

http://garage.grumpysperformance.co...-by-step-guide-with-pictures.5378/#post-71848